Table of Contents

What Are Pneumatic Fittings?

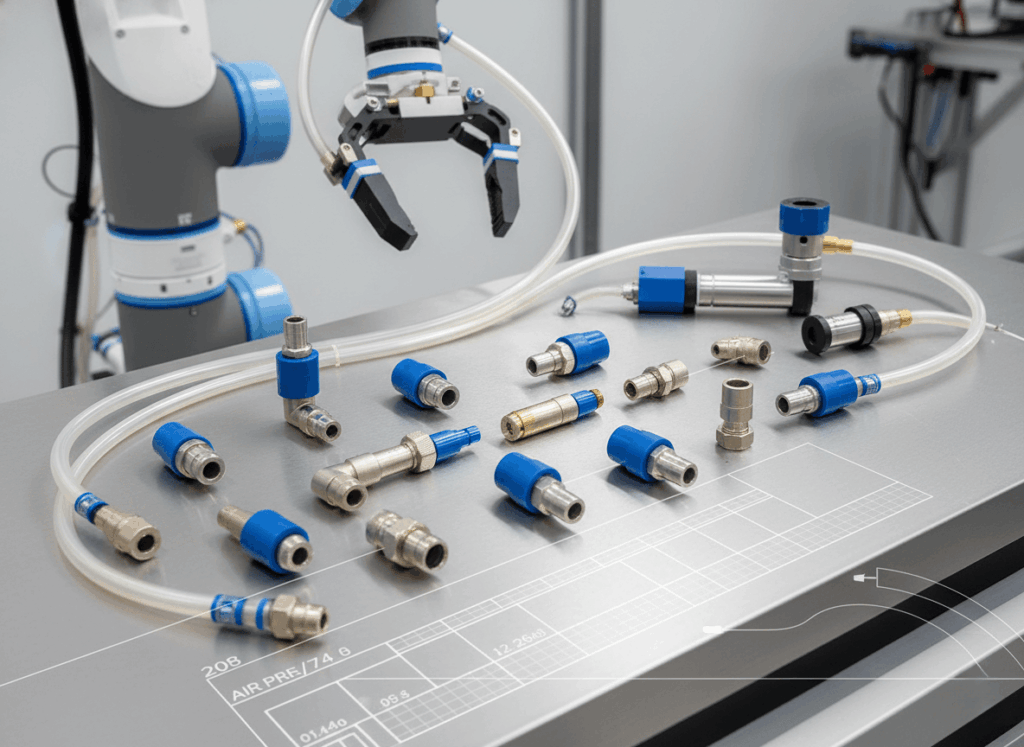

Pneumatic fittings are the connection interfaces that join compressed-air components such as tubing, valves, cylinders, and manifolds into a functioning pneumatic system. In any automation or robotics setup, pneumatic fittings determine how air is routed from one device to another, ensuring that each actuator receives the correct pressure and flow at the right moment. Because pneumatics rely on sealed air rather than hydraulic oil or electrical torque, the quality of these fittings directly impacts performance, reliability, and maintenance cycles.

Beyond simply joining parts, pneumatic fittings play a crucial role in leak prevention, airflow efficiency, and the overall responsiveness of a machine. The internal geometry of a fitting, the compatibility between thread types, and the match between tubing size and port diameter all influence how quickly a cylinder extends, how a gripper reacts, and how stable a system remains during high-speed operation. Well-chosen pneumatic fittings contribute to smooth, consistent motion and reduce energy waste by minimizing air losses.

In a broader context, pneumatic fittings form part of the foundational element set covered in the pneumatics overview, where compressed air is generated, conditioned, and distributed. Choosing the right fitting type, material, and connection standard ensures that this airflow remains controlled from source to actuator, allowing engineers to design systems that are safe, predictable, and efficient.

How Pneumatic Fittings Influence System Performance

Pneumatic fittings have a direct influence on system performance because they determine how efficiently compressed air travels through the network. Every fitting introduces some degree of flow resistance, and if the internal passage is too narrow or poorly matched to the tube or valve port, pressure drop occurs. This pressure drop can lead to slower cylinder extension, inconsistent gripper force, or reduced repeatability in high-speed robotic cycles. In fast automation environments, even a slight restriction caused by the wrong pneumatic fittings can accumulate into noticeable performance loss across thousands of cycles.

Leak prevention is another critical factor tied to pneumatic fittings. A small air leak does not only waste energy, it also changes pressure availability at the actuator, which affects response time and motion consistency. In robotics, where repeatability is essential, unstable pressure can translate into variations in pick height, grip strength, or slide positioning. High-quality sealing surfaces, correct threading standards, and proper tubing engagement are key to ensuring that pneumatic fittings support stable motion rather than introducing variability.

Sizing and material compatibility determine how well pneumatic fittings handle environmental and mechanical stresses. Tubing diameter must match both the flow demands of the actuator and the port sizes of the valves and cylinders to avoid starvation at peak load. Likewise, material choice affects corrosion resistance, chemical exposure tolerance, washdown suitability, and weight at the robot end-of-arm tooling. For example, stainless-steel pneumatic fittings are used in food and medical robotics for hygiene and durability, while lightweight polymer push-to-connect fittings are preferred for high-speed pick-and-place systems where mass at the end effector must be minimized.

Types of Pneumatic Fittings for Robotics & Automation

Pneumatic fittings come in several connection styles, each designed to balance speed of assembly, sealing reliability, weight, flow capacity, and ease of maintenance. In robotics and automation, the choice of pneumatic fittings depends heavily on how often the tooling changes, how tight the workspace is, how fast the actuators must respond, and how much vibration or side-loading the tubing routing will experience. Selecting the right style of pneumatic fittings ensures stable airflow while keeping the end-of-arm tooling clean, lightweight, and service-friendly.

Push-to-Connect Pneumatic Fittings

Pneumatic fittings that use a push-to-connect (or “push-in”) mechanism allow tubing to be inserted quickly and held securely by an internal collet and seal. These pneumatic fittings are widely used in robotic end effectors, compact assembly stations, and CNC loading systems because they enable fast installation, reconfiguration, and maintenance without special tools. Push-to-connect pneumatic fittings help maintain a lightweight setup, reducing inertia at the robot wrist and improving overall cycle time. However, proper tube cutting and alignment are essential to avoid micro-leaks or tube pull-out during repetitive motion.

Compression Pneumatic Fittings

Compression-style pneumatic fittings use a ferrule or compression ring to clamp the tubing mechanically. These pneumatic fittings excel in environments with vibration, swiveling motion, or shock loading, because the mechanical grip prevents the tube from loosening over time. Compression pneumatic fittings are commonly applied in mobile robots, industrial presses, or conveyor diverters where airflow stability and robustness matter more than rapid reconfiguration. While they offer higher security, compression pneumatic fittings typically require wrenches to assemble and disassemble, making them better suited for systems where layouts do not change frequently.

Barbed Pneumatic Fittings

Barbed pneumatic fittings connect flexible tubing through interference fit, commonly secured with clamps. These pneumatic fittings are cost-effective and simple, making them well suited for low-pressure utilities, prototyping benches, jigs, and simple pick-and-drop applications. However, barbed pneumatic fittings introduce more flow resistance and can be more prone to leakage if tubing ages, hardens, or is exposed to heat or oils. In robotics, barbed pneumatic fittings are used mainly where airflow is intermittent or non-critical, or where system simplicity takes priority over precision response.

Quick-Disconnect Pneumatic Fittings

Quick-disconnect pneumatic fittings enable tools, grippers, vacuum kits, and test fixtures to be swapped rapidly without depressurizing the entire air line. These pneumatic fittings are particularly valuable in robotic palletizers, collaborative robot workstations, and multi-SKU packaging systems, where changeover speed directly affects throughput. Quick-disconnect pneumatic fittings typically include internal shutoff valves to prevent pressure loss during disconnection, improving safety and convenience. Their durability, however, depends on seal quality and maintenance of clean mating surfaces.

Threaded Pneumatic Fittings (NPT, BSP, Metric)

Threaded pneumatic fittings form the interface between tubing systems and the ports on valves, cylinders, pressure regulators, and manifolds. Matching thread type is critical: NPT (tapered) seals by interference, while BSP and metric threads often rely on sealing washers or O-ring faces. Incorrectly mixing thread families can cause cross-threading, leaks, or component damage. Threaded pneumatic fittings influence long-term performance because thread interface sealing determines system stability, especially under cycling load, vibration, or thermal variation.

Manifold Blocks and Multi-Port Fittings

Manifold systems use grouped pneumatic fittings to distribute air from a single supply to multiple cylinders or grippers. These pneumatic fittings allow compact, organized tubing routing, reducing clutter and improving maintenance accessibility in robotic cells and automated assembly modules. For multi-axis end-effectors, manifolds minimize tubing length, reducing response time and improving control accuracy. Proper manifold mounting and flow path design ensure that each downstream device receives consistent pressure without starvation.

Tubing & Thread Standards and Compatibility

Pneumatic fittings only perform as intended when tubing sizes and thread standards are correctly matched across the system. In robotics and automation, it’s common to combine components sourced from different regions or vendors, which increases the risk of mismatched tube diameters or incompatible port threads. Because pneumatic fittings serve as the interface between these elements, selecting the correct standard ensures proper sealing, reliable airflow, and predictable actuator response.

Metric vs Inch Tubing

Pneumatic fittings are manufactured to support both metric tubing (e.g., 4 mm, 6 mm, 8 mm, 10 mm) and inch tubing (e.g., 1/8″, 5/32″, 1/4″, 3/8″). The critical point is that pneumatic fittings must match the exact outside diameter of the tubing, even a small mismatch leads to leaks or tube pull-out. In robotics applications where end-of-arm tooling weight matters, designers often choose smaller metric tubing to reduce mass and improve cycle speed. However, if the tubing is too small, pneumatic fittings will restrict flow, increasing cylinder extend times. The ideal choice balances responsiveness with compactness.

NPT vs BSP Threads

Not all pneumatic fittings share the same thread geometry. NPT (National Pipe Taper) threads seal by tightening under wedge friction, while BSP (British Standard Parallel) and metric straight threads typically seal with O-rings, bonded washers, or face seals. Mixing NPT with BSP threads is one of the most common causes of leaks or damaged ports in automated equipment. Understanding thread type markings on pneumatic fittings helps ensure that cylinders, valves, manifolds, and regulators connect securely and maintain stable pressure throughout high-cycle operation.

Sealants and When Not to Use Them

Sealants play an important role in ensuring that pneumatic fittings maintain airtight performance. PTFE thread tape can help seal tapered threads like NPT but should not be used on straight threads, as it may interfere with O-ring compression or face-seal contact. In robotics, over-application of PTFE tape can introduce debris into valves and cylinders, affecting motion accuracy. Anaerobic liquid thread sealants are often preferred for steel and brass pneumatic fittings in fixed installations, while O-ring face seals are ideal for components that require frequent removal or tool changes.

Why Compatibility Matters in Robotics

In robotic systems, pneumatic fittings with mismatched thread or tubing standards can cause subtle and progressive performance issues, such as slower actuator movement, inconsistent gripping force, or uneven airflow distribution across multi-head tooling. Ensuring compatibility at the design stage prevents downstream troubleshooting and reduces maintenance downtime. Because pneumatic fittings sit at the juncture of every airflow path, compatibility is not just a detail, it is a primary determinant of reliability.

Selecting Pneumatic Fittings for Robotics Applications

Choosing the right pneumatic fittings for a robotics system requires balancing weight, durability, routing convenience, response time, and environmental conditions. In robotic automation, every gram of mass and every millisecond of response time influences how fast and smoothly the machine operates. The selection of pneumatic fittings should therefore align with both the mechanical layout of the end-of-arm tooling and the pressure and flow requirements of the actuators being controlled.

Pick-and-Place and High-Speed EOAT

In high-speed pick-and-place applications, lightweight and compact pneumatic fittings help minimize inertia at the robot wrist. Push-to-connect pneumatic fittings paired with small-diameter, flexible tubing keep the tooling lightweight and responsive. Shorter tubing runs reduce cylinder extend time and increase repeatability by minimizing pressure lag. When pneumatic fittings are placed close to the actuator ports and routing paths are kept tight, the robot can run at higher acceleration without sacrificing positioning accuracy.

Systems Subject to Vibration or Motion Shock

In applications involving heavy loads, rapid stops, or vibration, such as palletizing robots, conveyor pushers, or machine tending arms, compression-style pneumatic fittings offer improved mechanical grip on tubing. These pneumatic fittings lock the tube in place using a ferrule or clamp sleeve, ensuring that hose movement or shock forces do not loosen the connection. This prevents pressure drops or intermittent leaks that could cause inconsistent gripping or indexing errors in fast, load-bearing robotic cycles.

Cleanroom, Food-Grade, and Washdown Environments

For pharmaceutical automation, semiconductor handling, or food processing, stainless steel or chemically resistant pneumatic fittings provide long-term durability and hygienic performance. These pneumatic fittings are designed to tolerate washdown chemicals, steam cleaning, or high-humidity conditions without corrosion or seal degradation. Polymer push-to-connect pneumatic fittings are also used in lab automation where low mass and contamination-free operation are priorities. Material choice directly impacts reliability in these controlled environments.

High-Speed End Effectors and Multi-Axis Tooling

In multi-axis assembly systems and collaborative robot tooling, minimizing airflow delay is critical. By strategically selecting pneumatic fittings that reduce internal flow resistance, and by minimizing the total number of connection points, engineers can improve actuator response and reduce cycle times. Using manifolds near the end effector and selecting swivel-style pneumatic fittings to prevent tubing twist can further enhance reliability and serviceability in dynamic robotic motion.

Material Choices & Environmental Considerations

The material of pneumatic fittings directly influences durability, corrosion resistance, weight, and suitability for the operating environment. Because robotic systems frequently operate inside compact cells, on mobile platforms, or near liquids or cutting oils, material selection has both performance and longevity implications.

Brass and Nickel-Plated Brass

Brass pneumatic fittings are widely used because they offer a strong balance of cost, durability, and corrosion resistance. Nickel-plated brass pneumatic fittings add increased wear resistance and a clean surface finish, making them suitable for general industrial automation. These fittings are often used in robotics actuators mounted near the base or mid-arm where mass is less critical.

Stainless Steel

Stainless-steel pneumatic fittings are preferred when corrosion, sanitation, or chemical exposure is a concern. Common in food, pharmaceutical, and medical robotics, these pneumatic fittings resist washdown, humidity, and cleaning agents. Stainless steel is heavier than polymer, so its use in end-of-arm tooling is balanced against overall weight and cycle time considerations.

Polymer and Composite Materials

Polymer push-to-connect pneumatic fittings are lightweight and vibration-resistant, making them ideal for grippers, sensors, and compact motion modules mounted near the robot wrist. These pneumatic fittings reduce moving mass and drivetrain load, allowing robots to accelerate faster and reach longer service intervals. Their temperature and chemical resistance must be evaluated to ensure they align with the operating environment.

Routing & Assembly Best Practices

Correct routing and assembly of pneumatic fittings directly influences reliability, speed, maintenance effort, and long-term consistency of motion. Even when high-quality components are chosen, poor tubing layout or improper installation can lead to leaks, slow actuator response, and premature fitting or seal failure. By treating pneumatic fittings as part of the motion system rather than as small accessories, engineers can significantly improve overall system performance.

Bend Radius and Kink Avoidance

Tubing connected to pneumatic fittings must follow gentle, controlled curves rather than sharp bends. When tubing is bent past its rated minimum bend radius, the internal flow pathway narrows and restricts airflow, causing pressure drop and delayed cylinder extension. Kinks near pneumatic fittings are especially damaging because they may introduce intermittent blockage when the robot arm moves, making the actuator response unpredictable. Using elbows or swivel-style pneumatic fittings at strategic routing points helps maintain consistent airflow during dynamic motion.

Strain Relief and Pull-Out Prevention

Repeated robot wrist rotation, cable chain movement, or end-effector vibration can pull on tubing and gradually loosen pneumatic fittings if strain relief isn’t accounted for. Clamps, grommets, and appropriately placed clip points ensure that tubing movement does not transfer load into the collet or threads of the pneumatic fittings. For tools that operate at high acceleration, swivel pneumatic fittings allow tubing to rotate freely, preventing twist buildup and extending both tubing and fitting service life.

Minimize Tubing Length to Improve Response Speed

In high-speed automation, shorter tubing runs improve actuator response because there is less air volume to fill when a valve opens. This is one of the simplest ways to improve cycle time without changing cylinders or valves, simply reduce the distance between actuator and valve, and adjust pneumatic fittings placement accordingly. Locating manifolds closer to moving tooling and selecting compact elbow or straight pneumatic fittings to minimize path length leads to faster, more repeatable motion, especially for pick-and-place or inspection slides.

Design for Quick Service and Tool Change

In robotic cells where end-effectors may be swapped for different product runs, pneumatic fittings should be chosen and placed to allow quick disconnect and reconnect of air lines. Quick-disconnect pneumatic fittings with integrated shutoff valves, or modular manifold plates with push-to-connect ports, reduce downtime and simplify retooling. Clear labeling and consistent fitting orientation enable technicians to replace or adjust tooling without trial-and-error, protecting both uptime and system reliability.

Common Leak & Failure Modes

Even well-designed pneumatic systems can experience failures if pneumatic fittings are poorly matched, incorrectly installed, or subjected to environmental stress. Recognizing common failure patterns helps prevent downtime and ensures stable operation over the lifetime of the system.

Tube Pull-Out and Slippage

If tubing is not cut squarely or is inserted without full engagement, the collet or compression sleeve in pneumatic fittings may not grip uniformly. Over time, motion shock, air pressure pulses, or thermal expansion can work the tube loose. Using clean, perpendicular cuts and applying strain relief near pneumatic fittings prevents this failure mode.

Thread Leakage and Misalignment

Cross-threading, mixing NPT with BSP or metric threads, or improper use of sealants can lead to slow leaks or unstable pressure. Thread-type identification must occur before assembling pneumatic fittings, and sealing methods must match thread geometry. For example: PTFE tape is appropriate for NPT, but O-ring face seals should not be taped.

Pressure Drop and Slow Actuators

When pneumatic fittings are undersized relative to actuator flow needs, they throttle airflow and reduce cylinder or gripper speed. This is especially noticeable in multi-actuator systems where downstream devices receive less pressure. Ensuring correct tubing diameter, minimizing total fitting count, and using manifolds close to actuators alleviates this issue.

FAQs About Pneumatic Fittings

What do pneumatic fittings do in a compressed air system?

Pneumatic fittings connect tubing, valves, cylinders, regulators, and manifolds so that compressed air can flow reliably between components. The performance of pneumatic fittings directly affects actuator speed, response time, and leak resistance in automation and robotics applications.

How do I identify whether a thread is NPT, BSP, or metric?

NPT threads are tapered, while BSP and metric threads are parallel. Many pneumatic fittings include thread markings, such as “R” or “G” for BSP or alphanumeric metric designations. Using thread gauges or checking manufacturer datasheets is the safest way to confirm thread type before installing pneumatic fittings.

When should I use push-to-connect fittings instead of compression fittings?

Push-to-connect pneumatic fittings are ideal for lightweight, modular, or frequently adjusted systems such as robotic end-of-arm tooling. Compression pneumatic fittings are better for high-vibration environments or when the tubing may be tugged, pulled, or routed over long distances.

Can pneumatic fittings be reused after disassembly?

Some pneumatic fittings can be reused depending on their sealing method. Push-to-connect and threaded pneumatic fittings can often be reused when tubing and threads are undamaged, while compression fittings may require new ferrules. Reuse should be verified case-by-case based on wear and sealing performance.

How do I prevent leaks in pneumatic fittings?

To avoid leaks, ensure that pneumatic fittings match the tubing diameter and thread standard, use proper thread sealant where required, avoid sharp tubing bends near the fitting, and confirm full seating of the tube. Routine leak checks and strain-relief planning extend the service life of pneumatic fittings significantly.

Conclusion — Ensuring Reliability Through the Right Pneumatic Fittings

Pneumatic fittings may be small components, but they play a central role in airflow control, actuator response, and overall system stability in robotics and automation. By selecting the right connection type, thread standard, tubing size, and material, engineers ensure that pneumatic fittings support fast, consistent, and energy-efficient motion. Smart routing practices, proper strain relief, and attention to sealing details help prevent leaks and performance drift over time.

Whether used in compact robotic grippers, multi-axis assembly stations, cleanroom automation, or machine tending work cells, pneumatic fittings must balance mechanical security, airflow efficiency, and serviceability. Matching fitting style to application environment, from lightweight polymer push-to-connect fittings to rugged stainless-steel washdown fittings, ensures long-term performance and reliability.

By applying the principles outlined in this guide, automation designers and sourcing engineers can confidently specify pneumatic fittings that support clean routing, fast actuation, and stable cycle-to-cycle performance, enabling robots to operate smoothly and efficiently across a wide range of tasks. If you’d like support selecting or sourcing the right pneumatic fittings for your automation or robotics system, feel free to contact us, we’re here to help.