Table of Contents

Introduction: why sourcing guides matter

In an era defined by supply chain volatility, China Sourcing Agents have evolved from simple reference materials into essential strategic partners. The pandemic, geopolitical tensions, and changing consumer expectations have shown that sourcing and product development are central to business resilience. Brands must understand how global manufacturing ecosystems work, how procurement decisions shape costs and quality, and how product cycles can be shortened without sacrificing integrity. A well-written sourcing guide offers frameworks to navigate decisions, consider sustainability, and manage risk.

Traditionally, procuring goods from overseas was handled by specialists or buying houses. Today every business that wants to scale needs to engage with international suppliers. Marketplaces like Temu and Shein have raised consumer expectations around price and variety, while also normalising short lead times. At the same time, conscious consumerism has increased scrutiny on how products are made and transported. Because of these pressures, modern China Sourcing Agents must help readers balance cost with quality, speed with ethics, and innovation with compliance. By emphasising relationships and transparency, they empower brands to build resilient supply chains that reflect their values.

New imperatives in global sourcing

In the past, companies sourced internationally mainly for low costs. Today the drivers are more complex: innovation, speed to market, and risk diversification are just as important as price. China Sourcing Agents must explain why the cheapest option is not always the smartest. Low prices can hide risks such as poor quality, unethical practices, or unreliable delivery. A single defective batch or delayed shipment can destroy trust and margins. Smart guides encourage calculating total cost of ownership, including freight, duties, compliance, and quality failures.

Agility is another imperative. Short product cycles mean manufacturers must produce smaller batches quickly and adapt to market feedback. This is critical for fashion and electronics where trends shift fast. Many Chinese factories now use flexible systems to support low MOQs and rapid prototyping. Modern China Sourcing Agents should teach readers how to negotiate MOQs, structure pilot runs, and scale production once demand is validated. They should also cover inventory and logistics management to avoid obsolete stock.

Finally, sourcing is increasingly regulated. Trade policies change quickly; for example, China once produced over 28% of global manufacturing, but tariffs and sanctions have reshaped competitiveness. Buyers must stay updated on customs duties, VAT, anti-dumping rules, and sustainability requirements. China Sourcing Agents that address these legal issues help businesses avoid costly mistakes. Since rules vary by product and destination, guides should show how to research regulations and work with customs brokers and freight forwarders.

Human‑centred procurement

Even as technology transforms manufacturing, the most successful sourcing programmes remain human at their core. Relationships, trust and communication still determine success or failure. A good China Sourcing Agents guide should stress soft skills alongside technical knowledge. Building rapport with suppliers helps secure better terms, honest updates on lead times, and smoother problem-solving. Understanding cultural nuances – like the role of guanxi in China – prevents miscommunication and builds respect.

Empathy is also essential when working with factory staff and logistics partners. Ethical sourcing means ensuring workers are treated fairly, paid appropriately and kept safe. Consumers now demand transparency from the brands they buy. By mid-2024, over 70% of Chinese state-owned enterprises had published ESG reports, signalling that sustainability is mainstream. China Sourcing Agents should help buyers evaluate suppliers not only on price but also on labour practices and environmental impact. ESG audits and social compliance certifications make this assessment easier.

Clear communication is another human factor. Many sourcing failures come from vague specifications or misinterpreted drawings. Effective China Sourcing Agents advise creating technical packs with material requirements, dimensions, tolerances, colours and packaging. Bilingual documents reduce translation errors, and suppliers should confirm agreement before production starts. Without this clarity, even strong partners can deliver subpar goods. To prevent miscommunication, guides recommend frequent updates via email, messaging apps and video calls to keep projects aligned.

Global manufacturing hubs: strengths and strategies

While China remains the world’s manufacturing powerhouse, a changing landscape has pushed businesses to consider multiple sourcing locations. China Sourcing Agents should provide clear assessments of each hub’s strengths and limitations so readers can design diversified supply chains.

China offers unmatched scale and expertise: Shenzhen excels in electronics, Guangzhou in textiles, and Zhejiang in eco-materials like bamboo. Its vast supplier networks allow rapid prototyping and mass production, though the sheer number of factories makes due diligence essential. Export controls and shifting geopolitics also add complexity. A strong China Sourcing Agents guide reminds brands to invest in verification, quality control and relationship-building to access advanced technologies such as AI-powered inspection robots.

Vietnam has become a leading alternative for apparel, footwear and certain electronics. With lower labour costs and trade deals like the EU–Vietnam Free Trade Agreement, it attracts brands diversifying risk. Yet infrastructure and supply chains remain less developed, and many raw materials are still imported from China. Practical China Sourcing Agents content advises evaluating total cost of ownership, including duties, lead times and material availability, not just the initial quote.

India provides advantages in organic cotton, handwoven textiles, handicrafts and engineering. Its craftsmanship adds authenticity and appeals to conscious consumers, while factories excel in low-volume, design-driven products. However, infrastructure challenges and cultural nuances can complicate business. A good China Sourcing Agents guide helps buyers decide when India is the right fit, while preparing them for longer lead times and more collaborative product development.

Diversifying across multiple countries creates resilience. Many brands adopt a “China + 1” strategy to hedge against tariffs, port closures or political risks. Although multi-country sourcing adds complexity, a robust China Sourcing Agents guide explains how to balance product categories, volumes, and compliance needs across regions to build stronger, more agile supply chains.

Supplier verification and due diligence

Before signing contracts, buyers must confirm that potential partners are legitimate manufacturers with sufficient capacity. Without proper checks, brands risk working with trading companies posing as factories. One key step emphasised by reliable China Sourcing Agents is verifying the supplier’s business licence and scope of business. For example, buyers can use government websites to confirm registration details and ensure the licence permits manufacturing, not just trading. If the registration is recent, further questions about experience are essential.

Another due diligence step is requesting product samples and comparing them to approved designs. Samples reveal whether a factory can meet quality standards and use the right materials. Industry experts recommend paying for samples via a registered bank account and ensuring the factory’s physical address matches the shipping address. Discrepancies could suggest a shell entity. Well-structured China Sourcing Agents also advise background checks in government databases to confirm that factories are legally registered and authorised to export.

Factory audits are a cornerstone of supplier verification. On-site inspections expose the production environment, equipment and workforce conditions. If visits are not feasible, third-party auditors can perform these checks, evaluating management systems, environmental practices and labour conditions. They may also identify subcontracting or capacity risks that suppliers don’t disclose. Comprehensive China Sourcing Agents recommend audits before production, during production and pre-shipment, combining documentation review, sample testing and audits into a robust process that reduces costly surprises.

Sourcing agents versus building your own supply chain

Sourcing agents versus building your own supply chain

Working with sourcing agents can simplify procurement, especially for companies new to international sourcing. An agent acts as an intermediary who identifies and vets suppliers, negotiates prices, manages logistics, and oversees compliance. They also leverage local networks and language skills to find manufacturers that may not appear on online platforms. For small or resource-strained businesses, China Sourcing Agents provide expertise without the cost of building an in-house procurement team.

However, not all agents are created equal. Some may prioritise commissions over the buyer’s interests, while others lack the capacity for ongoing quality control. China Sourcing Agents advise readers to choose carefully: verify transparency in fees, request references, check if they disclose factory details, and confirm policies against kickbacks. Contracts should clarify responsibilities, confidentiality terms and performance standards.

For larger companies with established procurement teams, direct relationships with factories can be more cost-effective. This model gives buyers greater control and facilitates long-term partnerships that support co-development and innovation. Well-structured China Sourcing Agents explain how to draft clear purchase orders, implement joint quality improvement programmes, share forecasts, and negotiate equitable payment terms. Even with direct sourcing, consultants may still be hired for audits or factory searches.

Ultimately, the choice between agents and direct sourcing depends on resources, product complexity and buyer experience. The key is to stay involved, ask detailed questions and insist on visibility into supplier operations. Reliable China Sourcing Agents emphasise accountability: intermediaries should never be a black box but partners who enhance transparency and quality.

Quality control and the role of technology and ESG

Ensuring quality is the foundation of any successful sourcing programme. It is not an afterthought but must be integrated into every stage of development and production. China Sourcing Agents encourage preventive measures such as drafting precise specifications, approving pre-production samples, and conducting inspections throughout the process.

Technology is transforming how quality is managed. In China, AI-powered robots with visual recognition inspect textiles during weaving and detect flaws in real time. These systems, built on databases of over 100 million defect samples, are deployed across thousands of factories. They reduce human error, accelerate detection, and enable automatic adjustments. China Sourcing Agents highlight that although such technology requires investment, it delivers long-term savings through reduced waste and improved consistency.

Environmental, social and governance (ESG) considerations are now central to quality control. The “Beautiful China” initiative and new ESG reporting framework launched in June 2024 require companies to disclose environmental data. This creates more transparency for buyers seeking sustainable partners. Factories that invest in renewable energy, waste reduction, and worker welfare stand out. China Sourcing Agents advise buyers to request ESG reports, verify certifications such as ISO 14001 and SA8000, and integrate ESG metrics into supplier scorecards. True product quality is achieved only when goods are made responsibly.

Procurement strategies and logistics planning

Once suppliers are verified and quality systems are in place, the procurement team must negotiate commercial terms and manage logistics. A comprehensive China sourcing agents guide teaches readers how to structure contracts to balance risk and flexibility. Payment schedules should be tied to milestones (for example, deposit at order placement, another payment after sample approval, and final payment after inspection) to ensure that suppliers meet quality and delivery commitments.

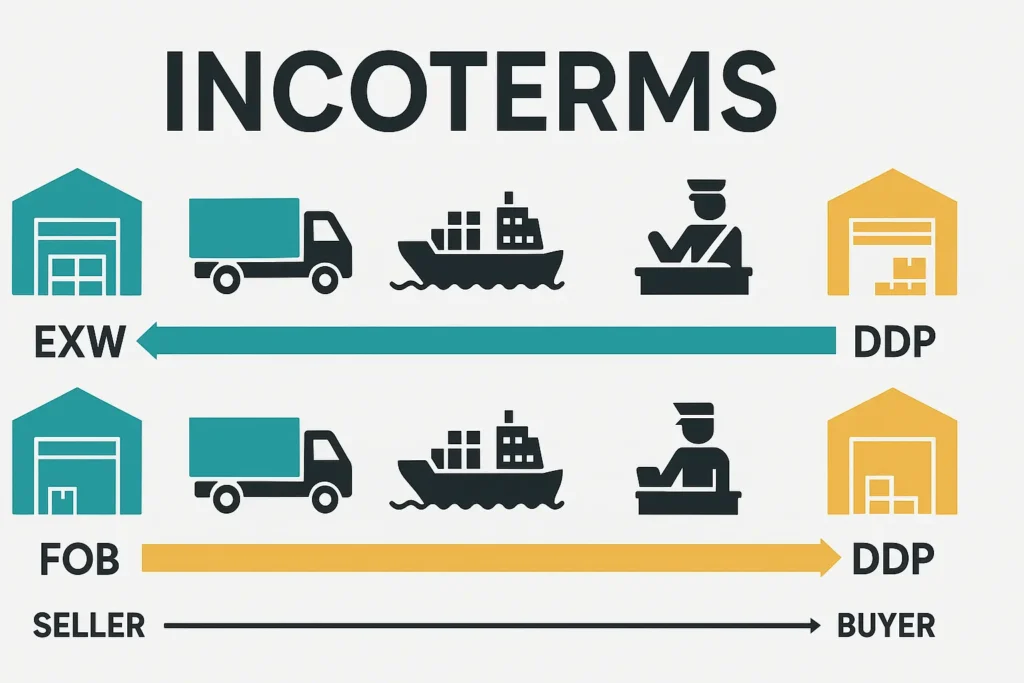

Incoterms (such as EXW, FOB, CIF or DDP) determine where ownership and risk transfer. Guides should explain the cost and risk implications of each term, helping readers choose the best option for their situation. For instance, buyers who want more control over shipping may choose FOB, taking responsibility for freight after the goods are on board, while those seeking convenience may opt for DDP, where the supplier handles duties and import clearance. Chinese sourcing agents often clarify these nuances so international buyers avoid costly mistakes.

Negotiating minimum order quantities and pricing requires an understanding of production economics. Factories set MOQs to cover set-up costs and ensure efficient production runs. Buyers should communicate realistic forecasts and be willing to pay higher unit prices for smaller runs. With the help of China sourcing agents, it becomes easier to benchmark factory expectations and align them with buyer capabilities.

As demand grows, they can negotiate price breaks for higher volumes. Transparent discussions about lead times and capacity will prevent surprises later. Chinese sourcing agents can also provide templates for requests for quotation (RFQ) that capture all relevant details, making it easier for suppliers to provide accurate quotes and avoid hidden costs.

Logistics planning covers everything from consolidating shipments to choosing freight modes. Air freight is fastest but costs more, making it suitable for urgent or high-value goods. Sea freight (LCL and FCL) is more economical but requires longer transit times. Rail freight between China and Europe via the Belt and Road Initiative offers a middle ground in terms of speed and cost. Working with China sourcing agents ensures freight decisions are optimized for both cost and timing.

Buyers should factor in port congestion, carrier reliability and seasonal fluctuations. Contingency plans are essential: natural disasters, strikes or policy changes can disrupt supply chains. By comparing freight options and building buffer times into schedules, Chinese sourcing agents help readers avoid delays and manage cash flow. The guide should also encourage working with freight forwarders who can consolidate shipments, negotiate rates and handle customs paperwork.

Sustainable materials and circular supply chains

Sustainability is no longer a niche concern; it is a mainstream expectation. Consumers and investors scrutinise brands for their environmental impact and social responsibility. A modern Sourcing Guide therefore explores sustainable materials and circular supply chain practices. Bamboo, for example, has gained popularity because it grows quickly, requires little water or fertiliser, and is biodegradable. Using bamboo fibre composites for consumer goods and packaging reduces dependence on fossil‑fuel‑based plastics. Other sustainable materials include recycled polyester (rPET), plant‑based bioplastics and innovative composites like mycelium leather. The guide should educate readers about the environmental benefits and challenges of each material, such as processing requirements, recyclability and consumer perception.

Sustainability also encompasses the energy and emissions of production and transportation. Factories that use renewable energy, practise responsible water management and minimise waste have a smaller carbon footprint. For example, the new ESG reporting requirements in China encourage companies to disclose environmental impacts, making it easier to identify sustainable partners. Circular supply chains aim to keep materials in use through recycling and reuse. This might involve designing products for disassembly, sourcing from suppliers who reclaim and recycle materials, and using packaging that can be composted or recycled. Sourcing Guides can introduce readers to circular design principles and provide checklists for evaluating suppliers’ sustainability programmes.

Adopting sustainable practices often requires balancing cost and environmental benefits. Some eco‑materials are more expensive than conventional options, and implementing recycling programmes may involve additional logistics. However, sustainability can also reduce costs over time through energy savings, waste reduction and improved brand reputation. As governments introduce carbon taxes and stricter environmental regulations, investing in sustainable sourcing becomes a risk management strategy. Well‑crafted Sourcing Guides help readers identify where sustainability investments yield the most impact and how to communicate these efforts to consumers to enhance brand value.

Conclusion: building resilience and innovation through sourcing guides

The supply chain challenges of recent years have shown that sourcing is not a back‑office function but a strategic lever. Companies that invest in knowledge and relationships outperform those that chase quick wins. High‑quality Sourcing Guides combine technical expertise, regulatory awareness and empathy to give businesses the frameworks they need to succeed. They encourage readers to think holistically about cost, quality, ethics and environmental impact. By teaching how to verify suppliers, negotiate fair contracts, implement preventive quality control and embrace sustainability, guides enable brands to build supply chains that are both resilient and innovative.

Yana Sourcing created its library of sourcing guides with this philosophy in mind. We recognise that behind every product is a community of people whose livelihood depends on a fair and transparent system. Our guides are conversations, not lectures; they ask you to reflect on your goals, challenge assumptions and be bold in experimenting. Whether you are launching your first product, scaling an established brand or diversifying across countries, these Sourcing Guides offer a roadmap you can trust. As you navigate the complexities of global trade in 2025 and beyond, remember that you are not alone. With the right knowledge, partners and processes, sourcing becomes not only a necessity but a source of creativity and growth.