Table of Contents

Introduction to Pneumatic Cylinders in Robotics and Automation

Pneumatic cylinders are the workhorses that convert compressed air into linear motion. In robotics and automation, pneumatic cylinders provide rapid, repeatable strokes for gripping, positioning and pushing tasks. Because pneumatics use clean, compressed air, systems remain lightweight and responsive while avoiding the contamination risks of hydraulic oil.

Pneumatic cylinders have long been staples in factory automation, but as robotics expands into collaborative work cells, autonomous mobile robots and flexible manufacturing lines, selecting the right pneumatic cylinders has become more critical than ever. This guide places pneumatic cylinders in the context of robotics, focusing on rodless and guided actuators that solve space and alignment challenges, while still covering traditional double‑acting, single‑acting, compact and rotary varieties. Throughout this article, every paragraph will include the focus keyword pneumatic cylinders to reinforce search relevance and ensure clarity.

Modern pneumatic cylinders operate as part of a larger compressed air system. An air compressor generates and stores compressed air, air preparation equipment filters and regulates it, valves control flow, and the pneumatic cylinders perform work. In robotics, these cylinders often combine with sensors, controllers and mechanical linkages to execute precise motion sequences.

The simplicity and cost‑effectiveness of pneumatics make them appealing, yet designers must carefully consider bore size, stroke length, mounting style and cylinder type to achieve the required performance. By understanding how pneumatic cylinders function and how to select them, engineers can design robotic systems that are both efficient and reliable.

Why Pneumatic Cylinders Matter in Robotics

Pneumatic cylinders offer several advantages over electric actuators and hydraulic cylinders. Compressed air is clean and nonflammable, making pneumatic systems safer in environments that prohibit oil leaks or sparks. Pneumatic cylinders can accelerate quickly and change direction rapidly because air flows easily through tubing and valves, providing high cycle rates suitable for pick‑and‑place robots.

They are relatively inexpensive and simple to maintain; seals and wear items are easy to replace, and the cylinders themselves have few moving parts. Pneumatic cylinders also excel in harsh conditions, dust, moisture and temperature extremes, where electromechanical components may fail. In robotics, these attributes translate to actuators that are lightweight, fast and resilient.

While electric motors provide precise positioning and high torque, they require complex controllers and often weigh more than pneumatic cylinders. Hydraulic cylinders deliver very high force, but they involve high pressures, leaks and maintenance. Pneumatic cylinders fill the gap by delivering adequate force for many robotic tasks while being inexpensive and easy to integrate.

For tasks such as end‑effector gripping, part transfer or vertical lifts within a collaborative robot cell, pneumatic cylinders offer an attractive balance of performance, cost and reliability. Still, designers must be aware of the limitations of pneumatics, including lower maximum force, compressibility of air leading to less precise positioning, and energy losses due to leakage and continuous compressor operation. These trade‑offs inform when pneumatic cylinders are appropriate and how to optimize them for robotics.

Overview of Pneumatic Cylinder Types and Their Role in Robotics

Pneumatic cylinders come in many varieties, each suited to specific tasks and environments. For robotics, the selection often hinges on envelope size, stroke length, load direction and the need for precision or guidance. The main types include:

- Rodless pneumatic cylinders — Provide long strokes without external rods protruding. Ideal for constrained spaces and clean cable routing.

- Guided pneumatic cylinders — Include guide rods or slides to manage side loads and prevent rotation. Perfect for robotics applications with off‑center loads or moments.

- Compact pneumatic cylinders — Deliver force in a short length, suiting tight spaces such as end‑effectors and tool changers.

- Double‑acting pneumatic cylinders — The traditional workhorse with air on both sides of the piston for balanced force and speed in both directions.

- Single‑acting pneumatic cylinders — Use air to extend and a spring to retract, employed for clamps, lifts and simple grippers.

- Rotary pneumatic actuators — Convert air into rotational motion; used for indexing, tool rotation and robotic wrists.

In robotics, rodless and guided pneumatic cylinders often take precedence because they solve common constraints. Long strokes and side loads occur frequently in articulated arms, pick‑and‑place gantries and collaborative robot end‑effectors. Compact cylinders enable integration into small end‑effectors, while double‑acting and single‑acting cylinders power general motion and clamping. Rotary actuators add rotation where electric motors may be overkill or too heavy. Understanding each type ensures that pneumatic cylinders are matched to the needs of modern robotic systems.

How Pneumatic Cylinders Work

All pneumatic cylinders, regardless of type, operate on the same principle: pressurized air enters a chamber containing a piston. The pressure differential pushes the piston, generating linear force proportional to the piston area and supply pressure minus friction losses. In double‑acting pneumatic cylinders, ports on both ends allow air to extend or retract the piston.

In single‑acting cylinders, one port pressurizes the piston while a return spring retracts it, resulting in force only in one direction. Piston movement typically occurs inside a tube or barrel sealed with O‑rings or sliding seals. The rodless variants do not use an external rod; instead, the piston connects to a carriage that rides along the cylinder body, enabling long strokes without protrusion. Guided cylinders add external rods or slides to handle side loads and maintain alignment.

The performance of pneumatic cylinders depends on air pressure, flow and the design of valves controlling them. Higher pressure increases force, but compressed air is limited to around 6–10 bar (90–145 psi) in most factories. Flow rate through valves and tubing determines speed; undersized valves restrict flow and slow cylinder response. Cylinder materials, aluminum, stainless steel, brass, affect weight and corrosion resistance. For robotics, engineers choose materials and seals based on factors like washdown requirements, cleanroom compatibility and magnetic sensing. In every case, understanding these fundamentals ensures that pneumatic cylinders function reliably and safely.

Rodless Pneumatic Cylinders — Long Travel and Clean Integration

Rodless pneumatic cylinders are ideally suited to robotics and automation where space is limited or where the external rod of a conventional cylinder would interfere with nearby components. These pneumatic cylinders feature an internal piston connected to an external carriage via a mechanical coupling or magnetic coupling. The piston moves along the cylinder barrel, and the carriage glides on external support rails. Because the carriage stays flush with the cylinder body, rodless pneumatic cylinders provide strokes equal to or greater than the cylinder length without additional space. This makes them invaluable for pick‑and‑place gantries, linear modules on collaborative robot arms, and conveyor diverters.

Two main coupling styles exist: mechanically coupled rodless cylinders and magnetically coupled rodless cylinders. Mechanically coupled versions use a band or slot through which the piston connects to the carriage; seals and covers prevent air leaks. They handle higher loads and side forces but must maintain integrity of the band.

Magnetically coupled rodless pneumatic cylinders use powerful magnets embedded in the piston and carriage to transfer force through the cylinder wall, resulting in a sealed chamber with no opening. While they support lower loads, magnetic rodless cylinders ensure leak‑free operation and minimal friction. Designers must weigh load capacity, seal complexity and price when choosing rodless pneumatic cylinders for robotics.

Applications of Rodless Pneumatic Cylinders in Robotics

Rodless pneumatic cylinders shine in robotics where long linear motion is required without protruding rods. In collaborative robot arms, rodless cylinders can drive linear extension modules for reaching into packaging bins or stacking parts. Because the carriage travels along the cylinder body, these pneumatic cylinders allow engineers to mount sensors, wiring and grippers directly on the carriage without worrying about rod stroke interfering with the rest of the arm. In overhead gantry robots, rodless cylinders move loads across several meters, enabling pick‑and‑place operations over wide workspaces. The absence of an external rod reduces the risk of collision with other equipment and simplifies guarding.

Another use case is when space below or behind the cylinder is limited, such as when actuators must fit inside slender robotic fingers or tool changers. Rodless pneumatic cylinders integrate neatly along the length of the end‑effector, leaving room for electrical wiring and vacuum lines. Because the carriage moves in line with the cylinder, designers can also route compressed air and cables through the same axis. In all these applications, rodless pneumatic cylinders provide the long stroke and clean integration that robotics demands.

Design Considerations for Rodless Pneumatic Cylinders

When selecting rodless pneumatic cylinders, pay close attention to load capacity, seal integrity and guidance. Mechanically coupled cylinders can support heavier loads and side forces but require regular maintenance of the band or slot seals. Magnetic rodless cylinders provide leak‑free operation with minimal maintenance but have limited load capacity.

Both types require precise alignment and support to prevent bending or jamming. Designers should consider adding external guide rails or slides if side loads exceed cylinder capabilities. Because the focus keyword is pneumatic cylinders, always verify that stroke length, bore diameter and pressure ratings match the performance required for the robotic application.

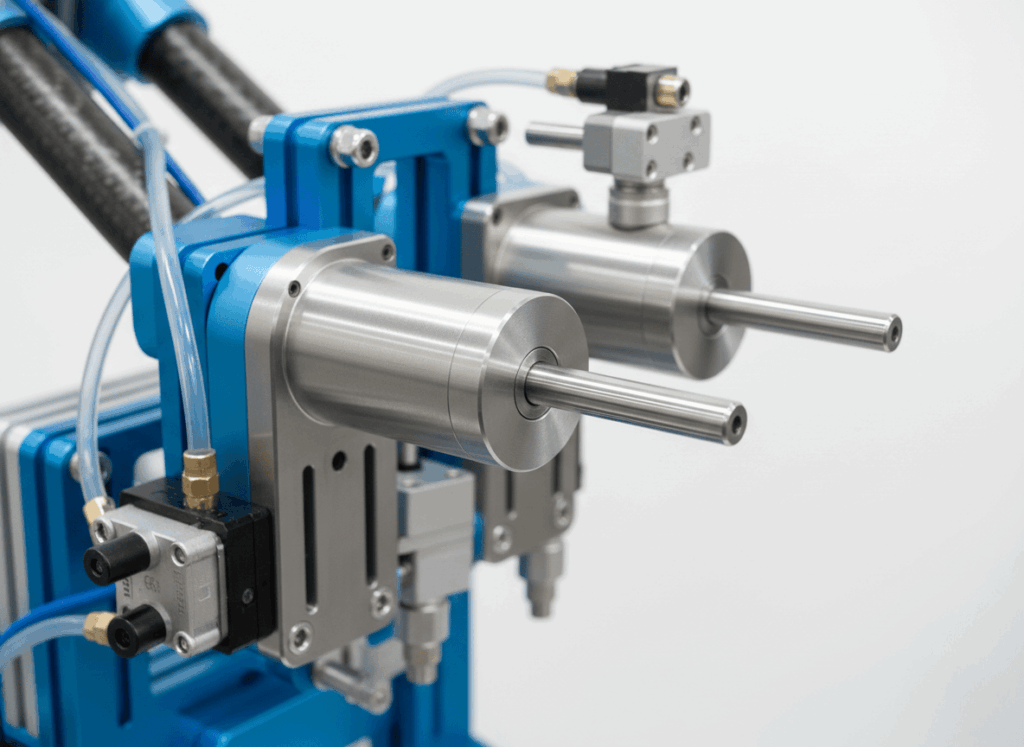

Guided Pneumatic Cylinders — Managing Side Loads and Precision

Guided pneumatic cylinders combine a traditional cylinder barrel with external guide rods, linear bearings or slides. They maintain the alignment of the rod and piston and absorb side loads, preventing bending and rotation. Guided pneumatic cylinders are essential in robotics, where loads may be off‑center or subject to moment forces. Without guidance, a conventional cylinder rod can deflect, causing seal wear, binding and premature failure. Guided designs allow pneumatic cylinders to handle higher side loads, enabling them to move heavy grippers or fixtures with confidence.

Benefits of Guided Pneumatic Cylinders in Robotics

For robotics, guided pneumatic cylinders solve the challenge of managing side loads and maintaining accurate alignment. In pick‑and‑place robots, payloads may be offset from the axis of motion, creating torque and side load on the cylinder rod. Guided pneumatic cylinders incorporate one or more guide rods parallel to the main cylinder rod, connected by a carriage plate. Linear bearings or bushings support the rods, taking up side loads and ensuring smooth, parallel motion. This arrangement isolates the cylinder from bending forces and prolongs seal life, ensuring pneumatic cylinders deliver reliable motion over millions of cycles.

Guided pneumatic cylinders also prevent rotation of the rod, which is crucial when the end‑effector must maintain orientation during travel. In robotic welding fixtures or assembly machines, orientation errors could cause misalignment or scrap parts. By using guided pneumatic cylinders, engineers maintain consistent alignment and guarantee that clamps, grippers and tools remain oriented correctly. Additionally, guided pneumatic cylinders often include built‑in cushioning to absorb impact at end‑of‑stroke and reduce noise, enhancing the longevity of the system.

Types of Guided Pneumatic Cylinders

Several forms of guided pneumatic cylinders exist, offering different balances of size, stiffness and cost. Twin‑rod cylinders feature two parallel rods attached to the same piston, running through bushings in the end caps. The rods provide guidance and resist twisting; they are compact and commonly used in pick‑and‑place modules.

Slide units integrate the cylinder body with a linear slide and carriage, offering higher precision and longer strokes than twin‑rod designs. Slide units may use recirculating ball bearings for smooth, accurate travel and can handle heavier loads. Flange‑guided cylinders use external guide rods connected by a plate that travels along the rods, providing robust guidance for larger loads. Engineers choose among these guided pneumatic cylinders based on payload, required precision and available space.

Selection Criteria for Guided Pneumatic Cylinders in Robotics

When selecting guided pneumatic cylinders for robotics, consider the following factors: payload weight, off‑center load distance, required precision, stroke length and environmental conditions. Guided pneumatic cylinders must support the combined weight of the end‑effector and payload without excessive deflection. If a heavy tool is cantilevered out from the carriage, choose a slide unit with high stiffness. For shorter strokes with moderate loads, twin‑rod cylinders offer a compact solution.

Pay attention to the bearing type; recirculating ball bearings offer greater precision but may require more maintenance than plain bushings. Also consider the environmental conditions—dust, coolant, and washdown; stainless steel guide rods and sealed bearings may be necessary in harsh environments. By carefully matching these criteria, engineers ensure that pneumatic cylinders provide reliable, repeatable motion for robotic tasks.

Compact and Mini Pneumatic Cylinders — Packing Power into Small Spaces

Compact pneumatic cylinders compress the cylinder’s length while providing respectable stroke lengths. They achieve this by integrating the end caps within the cylinder tube or using a larger bore relative to stroke length. Mini pneumatic cylinders are small‑bore variants that deliver force in extremely tight spaces. In robotics, compact and mini pneumatic cylinders are invaluable for end‑effectors, tool changers and robot joints where space is at a premium.

Applications of Compact Pneumatic Cylinders

Robots often have limited space at the end of arms or within collaborative work cells. Compact pneumatic cylinders fit into these spaces while still offering the stroke needed for gripping or pushing. For example, a compact cylinder can actuate the jaws of a robotic gripper without adding significant length to the end‑effector, allowing the gripper to reach into tight packaging cavities. In assembly automation, compact pneumatic cylinders actuate small presses or ejectors on rotary indexing tables. Mini pneumatic cylinders excel in lightweight pick‑and‑place tasks, such as sorting small components or operating micro‑tools in electronic assembly. By using compact pneumatic cylinders, designers maintain a small form factor while preserving functionality.

Design Considerations for Compact Pneumatic Cylinders

When choosing compact pneumatic cylinders for robotics, evaluate the available space and required stroke. Because compact cylinders use a shorter body, they often employ a larger bore to achieve the desired force. This increases air consumption, so ensure the air supply can handle the demand.

Pay attention to how the cylinder mounts; many compact cylinders use threaded holes on the body or specialized clamps, and alignment must be maintained to avoid binding. Magnetic sensors for position feedback may be harder to fit on compact pneumatic cylinders, so consider external sensors or mechanical switches if feedback is required. Finally, confirm that the compact cylinder’s material and seals are suitable for the environment, as smaller components may be more susceptible to contamination or wear.

Double‑Acting Pneumatic Cylinders — The Workhorse of Automation

Double‑acting pneumatic cylinders use compressed air to apply force in both directions. A piston divides the cylinder barrel into two chambers; when air flows into one chamber, the piston moves and the other chamber exhausts. Reversing the air flow moves the piston back. Double‑acting pneumatic cylinders deliver consistent force and speed in both extension and retraction, making them versatile for robotics. They are the most common type of cylinder in industrial automation.

Applications of Double‑Acting Pneumatic Cylinders in Robotics

In robotics, double‑acting pneumatic cylinders handle a wide range of tasks: lifting, pushing, clamping, indexing and pressing. For example, in a pick‑and‑place robot, a double‑acting cylinder may raise and lower the gripper head to pick parts off a conveyor. In an assembly cell, double‑acting pneumatic cylinders press components together or actuate tool changers. Because they provide force in both directions, they are ideal for reciprocating mechanisms such as stamping presses or linear indexing drives. Double‑acting pneumatic cylinders also serve as linear actuators in collaborative robots, where they deliver smooth motion with built‑in compliance when used with flow control valves.

Advantages of Double‑Acting Pneumatic Cylinders

Double‑acting pneumatic cylinders offer several advantages. They provide equal or balanced force in extension and retraction, enabling controlled movement in both directions. Their simple design means fewer moving parts and lower cost than hydraulic or electric actuators. They can achieve high cycle rates because air flows easily into and out of both chambers. In robotics, the ability to fine‑tune speed with flow control valves and cushioning systems ensures that double‑acting pneumatic cylinders deliver repeatable, gentle motion suitable for fragile parts. Additionally, double‑acting pneumatic cylinders can stop at intermediate positions by controlling the air supply, providing some level of positioning capability.

Design and Sizing of Double‑Acting Pneumatic Cylinders

To size double‑acting pneumatic cylinders for robotics, calculate the required force and choose a bore size accordingly. The force equals pressure multiplied by piston area; ensure the supply pressure and bore produce enough force for both directions. Stroke length must cover the required motion plus allowances for cushioning and mechanical tolerances.

Choose appropriate mounting, front or rear flange, clevis or trunnion, to accommodate the direction of force. Consider using adjustable cushions to absorb kinetic energy at end‑of‑stroke and prevent metal‑to‑metal impact. In robotic applications where speed matters, select valves with sufficient flow capacity and minimize restriction in tubing. When sensors or feedback are necessary, choose cylinders with magnetic pistons and attach reed switches or proximity sensors for position monitoring.

Single‑Acting Pneumatic Cylinders — Simplicity for Clamping and Return Strokes

Single‑acting pneumatic cylinders use compressed air to move the piston in one direction and a spring to return it. They are commonly used in situations where force is required only in one direction, such as clamps, ejection mechanisms or lifts. In robotics, single‑acting pneumatic cylinders are useful for end‑effectors that must close a gripper or push a part out of a fixture and then retract automatically. Their simplicity makes them inexpensive and easy to maintain, though their return force depends on the spring and they may suffer from slower retraction.

Advantages and Limitations of Single‑Acting Pneumatic Cylinders

The primary advantage of single‑acting pneumatic cylinders is their simplicity and cost. Because they only require a single air supply port, they use less air than double‑acting cylinders. They are lighter and have fewer seals, reducing friction and maintenance. However, the return stroke depends on a spring or external force, which may not provide consistent speed or force. For heavy loads or high cycle rates, spring wear can lead to failure. In robotics, single‑acting pneumatic cylinders are best for low‑force applications such as clamping or part ejection where the return stroke need not be powered strongly.

Selecting and Integrating Single‑Acting Pneumatic Cylinders

When choosing single‑acting pneumatic cylinders, consider the force needed on the extension stroke and ensure the spring provides adequate retraction. For vertical applications where gravity assists retraction, a lighter spring may suffice. For horizontal or upward movement, choose a stronger spring or double‑acting cylinder instead. In robotics, integrate flow control valves for smooth extension and use vent silencing to reduce noise during spring return. Since single‑acting pneumatic cylinders can trap air on the spring side, include a breather or exhaust port to allow venting and prevent back pressure. Monitoring the spring and seals in preventive maintenance schedules will keep single‑acting pneumatic cylinders performing reliably in robotic cells.

Rotary Pneumatic Actuators — Adding Rotation to Robots

While pneumatic cylinders primarily provide linear motion, rotary pneumatic actuators convert air pressure into angular movement. These actuators come in several forms: vane types, rack‑and‑pinion designs and rotary clamps. Vane rotary actuators use one or more vanes in a cylindrical housing; pressurized air moves the vane to create rotation.

Rack‑and‑pinion rotary actuators convert linear motion of a rack driven by a pneumatic piston into rotation of a pinion gear. Rotary clamps combine a small double‑acting cylinder with a cam mechanism to provide clamping and rotation in a compact unit. In robotics, rotary pneumatic actuators provide indexing, tool rotation and wrist movements when electric servos are unnecessary or too expensive.

Applications of Rotary Pneumatic Actuators

Robots often require rotational movement that does not demand the precision or cost of servo motors. Rotary pneumatic actuators fill this role. In material handling, vane or rack‑and‑pinion actuators rotate parts 90° or 180° on conveyors. In pick‑and‑place robots, rotary clamps hold and rotate parts to the correct orientation for assembly or packaging. Collaborative robots use rotary pneumatic actuators in tool changers to rotate grippers or end‑effectors into position. Because pneumatic rotation is quick and reliable, it is well suited to high‑cycle tasks. However, the travel of rotary pneumatic actuators is typically limited to discrete angles such as 90°, 180°, or 270°, and they may not offer fine positioning control.

Considerations for Rotary Pneumatic Actuators

When integrating rotary pneumatic actuators, consider the torque required and the angular travel. Choose a vane actuator for quick, lower‑torque rotation and a rack‑and‑pinion design for higher torque. Ensure that the actuator can handle the inertia of the load; oversizing may be necessary to accommodate sudden starts and stops. Use flow control valves to adjust rotation speed and soft stops to prevent impact. Because rotary pneumatic actuators depend on seals and vanes, ensure that air supply is clean and dry to prevent sticking or wear. In robotics, position feedback may be required; select actuators with integrated sensors or add external encoders for precise rotational indexing.

Key Specification Parameters for Pneumatic Cylinders

Designing with pneumatic cylinders demands careful attention to technical parameters to ensure performance and longevity. The following specification parameters apply to all types of pneumatic cylinders and are crucial in robotics:

Bore Size and Force Calculation

The bore size (diameter) of the cylinder directly determines the force output. Force equals pressure multiplied by piston area; doubling the bore diameter quadruples the piston area. Selecting the correct bore ensures that pneumatic cylinders deliver enough force to move the load while minimizing air consumption. Use the lower supply pressure available in the system (e.g., 6 bar) and multiply by piston area to compute force. Always add safety margins to account for friction and varying air pressure.

Stroke Length

Stroke length defines how far the piston travels. Longer strokes require more air and can lead to slower speeds if the air supply is undersized. For rodless pneumatic cylinders, the stroke can exceed the cylinder’s body length, while compact cylinders provide modest strokes relative to their length. Choose a stroke that covers the required motion plus an allowance for cushioning and mechanical tolerances; avoid using the full rated stroke to prevent end‑cap impacts.

Mounting and Alignment

Proper mounting prevents misalignment, bending and seal wear. Pneumatic cylinders may mount via clevises, flanges, trunnions or foot mounts. In robotics, ensure that the mounting style aligns the cylinder with the direction of force. Guided pneumatic cylinders require rigid mounting surfaces to support guide rods. For rodless pneumatic cylinders, provide support along the length to prevent sagging. Misalignment causes side loads that prematurely wear seals and bushings.

Speed and Flow Requirements

Cylinder speed depends on air flow to and from the chambers. Undersized valves and tubing restrict flow, slowing pneumatic cylinders and causing inconsistent operation. Choose valves with sufficient Cv or Kv rating to deliver the required flow at the operating pressure. Use flow control valves to adjust speed; restrict exhaust flow rather than supply flow for smoother control. For high‑speed robotics, minimize tubing length and bends. Consider using quick‑exhaust valves to vent air quickly from large double‑acting pneumatic cylinders.

Cushioning and End‑of‑Stroke Control

Cushioning absorbs kinetic energy near end‑of‑stroke, reducing impact noise and extending cylinder life. Adjustable pneumatic cushions use needle valves to throttle exhaust near the end of travel, while shock absorbers convert kinetic energy into heat. Guided pneumatic cylinders and slide units may integrate cushions to handle higher speeds and masses. In robotics, proper cushioning ensures that pneumatic cylinders decelerate smoothly and protect end‑effectors and parts from impact.

Environmental Considerations

Robotic systems may operate in harsh environments, exposure to dust, moisture, chemicals or washdown. Choose pneumatic cylinders with materials and seals suitable for the environment. Stainless steel barrels and guide rods resist corrosion; anodized aluminum offers light weight. Seals should withstand the temperature range and chemical exposure. For food and pharmaceutical robots, select pneumatic cylinders that meet sanitary standards and resist cleaning agents. In cleanrooms, choose cylinders with low particle emission and minimal lubrication to prevent contamination.

Sensor Integration for Position Feedback

While pneumatic cylinders are typically open‑loop, robotics often benefits from position feedback. Magnetic pistons allow reed switches or Hall‑effect sensors to detect end‑of‑stroke or intermediate positions. Some guided pneumatic cylinders and rodless cylinders integrate position feedback sensors or linear transducers. Adding sensors enables closed‑loop control or verification of motion sequences, enhancing reliability. When designing the sensor system, ensure cables and connectors integrate cleanly with robotic end‑effectors.

Sourcing and Quality Considerations for Pneumatic Cylinders

Selecting pneumatic cylinders for robotics also involves evaluating suppliers and quality. Sourcing high‑quality pneumatic cylinders ensures consistent performance, shorter lead times and reliable documentation. Consider the following when sourcing pneumatic cylinders:

Compliance with ISO Standards

Many pneumatic cylinders follow ISO standards, which define mounting dimensions, bore sizes, and stroke increments. ISO 15552 covers tie‑rod and profile cylinders, while ISO 6432 covers round miniature cylinders. Using ISO‑standard pneumatic cylinders allows interchangeability among manufacturers and simplifies sourcing and replacement. In robotics, standardized dimensions ease integration with frames and tooling.

Material and Surface Finish

Evaluate the materials used in the cylinder body, piston rod and seals. Stainless steel cylinders offer corrosion resistance in washdown environments; anodized aluminum provides light weight but may scratch. Chrome‑plated rods reduce friction and wear. For guided pneumatic cylinders, the hardness and finish of guide rods influence bearing life. Insist on quality certifications and inspection reports from suppliers.

Seal Quality and Lubrication

Seals are critical to pneumatic cylinder performance; poor seals lead to leakage, stick‑slip and reduced life. Choose suppliers with reliable seal materials and manufacturing processes. In robotics, low friction and low breakaway forces are vital for smooth motion. Some pneumatic cylinders incorporate pre‑lubricated seals; others require external lubrication. Verify the lubrication method and compatibility with your environment. For food or cleanroom applications, specify FDA‑approved or silicone‑free lubricants.

Lead Time and Availability

Robotics projects often have tight schedules; choose suppliers who maintain inventory or offer quick turnaround on standard pneumatic cylinders. Consider stocking spare cylinders or seals to minimize downtime. For custom or specialty pneumatic cylinders, such as rodless slide units with unique stroke lengths, work closely with manufacturers to understand lead times. Evaluate suppliers’ global reach and support to ensure replacement components are available worldwide.

Cost vs. Performance Trade‑Offs

While pneumatic cylinders are generally inexpensive, costs vary based on materials, guidance and customization. Guided and rodless pneumatic cylinders cost more than basic double‑acting cylinders due to their added features. Evaluate the performance benefits relative to cost. In robotics, paying more for guided pneumatic cylinders may be justified if they prevent downtime from misalignment or premature wear. Consider total cost of ownership, including energy consumption (air use), maintenance and replacement. Collaborate with purchasing teams to balance budget and performance.

Integration with Pneumatic Valves and Fittings

Pneumatic cylinders do not operate in isolation; they rely on valves to control air flow and fittings to connect tubing. Understanding how these components interact ensures smooth and efficient system operation.

Selecting Directional Control Valves for Cylinders

Directional control valves manage the supply and exhaust of air to pneumatic cylinders. For robotics, 5/2 or 4/2 solenoid valves are common for double‑acting cylinders. 5/2 valves provide separate exhaust ports, while 4/2 valves combine exhausts; the choice depends on whether you need to prevent cross‑contamination or control exhaust speed.

Consider whether a mono‑stable (spring return) or bi‑stable (latching) valve suits your application. Mono‑stable valves return to the default position when the signal stops, providing a fail‑safe state. Bi‑stable valves maintain their last state until the opposite signal arrives, useful for conserving compressed air during dwell times. For high‑speed robotics, choose valves with low response times and high flow coefficients.

Valve Configuration and Manifolds

In multi‑axis robotic systems, consolidating valves on a manifold simplifies plumbing and maintenance. Manifolds group multiple valves together, reducing tubing length and providing a neat installation. Some valve manifolds include fieldbus communication modules, allowing digital control and diagnostics. When designing a manifold for pneumatic cylinders, ensure each valve’s flow capacity matches cylinder requirements and that the manifold supports the number of valves required. Consider using quick‑disconnect electrical connectors for easy replacement of valves.

Flow Control and Cushioning Valves

Flow control valves adjust the speed of pneumatic cylinders by restricting exhaust or inlet flow. In robotics, flow control valves are typically installed on cylinder ports to control extension and retraction speed separately. Choose between meter‑in (controlling supply) and meter‑out (controlling exhaust) configurations; meter‑out control generally provides smoother motion. Cushioning valves or adjustable cushions integrated into cylinders allow tuning of end‑of‑stroke deceleration. For heavy loads, consider using external shock absorbers or deceleration cylinders in series with pneumatic cylinders.

Fittings and Tubing Considerations

Reliable connections ensure that pneumatic cylinders operate at full efficiency. Choose fittings and tubing based on pressure, environment and ease of maintenance. Push‑to‑connect fittings speed assembly and are popular in robotics because they enable quick changes without tools.

Compression fittings offer higher pressure ratings and secure connections, making them suitable for high‑load pneumatic cylinders. Match the tubing material to the environment; polyurethane is flexible, nylon offers good chemical resistance, and PTFE handles high temperatures. Use proper thread sealant on tapered threads and avoid mixing thread standards. For high‑speed robotics, minimize tube length and avoid sharp bends that restrict flow. Secure tubing away from moving parts to prevent wear.

Case Studies: Pneumatic Cylinders in Robotics Applications

Case Study 1: Collaborative Robot Gripper with Rodless Cylinder

A collaborative robot requires a long‑stroke gripper to pick food packages from a deep bin and place them on a conveyor. Space is limited between the robot’s wrist and the bin, and the gripper must avoid protruding rods that could collide with surrounding equipment. Engineers select a magnetically coupled rodless pneumatic cylinder with a 500 mm stroke and 20 mm bore. The carriage supports a parallelogram‑style gripper.

Because the rodless design keeps the moving carriage flush with the cylinder body, the entire actuator fits within the robot’s envelope. The cylinder’s magnetic coupling prevents air leakage and ensures smooth motion. Flow control valves set the extension and retraction speed for gentle handling of packages, and reed switches on the cylinder provide position feedback. The gripper’s pneumatic cylinders deliver reliable, long‑travel motion while maintaining the collaborative robot’s compact form factor.

Case Study 2: High‑Precision Slide Unit for Electronics Assembly

An electronics manufacturer needs to place microchips on circuit boards with high precision. The robotic cell uses a guided pneumatic cylinder in a slide unit configuration. The slide unit features a double‑acting cylinder with a 40 mm bore and 150 mm stroke, mounted to a linear rail with recirculating ball bearings. This guided pneumatic cylinder handles off‑center loads from the pickup tool and ensures repeatable positioning within ±0.01 mm.

To achieve high cycle rates, engineers use a 5/2 spool valve with a high flow coefficient and quick exhaust ports. Flow control valves fine‑tune the speed, and shock absorbers at the ends of the slide reduce impact. Sensors on the slide detect position for closed‑loop control. The guided pneumatic cylinder meets the demanding precision and reliability requirements of electronics assembly while remaining cost‑effective.

Case Study 3: Compact Cylinder for Tool Changer on Cobot

A collaborative robot needs to switch between two end‑effectors: a vacuum gripper and a finger gripper. The tool changer must be lightweight and fit within the robot’s limited payload. Engineers design a compact pneumatic cylinder with a 25 mm bore and 20 mm stroke integrated into the tool changer. The compact pneumatic cylinder actuates a locking mechanism that releases one tool and secures the other.

By using a compact cylinder, the changer maintains a low profile and adds minimal weight. The cylinder’s large bore ensures sufficient force to lock and unlock quickly. A 3/2 solenoid valve controls the cylinder, and the return stroke uses a spring. The cylinder includes a magnetic piston and reed switch to confirm the lock position. The compact pneumatic cylinder enables fast tool changes without exceeding the robot’s payload capacity.

Case Study 4: Rotary Pneumatic Actuator for Indexing Station

An assembly line requires rotating a workpiece 180° between two assembly operations. Designers choose a rack‑and‑pinion rotary pneumatic actuator rated for 100 Nm torque. The actuator mounts under the index table and rotates the fixture via a pinion shaft. A 5/2 solenoid valve controls the actuator; flow control valves adjust the rotation speed. A mechanical end stop ensures precise 180° rotation, and magnetic sensors detect the start and end positions. By using a rotary pneumatic actuator instead of an electric motor, the system simplifies wiring and reduces cost. The actuator delivers fast, reliable indexing at a rate of 20 cycles per minute. Its pneumatic design handles shock loads and requires minimal maintenance.

Case Study 5: Single‑Acting Cylinders for Product Ejection

In a packaging machine, products must be pushed off a conveyor into a reject bin when sensors detect defects. Engineers use single‑acting pneumatic cylinders with 16 mm bores and 10 mm strokes mounted above the conveyor. When a defective product passes, a 3/2 valve sends air to the cylinder, extending a pusher arm to eject the item. A spring retracts the cylinder for the next product. Single‑acting pneumatic cylinders are chosen because they require minimal air, are inexpensive, and provide rapid actuation for occasional ejection events. Flow control valves moderate the speed to prevent damaging adjacent products, and silencers reduce noise during spring return. This simple use of pneumatic cylinders effectively removes defective products without requiring complex servo systems.

Maintenance and Troubleshooting of Pneumatic Cylinders

Reliable operation of pneumatic cylinders depends on regular maintenance and proper troubleshooting. Even the best designs can fail if air quality is poor or if components wear out prematurely. Follow these practices to maximize uptime in robotics:

Ensure Clean and Dry Air

Contaminants in compressed air, such as water, oil and particulates, can cause seals to swell, stick or wear. Install filters, dryers and lubricators in the air supply to ensure clean, dry and lubricated air. For robotics applications requiring oil‑free operation, use oil‑free compressors and dry lubrication in cylinders. Regularly inspect and replace filters to maintain air quality.

Check for Leaks

Air leaks reduce system efficiency and cause inconsistent cylinder motion. Inspect fittings, tubing and seals for leaks; use soapy water or ultrasonic leak detectors. For rodless pneumatic cylinders, inspect the band or magnetic coupling for wear. Guided pneumatic cylinders may develop leaks around guide rods if seals deteriorate. Tighten fittings, replace seals and repair or replace damaged components promptly. Implement leak detection programs to catch leaks before they cause problems.

Lubrication and Seal Replacement

Many pneumatic cylinders require periodic lubrication to reduce friction and wear. Lubricate rods and seals with the manufacturer’s recommended lubricant. For food‑grade or cleanroom applications, use appropriate lubricants that meet regulatory requirements. Replace seals when cylinders begin to leak or exhibit stick‑slip. Some pneumatic cylinders have sealed‑for‑life lubrication; verify the specification and follow maintenance intervals accordingly. Maintenance schedules should include inspection of guided pneumatic cylinders’ bearings and slide units to ensure smooth operation.

Inspect Mounting and Alignment

Misalignment leads to uneven wear on seals and bearings, causing pneumatic cylinders to stick or leak. Check mounting brackets, clevis pins and alignment regularly. For guided pneumatic cylinders, inspect guide rods and bearings; replace them if worn. Ensure that rodless pneumatic cylinders have proper support and alignment along their length. Adjust flow control valves to ensure smooth acceleration and deceleration, reducing mechanical shock.

Troubleshoot Unusual Behavior

If pneumatic cylinders exhibit erratic movement, slow speed or failure to reach end position, troubleshoot methodically. Check supply pressure to ensure adequate pressure at the cylinder. Inspect valves for contamination or sticking; clean or replace them. Examine tubing for kinks or restrictions. For rodless pneumatic cylinders, verify that the carriage moves freely and that the coupling is intact. For guided pneumatic cylinders, check for dirt in bearings. Consult the manufacturer’s documentation and use the provided diagnostic steps. In robotics, integrate sensors and feedback to detect failures early and trigger alarms for maintenance.

Conclusion — Designing the Future with Pneumatic Cylinders

Pneumatic cylinders remain indispensable in robotics and automation, offering unique benefits of speed, simplicity and cost‑effectiveness. By understanding the diverse types, rodless, guided, compact, double‑acting, single‑acting and rotary, engineers can match pneumatic cylinders to the precise needs of modern robots. Rodless and guided pneumatic cylinders excel in robotics by enabling long strokes and handling side loads, while compact cylinders and rotary actuators add versatility for grippers and indexing tasks. Key selection criteria, including bore size, stroke, mounting style, flow capacity and environmental suitability, ensure that pneumatic cylinders perform reliably.

Integrating pneumatic cylinders with appropriate valves, fittings and sensors provides a complete system that meets the demands of high‑speed automation. Real‑world case studies demonstrate how pneumatic cylinders power collaborative robot grippers, precision assembly slides, compact tool changers, indexing stations and reject ejection mechanisms. Maintenance practices, clean air, leak detection, lubrication and alignment checks, ensure long life and consistent performance. By harnessing the strengths of pneumatic cylinders and understanding their limitations, robotics engineers and sourcing professionals can design systems that are efficient, safe and adaptable to future needs.

As you continue to design and innovate with pneumatics, remember to embrace digital monitoring and energy optimization. The synergy of traditional compressed air technology with modern sensors, smart valves and predictive maintenance will keep pneumatic cylinders relevant and powerful in the evolving landscape of automation.

With careful selection, integration and upkeep, pneumatic cylinders will continue to drive robots that assemble our electronics, package our food, transport goods and collaborate safely with humans. By applying the insights in this robotics‑oriented guide, you can confidently specify and implement pneumatic cylinders that deliver precision, reliability and cost savings, ensuring success in both the robots of today and the smart factories of tomorrow. If you’d like practical guidance or sourcing support for pneumatics in your robotic systems, feel free to contact us, we’re here to help.