Table of Contents

Introduction

Specific product sourcing is about more than just finding goods to resell. It’s the art of identifying niche or custom items that align precisely with your brand’s vision, then partnering with the right suppliers to bring those ideas to life. In a world where generic goods flood marketplaces, securing a unique product can set your business apart – but only if you understand the deeper mechanics of sourcing. This guide explores the specific product sourcing process end‑to‑end, with candid insights into the power dynamics, risks and opportunities that shape the supply chain. Think of it as a roadmap that balances data, relationships and creativity.

In 2025 and beyond, specific product sourcing isn’t just about filling shelves with products that already exist. The market has shifted under our feet. Platforms like Shein and Temu have redefined speed and variety, while TikTok has turned micro-trends into million-dollar opportunities overnight. If you’re sourcing the same generic items as everyone else, you’re not really sourcing, you’re surviving. Specific product sourcing means being intentional: selecting items that express your brand’s values, match your audience’s lifestyle, and create an emotional connection. It’s about turning sourcing into strategy, where every product decision strengthens your brand identity instead of diluting it.

1. What Makes Specific Product Sourcing Different?

- Targeted products rather than commodities – When you engage in specific product sourcing, you’re searching for a product with a precise function or differentiator (e.g., a specialized material, an eco‑friendly feature or custom design). This requires deeper market research and closer collaboration with manufacturers.

- Customization and private label options – Specific product sourcing often requires custom molds, packaging, or features. Special packaging and custom labels can differentiate your goods and are easier to implement when you work closely with suppliers.

- Smaller minimum order quantities (MOQs) – To test niche products, you need partners willing to produce low volumes without exorbitant costs. Dropshippers and wholesalers can help, but direct manufacturers may be required for full customization in specific product sourcing.

- Higher stakes, higher rewards – Unique products can command better margins and customer loyalty, but poor execution can harm your reputation. Risk management, quality control and ethics become critical in specific product sourcing.

Before you dive into the mechanics of supplier research and sampling, let’s pause on the most overlooked step in specific product sourcing: choosing the right product to source in the first place. It sounds obvious, but many brands chase whatever looks hot, only to end up with dead stock. A smarter approach blends data with intuition. Check Google Trends, SEMrush, or even TikTok hashtags to validate if there’s sustained interest, not just a one-week spike. Balance risk by testing with small MOQs before scaling. And most importantly, think about differentiation. Could a minor design tweak, eco-friendly material, or creative bundling make the product stand out? In the era of infinite choices, specific product sourcing turns details into competitive advantage.

2. Step‑by‑Step Specific Product Sourcing

2.1 Identify and Validate the Right Product Idea

Start your specific product sourcing project with research, not guesswork. Determine which products to sell by analysing market trends, consumer preferences, and the competitive landscape. Use tools like Google Trends and Amazon’s bestseller categories to see what people are searching for. Conduct focus groups and surveys, especially if you’re creating a new product, to make sure your specific product sourcing idea has real demand.

Next, define criteria such as shipping speed, customization ability, order quantity and middleman costs. Decide whether you need a manufacturer for maximum customization, a wholesaler for faster shipping, or a dropshipper if you want to avoid storage requirements. Clarify non‑negotiables like acceptable MOQs and storage capacity before approaching suppliers in specific product sourcing.

2.2 Research and Verify Suppliers

Finding reliable partners is arguably the most critical part of specific product sourcing. Research suppliers via online marketplaces such as 1688, Taobao, or Alibaba, by working with sourcing agents, or by attending trade shows. Each method has pros and cons:

| Method | Advantages | Challenges |

|---|---|---|

| Online marketplaces (Alibaba, 1688) | Access to millions of suppliers; built‑in payment and review systems. | Language barriers and difficulty verifying legitimacy; not all sellers are manufacturers. |

| Sourcing agents | Agents negotiate, vet suppliers and perform quality control, overcoming cultural and logistical barriers. | You rely on a third party for supplier relationships; misaligned incentives can increase costs or obscure information. |

| Trade shows | In‑person interaction; ability to see and touch samples and evaluate equipment. | Expensive to attend; limited frequency; travel, visa and translation costs. |

Whichever route you choose, verify suppliers’ credentials. Check official business registration databases to confirm licences, look for export licences, and review financial documents or credit reports via third-party services. Search the supplier’s name plus words like “fraud” or “scam,” and read customer reviews. Request copies of business licences and certifications (ISO, CE, FDA) and verify that these match the supplier’s profile. Evaluate supplier longevity and look for badges or memberships that show commitment to quality and stability. Remember, a thorough verification process will save countless headaches down the line in specific product sourcing.

2.3 Evaluate Supplier Capabilities and Fit

Supplier reliability is the foremost consideration in specific product sourcing. Compare direct manufacturers, trading companies and wholesalers based on communication, cost and product range. Manufacturers offer direct control and customization; trading companies provide variety and easier communication; wholesalers allow small orders but limited customization. Evaluate your supplier’s production capacity, scalability and R&D capabilities, important if you expect to scale or iterate on the product in specific product sourcing.

When working with sourcing agents or consultants, vet them thoroughly. Review the agent’s track record, references, communication skills and industry knowledge. A good agent acts as an extension of your team, aligning with your goals and providing transparency.

2.4 Visit Factories and Request Samples

Quality cannot be outsourced to good intentions. It is recommended to visit factories personally or through a trusted representative to assess equipment, working conditions and legal compliance. If travel isn’t feasible, hire a third‑party inspection service.

Once you’ve shortlisted suppliers, request samples or small test orders to check product quality and adherence to specifications. Factory visits or audits reveal conditions, machinery and quality control measures. Ask about their quality assurance processes and how they handle previous issues. Make sure to track progress from raw materials to finished goods to ensure product quality.

Imagine this: a brand ordered 10,000 eco-friendly tumblers through specific product sourcing. The samples passed, the factory looked legitimate, and the price was irresistible. But when the shipment arrived, the stainless steel grade was downgraded, invisible to the eye, but a disaster when customers complained about rust within weeks. Without a thorough on-site inspection and batch testing, this kind of nightmare slips through easily. Quality control isn’t just a box to tick; it’s the shield between your reputation and the hidden shortcuts suppliers might take under pressure. Because specific product sourcing often involves unique designs or custom features, the risks are magnified, and every overlooked detail can unravel months of work.

2.5 Prioritise Quality Control Throughout Production

Quality control should start with clear specifications, including materials, dimensions and tolerances. Implement inspections at multiple stages: incoming materials, production, and pre‑shipment. Use both in‑house checks and independent third‑party inspectors. Address any issues collaboratively and develop corrective action plans. Regularly review and update quality standards to adapt to evolving needs and maintain excellence in specific product sourcing.

2.6 Negotiate and Build Relationships

Negotiation isn’t just about price. Preparation, including understanding market conditions and realistic pricing, is essential. In Chinese business culture, the initial offer is rarely final, and there is an expectation of bargaining, but negotiation should be respectful to preserve long‑term relationships. Be clear about product specifications, delivery timelines and payment terms, and put everything in writing (translated into Chinese if possible).

Building rapport (guanxi) is vital in specific product sourcing. Personal relationships and cultural understanding can open doors and smooth negotiations. Face‑to‑face meetings, social events and small gestures of respect, such as exchanging business cards with both hands, can foster trust. Flexibility, such as trading price for better quality or faster turnaround, can create win‑win situations.

Let’s be honest: the price you negotiate with a supplier in specific product sourcing is only half the story. The real cost shows up in the hidden corners: mold fees for new designs, certification costs for FDA or CE approvals, labeling compliance, or even “small extras” like upgraded packaging. And then there’s the cost of time: delays at ports during peak season, customs asking for extra paperwork, or a supplier missing a promised ship date. Smart brands anticipate these invisible expenses from day one. Those who treat specific product sourcing as a complete financial picture, not just a factory invoice, walk into negotiations with clarity and confidence.

2.7 Manage Logistics, Compliance and Payments

Logistics choices have a major impact on cost and timing in specific product sourcing. Sea freight is cost‑effective but slow; air freight is faster but expensive; rail freight offers a balance and is growing for shipments to Europe. Factor in customs, import duties and potential delays, and work with experienced freight forwarders or logistics partners to navigate procedures and avoid unnecessary delays. Building relationships with reliable logistics partners can also provide advice on routes, warehousing and tracking.

Understand import regulations in your home market and ensure both you and your supplier comply. Regulations vary by product category, electronics may require CE/FCC certifications, toys may have specific safety standards, and failure to comply can result in customs delays or seizures. Labeling, packaging and documentation must meet requirements (e.g., correct product descriptions, country of origin labels).

Payment and currency management can be complex. Many Chinese suppliers accept only onshore CNY (renminbi), not offshore CNH, so businesses need a presence in mainland China or a partner to handle conversions. Multi‑currency accounts or payment services integrated with marketplaces (e.g., 1688) can reduce costs and currency risks. Always use secure payment platforms and keep written records of transactions to protect against disputes in specific product sourcing.

2.8 Mitigate Risks and Build Long‑Term Partnerships

Specific product sourcing involves inherent risks: supplier fraud, quality issues, intellectual property violations and logistical disruptions. Reduce exposure by vetting suppliers carefully, visiting factories, using detailed contracts, securing proper licences and diversifying suppliers. Request multiple quotes and maintain a buffer stock to handle delays in specific product sourcing.

Long‑term relationships are an investment. Fostering mutual trust involves regular communication, support during challenges and shared growth. Regular visits, calls and participation in trade fairs keep you connected. In Chinese culture, relationships built on trust can lead to preferential pricing and priority treatment, while neglecting relationships can result in sudden price hikes or lost supplier access.

3. Special Considerations for Unique Product Categories

3.1 Custom Packaging and Branding

When your product must stand out in specific product sourcing, packaging becomes part of the value proposition. Special packaging and custom labels are readily available if you collaborate with suppliers who handle design and printing. Provide your design specifications and request packaging samples as part of your quality control process. Consider using eco‑friendly materials and packaging that enhance unboxing experiences. Proper packaging also ensures compliance with import regulations (e.g., fumigation for wooden packaging). Specific product sourcing becomes a branding exercise when your packaging tells the story of your brand.

3.2 Low‑MOQ and Prototype Runs

For niche products, you often need to test the market without committing to large volumes. Identify suppliers willing to accommodate low MOQs or small batch orders. Use pilot orders to refine the product and packaging, and treat these runs as learning opportunities. Some manufacturers may charge a premium for low volumes; factor this into pricing models. In specific product sourcing, low MOQ runs give you the freedom to experiment while minimizing risk.

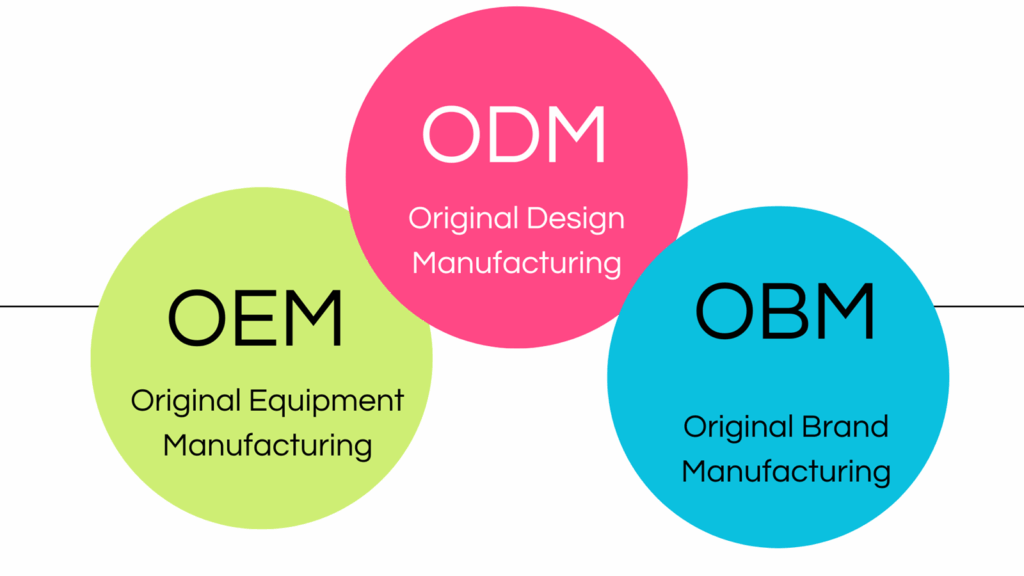

3.3 ODM/OEM and New Materials

If your product requires custom molds or new materials, partner with manufacturers experienced in ODM (original design manufacturing) or OEM (original equipment manufacturing). Work closely with the factory’s engineers, supply clear CAD files and request prototypes for evaluation. Intellectual property protection is crucial; sign non‑disclosure agreements and consider registering trademarks or patents in China. Specific product sourcing at this level means co-creating with suppliers, not just placing an order.

3.4 Compliance for Special Products

Certain product categories have stringent compliance requirements, chemicals, electronics, medical devices and food contact items. Work with suppliers that provide the necessary certifications and testing reports, and verify authenticity with the issuing bodies. Stay current on changing regulations in target markets and build extra time into your project timeline for testing and certification. Non‑compliance can result in recalls, fines and reputational damage, risks that specific product sourcing cannot afford.

4. The Yana Sourcing Approach

At Yana Sourcing, we live and breathe specific product sourcing. We don’t simply match you with suppliers; we become an extension of your team, integrating market insights, design thinking and supply chain agility. Our mission is to help brands lead by innovating, not just competing on cost. We achieve this by:

- Trend anticipation – We monitor emerging industries and consumer behaviour to identify the next wave of products, from next‑gen electronics to sustainable materials, then help you act fast.

- Agile sourcing and low MOQs – Whether you need small test runs or scalable production, we have relationships with factories willing to accommodate flexible volumes, including private label and custom packaging.

- Integrated services – Beyond sourcing, we arrange dropshipping, custom packaging, multi‑product bundling and eco‑conscious solutions, ensuring that specific product sourcing is seamless and cohesive.

- Quality and compliance – We enforce rigorous quality inspections and maintain continuous production oversight, ensuring your products meet regulatory standards and surpass customer expectations.

- Transparency and ethics – We prioritise honest communication and sustainable practices, balancing speed, quality and profitability. Yana is not just a service provider; we are your strategic partner in a volatile global market.

5. Pitfalls to Avoid in Specific Product Sourcing

- Failing to verify suppliers – Trust but verify. Don’t rely solely on platform badges or agent assurances. Check licences, certifications and third‑party reviews.

- Ignoring quality control – Pre‑shipment inspections alone are inadequate. Implement quality checks at every stage and maintain clear specifications.

- Overlooking cultural nuances – Aggressive negotiation or lack of personal connection can strain relationships. Invest time in guanxi and respect local etiquette.

- Assuming all suppliers can scale – Assess long‑term capabilities and scalability early. A small factory may not be able to handle rapid growth or complex changes.

- Underestimating regulatory hurdles – Stay informed about import regulations, product certifications and packaging rules. Non‑compliance can lead to delays or seizures.

- Neglecting risk management – Prepare for geopolitical shifts, currency volatility, pandemics and logistics disruptions. Diversify suppliers, hold buffer stock and use secure payment methods.

Conclusion

Specific product sourcing isn’t just a checklist of tasks; it’s a mindset that combines strategic research, meticulous verification and human relationships. By understanding market demand, verifying suppliers, maintaining quality and nurturing partnerships, you can unlock the potential of unique products that elevate your brand. In doing so, you’ll also uncover the deeper truths about global trade: that trust, transparency and mutual respect are as crucial as price negotiations or logistics plans in specific product sourcing.

The future of specific product sourcing is already being written. AI-driven platforms are beginning to match buyers with suppliers faster than ever, reducing the guesswork in early-stage research. At the same time, regulators in the EU and US are tightening sustainability reporting, meaning suppliers who can’t track emissions or waste will soon be locked out of major markets.

And geopolitics is pushing diversification, sourcing hubs are expanding beyond China into Vietnam, India, and nearshoring options. What doesn’t change is the need for human judgment, cultural understanding, and a partner who knows when to push for speed and when to hold for quality. At Yana, we see ourselves not as agents but as allies. Because specific product sourcing isn’t just business mechanics, it’s the art of building brands that last in a volatile, impatient world.

At Yana Sourcing, we’re here to help you navigate this complex landscape with intelligence, creativity and heart. When you’re ready to move from generic goods to truly remarkable products, you won’t be alone, you’ll have a partner committed to helping you win.

Related Links

Product Sourcing from China: The 2025 Guide for Confident Growth