Table of Contents

In the realm of mechanical engineering, gears and transmissions play a pivotal role in transforming motion, amplifying or reducing torque, and coordinating mechanical actions with precision. Without carefully selected gears and transmissions, machines would be noisy, imprecise, and unreliable. This article delves into the types, roles, and selection principles of gears and transmissions, their integration with other mechanical components, and Yana’s approach to sourcing these critical parts. Throughout this article, the focus phrase “gears and transmissions” appears in every paragraph, ensuring consistency and reinforcing the importance of these components.

Introduction: Why Gears and Transmissions Matter

Gears and transmissions are not merely components; they are the essence of controlled motion and effective power transfer. From the smallest timepiece to large industrial machinery, the choice of gears and transmissions determines whether a device operates smoothly or stutters through its motion, whether it is efficient or wasteful, and whether it lasts for decades or breaks prematurely.

Precision in gears and transmissions is what makes motion feel intentional, balanced, and quiet. When engineers develop a product, they recognize that gears and transmissions must be considered early in the design process. The forces, speeds, and load conditions present in the machine all interact through gears and transmissions. If the gears and transmissions are poorly chosen or poorly manufactured, the entire system can fail. Conversely, well‑chosen gears and transmissions enable designers to express their intent with a real, tangible smoothness.

The Language of Motion: Translating Torque and Speed

At its heart, a gear is a device for translating torque and speed. Gears and transmissions allow a high‑speed low‑torque motor to drive a low‑speed high‑torque axle, or vice versa. In many cases, multiple gear pairs combine to form gear trains that achieve large overall gear ratios.

The “transmission” portion often refers to an assembly that includes multiple gears arranged so that the output speed can be varied relative to the input speed, as in automotive gearboxes or mechanical gear changers. Without gears and transmissions, motors would have to be huge to generate enough torque, or machines would have to endure high speeds that lead to wear. Therefore, gears and transmissions form the fundamental link between power sources and the working components they drive.

Precision and Feel

When experienced engineers or users interact with machinery, the “feel” of a mechanism is often the first thing they notice. Does the handwheel turn with a smooth, even resistance? Does the machine accelerate and decelerate under control? Gears and transmissions shape these qualities. Poorly manufactured gears and transmissions introduce backlash, excessive play that manifests as slop and inaccuracy. Excess backlash can make precision motion impossible, leading to errors in positioning or sloppy interactions.

Conversely, extremely tight tolerances and smooth gear teeth enable crisp, repeatable movement. The control of backlash is one of the most important reasons to invest in good gears and transmissions. If you can hear the gear teeth clanking together or feel the vibration through the handle, the gears and transmissions are not doing their job. Instead, a properly designed system uses gears and transmissions to guide motion along a predetermined path, ensuring that the product feels premium and functions reliably.

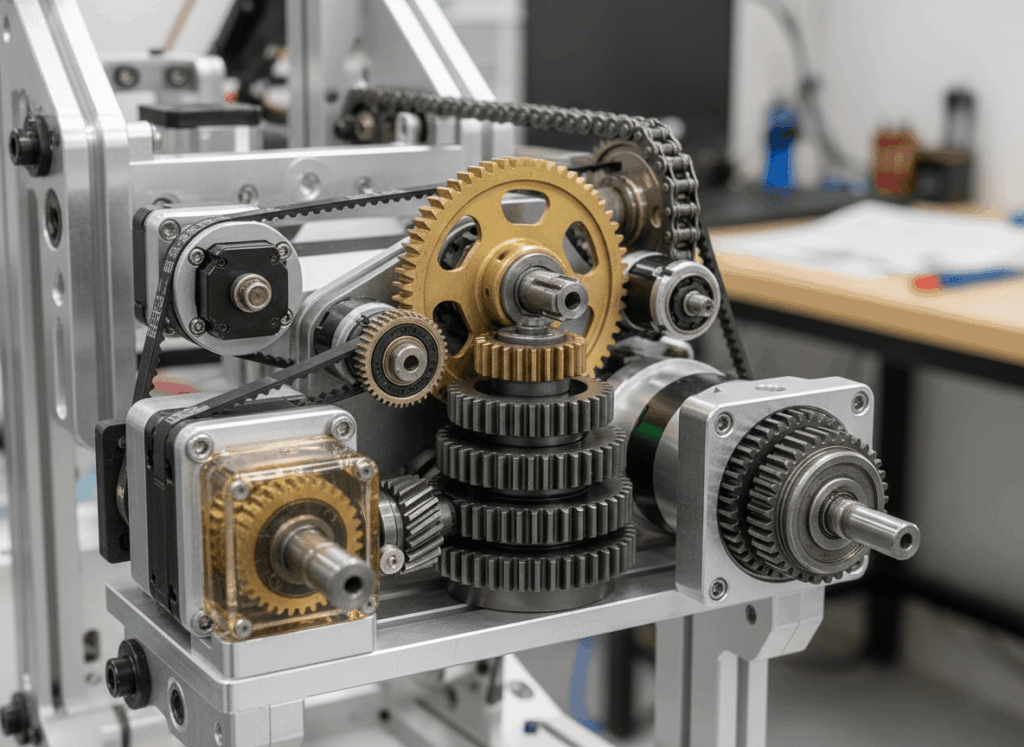

Types of Gears and Their Uses

Within the world of gears and transmissions, there are many different gear types, each designed for specific applications. Some types of gears allow for motion transfer between parallel shafts, others permit motion at right angles, and still others convert rotational motion into linear motion. The selection of gear type depends on the application requirements, including desired gear ratio, space constraints, noise levels, and load capacity. Let’s explore the common gear types used in gears and transmissions.

Spur Gears

Spur gears are the simplest and most common type of gear. They have straight teeth that run parallel to the axis of rotation. In gears and transmissions, spur gears are used when shafts are parallel and when simplicity and efficiency are prioritized. Because the teeth on spur gears mesh directly, they produce minimal axial thrust and are relatively straightforward to manufacture. However, spur gears can be noisy at high speeds because the teeth engage all at once. In applications where noise is a concern, spur gears may be replaced by helical gears or other types.

Helical Gears

Helical gears use angled teeth that cross the face of the gear at a helical angle. In gears and transmissions, helical gears are favored for their quieter operation compared with spur gears. Because the teeth engage gradually and overlap as they mesh, there is less vibration and less noise.

Helical gears can transmit higher loads at higher speeds than spur gears. However, the helical design introduces axial thrust, which must be accommodated by bearings or thrust collars. Helical gears can be used to connect parallel shafts or shafts that are at an angle, provided the gears are configured appropriately (e.g., double‑helical or herringbone gears can cancel axial thrust).

Bevel Gears

Bevel gears are used when motion must be transmitted between intersecting shafts (often at a 90‑degree angle). These gears resemble conical shapes, with teeth cut on the conical surfaces. In gears and transmissions that require directional change of rotation, bevel gears are commonly used. They come in various forms: straight bevel gears (with straight teeth), spiral bevel gears (with curved teeth for smoother engagement), and zerol bevel gears (a mix of straight and spiral). The choice of bevel gear type depends on the desired smoothness, load capacity, and cost.

Worm Gears

Worm gears consist of a worm (a screw‑like shaft) and a worm gear (similar to a helical gear). They allow shafts to transmit motion at right angles with high gear reductions. In gears and transmissions used for elevators, conveyors, or tuning instruments, worm gears provide large reductions in speed with the advantage of self‑locking properties. Because the worm’s screw and the gear’s teeth create a sliding contact, worm gears exhibit more friction and lower efficiency than spur or helical gears. However, their self‑locking nature can prevent back driving (where the output shaft turns the input), which is beneficial in some applications.

Planetary (Epicyclic) Gears

Planetary gearsets are named because of their resemblance to a solar system. They consist of a central sun gear, planet gears that revolve around the sun, and an outer ring gear. In many gears and transmissions, planetary gearsets are used because of their compactness and ability to handle high torque.

By selecting which member of the gearset is held, which is input, and which is output, multiple gear ratios can be achieved within a single assembly. Planetary gears are widely used in automatic transmissions, industrial drives, and certain robotics applications. Their advantage is that they can produce large gear ratios in a small volume and can distribute the load across multiple planets, improving load handling.

Rack and Pinion

A rack and pinion system converts rotational motion into linear motion. The pinion is a small gear that meshes with a linear toothed rack. In gears and transmissions for steering systems or linear actuators, rack and pinion mechanisms provide a direct way to transform motion. They can be combined with other gear types to achieve specific speeds and forces. The choice of pitch and tooth shape affects how smoothly the rack moves and how much backlash is present. In high‑precision linear stages, fine pitch rack and pinion systems are engineered to have minimal backlash and excellent repeatability.

Gear Parameters and Design Considerations

When selecting gears and transmissions, several parameters determine the performance of the system. The gear ratio, pitch, module, pressure angle, and tooth profile all influence how gears engage and how effectively they transmit motion.

Gear ratio is the ratio of the number of teeth on two mating gears. A gear ratio greater than one means the output gear will rotate slower and produce more torque relative to the input. A gear ratio less than one means the output gear will rotate faster. In gears and transmissions for speed reduction (e.g., in industrial machinery), gear ratios can be quite high. For example, a ratio of 100:1 means the input must rotate 100 times to make the output rotate once.

Pitch and module describe the size of the gear teeth. Module is the ratio of the pitch circle diameter to the number of teeth and is a common metric used in gear design. Larger modules mean larger teeth and stronger gear teeth that can handle more load, but they also require larger center distances. The pitch must match for gears to mesh properly.

Pressure angle refers to the angle between the line of action (force transmission) and the tangent to the pitch circle. Typical pressure angles are 20° or 14.5°. A higher pressure angle increases tooth strength at the cost of increased radial load. Lower pressure angles reduce load on bearings but may result in more bending stress on gear teeth.

Tooth profile determines how gears engage. The most common profile for gears and transmissions is the involute profile. An involute gear tooth has a specific curve that ensures constant transmission of motion, with a constant gear ratio and minimal variation in torque. Non‑involute profiles (e.g., cycloidal gears) exist but are less common in general mechanical design.

Noise, Vibration, and Surface Finish

Gears and transmissions that operate quietly and without vibration signal quality. Poorly cut gear teeth or rough surfaces cause noise and shorten the life of gear teeth. Surface finish of the tooth flanks influences friction and wear. Gears that have been ground or lapped to high precision show smoother surfaces and more consistent tooth geometry. This results in reduced friction losses, lower heat generation, and quieter operation. In precision products, manufacturers choose fine finishes, moderate pressure angles, and improved tooth profiles to achieve the desired feel and reliability.

Gearboxes and Transmissions

In many applications, individual gears and transmissions are packaged in a gearbox. A gearbox contains multiple gears arranged to allow multiple speed ratios or torque conversions. Consider a standard automotive gearbox: it has a set of gears that provide first, second, third, and reverse speeds. The driver selects a gear ratio appropriate for the speed and load conditions.

The design of a gearbox must take into account gear tooth strength, friction losses, heat dissipation, lubrication, and assembly constraints. In the field of robotics, transmissions are often built into actuators to provide torque conversion in a compact form factor. Harmonic drives, strain wave gears, cycloidal reducers, and planetary gearboxes are common in robotics and motion control applications. Each type has unique strengths and weaknesses related to gear ratio, backlash, and load handling.

In selecting gears and transmissions for a product, engineers must decide whether to use off‑the‑shelf gearboxes or design custom solutions. Custom solutions can be precisely tailored to the desired performance and space envelope, but they are more expensive to design and manufacture. Standard gearboxes may require compromise in dimensions or gear ratios, but they are readily available and cost-effective. Yana helps clients evaluate these trade-offs and find the right gear solution for their product’s needs.

Selection Principles and Trade‑Offs

Selecting gears and transmissions is a balancing act. Engineers must consider torque, speed, life expectancy, efficiency, noise, cost, and space. For example, a high gear ratio may reduce input speed to the desired output speed but can also reduce efficiency due to friction. A gear that is too small may not handle the torque, while an oversized gear may take up too much space.

Load capacity is crucial. Each gear tooth must withstand bending and contact stresses under normal operation. Standard formulas derived from gear theory (such as Lewis’s formula) are used to calculate allowable tooth strength. Gear manufacturers specify ratings in power and speed. If a gear is overloaded, it may crack, break, or wear prematurely.

Backlash is another major consideration. Backlash is the play between mating teeth. It must be minimized to achieve precision, but too little backlash can cause binding or thermal expansion problems. In instrumentation and robotics, low backlash gears and transmissions are key to accuracy. In some heavy‑duty transmissions, moderate backlash may be acceptable because the primary concern is transmitting power, not precision.

Lubrication is essential. Gear teeth must remain lubricated to reduce wear and friction. Many gears and transmissions have enclosed casings filled with oil or grease. Others rely on self‑lubricating materials or sealed bearings. Proper lubrication ensures that gears operate smoothly and helps dissipate heat. In high-performance gearboxes, oil pumps and cooling systems may be incorporated to maintain optimal temperature and prevent gear damage.

Alignment is critical. Misaligned shafts cause uneven loading, increased noise, and premature wear. Bearings, shafts, and couplings must keep the gears aligned. High-precision gearboxes often have alignment features built into the housing. In assembly, shims and fixtures ensure that gears align properly during installation.

Materials also matter. Common gear materials include steel (for strength and wear resistance), cast iron (for damping and stability), brass or bronze (for lower friction), and plastic (for light loads and quiet operation). High performance gear materials may include alloy steels, case hardened steels, or composite materials. The choice depends on the required load capacity, environmental conditions, and noise requirements.

Manufacturing Considerations

The manufacturing process of gears and transmissions includes cutting the teeth (hobbing or shaping), heat treating to achieve desired hardness and toughness, and finishing processes like grinding and lapping to achieve precise tooth profiles. Quality control involves inspecting tooth profiles, measuring pitch errors, and verifying surface roughness. Because gears are critical components, quality standards such as AGMA (American Gear Manufacturers Association) or ISO ratings help specify the allowed tolerances.

Advances in manufacturing, including gear grinding and CNC machining, have significantly improved the precision and quality of gears and transmissions. Modern processes allow extremely tight tolerances and consistent tooth geometry. Additionally, additive manufacturing is beginning to be used for gears and transmissions, particularly for prototypes or small batch production. However, the mechanical properties of 3D‑printed gears still present challenges in terms of fatigue and surface finish.

Heat treating increases the hardness of gear teeth to resist wear. Case hardening methods such as carburizing, nitriding, and induction hardening are commonly used. These processes produce a hard surface with a tough core, preventing cracking. Surface treatments such as coatings and shot peening further increase fatigue life and reduce friction.

Integration with Other Components

Gears and transmissions do not operate alone. They rely on bearings, shafts, couplings, housings, and seals to function properly. For example, a gear shaft must be supported by bearings that handle radial and axial loads. Couplings must connect the gear shaft to a motor or another shaft, accommodating misalignment while transmitting torque.

The housing must maintain precise center distance between gears. If the center distance deviates, the gear teeth will not mesh properly, leading to vibration and wear. Yana understands that gears and transmissions must be integrated into the entire system. We help engineers evaluate the interaction between gears and transmissions and other components, ensuring that the final product feels cohesive and reliable.

Yana’s Approach to Sourcing Gears and Transmissions

At Yana, gears and transmissions are not just catalog items. Each selection is a relationship between design intent, manufacturing expertise, and assembly practice. We approach gears and transmissions as critical parts of the product’s character. First, we listen to the engineering team to understand the desired feel, performance, noise level, and service life.

Next, we identify potential suppliers based on their technical capabilities, quality standards, and manufacturing methods. A reputable gear manufacturer must have consistent tooth profile control and material traceability. We evaluate sample gears and transmissions using dimensional inspection, run‑out measurement, and noise analysis. Only suppliers that meet Yana’s criteria become part of our network.

Once the right supplier is selected, we oversee production to ensure that gear quality remains consistent from batch to batch. We maintain communication with gear manufacturers, sharing feedback from assembly and field performance. If issues arise, such as increased backlash or surface imperfections, we work with the supplier to correct them. We also manage logistics and storage to prevent damage and contamination. All gears and transmissions are packaged to protect tooth surfaces and stored properly to prevent corrosion.

In many projects, standard gears and transmissions may not satisfy the desired performance. Yana can coordinate the design of custom gear sets. We work with partners to develop tooth profiles, gear ratios, and assembly configurations that match the product requirements. Through careful specification and supplier collaboration, custom gear solutions become reliable parts of the supply chain. We prefer to design for manufacture, ensuring that custom gears and transmissions can be produced consistently and cost-effectively.

Future Trends and Innovations

The world of gears and transmissions continues to evolve. New materials, manufacturing processes, and design approaches promise more efficient, quieter, and more reliable power transmission. For example:

- Advanced Materials: Composite materials, powder metals, and new alloys enable gears with lighter weight and greater wear resistance. Hybrid gear sets combine steel with polymer gear stages for improved damping and noise reduction.

- Additive Manufacturing: 3D printing and additive manufacturing allow rapid prototyping of gears and transmissions. While currently limited to small batch production and low load applications, additive manufacturing may eventually enable complex geometries and integrated features, such as internal cooling passages or lightweight structures.

- Micro‑Gears and Micro‑Transmissions: In microsystems and miniature robotics, micro‑gears and micro‑transmissions are critical for creating precision motion in tiny devices. Micro‑fabrication techniques and MEMS technology are being applied to create gear trains on the scale of millimeters or smaller.

- Smart Gearboxes: Sensors and electronic monitoring integrated into gears and transmissions can track parameters such as temperature, vibration, and wear. Smart gearboxes enable predictive maintenance and early detection of faults.

- High‑Efficiency Gear Trains: Innovative gear profiles and lubrication techniques reduce friction and increase efficiency. For instance, double enveloping worm gears can achieve efficiency comparable to helical gears while still providing high gear reduction.

- Integrated Actuation: In robotics and automation, actuators with integrated gears and transmissions (e.g., harmonic drives, cycloidal reducers, strain wave gears) offer compact and high torque density solutions. These integrated drives reduce the number of components, simplify assembly, and provide low backlash.

- Quiet Operation: Ongoing research aims to reduce noise and vibration in gears and transmissions, particularly in consumer products and precision instruments. Spiral bevel and hypoid gears offer quieter operation at high speeds, while tooth shapes optimized by computer‑aided design can further reduce dynamic loads.

- Standardization and Modularity: As engineering moves toward modularity, manufacturers develop standard gear modules that can be combined to create custom gear trains. This approach shortens development time and enables rapid configuration of gears and transmissions.

Conclusion: The Heart of Reliable Motion

Gears and transmissions are often overlooked by the untrained eye. Yet they are the heart of reliable motion, shaping how machines behave and how products feel. By selecting the right gears and transmissions, engineers ensure that their products perform with precision, confidence, and longevity. In the world of mechanical design, details matter, and Yana is committed to making those details work for you.

Our approach to gears and transmissions goes beyond catalog specifications; it encompasses listening, understanding, and delivering the components that make motion a pleasure rather than a problem. If you are designing a product, whether it is a robotic arm, an industrial machine, or a consumer device, contact us today, our expertise in gears and transmissions can help you achieve your goals.