Table of Contents

Introduction: giving robots an inner sense of motion

Robots move and manipulate the world with actuators, but they know how they are moving thanks to IMU sensors for robotics. An inertial measurement unit (IMU) combines tiny accelerometers, gyroscopes and sometimes magnetometers into a single package to measure linear acceleration, angular velocity and orientation. These solid‑state devices convert inertia into data and give robots an inner sense of balance and motion.

Without IMU sensors for robotics, a mobile robot would have no awareness of how it was accelerating or rotating and could easily drift off course or fall. Advances in micro‑electromechanical systems (MEMS) technology have made IMU sensors for robotics small, low‑power and inexpensive enough to be embedded in smartphones, drones and industrial arms. In this article we explore how they work, what specifications matter and how to choose and source the right IMU sensors for robotics.

Working principles of IMU sensors for robotics

At their core, IMU sensors for robotics are electromechanical systems that sense changes in inertia. An IMU typically contains multiple accelerometers, which measure linear acceleration along orthogonal axes, and gyroscopes, which measure angular rate around those axes. The Advanced Navigation guide explains that an IMU detects forces created by an object’s resistance to changing direction and converts them into output data representing the motion.

The raw IMU output usually consists of three‑axis acceleration and three‑axis angular velocity signals. Some units include magnetometers to measure the Earth’s magnetic field; these sensors can correct gyroscope drift and provide a compass heading, particularly useful in IMU sensors for robotics used for navigation. Thus a six‑axis IMU (3 gyros + 3 accelerometers) provides orientation and motion data, while a nine‑axis IMU adds magnetometer readings for absolute heading.

The sensing principles vary by component. MEMS accelerometers use a tiny proof mass on springs; when the robot accelerates, inertia causes the mass to deflect relative to its frame, changing the capacitance between comb electrodes. Measuring this capacitance yields acceleration. Gyroscopes exploit conservation of angular momentum.

In a classical spinning‑disk gyroscope, a mass maintains its orientation; MEMS gyroscopes replicate this with vibrating masses or Coriolis forces. Fibre‑optic gyroscopes (FOG) and ring laser gyros send light around a fibre coil and detect phase shifts to measure rotation. Magnetometers sense the Earth’s magnetic field using Hall‑effect or anisotropic magnetoresistive elements. Modern IMU sensors for robotics leverage MEMS technology because it delivers small size, low power and high reliability. MEMS manufacturing processes allow accelerometers and gyroscopes to be etched onto silicon, and the Advanced Navigation article notes that MEMS inertial sensors are extremely small, low power and cost‑effective.

Why robots need IMU sensors

The primary purpose of IMU sensors for robotics is to sense motion without external references. Accelerometers and gyroscopes provide the raw data that a robot’s control system uses to infer orientation, velocity and position. Without them, a robot would have no way of knowing whether it was tipping, accelerating or rotating. The 221e article calls the IMU “a robot’s sixth sense,” allowing it to perceive orientation, movement and position in space and to make split‑second adjustments for balance or navigation.

Whether balancing on two legs, flying through turbulence or rolling down a warehouse aisle, robots rely on IMU sensors for robotics to maintain stability. In industrial settings, IMUs help robots position tools precisely and monitor vibrations to detect wear. Surgical robots depend on IMUs for hand–eye coordination and to adjust micro‑scale movements in real time. Mobile robots and drones fuse IMU data with GPS and vision to localize themselves even when GPS signals are unavailable, such as in indoor environments or urban canyons.

IMUs also enable safety and diagnostic features. Sudden spikes in acceleration can indicate collisions or falls, triggering emergency stops. Long‑term vibration analysis from IMU sensors for robotics can reveal misalignment or bearing wear in an actuator. Exoskeletons and rehabilitation devices use IMUs to monitor joint movement and provide feedback to users. In short, IMUs are critical across robotics domains: autonomous vehicles, drones, humanoids, industrial arms, mobile platforms, surgical systems and wearable exosuits all rely on IMU sensors for robotics to deliver safe, smooth and responsive performance.

Components of IMU sensors for robotics

Accelerometers: The accelerometer portion of IMU sensors for robotics measures linear acceleration along X, Y and Z axes. The Autonomous Robots Lab notes that accelerometers can measure both static forces (gravity) and dynamic forces (vibration and motion). In a MEMS accelerometer, a proof mass suspended on springs moves relative to the sensor body. The change in capacitance between the moving mass and fixed electrodes is proportional to acceleration.

Accelerometer specifications include range (e.g. ±2 g, ±16 g), noise density and bias stability. A wide range allows a robot to detect high‑g shocks, while low noise is necessary for smooth control. In robotics, accelerometers are used for vibration monitoring, detecting impacts and as part of sensor fusion to estimate velocity and position.

Gyroscopes: Gyroscopes measure the angular velocity of a robot’s body or joints. As described on the Autonomous Robots Lab site, gyroscopes operate on the principle of angular momentum: a spinning mass maintains its orientation unless acted on by external torque. MEMS gyroscopes use vibrating resonators to detect Coriolis forces; ring laser and fibre‑optic gyroscopes use optical interference and provide much higher accuracy at the cost of size and price. Gyroscope specifications include range (e.g. ±250°/s to ±2000°/s), bias stability and angle random walk. For many IMU sensors for robotics, the gyroscope is the dominant noise contributor; high‑end robots may use tactical‑grade MEMS or FOG gyros for low drift.

Magnetometers: Many IMU sensors for robotics incorporate magnetometers to measure the Earth’s magnetic field. According to the PNI Sensor article, magnetometers detect magnetic field strength and provide absolute heading relative to magnetic north. In robotics, magnetometers are useful for compass‑based navigation and for correcting gyroscope drift over long durations. However, they are sensitive to magnetic interference from motors and steel structures, so careful placement and calibration are required.

Barometers and additional sensors: Some IMUs integrate barometric pressure sensors to estimate altitude, useful for drones and autonomous vehicles. High‑end inertial navigation systems (INS) combine IMUs with GPS, odometers, vision and other sensors in a single unit. The Advanced Navigation article notes that combining multiple sensor technologies with on‑board processing creates an attitude and heading reference system (AHRS) which outputs full orientation and position data.

Technical performance parameters

Selecting IMU sensors for robotics requires understanding key specifications:

- Range: Accelerometer range is the maximum measurable acceleration (±2 g to ±200 g), while gyroscope range refers to maximum angular velocity (±125°/s to ±2000°/s). Higher range enables measurement of faster or more forceful motions but can reduce resolution at low speeds. Applications such as drone flight control might require ±16 g accelerometers and ±2000°/s gyros, whereas precision industrial arms can use ±2 g and ±250°/s sensors.

- Resolution and noise: Resolution is the smallest change an IMU can detect. Noise density describes random fluctuations (often given in m/s²/√Hz for accelerometers or °/s/√Hz for gyros). Low noise is critical for precise position estimation and stable control. MEMS technology improvements continue to reduce noise and allow IMU sensors for robotics to approach performance previously reserved for FOG units.

- Bias and drift: Bias is a constant offset in the sensor output; drift is the bias change over time. Bias stability (measured in °/hr for gyros) is critical; high‑end FOG gyros can achieve <0.001°/hr while consumer MEMS gyros may be around 20°/hr. Over long durations, even small bias errors accumulate, causing position errors during dead reckoning.

- Bandwidth and sampling rate: Bandwidth defines the frequency range over which the sensor accurately responds. Industrial IMU sensors for robotics often have bandwidths of 100 Hz to 10 kHz. Sampling rate is how often data is output; higher sampling rates provide finer temporal resolution but require more processing.

- Alignment and cross‑axis sensitivity: Misalignment between sensor axes and the robot’s reference frame introduces cross‑axis errors. High‑end IMU sensors for robotics specify alignment error below 0.05 %.

- Interface and digital output: IMUs output data via interfaces such as SPI, I²C, UART, CAN or more industrial protocols like RS‑232, RS‑485 or Ethernet. Choosing a sensor with a compatible interface and bandwidth ensures seamless integration.

- Environmental and mechanical properties: Shock and vibration tolerance, operating temperature range, and enclosure sealing matter when IMU sensors for robotics are used in harsh industrial or outdoor conditions. MEMS IMUs are typically rated –40 °C to 85 °C or higher; some FOG or tactical units operate from –55 °C to +125 °C.

Sensor fusion and filtering in robotics IMUs

Raw outputs from IMU sensors for robotics cannot directly provide position and orientation due to noise, bias and integration drift. Sensor fusion algorithms combine accelerometer, gyroscope and magnetometer data (and often external sensors like GPS and wheel encoders) to estimate orientation and position. The PNI Sensor article notes that sensor fusion algorithms such as Kalman filters and machine‑learning methods combine multiple sensor outputs to create a more accurate picture of an object’s movement and orientation.

In a complementary filter, high‑frequency motion is taken from the gyroscope and low‑frequency orientation is derived from accelerometer and magnetometer readings. Extended Kalman filters (EKF) maintain a state estimate of orientation and velocity and correct it with incoming sensor measurements, making them suitable for IMU sensors for robotics performing simultaneous localization and mapping (SLAM).

Sensor fusion also mitigates the limitations of individual sensors. GPS can be jammed or lost indoors, but an IMU can bridge short outages by dead reckoning. Vision sensors can provide absolute position but may fail in poor lighting; an IMU provides continuous motion estimates. The 221e article emphasises that combining IMU data with GPS and cameras allows robots to navigate accurately even when one sensor is compromised. In practice, robots often incorporate multiple IMUs for redundancy and cross‑validation.

Integration and placement considerations

Integrating IMU sensors for robotics properly is vital for accurate measurements. The placement of the IMU relative to the robot’s center of mass affects how easily raw acceleration can be converted to motion. Mounting the IMU at or near the center of mass minimises rotational effects on linear acceleration measurements. For mobile robots, IMUs are often mounted on the chassis; for manipulators, they may be placed on each joint or in the wrist to capture joint movements. In exoskeletons and wearable robots, IMUs are mounted on limb segments.

Mechanical isolation is important: vibrations from motors and transmissions can corrupt IMU readings. Elastomer mounts or vibration‑isolating pads are often used between IMU sensors for robotics and robot frames. Thermal isolation can reduce drift caused by temperature changes. Electrical considerations include shielding and grounding; high currents in motor cables can induce electromagnetic interference in IMU outputs, particularly for magnetometers.

Aligning the IMU axes with the robot’s coordinate system and recording the transform between them ensures correct interpretation of data. Calibration procedures involve static and dynamic tests to determine scale factors, misalignment and bias; many high‑end IMU sensors for robotics include factory calibration data and self‑test routines.

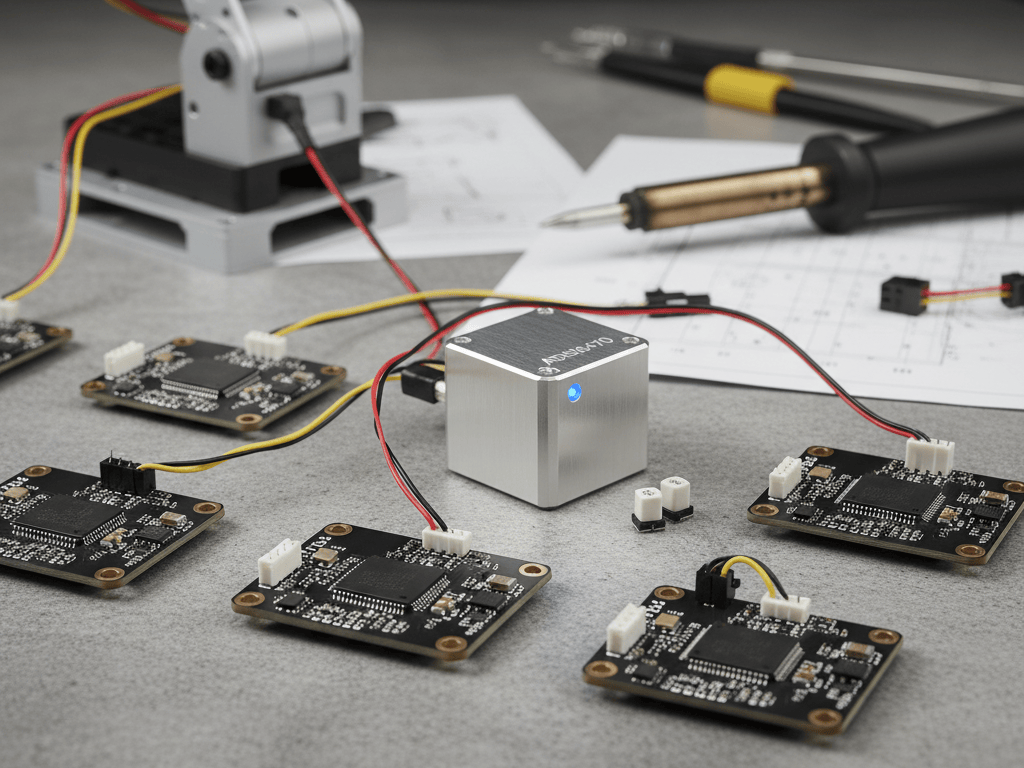

Manufacturing and sourcing insights

Modern IMU sensors for robotics are largely produced using MEMS manufacturing methods, which involve micro‑etching silicon wafers and assembling moving structures at micrometre scale. This approach offers low unit cost, high reliability and compact size. MEMS IMUs are packaged in small plastic or ceramic packages and often sealed against moisture; their small size makes them ideal for drones and consumer robots.

However, MEMS devices suffer from higher bias instability compared with fibre‑optic gyros (FOG). FOG and ring laser gyros use optical interference to achieve extremely low drift but remain larger and more expensive. Tactical‑grade IMUs for defence and aerospace may combine MEMS sensors with advanced calibration and compensation to approach FOG performance.

When sourcing IMU sensors for robotics, evaluate several factors:

- Performance grade vs cost: The Advanced Navigation article notes that MEMS technology’s affordability has opened up inertial sensing to a broad range of applications. Consumer‑grade IMUs cost just a few dollars and offer adequate performance for hobby robots; industrial‑grade units cost more but provide lower noise and drift. FOG‑based INS are used only when the highest precision and low drift are required and budgets permit.

- Factory calibration and test data: Suppliers should provide calibration certificates detailing bias, scale factor and misalignment. Evaluate whether the sensor includes on‑board temperature compensation and bias calibration.

- Interface and software support: Ensure that the IMU sensors for robotics support your communication protocol (SPI, I²C, UART, CAN, Ethernet). Availability of drivers for ROS 2 or other middleware simplifies integration.

- Environmental ratings: Check the rated temperature range, shock tolerance and sealing (IP rating). For field robots or drones operating outdoors, choose sensors rated for –40 °C to +85 °C or wider.

- Supply chain and lead time: High‑end IMUs may have long lead times or export restrictions; plan accordingly. Working with a sourcing partner like Yana Sourcing can help identify reliable suppliers and manage procurement.

Major manufacturers and suppliers

The market for IMU sensors for robotics includes numerous suppliers ranging from consumer‑grade chip makers to defence contractors. A few representative vendors include:

| Manufacturer | Region | Notes |

|---|---|---|

| TDK InvenSense | Japan/USA | Produces the popular MPU and ICM series MEMS IMUs used in drones, wearables and smartphones; offers 6‑axis and 9‑axis sensors with embedded digital motion processors. |

| Bosch Sensortec | Germany | Supplies BMP/BMI series IMUs combining accelerometer, gyroscope and magnetometer; widely used in consumer electronics and robotics research. |

| STMicroelectronics | Europe | Provides LSM and I3G series sensors used in industrial and automotive systems; offers high‑performance 6‑axis IMUs with integrated machine‑learning cores. |

| Analog Devices | USA | Manufactures ADIS series industrial and tactical‑grade IMUs, including MEMS gyroscopes with low bias drift and sensors qualified for aerospace and defence. |

| Honeywell | USA | Produces ring laser and MEMS IMUs for aviation, spacecraft and precision navigation; offers combined inertial navigation systems (INS). |

| ACEINNA / CHINA OEMs | USA/China | Provides open‑source, open‑sourced IMUs such as the OpenIMU and high‑accuracy inertial navigation modules; several Chinese suppliers produce cost‑effective modules with SPI/UART outputs and integrated magnetometers. |

| Advanced Navigation | Australia | Offers MEMS and FOG inertial navigation systems like Motus and Boreas; emphasises compact size and low SWaP‑C while delivering high accuracy. |

When selecting a supplier, examine the vendor’s datasheets for bias stability, noise density, sampling rate and calibration. Evaluate whether the supplier provides software libraries or drivers for ROS, C++ or Python. For high‑volume production, consider modules with surface‑mount packaging and automated calibration to minimise manual assembly. Yana Sourcing can assist with vetting suppliers, negotiating pricing and coordinating custom modifications or private‑label arrangements.

Applications across robotics domains

Mobile robots and autonomous vehicles: Wheeled and tracked robots use IMU sensors for robotics for odometry and dead reckoning. By integrating acceleration and angular rate, an IMU provides velocity and heading estimates that bridge gaps between GPS fixes or when GPS is unavailable. Indoor robots performing SLAM fuse IMU data with laser scanners or cameras to estimate trajectory. In agriculture and construction, IMUs help vehicles maintain level orientation on uneven terrain and monitor vibration to detect wear.

Drones and aerial robots: Flight controllers rely on high‑bandwidth gyroscopes and accelerometers to stabilise multirotor drones. The PNI Sensor article notes that IMUs are essential for drone stabilization and can guide missiles and rockets without external signals. Small consumer drones typically use ±16 g accelerometers and ±2000°/s gyroscopes for agile manoeuvres. Larger UAVs and fixed‑wing aircraft may use tactical‑grade IMUs with barometric pressure sensors and magnetometers for long‑range navigation and autopilot functions.

Humanoid and legged robots: To maintain balance and posture, bipedal robots require continuous feedback on their center of mass and limb orientation. The 221e article describes how IMUs allow robots to make split‑second adjustments to stay upright. Gyroscope and accelerometer data feed into whole‑body control algorithms that coordinate multiple joints. Prosthetic limbs and exoskeletons also use IMUs to measure joint angles and user intent.

Industrial manipulators and cobots: Although joint encoders provide position feedback, high‑resolution IMU sensors for robotics can monitor vibrations and detect collisions on end‑effectors. Sensors placed on grippers or tool cartridges can detect subtle forces and adjust grip or feed rates accordingly. Monitoring vibration helps predict maintenance needs, while detecting sudden deceleration can signal impacts or misalignment.

Augmented reality, VR and motion capture: IMU modules integrated into controllers, headsets and suits track orientation and movement. MEMS sensors provide low‑latency tracking for gaming and telepresence. Motion capture suits for animation and biomechanics rely on arrays of IMU sensors for robotics to record body motions accurately.

Emerging trends in IMU sensors for robotics

The landscape of IMU sensors for robotics is rapidly evolving. Key trends include:

- Miniaturisation and SWaP‑C reduction: MEMS technology continues to shrink sensor size, weight and power (SWaP) while reducing cost. Advanced Navigation notes that the Motus MEMS IMU weighs only 26 g and consumes 1.4 W while delivering high accuracy. Smaller sensors enable more compact robots, wearable devices and drones.

- Integration and smart sensors: Manufacturers are embedding IMUs into integrated modules with sensor fusion processors, machine‑learning cores and advanced algorithms on chip. Such modules output orientation directly, reducing processor load on the robot. Some integrate additional sensors (barometer, GNSS, odometers) and provide full inertial navigation solutions (INS). Smart IMUs support diagnostic features like self‑testing, temperature compensation and built‑in filtering.

- Performance improvements: MEMS gyroscopes continue to close the gap with FOG performance. Advanced calibration, temperature compensation and materials improvements are lowering bias instability and noise density. Hybrid systems combine MEMS sensors with optical gyroscopes to offer high dynamic range and low drift.

- Sensor fusion and AI: Software frameworks such as ROS 2 provide standard drivers and IMU integration tools. AI‑based filtering techniques leverage deep learning to model sensor biases and noise, improving estimation. Edge processing on IMU modules reduces latency and network load in distributed robotic systems.

- Niche applications: Radiation‑hardened IMUs for space robotics, low‑power IMUs for implantable medical devices and ruggedised units for deep‑sea robots show that IMU sensors for robotics are entering highly specialised domains.

Practical sourcing tips

To choose and procure reliable IMU sensors for robotics, consider the following guidelines:

- Define performance requirements: Determine the required bias stability, noise density and measurement range based on the robot’s dynamics. Avoid overspecifying; higher accuracy sensors cost more and may require more power.

- Check calibration and quality: Review supplier calibration certificates, bias drift data and temperature compensation charts. Ask for sample test data across the temperature range.

- Evaluate communication interfaces: Choose sensors that support the bus your controller uses (I²C, SPI, UART, CAN, Ethernet) and verify available drivers for your software stack (ROS, ROS 2, etc.).

- Inspect environmental ratings: For outdoor or industrial robots, ensure the IMU is rated for the expected temperature extremes, vibration and shock. Consider IP‑rated packaging or potting to protect from dust and moisture.

- Select the right grade: Use consumer‑grade IMUs for prototypes and non‑safety‑critical applications. Choose industrial‑grade or tactical‑grade sensors for mission‑critical or safety‑relevant applications.

- Consider integrated solutions: Some vendors offer complete inertial navigation systems (INS) combining IMUs with GNSS, barometer and odometers. These can simplify integration at the expense of cost and flexibility.

- Leverage sourcing specialists: Working with an experienced sourcing partner like Yana Sourcing can help vet suppliers, negotiate pricing, ensure quality control and coordinate logistics. Specialists have relationships with manufacturers and know which IMU sensors for robotics meet specific requirements.

Conclusion

IMU sensors for robotics give robots their internal sense of motion and orientation. They convert accelerations and rotations into electrical signals, enabling controllers to keep robots balanced, navigate without external references, perform precise manipulation and detect anomalies. Advances in MEMS technology have made IMUs small, low‑power and affordable, while high‑end fibre‑optic gyros provide unmatched precision for demanding applications.

Careful selection, integration and sensor fusion ensure that IMU sensors for robotics deliver reliable data under real‑world conditions. As robotics applications expand into ever more challenging environments, from underwater inspection to space exploration, sourcing the right IMU will be crucial. For help identifying and procuring the best IMU sensors for robotics, Yana Sourcing offers end‑to‑end support, connecting buyers with trusted manufacturers and ensuring that motion control and navigation systems meet the highest standards.

Ready to Source High-Precision IMU Sensors?

Finding reliable IMU sensors for robotics suppliers can be challenging. At Yana Sourcing, we connect you with verified manufacturers of high-performance inertial sensors, tested for bias stability, temperature drift, and long-term reliability.

Whether you need industrial-grade MEMS or precision FOG units, our sourcing specialists ensure quality, speed, and cost efficiency.

👉 Contact Us Now to start your custom IMU sensor sourcing project.