The Role of Complete Joints in Robotic Motion Systems

A complete joint is more than a collection of parts, it is a self‑contained motion unit that combines the motor, reducer, servo driver, control logic and sensory feedback into one precisely engineered assembly. In modern robotics, complete joints are the building blocks that allow engineers to assemble articulated arms, collaborative robots and autonomous vehicles without reinventing the wheel each time. These modules simplify design and shorten development cycles because the kinematic performance, thermal management and control loops are already validated. Instead of wiring discrete motors, external gear reducers and standalone servo drivers, a complete joint integrates everything into a single, sealed package.

This integration reduces cabling and eliminates many of the points of failure found in traditional systems where separate servo drives generate heat, latency and size problems. For robotics companies that value clarity and margin, using complete joints yields repeatable performance and easier service, while also lowering assembly time. Yana Sourcing works with manufacturers that understand these benefits and ensures the complete joint modules you source are designed for long‑term reliability and human‑safe interaction.

Why Complete Joints Reduce Integration Burden

The transition from discrete components to complete joints mirrors the evolution from hobbyist kits to industrial platforms. When motors, reducers, sensors and servo drivers are purchased separately, engineers must worry about mechanical alignment, torque compatibility, thermal dissipation and control latency. General‑purpose servo controllers designed for industrial machines often prove unsuitable for robot joints because they are too big, too heavy and dissipate too much heat. Complete joints solve this by embedding a purpose‑built servo drive within the joint housing.

Integrated control hardware reads torque and position sensors, then sends current and voltage signals to the motor via high‑speed EtherCAT or CANOpen buses. This closed‑loop control not only improves accuracy but also ensures safety through features like Safe Torque Off (STO) and redundant end‑stops. By sourcing complete joints, you eliminate the need to select separate servo controllers and cabling, reduce the chance of mis‑wiring and gain the confidence that each module has been factory‑tested under rated loads and duty cycles. In short, complete joints take away integration headaches and free you to focus on product design, user experience and differentiation.

Performance, Reliability and Assembly Simplification

Complete joints bring three transformative advantages to your robotics projects: performance, reliability and assembly simplification. Performance comes from precise matching of motor torque, gear ratio and encoder resolution. In a complete joint, the servo driver uses pulse‑width modulation to modulate voltage and current; longer pulses provide more torque and faster rotation, while the controller’s PID loop, proportional, integral and derivative, keeps the error between desired and actual position minimal. Reliability comes from the compact, sealed design: instead of wires running between separate modules, the power electronics and control board are embedded right next to the motor and reducer.

Many complete joints include integrated torque sensors; these sensors allow safety functions like Safe Torque Off and over‑current protection. Finally, assembly becomes simpler: rather than aligning shafts and couplers and calibrating separate components, technicians mount the complete joint via standardized flange patterns and connect a single communication cable. This reduction in parts counts lowers the risk of mechanical misalignment and ensures that the system is easier to service. The margin you gain from less assembly time and fewer field failures is margin you can reinvest in better design or pass on to customers as premium value.

Architecture of a Complete Robotic Joint

Motor, Reducer, Sensor and Driver Integration

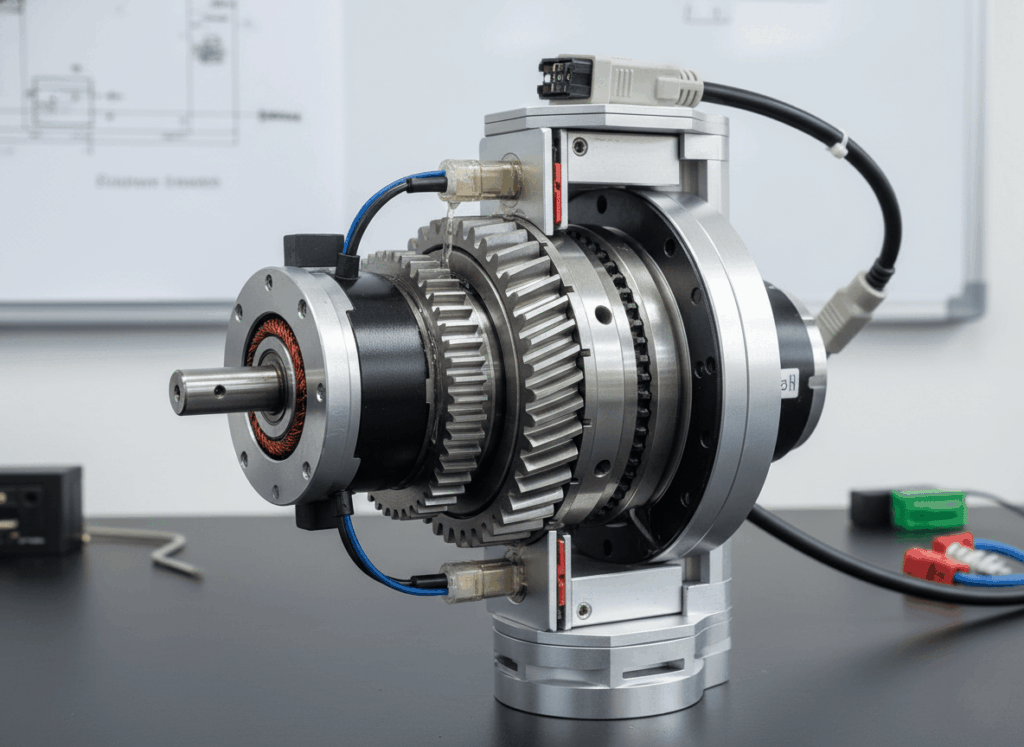

At the heart of every complete joint is a high‑torque motor, often a brushless DC or AC servo motor, paired with a harmonic, cycloidal or planetary reducer. These reducers trade speed for torque and provide the stiffness needed to position robot arms precisely. Integrated servo drives act as amplifiers, converting low‑current control signals into the high‑current pulses that motors require. The driver’s microcontroller reads position feedback from encoders and torque sensors, then computes the corrective action via PID control.

By placing the drive board inside the joint housing, thermal paths are shorter, and heat sinks can be designed around the full system. This proximity reduces electromagnetic interference and improves bandwidth. Sensors such as Hall effect encoders, torque transducers and temperature probes are mounted directly on the shaft and gear stages, providing high‑resolution feedback to the drive and allowing advanced features like torque control and load monitoring. With everything packaged together, complete joints deliver smooth, repeatable motion even under complex trajectories.

4.2 Housing, Heat Dissipation and Mechanical Tolerances

The mechanical housing of a complete joint does more than hold the internal components; it is the structural backbone that ensures stiffness, thermal management and environmental protection. A typical housing integrates mounting flanges compatible with standard ISO patterns so that engineers can attach joints to frames or connecting links without custom adapters. The internal surfaces and external fins act as heat sinks, drawing thermal energy from the motor, servo drive and reducer.

New semiconductor technologies, such as silicon carbide or gallium nitride transistors, enable high power density within small packages and allow drives to operate at lower junction temperatures. The mechanical tolerances of the housing maintain alignment between the motor rotor and the reducer output, minimizing friction and backlash. Seals and gaskets keep dust and moisture out, ensuring the joint can operate in industrial environments. For collaborative robots, the outer shell may include soft edges and torque sensors to detect human contact, further enhancing safety. All these design considerations, supported by integrated servo technology, result in complete joints that deliver consistent performance over thousands of cycles.

Cabling, Connectors and Field‑Maintenance Considerations

One of the unsung advantages of complete joints is the simplification of cabling. Instead of running separate power, control and feedback wires between disparate components, complete joints consolidate the connections into a single or dual cable harness. Many integrated joints use industrial buses such as EtherCAT, CANOpen or RS‑485 to carry command, feedback and power over the same connector. This reduces electromagnetic interference and eases troubleshooting.

Additionally, connectors are often designed with keyed, locking mechanisms to prevent accidental unplugging in high‑vibration environments. Field maintenance becomes easier when the joint is a replaceable unit, swap out the entire joint, plug in the cable, and recalibrate the system. Because the control electronics are tuned to the motor and reducer, there is no need to update drive parameters after replacement. For high‑end systems, Yana can arrange for custom cable lengths, strain reliefs and protective conduits to suit your application, ensuring that the complete joint modules are robust from factory floor to field deployment.

Key Variants of Complete Joints

Compact Actuator Modules

Compact actuator modules are complete joints designed for small payloads and limited spaces. They are used in camera gimbals, medical devices, micro‑robots and autonomous sensors. These modules often use planetary or harmonic reducers with ratios between 50:1 and 200:1 and deliver torque from 0.2 to 3 Nm. Their motors may be coreless or slotless to reduce cogging, and they often include integrated drivers with digital current loops operating at 20 kHz or higher.

Because these applications demand high precision and low noise, the servo drivers rely on advanced PWM modulation and PID tuning. Encoders provide sub‑degree resolution, and torque sensing may be omitted in favor of smaller size. Engineers select compact complete joints when weight, footprint and low inertia are critical. In consumer products, these modules enable smooth video stabilization and precise motion control without requiring customers to think about the complexity inside.

Collaborative Robot Joint Modules

Collaborative robot (cobot) applications require complete joints that combine high torque, precise control and intrinsic safety. These joints typically integrate harmonic or cycloidal reducers with torque ratings between 20 and 200 Nm and gear ratios up to 120:1. Safety is paramount; therefore, the drive includes Safe Torque Off (STO) functionality and monitors torque sensors at a high sampling rate. Redundant encoders provide position verification, and the outer housing is smooth and rounded to minimize pinch points.

The servo drivers provide high peak current for acceleration but have software limits to restrict torque when humans are near. Because cobots are reprogrammable, the integration software inside complete joints must support field‑bus protocols like EtherCAT and allow parameter tuning through standard interfaces. When sourcing cobot joints, Yana ensures that suppliers have certifications for human‑robot interaction and that the safety functions comply with ISO/TS 15066 and IEC 62061. This diligence protects your brand and your customers while delivering reliable performance.

Industrial Arm and AGV/AMR Wheel‑Joint Modules

Industrial robotic arms and autonomous mobile robots (AGVs/AMRs) need complete joints that handle high payloads, operate at high duty cycles and withstand harsh environments. Arm joints may deliver hundreds or thousands of newton‑meters of torque and often use RV (cycloidal) reducers for their shock load capacity. Wheel joints in AGVs use planetary reducers with integrated motor windings tailored for direct wheel mounting; they offer high radial load capacity, integrated brakes and IP65 sealing.

The servo drivers controlling these joints are optimized for efficiency and heat management using new transistor technology. They include regenerative braking to recover energy during deceleration. For both arms and mobile platforms, integrated temperature, vibration and current sensors feed data to predictive maintenance algorithms. Yana partners with suppliers who build modular industrial joints with standardized connectors, enabling quick replacement and minimizing downtime.

Quick Comparison of Torque Range, Ratio and Mounting

While each robot design is unique, comparing complete joints across torque range, gear ratio and mounting patterns helps in selection. Low‑torque modules (<5 Nm) often use planetary or harmonic gear trains and mount with small ISO flanges. Medium‑torque modules (5–200 Nm) use harmonic or cycloidal reducers with integrated torque sensors. High‑torque modules (>200 Nm) rely on cycloidal or planetary gearboxes and may include cooling channels and multiple bearings to handle heavy loads.

Gear ratios vary: 50:1–100:1 for fast applications; 100:1–160:1 for balanced applications; 160:1–300:1 for heavy lifting. Mounting patterns follow ISO‑9409‑1 or custom patterns depending on the manufacturer. Yana’s sourcing specialists compare these parameters across suppliers and recommend the best complete joint modules based on your payload, speed, safety and cost targets. This multi‑dimensional evaluation ensures that you invest in the right modules the first time.

Performance Selection Guidelines

Evaluate Torque, Backlash and Stiffness Requirements

When selecting complete joints, start with torque requirements and reduction ratio. The torque must handle peak loads and shock; the gear reducer ratio multiplies motor torque but reduces speed. Backlash, the slight play between gear teeth, affects positioning accuracy. Harmonic and cycloidal reducers provide near zero backlash; planetary reducers offer moderate backlash but higher efficiency. Stiffness of the joint influences how quickly the system responds to dynamic loads.

An under‑stiff joint may oscillate or produce vibration. With complete joints, these parameters are fixed by design; therefore, careful matching of the joint torque and ratio to your robot’s needs is essential. Yana helps you calculate the torque budget for each axis and selects modules with appropriate safety margins so that you can deliver high precision without overspending on torque you don’t need.

Choose Encoder Resolution and Feedback Quality

Feedback quality is a critical differentiator among complete joints. High‑resolution encoders provide more precise position feedback and improve control accuracy. Magnetic encoders are robust and cost‑effective but may be susceptible to drift under temperature changes; optical encoders offer high resolution but require clean environments. Many integrated joints combine multiple encoders or embed multi‑turn absolute encoders. The servo drive uses this feedback to generate PWM signals that control motor voltage.

More precise feedback allows the controller’s PID algorithm to maintain stability and reduce overshoot. For collaborative robots, integrated torque sensors are also vital; they enable instantaneous detection of contact and limit applied force. Yana works with suppliers who calibrate encoders and torque sensors at the factory, ensuring that each complete joint ships with verified accuracy. Our engineers can advise you on the trade‑offs between cost, resolution and robustness based on your application.

Consider Duty Cycle, Heat Stability and Service Life

Duty cycle defines how long a complete joint can operate at rated torque without overheating. Motors and reducers produce heat; servo drives produce additional heat due to power conversion and switching losses. A well‑designed joint uses efficient transistors and good thermal paths to dissipate heat. Cooling may be passive, using fins and conduction, or active with air or liquid channels.

For high‑duty applications like industrial arms or AGVs, ensure that the joint can continuously run at the required load without reaching thermal limits. Service life depends on bearing design, lubrication, sealing and gear tooth profile. Yana verifies the rated life of the reducers and motors, the expected number of cycles before maintenance, and whether replacement parts are available. Selecting complete joints with longer service intervals and better thermal stability reduces downtime and improves ROI.

Account for Environment and Safety Certifications

Environment conditions, dust, moisture, vibration, temperature, affect complete joints. For outdoor or harsh industrial settings, joints should have IP ratings (e.g., IP65 or IP67) and robust sealing. For medical or food applications, hygienic design with stainless housings may be required. Safety certifications matter too: collaborative robot joints need features like Safe Torque Off and compliance with ISO/IEC safety standards. Some industries require certification for electromagnetic compatibility (EMC) and functional safety. When Yana sources complete joints, we verify that the modules carry necessary certifications and that documentation is available. This diligence saves you time during regulatory approval and ensures that the modules meet both technical and legal requirements.

Synchronize Complete Joints with Control and Actuation

Complete joints do not operate in isolation; they must synchronize with control boards, integration software and other actuators. The servo drive inside the joint communicates via bus protocols (EtherCAT, CANOpen). The control board must have enough ports and bandwidth to handle the number of joints and the motion profiles. For example, in a multi‑axis system, the control board must coordinate acceleration and deceleration across joints to avoid mechanical stress.

Motion profiles may be pre‑computed or generated in real time by the integration software. Network latency and jitter can affect performance. Yana examines your full control architecture and ensures that the selected complete joints use compatible protocols and support features such as synchronous cyclic control and interpolation. This integrated approach prevents mismatches between the joint and controller and delivers smooth, coordinated motion.

Supply Chain, Quality Control and OEM Options

Supplier Landscape Across Guangdong, Shenzhen and Jiangsu

China’s robotics ecosystem has matured rapidly, and several provinces have become hubs for complete joints manufacturing. In Guangdong and Shenzhen, companies leverage the electronics supply chain to produce integrated drives, PCBs and motors. Jiangsu and Zhejiang have clusters of precision machining firms that manufacture harmonic and cycloidal reducers.

When sourcing complete joints, Yana evaluates the entire supply chain: from raw materials to assembly. We select suppliers who produce both the mechanical and electronic components in‑house or have strong partnerships to ensure consistent quality. We also evaluate supply chain resilience, whether the factory can handle component shortages and scale production without compromising quality. This holistic view safeguards your project against delays and quality issues.

Customization Tiers: From Re‑branding to Deep Co‑Development

The market for complete joints offers varying levels of customization. Some suppliers provide off‑the‑shelf modules that you can re‑brand with minimal changes. Others allow parameter changes such as gear ratio, encoder type or connector orientation. At the highest level, you can work with OEMs to co‑develop joints tailored to your robot’s specific kinematics and control strategies. Yana facilitates these co‑development relationships, bridging cultural and technical gaps. We help you define requirements, evaluate proposals and manage milestones to ensure that customization does not derail the schedule. Co‑development yields modules that reflect your brand’s quality and performance while sharing risk and reward with the manufacturing partner.

Testing Standards and Failure Analysis

Quality control for complete joints involves more than visual inspection. Each module must pass electrical testing for insulation, current consumption and noise; mechanical testing for backlash, torque and vibration; and environmental testing for temperature, humidity and IP sealing. For servo drives, functional testing ensures that PWM generation and PID loops operate correctly under dynamic loads.

For reducers, cycle testing measures wear and evaluates gear tooth profiles. When failures occur, failure analysis is essential. Yana works with suppliers to perform root‑cause analysis on returned joints, often identifying issues in lubrication, bearings or control algorithms. We then feed those lessons back into design and production. This continuous improvement ensures that each batch of complete joints is better than the last.

Cost, MOQ and Long‑Term Serviceability

Cost is always a factor when sourcing complete joints, but total cost of ownership (TCO) matters more than unit price. Yana helps you evaluate TCO by considering life cycle cost, energy efficiency and maintenance intervals. Minimum order quantities (MOQs) can vary: off‑the‑shelf modules may require orders of only 10–20 units, while custom modules might require 100 or more units to justify tooling and design. Long‑term serviceability is another cost driver. Can the gear set be replaced? Are spare servo drives available? Does the manufacturer provide firmware updates? We ask these questions because they affect your margin and product roadmap. Choosing the right supplier and module means balancing cost, flexibility and support.

Future Directions in Complete Joint Design

Higher Torque Density and Lightweight Materials

Engineering advances continue to push the envelope of complete joints. New transistor materials like gallium nitride (GaN) enable drives that handle higher voltages and currents with less heat dissipation. Improved magnetic materials and winding techniques increase motor torque density. Lightweight composite housings and hollow shaft designs reduce mass without sacrificing stiffness. These innovations combine to create modules that deliver more torque in smaller packages, opening new possibilities for mobile robots, drones and exoskeletons. By sourcing from suppliers who adopt these technologies, you stay ahead of competitors and deliver products that feel lighter, run cooler and operate longer on a single charge.

Smart Joints with Embedded State Estimation

The next generation of complete joints will embed more intelligence at the edge. Integrated microcontrollers will not only drive motors but also run algorithms for state estimation and predictive maintenance. By fusing data from encoders, torque sensors and temperature probes, the drive can estimate load inertia, detect wear and adapt control gains on the fly.

Integrated joints will support network protocols with high bandwidth and deterministic timing, enabling real‑time data streaming to cloud platforms. This convergence of drive and sensor technology will allow robots to become more aware of their health and environment. Yana looks for suppliers who have roadmaps for smart joints and can provide upgrade paths for existing designs.

Modular Standardization Across Robot Families

As the robotics market matures, standardized complete joints will become available across robot families. Imagine selecting a series of joint modules with the same communication interface, mounting pattern and calibration procedure that can be used in a pick‑and‑place arm, a mobile platform and a humanoid robot. Standardization reduces learning curves and inventory complexity.

However, it also requires cooperation among manufacturers and supply chain partners. Yana advocates for industry standards and works with multiple suppliers to encourage interoperability. Our team participates in industry consortia and helps clients develop specification documents that encourage standardized joint modules. This collaborative approach reduces engineering overhead and accelerates time to market.

Repairable, Sustainable and Upgrade‑Friendly Units

Sustainability is becoming a key consideration in robotics. Future complete joints will be designed for repair and upgrade rather than replacement. Modular gears, replaceable seals and firmware‑updateable servo drives will extend the lifespan of each unit. Manufacturers will use recyclable materials and adopt production processes that minimize environmental impact. Yana selects partners who prioritize sustainability; we ask about recycling programs, material sourcing and environmental certifications. By choosing repairable complete joints and suppliers committed to sustainability, you align with consumer expectations and regulatory trends while protecting your bottom line.

9. Source Complete Joints with Yana — The SMART + HEART Approach

Yana Sourcing is not just a procurement agent; we are your strategic partner for complete joints and other critical robotics modules. Our approach combines SMART, Structured, Measurable, Agile, Resilient, Transparent; with HEART, Human‑centered, Ethical, Artful, Reliable, Thoughtful. We ensure each joint has been verified for mechanical precision and safe operation. We evaluate suppliers not just on price but on their engineering culture, sustainability practices, and ability to support innovation.

We treat sourcing as a higher‑dimensional discipline: not only do we match torque ratios and gear types, but we also consider your market position, margin structure and long‑term product roadmap. When you work with Yana, you gain access to a curated network of manufacturers, a team of engineers who speak the language of robotics and the business acumen to ensure that your investment in complete joints yields maximum returns. If you’re ready to build the next generation of robots with modules that feel as complete as your vision, contact Yana today and let’s start building the future together.