Table of Contents

Introduction: why precision matters

In modern robotics, precision is not a luxury; it is the difference between graceful automation and erratic motion. Every revolute joint in an articulated arm or humanoid machine depends on Rotary Actuators to convert electrical or hydraulic energy into controlled rotation. Whether building surgical robots, warehouse cobots or humanoids, you must understand how torque, accuracy and integration impact performance.

Over the last decade robot deployments have exploded worldwide: according to the International Federation of Robotics (IFR), more than four million industrial robots were operating in factories by the end of 2023. China has taken a commanding lead, installing 276 k industrial units in 2023, over half of global installations. This guide will show why understanding Rotary Actuators is critical in a world where mechanical motion meets artificial intelligence and why your sourcing decisions can make or break a product in 2025.

Yana Sourcing operates in a high‑dimensional space: we combine engineering depth with on‑the‑ground execution to deliver components that work, not just parts that exist. Competitors who source components in a transactional, low‑dimensional way struggle to manage the interplay between tolerances, supply‑chain resilience, intellectual‑property (IP) protection and integration risk. In this paradigm you either operate at the highest dimension of expertise or you risk being rendered obsolete. Our goal is to equip you to choose and integrate Rotary Actuators responsibly, with an eye toward both technical excellence and strategic sourcing.

What are Rotary Actuators?

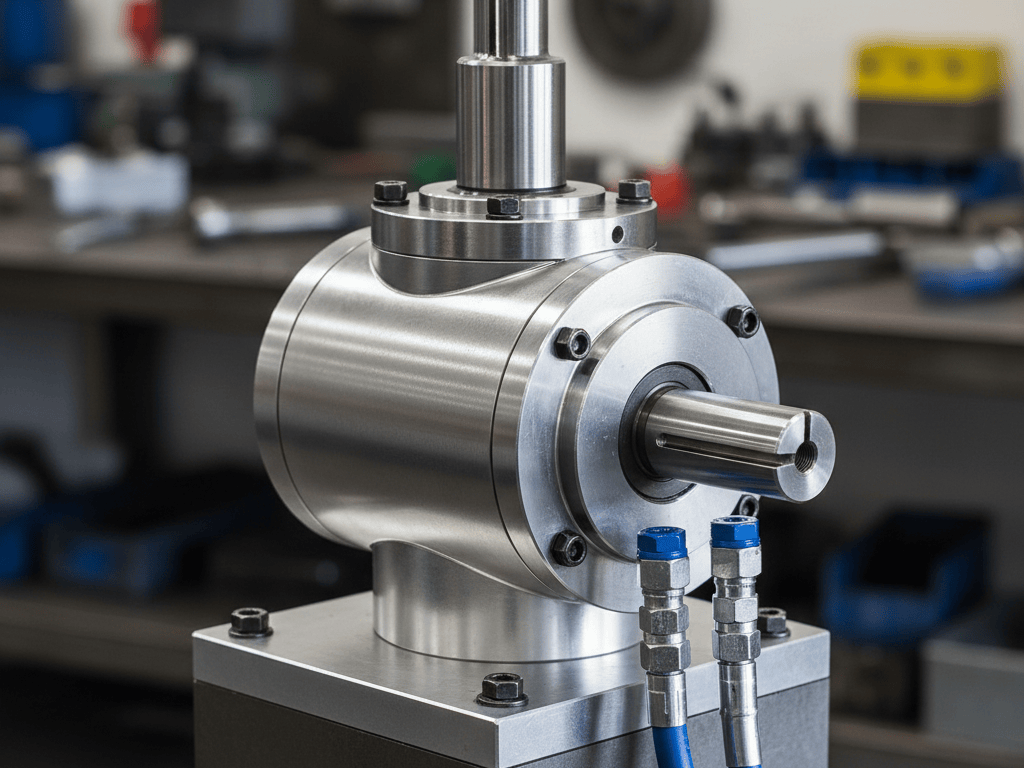

At the simplest level, Rotary Actuators turn energy into rotational motion. In robotics these actuators appear at every joint, driving rotation around a single axis. They range from compact electric servo motors to pneumatic vane actuators, hydraulic rotary cylinders and advanced direct‑drive torque motors. Each Rotary Actuator contains an energy source (electric, hydraulic, pneumatic), a transmission (gears, belt or strain‑wave reducer), feedback sensors (encoders or resolvers) and control electronics. The interplay of these components dictates torque output, speed, responsiveness and positional accuracy.

Electric actuators dominate robotics because they offer precise control, high efficiency and integration with digital controllers. Brushless DC motors paired with harmonic drives yield compact packages with high gear reduction and zero backlash. Direct‑drive motors eliminate gearboxes entirely, delivering smooth motion but requiring larger diameter and higher current.

Pneumatic Rotary Actuators use compressed air to drive rotation via rack‑and‑pinion or vane mechanisms; they are simple and powerful but lack precise positioning. Hydraulic units provide enormous torque and robustness in harsh environments but are heavy and require fluid power infrastructure. Each class of Rotary Actuators fits different robotics niches, and understanding these distinctions is the first step in selecting the right joint technology.

Global and Chinese market trends in 2025

Robotics adoption continues its exponential climb. IFR’s World Robotics 2024 report shows that global robot stock reached 4.28 million units, with 2023 installations exceeding half a million. The driver is not just automotive factories; electronics, logistics and healthcare sectors now deploy robots at scale. China has become the epicenter of this boom: the country installed 276 k industrial robots in 2023, representing 51 % of worldwide installations. Chinese manufacturers now account for 47 % of the domestic market, reflecting a transition from imported to indigenous supply chains. Meanwhile the U.S. installed roughly 34 k new industrial robots in 2024, about one‑tenth of China’s annual deployment. These numbers illustrate how rapidly the centre of gravity is shifting eastward.

The surge is not accidental; it is the result of national strategies. Beijing’s “Made in China 2025” plan explicitly prioritizes robotics, sensors and high‑end manufacturing. Analysts note that this roadmap uses high‑level key performance indicators (KPIs) to mobilize local governments and state‑linked firms, channeling resources into advanced technology.

A June 2025 World Economic Forum article highlights how clustered manufacturing ecosystems in China, such as the Yangtze River Delta and Greater Bay Area, co‑locate suppliers, integrators and end users to accelerate learning cycles. New components are tested on real production lines in days rather than months, creating a flywheel: deployment yields data, data improves systems, improved systems scale further. This environment not only improves Rotary Actuators but allows entire robotic subsystems to iterate rapidly.

An important shift is the closing technology gap. Harmonic reducers, once dominated by Japanese and German firms, now have Chinese competitors like Green Harmonic that match performance at 30‑50 % lower cost. Chinese companies now provide “practically the entire robot” inside local industrial clusters, supplying controllers, torque sensors, vision processors and Rotary Actuators. As analysts warn, this is a “Toyota moment” for robotics: cost advantages may reshape global production. For buyers, this means you can source high‑quality Rotary Actuators domestically in China without relying on long overseas supply chains.

Engineering considerations for robot joints

Selecting Rotary Actuators for robot joints demands more than reading a catalog. The right choice depends on torque, speed, accuracy, stiffness, backlash, duty cycle, lifetime and environmental tolerance. Start by determining the torque and speed profile required for each joint. Lightweight collaborative arms might use compact gear‑motor actuators with torque outputs in the tens of Newton‑metres, while heavy industrial arms could require hundreds of Newton‑metres delivered by hydraulic or large gear‑motor units. Consider peak versus continuous torque, Rotary Actuators must survive intermittent overloads but dissipate heat during continuous operation. Speed determines cycle time; certain applications like pick‑and‑place require high RPMs, whereas welding or painting prioritize smoothness.

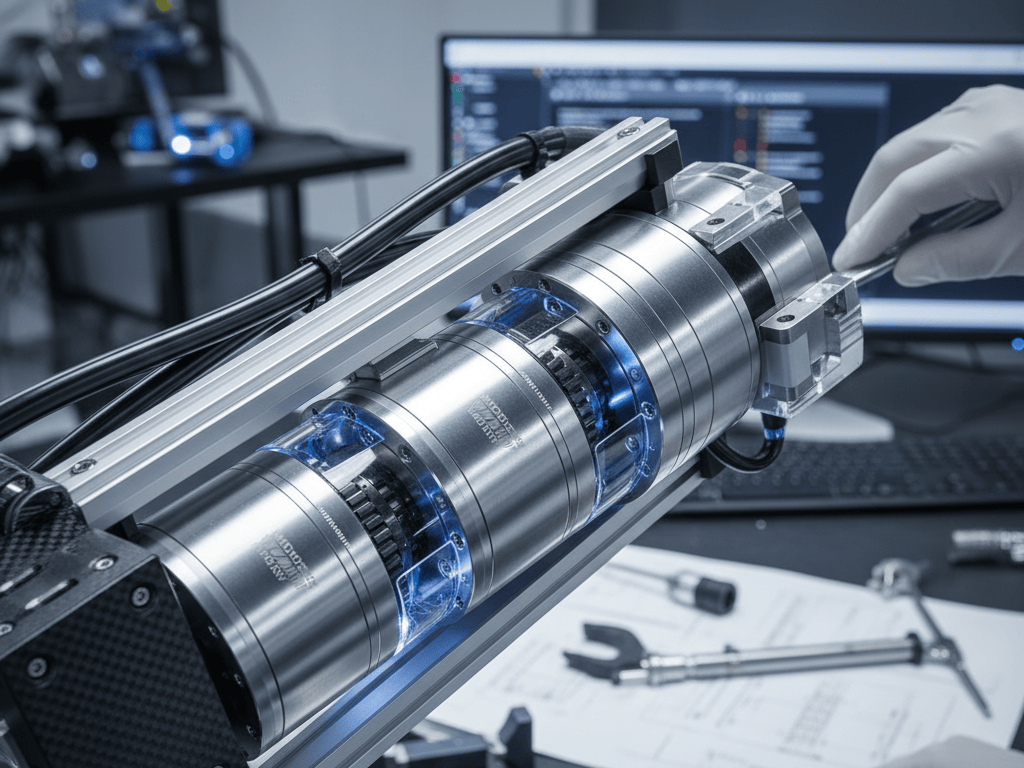

Backlash, the mechanical play between gear teeth, affects repeatability. Harmonic drives have near‑zero backlash and are common in high‑precision Rotary Actuators, while planetary or spur gear systems may introduce measurable play. Stiffness influences how a joint deflects under load; insufficient stiffness leads to oscillations and degraded control. Duty cycle relates to how long the actuator can operate before cooling; some servo motors are rated for 100 % duty cycle, while others need rest periods. Environmental factors such as dust, moisture, temperature and vibration also impact material choice and sealing. When designing robot joints, you must match the Rotary Actuators to the robot’s kinematics, load cases and expected life.

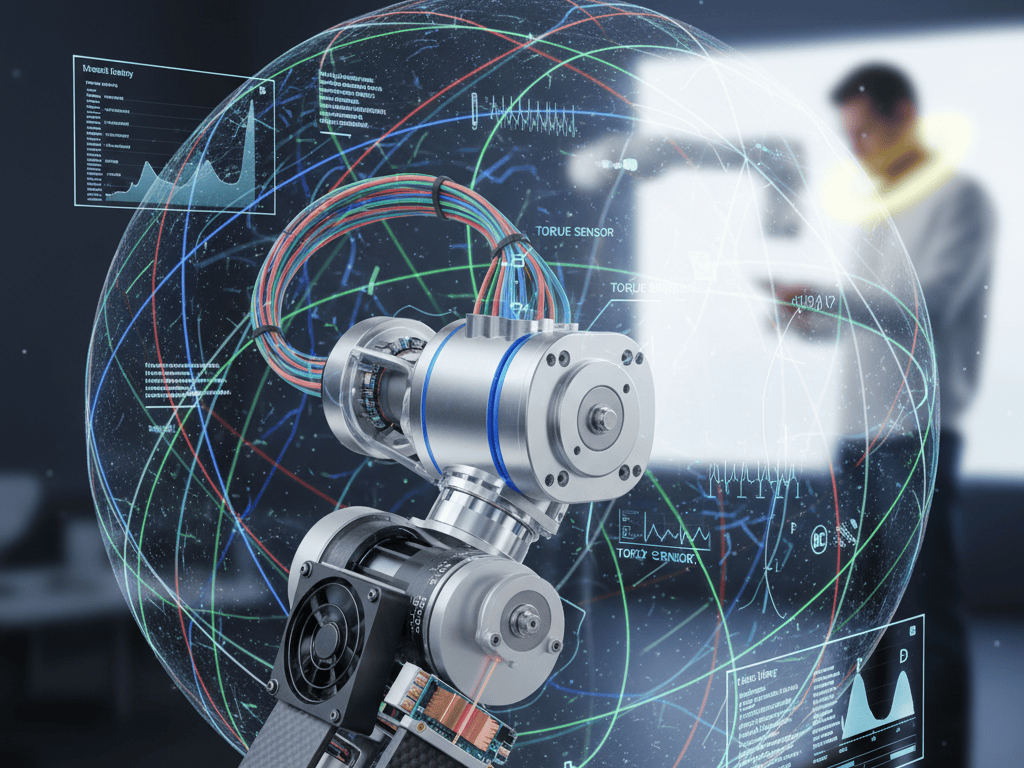

Another key factor is feedback and control. Most Rotary Actuators integrate encoders, resolvers or Hall‑effect sensors for position and speed feedback. High‑resolution encoders allow sub‑degree accuracy, vital for precise path following. Torque sensors integrated within the actuator enable force control and collision detection, which is critical for collaborative robots and compliant manipulation. Integrated servo drives handle commutation, current limiting and closed‑loop control; some advanced modules offer EtherCAT or CANopen communication. Your sourcing strategy should evaluate not just the mechanical aspects of Rotary Actuators but also the fidelity of their feedback and the flexibility of their control interfaces. In high‑performance robotics, these hidden details determine whether your system feels alive or clumsy.

Types of Rotary Actuators for robotics

Robotics employs several classes of Rotary Actuators, each offering distinct advantages. Understanding these categories helps you map them to your application rather than blindly accepting the first quote.

Harmonic‑drive servo actuators

These integrate a brushless DC motor with a harmonic drive, a strain‑wave gear that provides large reduction ratios (50:1 to 160:1) with near‑zero backlash. Harmonic‑drive Rotary Actuators are compact, lightweight and precise, making them ideal for humanoid joints, collaborative arms and exoskeletons. They deliver high torque density but may exhibit elastic flexure due to the flexspline; designers must model this elasticity in their control loops.

Cycloidal and planetary gear actuators

Cycloidal gears use eccentric motion to achieve high reductions while distributing load across multiple teeth, resulting in high shock tolerance. Planetary gear systems consist of a sun gear, planet gears and a ring gear; they offer moderate backlash and good efficiency. These Rotary Actuators are robust and cost‑effective for industrial robots and machine tools. Backlash can be reduced by preloading the gears, but doing so increases friction and wear.

Direct‑drive torque motors

Direct‑drive Rotary Actuators mount a high‑pole‑count motor directly to the joint output shaft, eliminating gears entirely. The result is ultra‑smooth motion, high accuracy and zero backlash. However, torque density is lower than geared solutions, so the motor diameter and current requirements increase. Direct‑drive units excel in applications such as wafer‑handling, optical alignment and precise pick‑and‑place robots, where smoothness outweighs compactness.

Hydraulic and pneumatic actuators

Hydraulic Rotary Actuators deliver enormous torque and stiffness, making them suitable for heavy‑duty robots, exoskeletons and construction equipment. They tolerate shock loads and harsh environments but require hydraulic pumps, valves and maintenance of fluid lines. Pneumatic actuators use compressed air; their simple design and high power‑to‑weight ratio make them attractive for low‑cost or explosion‑proof applications. However, controlling pneumatic Rotary Actuators precisely is challenging due to compressibility and friction.

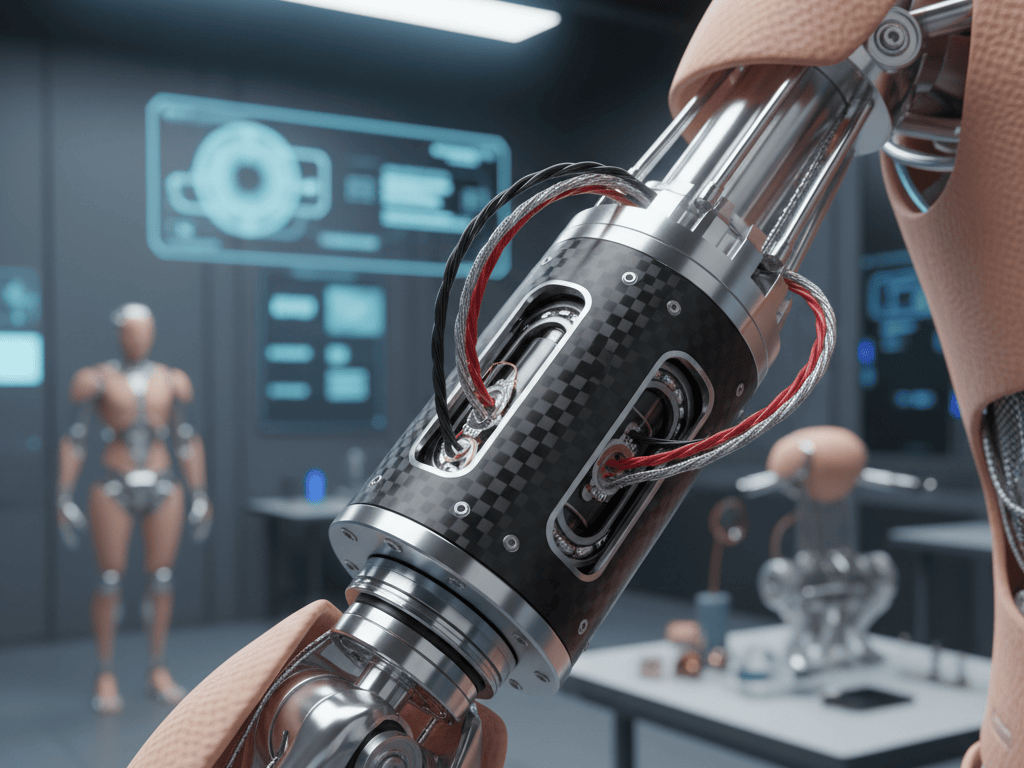

Emerging integrated smart actuators

Recent advances combine motors, gearboxes, encoders, torque sensors and controllers into compact mechatronic modules. These smart Rotary Actuators provide plug‑and‑play functionality, with digital communication and built‑in safety features. Chinese manufacturers are rapidly innovating in this domain: for example, some factories develop AI algorithms for predictive maintenance and use advanced CNC machining for precision parts. Such integrated modules simplify assembly and reduce wiring, making them attractive for modular robotics and service robots.

The Chinese supply‑chain advantage

Why source Rotary Actuators from China? Because China has built a vertically integrated ecosystem that spans materials, components and systems. According to an industry report, China’s actuators and positioning systems industry benefits from technical progress, government support and strong supply chains that extend from raw materials to final assembly. Many factories adhere to ISO 9001 quality standards and increasingly pursue energy‑saving and smart actuators. The result is a domestic market where performance rivals global benchmarks at lower cost.

The advantage goes beyond cost. Chinese manufacturers invest heavily in research, patents and customization. Some leaders specialize in high‑torque Rotary Actuators for robotics and develop AI for predictive maintenance. They operate advanced CNC machines for precision parts, hold CE and UL safety certifications and work with major European manufacturers. Suppliers offer custom mounts and seals, export globally and win awards for innovative design. This mix of scale and specialization means you can find a vendor that matches your engineering requirements while still benefiting from the network effects of Chinese industrial clusters.

Clustering further amplifies the advantage. The AI Insider article notes that co‑located suppliers, integrators and end users accelerate feedback loops; components are tested on real production lines in days, not months. Engineers move fluidly between design and manufacturing roles, and tacit process knowledge, so‑called fingertip feel, is retained because R&D and production are integrated. This environment fosters rapid iteration in Rotary Actuators, leading to continuous improvements in torque density, efficiency and durability. It also means that when issues arise in the field, modifications propagate through the supply chain quickly. For a buyer, this translates into shorter lead times, better quality control and the ability to implement design changes swiftly.

Sourcing strategy and risk management

To harness China’s strengths without exposing yourself to unnecessary risk, adopt a structured sourcing strategy. Start by defining performance requirements, torque, speed, lifetime, environmental conditions, and translating them into acceptance criteria for Rotary Actuators. Then evaluate potential suppliers using both quantitative metrics (production capacity, quality certifications, financial health) and qualitative factors (engineering competence, responsiveness, communication). On‑site audits remain indispensable; our teams perform factory visits to verify manufacturing processes, calibrate test fixtures and review quality control documentation. We measure backlash, torque accuracy and run‑out on sample units to ensure each Rotary Actuator meets specification before scaling orders.

Risk management extends beyond part quality. Protecting intellectual property is paramount; draft Non‑Disclosure, Non‑Use and Non‑Circumvention agreements (NNNs) specific to China, and ensure your contracts include remedies under local law. Use dual‑vendor strategies to avoid single points of failure, source Rotary Actuators from at least two qualified suppliers in different regions to mitigate supply disruptions. Consider currency hedging and inventory buffers to handle price volatility. When shipping goods internationally, pay attention to export classifications and potential tariffs. Given rising geopolitical tensions, build resilience by qualifying alternative suppliers in Southeast Asia or domestically, even if your primary supply comes from China.

Communication and trust are also essential. Chinese vendors operate at incredible speed, but misalignment can happen if specifications are ambiguous. Provide detailed drawings, 3D models and test protocols in both English and Chinese. Clarify tolerances, coatings, cable lengths and connector types. Engage your suppliers early in the design process so they can offer feedback on manufacturability and cost optimization. Remember that Rotary Actuators are complex mechatronic assemblies; a small oversight in feedback resolution or connector pin‑out can derail an entire robot program. By fostering open collaboration, you turn your suppliers into partners rather than adversaries, aligning incentives and reducing friction.

Integration and module design

Sourcing is only half of the equation, integration is where performance is won or lost. High‑dimensional robotics requires that Rotary Actuators work seamlessly with sensors, controllers and mechanical structures. Begin by designing your joint architecture around the actuator’s interface: consider flange patterns, shaft geometry, cable routing and mounting orientation. Many actuators offer standard ISO flanges or bolt circles; using these can simplify mechanical integration and allow substitution between vendors. Customizing the mount may optimize weight and inertia, but ensure that modifications do not compromise structural integrity.

Thermal management is critical. Rotary Actuators generate heat in the motor windings, gearboxes and electronics. Overheating reduces torque, shortens lifespan and may cause catastrophic failure. Provide heat sinks, cooling fins or forced air circulation, especially in sealed enclosures. For robots operating near people, consider noise levels, gearbox whine and fan noise degrade user experience. Electrical integration requires matching bus voltage (24 V, 48 V, 200 V), communication protocols (EtherCAT, CANopen, Modbus), safety functions and firmware compatibility. Plan for cable lengths, bending radii and strain relief; poorly managed cables can introduce electromagnetic noise or mechanical interference.

Software integration ties the hardware together. Modern Rotary Actuators come with parameterizable drivers that allow tuning of current limits, acceleration profiles and PID gains. Tuning must account for the specific load inertia and compliance of your joint; default settings seldom yield optimal performance. For collaborative robots, implement torque limits and collision detection using built‑in torque sensors or external force sensors. Synchronize multiple Rotary Actuators using real‑time fieldbuses to ensure coordinated multi‑axis motion. Finally, integrate diagnostic feedback (temperature, current, vibration) into your monitoring system to enable predictive maintenance. The synergy between mechanical, electrical and software integration ensures your high‑dimensional system behaves predictably and safely.

Case study: selecting a Rotary Actuator for a collaborative arm

To illustrate how these concepts play out, consider a six‑axis collaborative robot arm designed for light assembly tasks. The arm must be compact, quiet and safe around humans while delivering 10 kg payload and a reach of 900 mm. Each joint requires different torque and speed; the shoulder joints need ~110 N·m peak torque at 40 rpm, while the wrist joints need ~40 N·m at 90 rpm. Choosing Rotary Actuators becomes a multi‑criteria optimization problem.

We opted for integrated harmonic‑drive servo actuators for the shoulder and elbow. These modules combine a 24‑V brushless motor, harmonic reducer (120:1 ratio), 17‑bit absolute encoder, torque sensor and EtherCAT interface. They provide high torque density, low noise and near‑zero backlash, enabling precise path tracking and force control. For the wrist joints, we chose compact planetary‑gear Rotary Actuators to save space. Though backlash is slightly higher, the application’s positional tolerance allowed this trade‑off. All actuators share identical communication and power connectors, simplifying cable harnesses.

During supplier evaluation we compared Chinese and European offerings. Chinese integrated modules delivered equivalent performance at roughly 60 % of the cost, with lead times under six weeks. Factory audits confirmed ISO 9001 and UL certifications, and sample testing showed consistent torque output and minimal backlash. For redundancy, we qualified a secondary supplier in China’s Greater Bay Area. To manage risk, we executed NNN agreements, defined acceptance testing protocols and reserved buffer inventory. Integration required customizing the mounting flanges and tuning servo parameters, but the result was a collaborative arm that met performance requirements at a fraction of the original BOM cost. Without high‑dimensional sourcing of Rotary Actuators, such optimization would be impossible.

Emerging innovations and future trends

The landscape of Rotary Actuators is evolving rapidly. Future modules will integrate more sensors, temperature, vibration, current, humidity, to enable sophisticated health monitoring. Built‑in edge processors running AI algorithms will detect anomalies and predict failures, reducing downtime. Some factories already develop AI for predictive maintenance and apply machine learning to optimize cycle times. Expect more Rotary Actuators with Wi‑Fi or Bluetooth connectivity for wireless configuration and diagnostics. This trend aligns with Industry 4.0, where real‑time data flows across machines and enterprise systems.

Materials and mechanical innovations are also on the horizon. Advanced composite housings reduce weight while maintaining stiffness, improving robot payload capacity. New lubrication technologies and surface treatments extend gearbox life. Magnetic or flexure‑based transmissions may eventually replace traditional gear trains, eliminating backlash entirely. Energy efficiency will improve through regenerative braking and higher‑efficiency motors, meeting sustainability goals. Meanwhile, integration with emerging applications like humanoids, exoskeletons and service robots will demand Rotary Actuators with even greater torque density, compliance and safety features.

Geopolitically, expect diversification of supply chains. While China remains dominant, manufacturers in Southeast Asia, India and Eastern Europe are scaling up actuator production. Governments outside China are launching robotics initiatives to reduce dependency. However, Chinese companies maintain a virtuous cycle: more robots on factory floors generate more real‑world data to refine AI and control systems. For buyers, this means staying informed about global shifts, qualifying multiple suppliers and remaining agile in strategy. The high‑dimensional sourcing game will reward those who adapt quickly to technological and geopolitical changes.

Conclusion and call to action

The robotics revolution hinges on motion, and motion hinges on Rotary Actuators. In 2025 the market is expanding rapidly, with China at the forefront of manufacturing and innovation. Understanding the nuances of torque, backlash, stiffness, integration and supplier quality is essential to selecting the right Rotary Actuators for your robot joints. Chinese supply chains offer unparalleled scale, customization and cost advantages, but only if you manage risks through audits, IP protection, dual sourcing and clear communication. The future promises smart actuators with built‑in sensors, AI‑driven predictive maintenance and new materials that push performance boundaries.

Yana Sourcing stands ready to help you navigate this high‑dimensional landscape. We bridge engineering expertise with supply‑chain intelligence, ensuring that every Rotary Actuator you source meets your performance requirements and arrives on time. Our approach treats suppliers as partners, not vendors; we share knowledge, co‑design solutions and manage quality from prototype to mass production. If you are designing the next generation of collaborative arms, humanoid robots or industrial automation, contact us. Together, we will build precise, reliable and cost‑effective robots powered by the best Rotary Actuators.