Table of Contents

Introduction: Why Robotics Integration Is More Than Parts Assembly

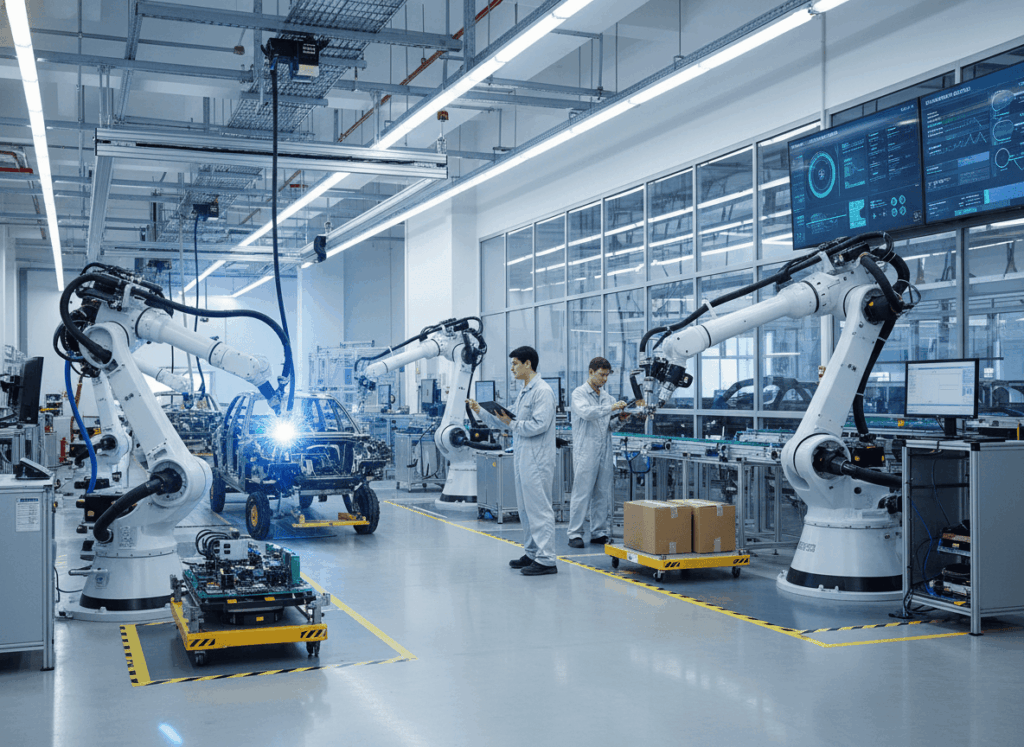

Robotics integration is the art of turning individual components, motors, sensors, controllers, software, into a coherent system that behaves as one. It might sound straightforward, but robotics integration goes far beyond bolting parts together; it requires harmonizing mechanical tolerances, electrical signals, control algorithms, and software architectures. When done well, robotics integration transforms discrete modules into machines that feel fluid and alive; when done poorly, it creates frustration, risk and lost margin. In every paragraph of this article, we will use the phrase robotics integration to underscore how central it is to every decision you make in modern automation.

Robotics integration matters because machines are moving from isolated tasks to interconnected ecosystems. Industrial arms talk to mobile robots; vision systems talk to cloud apps; cobots learn from human collaborators. Hardware and software must align not only within a machine, but across supply chains and factories. As companies look for higher margins and less commoditized business models, they realize that robotics integration, done with vision and discipline, is their edge. In the paragraphs that follow, we’ll explore why integration is so much more than assembly and how Yana brings calm precision to the process.

The Role of Robotics Integration in System‑Level Behavior

Robotics integration defines how the parts of a machine work together. A motor may offer torque and speed, but unless the control board, servo driver and sensor are tuned to that motor, its potential is wasted. A sensor may produce accurate readings, but if the software can’t process them in time, the robot will stutter. Without robotics integration, a machine becomes a collection of misaligned parts; with integration, it becomes a seamless system. This systemic view is why we emphasize robotics integration as the heartbeat of high‑margin robotics.

At the simplest level, robotics integration begins with understanding how signals travel. Servo drivers convert commands into pulse‑width modulation (PWM) signals that manage voltage and speed. Motion control boards read high‑level instructions and translate them into motor commands. Sensors feed back position and torque, and software algorithms adjust accordingly. The loop only works when timing and protocols match. For example, a poorly integrated servo drive can overheat, add latency and take up unnecessary space, undermining overall system performance. True robotics integration respects these dependencies from day one.

The Hidden Cost of Poor Integration

Many robotics projects fail not because components are bad, but because the integration between them is neglected. When off‑the‑shelf servo controllers designed for general machinery are shoved into robot joints, they generate excess heat, latency and bulk. When motion control boards are not designed for real‑time multi‑axis synchronization, they cannot provide the precise timing that robots need. These hidden mismatches manifest as jerky movements, premature wear and increased energy consumption. Poor robotics integration costs more than upgrading a part, it costs time, reputation and customer trust.

Consider how servo drives rely on integrated safety. Modern drives read torque sensors and send feedback via buses like EtherCAT; they implement Safe Torque Off (STO) to prevent unexpected motion. If the system integrates drives without proper communication or safety protocols, the risk of injury or damage increases. Robotics integration must therefore treat safety as a design constraint, not an add‑on. A small misalignment in torque feedback can lead to large deviations in trajectory, so integration is not optional; it is essential.

Reliability, Feel and User Experience as Differentiators

In high‑margin markets, customers pay for reliability and experience, not just function. A robot that moves smoothly, responds predictably and feels intuitive is the result of careful robotics integration. Integrating servo drivers using PID control loops, for example, ensures that error corrections are proportional, integral and derivative so that motors react precisely to deviations. Poorly tuned integration leads to overshoot, oscillations or sluggish response. These subtleties determine whether a robot delights or disappoints.

Moreover, robotics integration shapes how the machine interacts with humans. Collaborative robots must integrate sensors, drives and control boards to detect contact and adjust torque quickly enough to prevent harm. Logistics robots must integrate vision systems and navigation software to avoid obstacles gracefully. The feel of a robot is not just an aesthetic choice; it’s a business strategy. By focusing on robotics integration, Yana helps clients deliver experiences that justify premium pricing and long‑term loyalty.

Core Layers of Robotics Integration

Mechanical Integration: Fit, Tolerances and Co‑Stiffness

Mechanical integration is the foundation of robotics integration. It ensures that motors, reducers and sensors fit physically, align with shafts and gears, and share stiffness. A complete joint integrates a motor, gear reducer, encoder and driver in one housing. If these parts are misaligned by even a fraction of a millimeter, backlash and vibration increase, degrading system performance. Mechanical integration also addresses heat dissipation; new transistor technologies allow integrated servo drives to manage heat more efficiently, but the housing must conduct heat away from sensitive electronics. Without mechanical integration, no amount of clever software will rescue you.

Electrical Integration: Wiring, Connectors, EMI and Grounding

Electrical integration ensures that power and signals flow reliably. Wiring harnesses must handle current and voltage without introducing resistance or electromagnetic interference (EMI). Connectors must lock securely and be rated for the environmental conditions they face. Grounding schemes must prevent voltage differences that can damage electronics. Robotics integration requires careful selection of cable types, lengths and shielding; a data cable running alongside a power cable may introduce noise that confuses sensors. Integrating servo drivers into joints reduces wiring complexity by minimizing cable runs, but it requires planning of connectors and bus protocols like CANOpen or EtherCAT.

Control Integration: Drivers, Boards and Protocols

Control integration is where robotics integration touches heart and mind. Servo drivers convert high‑level motion commands into PWM signals; control boards process feedback and coordinate multiple axes; unified motion controllers integrate robot kinematics and machine logic. When separate controllers and PLCs communicate over multiple networks, delays and conversion errors can emerge. Integrated controllers reduce hardware and software complexity, speeding development and improving reliability. Robotics integration must therefore include decisions about whether to use standalone servo drives or integrated control chips. It also involves choosing protocols, EtherCAT for high‑speed synchronization, CANOpen for robust industrial networks, or ROS for flexible research platforms.

Software & Perception Integration: Kinematics, Vision and Calibration

Software integration binds hardware components into intelligent behavior. In robotics integration, software manages kinematics calculations, motion planning, vision processing and machine learning. It fuses data from encoders, force sensors and cameras to understand the world. It also calibrates coordinate frames so that motion commands map correctly to physical locations. Poor software integration leads to inconsistent behavior, misalignment between perception and action, and difficulty updating code. A strong robotics integration strategy involves modular software that can adapt to new sensors or algorithms, and that supports simulation and digital twins for faster testing. By integrating software deeply into the design, Yana helps clients build robots that learn and evolve.

Integration for Different Robotics Classes

Personal and Consumer Robotics

Personal robots and consumer devices demand robotics integration that balances cost, aesthetics and reliability. Integration must be compact and unobtrusive; wires and heat sinks are hidden beneath sleek exteriors. Motors and gears are quieter, sensors are more discrete. Software integration is user‑friendly, allowing consumers to calibrate or update devices easily. Since personal robots often operate in uncontrolled environments, integration must account for varied lighting, uneven floors and user unpredictability. By focusing on robotics integration, designers ensure that devices remain robust while delighting consumers.

AGV/AMR and Logistics Systems

Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) operate in warehouses, ports and factories. Their robotics integration must handle high payloads, long run times and dynamic obstacles. Mechanical integration emphasises robust frames and shock absorption; electrical integration handles high currents for drive motors; control integration coordinates wheels or tracks and often integrates lidar or vision sensors for navigation. Software integration combines path planning, fleet management and warehouse management systems. Poor robotics integration can lead to collisions or downtime; strong integration enables reliable 24/7 operations.

Collaborative Arms and Manufacturing Automation

Collaborative robot arms must integrate torque sensors, servo drives and control boards to detect human contact and adjust in milliseconds. They must integrate safety features like STO and compliance to meet ISO standardsingeniamc.com. Mechanical integration includes designing joints with minimal backlash and appropriate gear ratios. Electrical integration includes ensuring safe cable routing through hollow arms. Control integration means selecting boards with enough processing power to execute complex kinematics and coordinate multiple axes. Robotics integration in this segment demands a balance of speed and sensitivity, as well as ease of programming.

Micro‑Robotics, Gimbals and Precision Positioning Units

Tiny robots and precision devices require robotics integration at the microscale. Components like voice‑coil actuators or piezoelectric drives must be integrated with miniaturized drivers and high‑resolution encoders. Mechanical integration focuses on lightweight materials and vibration isolation. Electrical integration uses flex circuits and micro‑connectors. Control integration uses low‑power boards and algorithms that minimize computational load. Software integration may involve custom firmware because off‑the‑shelf systems cannot handle micrometer‑level precision. By applying high‑dimensional thinking, Yana helps clients integrate these delicate systems without compromising performance or profitability.

System Stability, Safety and Performance Tuning

Latency, Bandwidth and Synchronization

One of the most overlooked aspects of robotics integration is timing. Machines often involve multiple axes and sensors that must coordinate at high frequencies. If the servo drive updates at 10 kHz but the controller runs at 1 kHz, the control loop cannot respond quickly enough to disturbances. Latency and jitter—variation in timing—introduce vibration and error. Protocols like EtherCAT offer high‑bandwidth, deterministic communication for robotics integration. Unified controllers integrate machine logic and kinematics to eliminate communication delayscontroleng.com. By aligning sampling rates and choosing the right bus, integrators ensure that data flows at the right pace.

Feedback Loops and Motion Smoothness

Robotics integration is about closing the loop: sensors feed information to the controller, which adjusts the output to keep the system on track. Servo drives use PID algorithms to manage error; the proportional term drives immediate response, the integral term corrects steady‑state error and the derivative term damps oscillationsrozum.com. System tuning is an integration art; too much gain and the robot oscillates, too little and it feels sluggish. When integrated properly, feedback loops deliver smooth, quiet motion that feels human. Yana uses real‑time data and experience to tune loops for each application.

Heat, Wear and Long‑Term Operating Life

The physical integration of heat management and durability is essential to robotics integration. Innovations like gallium‑nitride transistors and improved gate drivers increase power density and reduce heatingeniamc.com, enabling integrated servo drives in compact joints. However, system designers must still account for ambient temperature, airflow and materials. Robots that operate 24/7 in factories require integration strategies that distribute heat and minimize wear. Sensors can monitor motor temperatures and vibration levels; integration ensures that data is captured and acted upon before failure occurs.

Field Calibration and Auto‑Adjustment Routines

Robotics integration is not only about the factory floor; it must extend to deployment. Robots often operate in environments different from those in which they were built. Calibration routines for sensors and motors ensure that coordinate frames align, backlash is accounted for and gravitational offsets are corrected. Auto‑adjustment routines allow robots to adapt to wear or load changes over time. Integration ensures that these routines have access to sensors and actuators and that they can run without disrupting production. For clients, this means fewer service calls and longer uptime.

Supplier and Partner Ecosystem Strategy

When to Standardize vs. Customize

Deciding whether to use standard modules or custom designs is a core robotics integration decision. Standard complete joints and controllers reduce development time and cost, but may limit performance or differentiation. Custom integration offers precise optimization but requires engineering resources. At Yana, we help clients evaluate trade‑offs based on volume, margin and time to market. For example, integrated servo drives can reduce wiring and latencyingeniamc.com, but customizing them may be necessary to achieve specific torque or safety requirements. A hybrid strategy often works best: standardize where the market sees no value in difference, customize where your brand can stand apart.

Selecting Suppliers Who Understand System Behavior

Robotics integration requires suppliers who appreciate the system’s behavior, not just their own part. A control board vendor must understand real‑time requirements and multi‑axis coordinationanypcba.com. A servo drive supplier must provide not just power but data and safety featuresingeniamc.com. A sensor provider must know how their devices interface with your software and wiring. At Yana, we vet suppliers based on technical capacity and collaboration style. We look for partners who talk about systems—not just components—and who share our commitment to high‑margin, high‑quality products.

Integration as a Competitive Business Model

Some companies still compete on price and capacity; Yana’s clients compete on integration. By mastering robotics integration, you can offer products that command higher prices because they deliver reliability, agility and ease of deployment. You also reduce warranty costs and service calls. Integration becomes part of your brand: customers know that your robots work out of the box, adapt to their needs and last longer than expected. This is how robotics integration becomes a competitive business model—not an engineering afterthought.

Case Example: High‑Margin Robotics Without Racing to the Bottom

A European startup wanted to build a collaborative arm for high‑precision assembly. They could have sourced low‑cost motors and controllers separately, but they chose to integrate them deeply. They partnered with Yana to find integrated servo drives with torque feedback and STO functionsingeniamc.com. They selected a control board that could handle multi‑axis coordination and had an open APIcontroleng.com. They integrated sensors and software so that the arm could calibrate itself during installation. As a result, the product commanded a premium price and a reputation for reliability, proving that robotics integration can unlock higher margins.

Future of Robotics Integration

Unified Control Stacks

In the near future, robotics integration will be driven by unified control stacks—hardware and software platforms that handle everything from sensor fusion to motion control. The current trend towards unified controllers, where robot kinematics and machine logic run on the same devicecontroleng.com, will accelerate. Open standards like ROS 2 and industrial Ethernet protocols will bridge the gap between research and production. Integration will become easier thanks to plug‑and‑play architectures and standardized interfaces, but the ability to optimize these stacks for specific applications will still separate leaders from followers. Yana anticipates these trends and guides clients in choosing platforms that scale and adapt.

Edge AI Motion Adaptation

Artificial intelligence is moving to the edge, embedded in servo drives and control boards. These systems will learn the machine’s dynamics, adapt control parameters and predict failures. Robotics integration will involve training models on simulation data and fine‑tuning them on real machines. Edge AI will help robots respond to unknown situations, such as unexpected payloads or changed friction conditions, by adjusting control loops on the fly. Integration will evolve from static design to continuous learning, demanding new expertise. Yana’s role will be to bridge machine learning and supply chain, ensuring that AI‑enabled hardware arrives on time, on cost and fully integrated.

Self‑Calibrating, Self‑Diagnosing Machines

Future robotics integration will enable machines to calibrate and diagnose themselves. Self‑calibrating robots will run routines to measure joint offsets, align coordinate frames and set tool tip positions. Self‑diagnosing systems will monitor vibration, temperature and current to detect wear and generate maintenance alerts. Integrated sensors and software will make these capabilities standard, not special features. Such advancements will reduce downtime and service costs, making integration a profit center rather than a cost line. Yana stays ahead of these trends by sourcing components with built‑in diagnostics and designing integration frameworks that support self‑services.

Work with Yana for Integration Done Right

Calm Precision, Transparent Communication and Real Partnership

At Yana, we approach robotics integration with calm precision. We know that your business depends on systems that work first time and keep working. We understand that you operate with lean teams and cannot afford endless design iterations. We integrate mechanical, electrical, control and software layers into coherent solutions that deliver high margin and high performance. We communicate transparently about lead times, costs, risks and trade‑offs. We partner with you—whether you are a startup building your first robot or an enterprise optimizing a global supply chain—because robotics integration is not a commodity. It is a craft.

Yana sees what others don’t. We stay ahead of technology trends and supply‑chain realities. We know which suppliers are investing in edge AI drives or unified control architectures. We know when to use a standard module and when to design a custom board. We know how to align your product roadmap with innovation cycles so you don’t get stuck in the wrong generation of hardware. Our high‑dimensional perspective means we see beyond parts and even beyond systems; we see how robotics integration influences your business model, margin and brand.

If you’re ready to move beyond assembly and into the realm of true robotics integration, where every component works together to amplify your vision, then contact Yana. We don’t just deliver hardware; we deliver harmony. And harmony is what makes robots powerful, products profitable and customers loyal. Join us, and together we’ll build machines that move with calm precision and speak the language of the future.