Table of Contents

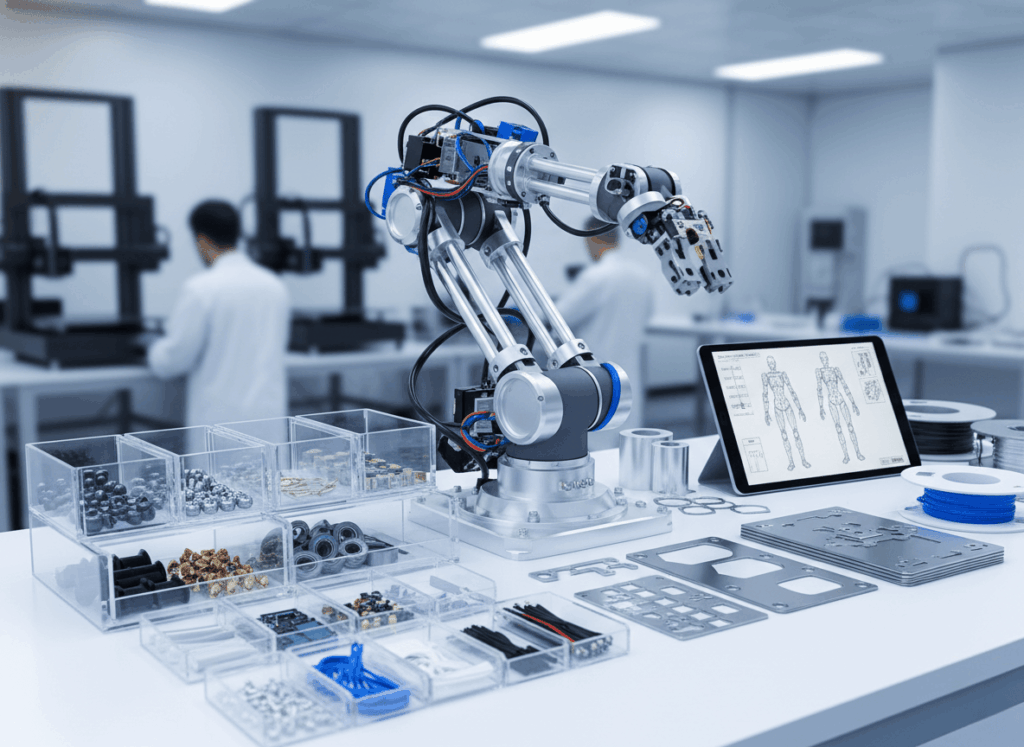

The catalog is not just a list of parts; it is a curated, intentional universe of curated hardware systems and components that we understand deeply and can bring to life with you. From the microscopic movements of bearings to the macro‑motion of robot arms, from the shimmer of aerospace metals to the silent calm of elastomers, each component in our catalog exists because it has earned its place through performance, reliability and feel.

Build From the Inside Out

Great products are built from the inside out. Before you see a beautiful device, you feel its solidity, hear its precision and trust its motion. These sensations come from curated hardware systems and components that work together as one. A motor that produces the right torque at the right speed is only possible because a reducer uses the correct gear ratio and a sensor measures the angle with enough resolution.

When designers ignore these details or source cheap substitutes, they end up with machines that buzz, stutter and overheat. We start our catalog by reminding you that every “feel,” every “click,” every moment of stability comes from a network of parts that we think about holistically. The difference between something that moves and something that moves well is not accidental; it is the result of deliberate choices guided by high‑quality hardware components for innovation.

A Product Is the Sum of Its Invisible Decisions

Whenever you hold a finished product, you hold the sum of thousands of invisible decisions. The stiffness of a frame, the smoothness of a hinge, the silence of a gear train, all are the result of choosing curated hardware systems and components and combining them in ways that respect material limits.

In robotics this concept is amplified: a servo motor designed for an industrial machine may not suit an integrated joint because it generates too much heat, latency and physical bulk; a unified motion controller that combines machine logic and robot kinematics eliminates the communication delays that plague separate PLCs.

These are not trivial differences; they are the difference between smooth motion and jerky motion, between safe operation and risk, between high margin and commoditisation. Our catalog invites you to study these decisions, to see how they scale from the micro to the macro, and to choose high‑quality hardware components for innovation in every step.

Explore the Catalog

Our catalog is organised into three domains, Robotics, Components and Materials, each serving a unique role in the product creation process. Yet each shares the same intent: to provide high‑quality hardware components for innovation that feel right, work right and last. We describe each domain not as a list of things to buy but as systems of meaning and performance. This is the map to your engineering universe.

Robotics — Systems of Motion and Intelligence

Robotics is where motion and intelligence meet. In our catalog, robotics is not defined by a single robot but by the systems that make robots possible. These systems are divided into logical families, each offering high‑quality hardware components for innovation:

Actuators

Actuators transform energy into movement. Rotary actuators, linear actuators and hybrid actuators each serve different motion profiles. A rotary actuator uses gear trains to convert high‑speed motor rotation into high torque; a linear actuator converts rotary motion into straight‑line travel using ball screws or belts; hybrid actuators merge technologies for unique space or performance constraints.

When you choose high‑quality hardware components for innovation in actuators, you avoid heat and latency issues that come from generic controllers and harness innovations like non‑silicon transistors that improve power density and reduce heat dissipation. The result is quieter, cooler and more reliable movement that contributes to the overall feel of your product.

Motors

Motors are the heart of robotic movement. Servo motors, BLDC (brushless DC) motors, stepper motors, torque motors, frameless motors, linear motors, voice‑coil motors and planetary gear motors each offer unique performance profiles.

Servo drives produce pulse‑width modulation (PWM) waveforms to orchestrate precise angular displacement and deliver the voltage needed for slow, stall‑free rotation. Integrated microcontroller chips generate PWM signals, interface with sensors via protocols like CANOpen and implement proportional–integral–derivative (PID) algorithms to maintain speed and position.

Choosing high‑quality hardware components for innovation in motors means embracing feedback, safety and integration: integrated servo drives with torque sensors and Safe Torque Off (STO) help prevent accidents and ensure compliance, while innovations in transistor materials allow motors to be smaller and lighter without sacrificing power.

Reducers

Reducers translate high‑speed input into high‑torque output and are essential for fine control. Harmonic reducers, RV (cycloidal) reducers and planetary reducers each offer different trade‑offs in stiffness, backlash, efficiency and size. A harmonic reducer provides zero‑backlash precision ideal for collaborative robots; a cycloidal reducer offers high rigidity and shock resistance for industrial arms; a planetary reducer balances cost and performance for general motion.

Your choice of reducers influences the feel of your robot, its smoothness, its responsiveness and its energy consumption. Integrated designs that combine motor, reducer, sensor and driver into complete joints show how high‑quality hardware components for innovation can simplify complexity, reduce installation errors and produce modular, repairable systems.

Controllers

Controllers coordinate everything, from servo drivers to control boards to integration software.

Servo drivers are amplifiers that regulate current and voltage delivered to motors; standalone drivers provide flexibility but add bulk and complexity.

Control boards convert high‑level commands into PWM signals, integrating microcontrollers, motor drivers and communication interfaces to manage multiple axes.Poorly designed boards lead to jerky movement and increased energy consumption, while unified motion‑centric controllers reduce communication delays and improve reliability.

Integration software orchestrates the conversation between hardware and code, ensuring timing, safety and predictability. By selecting high‑quality hardware components for innovation across controller subsystems, you build machines that respond with intelligence and grace.

Complete Joints and Integration

Complete joints integrate motors, reducers, sensors and drivers into a single package. They simplify installation, reduce wiring complexity and improve heat management. Whether you’re building a collaborative arm or an AGV, a high‑quality complete joint accelerates time to market and ensures that every motion feels deliberate.

Integration is the final stage of robotics: connecting complete joints, sensors, materials and control software into a coherent whole. Integration matters because even the best components fail if they are not combined properly. When we help you design integration architectures, we draw on insights from servo control loops, sensor fusion and system engineering to make sure your high‑quality hardware components for innovation work together seamlessly.

Components — Functional Building Blocks

Components are the building blocks of any hardware system. They are grouped into mechanical, electrical, sensing and pneumatic categories, each with subcategories that deliver high‑quality hardware components for innovation.

Mechanical Components

Mechanical components include bearings, screws and ball screws, couplings, linkages and gears and transmissions. Bearings reduce friction and support loads; ball screws convert rotary motion into linear travel with high efficiency; couplings connect shafts and compensate for misalignment; linkages transfer motion along complex paths; gears and transmissions trade speed for torque or vice versa. Choosing high‑quality hardware components for innovation in mechanical parts means understanding preload, backlash, material and finish.

The wrong bearing can introduce play and noise, while a precisely preloaded bearing keeps your mechanism quiet and smooth. Screws and ball screws need the right lead, diameter and nut design to deliver the desired force and precision. Couplings must be selected for stiffness and misalignment tolerance to prevent servo hunting and excessive vibration. High‑quality linkages maintain geometry under load, and gears with surface treatments resist wear and corrosion. Each choice influences the tactile feel of your product.

Electrical Components

Electrical components span PCBs, connectors, wiring harnesses and power supplies. Printed circuit boards (PCBs) are the nervous system of a product; they host microcontrollers, drivers and sensors.

Board design affects performance: copper weight, dielectric material and routing can determine whether signals are clean or noisy and whether motor drivers run cool or overheat. Connectors create interfaces between boards and other systems; the right connector ensures contact integrity under vibration and repeated mating. Wiring harnesses organise cables, protect them from abrasion and maintain signal integrity.

Power supplies deliver stable voltage and current, often regulated and protected to avoid surges that damage components. High‑quality hardware components for innovation in electrical systems prevent noise, brownouts and thermal failure, ensuring that your system performs as intended.

Sensing Components

Sensors give your product awareness. Encoders measure motion; force–torque sensors measure interaction forces; lidar and vision sensors provide environmental perception. High‑quality encoders offer high resolution and low latency, enabling tight control loops in servo systems. Force–torque sensors allow collaborative robots to sense and react to external forces, improving safety and compliance.

Lidar and vision sensors perceive obstacles and surfaces; they rely on accurate calibration and robust data processing to function in changing environments. Choosing high‑quality hardware components for innovation in sensing ensures closed‑loop confidence: the system knows where it is, what it touches and how to respond. When you pair good sensors with integrated servo drives and robust control algorithms, the result is fluid, responsive motion and safe interaction.

Pneumatic Components

Pneumatic components include cylinders, valves and fittings. While pneumatics are sometimes considered “old‑school,” they offer unmatched force density at low cost. A well‑selected cylinder provides smooth extension and retraction; a valve regulates flow and speed; fittings ensure sealing and connection integrity.

High‑quality pneumatic systems remain essential for end effectors, grippers and simple actuators. They must be chosen for bore size, stroke length, response time and reliability in harsh environments. When you choose high‑quality hardware components for innovation in pneumatics, you can achieve consistent force and motion control in industrial settings without sacrificing safety or efficiency.

Materials — Substances You Shape

Materials define the boundaries of physical possibility. They determine weight, strength, conductivity, corrosion resistance and aesthetics. Our catalog of materials includes metals, stainless steel, titanium, copper, magnetic materials, polymers, elastomers, rare earths and composites. Each category offers high‑quality hardware components for innovation at the atomic level.

Metals and Alloys

Aluminum alloys provide lightweight strength and heat dissipation. Stainless steels offer corrosion resistance and high tensile strength. Titanium delivers exceptional strength‑to‑weight ratio for aerospace and medical applications. Copper provides thermal and electrical conductivity. Magnetic materials enable motors and sensors.

Each metal choice reflects a trade‑off: weight versus stiffness, cost versus performance, machinability versus durability. High‑quality hardware components for innovation begin with metals that align with your design intent. For example, using a high‑strength aluminum alloy in a robot arm can reduce inertia and improve responsiveness.

Polymers and Elastomers

Polymers include plastics like ABS, polycarbonate and nylon. They provide insulation, impact resistance and manufacturability. Elastomers (rubbers) like silicone and nitrile deliver sealing, damping and flexibility. These materials influence tactile feel, noise damping and environmental resistance.

The right polymer can reduce weight and cost while maintaining structural integrity. The right elastomer can absorb vibration and protect delicate components. Using high‑quality hardware components for innovation in polymers and elastomers ensures that your product feels sturdy, comfortable and durable.

Rare Earths and Composites

Rare earth materials like neodymium and samarium are essential for magnets in motors and sensors. Composites combine fibers (carbon, glass, aramid) with resins to produce materials with high specific strength and stiffness. Rare earths enable compact, high‑power motors and sensors that deliver responsiveness and efficiency.

Composites allow the creation of structures that are strong, lightweight and vibration‑damping. High‑quality hardware components for innovation include using the right rare earth magnet to achieve the desired torque density and the right composite layup to achieve the desired stiffness. When you choose these materials thoughtfully, you enable designs that look and feel like the future.

Selection Principles for Reliable Product Development

Selecting the right components and materials goes beyond catalog browsing. It requires understanding technical factors, environment, duty cycle and quality standards. High‑quality hardware components for innovation are those that meet your technical specifications and integrate well with the rest of your system.

Technical Selection Factors

For mechanical parts, consider torque rating, preload, stiffness, backlash and duty cycle. Bearings must handle radial and axial loads; ball screws must deliver efficiency and precision; couplings must accommodate misalignment without introducing compliance. For electrical parts, evaluate power rating, noise immunity, thermal management and signal integrity.

PCBs must manage heat and maintain signal integrity at high frequency; connectors must maintain contact under vibration; wiring harnesses must resist electromagnetic interference. For sensors, resolution, bandwidth and noise floor determine system responsiveness and accuracy. High‑quality hardware components for innovation are those that meet or exceed these technical criteria.

Environmental and Duty Cycle Considerations

Real products operate in real environments. Consider temperature, humidity, dust, vibration and shock. A bearing or gear may fail if it is not sealed against dust; a power supply may fail if ambient temperatures exceed its rating. Duty cycle, the fraction of time the component spends operating, affects material fatigue and heat buildup. Selecting high‑quality hardware components for innovation means choosing parts rated for the actual duty cycle and environment of your product, ensuring longevity and performance.

Tolerance, Precision and Quality Standards

Tolerance and precision matter. They are the difference between a mechanism that binds and one that glides. Tighter tolerances reduce backlash and vibration; they require precision machining, finishing and assembly. Quality standards such as ISO 9001, CE, UL, IP ratings and RoHS certifications indicate that a component or material meets specific criteria for safety, performance and environmental compliance. High‑quality hardware components for innovation come with certificates, test reports and traceability. They allow you to meet regulatory requirements and reassure your clients that you build with integrity.

Supply Chain & Sourcing Realities

Sourcing is not just about price and minimum order quantity. It is about relationships, trust and the ability to deliver high‑quality hardware components for innovation repeatedly. Here are the considerations that matter.

Regional Production Clusters

Different regions specialise in different components. Guangdong and Shenzhen dominate electronics and PCBs; Jiangsu and Zhejiang excel at mechanical machining and gear manufacturing; Tianjin and Dalian specialise in heavy industrial components; Sichuan and Chongqing produce magnets and rare earth materials. Understanding where your parts come from helps you navigate lead times, communication, language and quality culture. We leverage these regional strengths to source high‑quality hardware components for innovation.

Price vs Performance Trade‑offs

There is always a trade‑off between cost and performance. Sometimes a standard catalogue part meets your needs; other times you need a customised part with higher precision or better material. High‑quality hardware components for innovation do not always mean the highest price; they mean the right performance at the right cost. We help you decide when to choose commodity components and when to invest in custom solutions, balancing margin with quality and feel.

Customisation, MOQ and Lead Times

Customisation can improve performance, integrate features and reduce assembly time. However, it usually comes with higher minimum order quantities (MOQ) and longer lead times. We work with suppliers who understand system behaviour and are willing to co‑develop components. For example, a custom gear reduction with integrated sensor mount can reduce alignment errors and improve installation speed. Choosing high‑quality hardware components for innovation means understanding MOQ constraints and negotiating lead times that match your project schedule.

QC, Testing and Traceability

Quality control (QC) is non‑negotiable. We require factory audits, incoming inspection, and test reports for every batch. Our partners use coordinate measuring machines (CMM), high‑speed cameras, thermal chambers and vibration tables to test components. We track production lots, serial numbers and materials certificates so that if an issue arises, we can trace it back to its source. High‑quality hardware components for innovation are verified, not assumed. This approach prevents surprises, reduces recalls and protects your brand.

Built for Innovators Who Care About Quality

Our catalog exists for innovators who care about how their products feel and perform. It is not a commodity list but a toolbox for those who refuse to settle. We built this catalog for:

Startups Creating Their First Real Hardware Product

Your first hardware product is both exciting and daunting. You have a vision, but you may be overwhelmed by the options. Our catalog distills complexity into clarity. We guide you through selecting high‑quality hardware components for innovation without drowning you in jargon. We connect you with suppliers who will take your prototype seriously, helping you avoid the race to the bottom and build something you can be proud of.

Established Companies Refining Performance and Feel

If you already have products in the market, you know that competition never sleeps. Improving performance means going deeper into your components, reducing backlash, lowering noise, improving thermal stability, enhancing sensor accuracy. Our catalog provides access to high‑quality hardware components for innovation that help you refine your product without redesigning from scratch. Whether you are upgrading motors to integrated servo drives or switching to higher‑precision gears, we can help you increase quality and margin simultaneously.

Teams Avoiding the Race to the Bottom

Some organisations are tempted by lower prices at any cost. We are not the partner for them. We work with teams who understand that quality is not negotiable. They know that high‑quality hardware components for innovation may cost more initially but save money through reliability, differentiation and customer satisfaction. If you want to win on performance and trust rather than price, this catalog is for you.

People Who Want to Build Something That Lasts

Designing for longevity is a radical act in a world of disposable products. Longevity requires choosing materials that resist wear, components that tolerate duty cycles, processes that ensure alignment and suppliers who provide consistency. High‑quality hardware components for innovation help you build products that last—not just physically but reputationally. When your customers experience products that feel solid and perform smoothly for years, they become loyal ambassadors. That loyalty translates into margin and stability.

How We Curate and Source

Our catalog does not happen by accident. It is the result of an ongoing vetting process that blends engineering knowledge, manufacturing expertise and market insight.

We Understand System Behaviour

We think like engineers and systems designers. We know that a good component on its own means nothing if it does not integrate well. A motion control board may generate PWM signals, but if it is connected to a servo drive with mismatched feedback, the system will fail. We analyse how components interact, mechanically, electrically and in software, to ensure that when you assemble them, they behave as a coherent system. This systems thinking is at the heart of our ability to supply high‑quality hardware components for innovation.

We Vet for Longevity, Consistency and Fit

Our evaluation criteria go beyond datasheets. We audit factories, review process control charts, examine packaging and test real samples. We look for manufacturing discipline, supply chain resilience and ethical practices. We check whether the supplier understands our need for high‑quality hardware components for innovation and whether they can scale while maintaining consistency. We emphasise not just component performance but also physical fit and finish because we know that feel matters.

Less Vendors, More Trust, Fewer Surprises

We believe in deep relationships with a select group of vendors. Working closely with fewer suppliers allows us to negotiate better control over materials, processes and lead times. It reduces the risk of miscommunication and quality drift. In a world where supply chains can be fragile, having trust in your suppliers is crucial. Our curated vendor network enables us to deliver high‑quality hardware components for innovation reliably, even in turbulent times.

Work With Yana

Calm, Clear Partnership

Working with us feels like collaboration, not procurement. We listen to your needs, ask critical questions and explain your options without jargon. We share the lessons we have learned from hundreds of projects across robotics, consumer electronics and industrial equipment. When you ask about a bearing or a connector, we do not just quote you; we help you understand how that choice affects the rest of your design. We are here to ensure that you choose high‑quality hardware components for innovation in a way that fits your vision.

We Help You Make Better Decisions With Less Noise

One of the biggest challenges in hardware design is the noise, marketing promises, conflicting reviews, endless datasheets. We cut through that noise by focusing on data, tests and real‑world performance. We tell you which servo drives avoid heat issues, which control architectures eliminate communication delays, and which materials offer the right balance between weight and strength. By anchoring our recommendations in evidence, we help you confidently select high‑quality hardware components for innovation.

Get in Touch — Let’s Build the Right Thing, the Right Way

The world does not need more disposable gadgets. It needs products that feel like an extension of their users, solid, responsive and trustworthy. To achieve that, you need high‑quality hardware components for innovation combined with a partner who understands the craft of performance. Let’s build something that feels right, works right and lasts. Contact Yana to start a calm, thoughtful conversation about your next project. Together we can curate, design and source the components, systems and materials that bring your vision to life.