Table of Contents

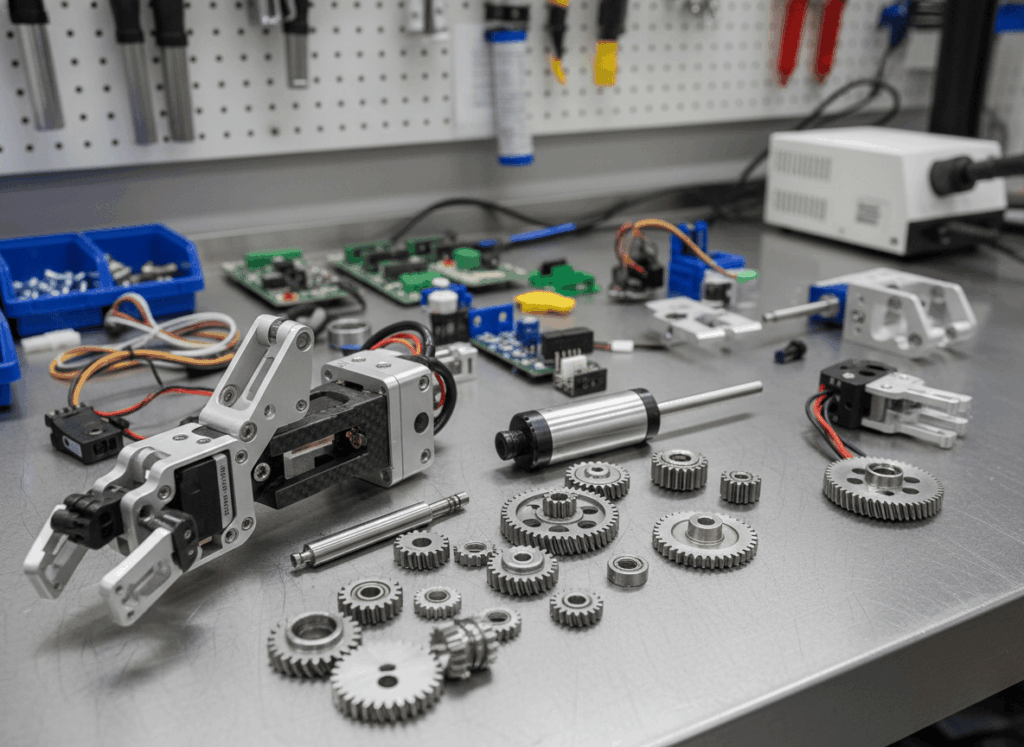

You can feel quality in the way a mechanism comes to rest. In high‑precision systems the physical feel of motion is more than an aesthetic flourish; it is a direct expression of the precision mechanical components that lie beneath the surface. When a robotic arm glides to a halt without chatter, when a camera gimbal returns to centre without hunting, or when a handheld device feels solid and purposeful, you are experiencing the cumulative effect of every bearing, screw, coupling and linkage working together.

This article is your guide to the world of precision mechanical components , explaining how they influence motion, describing the major subtypes, offering selection guidelines, unpacking supply‑chain realities and showing how Yana helps you make decisions that resonate with your values.

The Role of Mechanical Components in System Performance

Mechanical transmission defines character

At the heart of every machine is a chain of mechanical components converting forces into purposeful movement. Bearings reduce friction and support rotating shafts; screws and ball screws transform rotation into linear displacement; couplings connect shafts while compensating for misalignment; linkages distribute motion between multiple axes; and gears and transmissions convert speed and torque. When specified correctly, these precision mechanical components give a machine its desired “feel” – whether that is the smoothness of a precision telescope mount or the firmness of a collaborative robot arm. When specified poorly, the same chain becomes the root of vibration, backlash, noise and shortened life.

Feel, stability and longevity

Consider a servo drive controlling a motor: if the control loop is tuned to perfection but the mechanical elements have inconsistent backlash or excessive friction, the overall system will still feel sloppy. Studies of servo controllers have shown how general‑purpose servo drives not optimised for the application produce excess heat and latency; by analogy, generic mechanical components introduce their own latent performance penalties.

The feel of a mechanical assembly is tied to stiffness, inertia, damping and mass distribution. High‑quality bearings and gears reduce frictional drag and variation; precision screws and couplings ensure consistent pitch and torque transmission; well‑designed linkages distribute forces evenly, preventing localised wear. These precision mechanical components are the difference between hardware that inspires confidence and hardware that feels unpredictable.

Failure modes and hidden pitfalls

Mechanical parts fail in ways that are often invisible until damage accumulates. Bearings can seize because of contamination, misalignment or insufficient lubrication; ball screws can jam if preload is inconsistent; couplings can crack under cyclic torque; linkages may become loose if fasteners back out; gearboxes can develop backlash or broken teeth.

Many of these failures occur because initial selection did not consider the full operating envelope – duty cycle, load variation, vibration, shock and temperature. Just as integrated servo drives with torque feedback and Safe Torque Off (STO) circuits protect motors from overloads, mechanical systems require built‑in safeguards against misuse and design oversights. In the remainder of this article we will examine each component family and provide guidelines for choosing the right part for your product.

Subcategories Within Mechanical Components

Bearings

Precision mechanical components start with bearings because they enable motion with minimal friction and controlled support. The most common types are deep‑groove ball bearings, angular contact bearings and roller bearings. Deep‑groove bearings handle radial loads and moderate axial loads; angular contact bearings are designed for high axial loads and high speed; roller bearings handle heavy radial loads.

Selection criteria include load capacity, speed rating, stiffness, preload, lubrication type and sealing. In robotics, low‑friction seals and consistent preload are essential for smooth motion. For very high precision applications, cross‑roller bearings offer minimal runout at the cost of more complex preload adjustment. Misjudging bearing selection can cause heat buildup and friction analogous to using a general‑purpose servo drive in an integrated robot joint.

Screws and ball screws

Screws convert rotational motion into linear motion. Standard machine screws provide general fastening, while trapezoidal lead screws offer moderate efficiency for linear actuation. Ball screws, which use rolling balls between the screw and nut, achieve efficiency >90% and very low backlash. These are the preferred choice for CNC machines, 3D printers and robotics.

Critical parameters for ball screws include lead accuracy (error per 300 mm), diameter, pitch, preload (light versus heavy), and backlash. The interplay between screw stiffness and servo loop tuning is critical; a high‑lead screw can increase responsiveness but requires careful damping, similar to how servo drivers must be tuned with the proper PID coefficients. When specifying screws, also consider end support bearings, lubrication methods and environmental sealing to prevent contamination.

Couplings

Couplings connect two rotating shafts, transmitting torque while accommodating misalignment, axial motion or vibration. The common types include rigid couplings, flexible beam couplings, bellows couplings and jaw/spider couplings. Rigid couplings offer high torsional stiffness but require precise alignment; flexible beam and bellows couplings allow for angular and axial misalignment while maintaining low backlash; jaw couplings provide damping and are often used on stepper motors.

Key selection factors are torque capacity, misalignment tolerance, torsional stiffness and backlash. In high‑performance systems the coupling must not introduce deadband; the same principle that motivates integrated servo drives with minimal latency applies to mechanical couplings. Material choice (aluminium, stainless steel) influences inertia, corrosion resistance and cost.

Linkages

Linkages translate motion between shafts or convert rotary motion into complex patterns. Common linkages include four‑bar linkages, spherical joints, universal joints and belt‑chain linkages. A four‑bar linkage can act as a parallelogram to maintain orientation, while a universal joint transmits torque between non‑co‑axial shafts. Chain or belt drives allow for long distance power transmission with tensioning.

The design of linkages must account for joint friction, backlash, acceleration limits and load distribution. For example, in collaborative robot arms, parallelogram linkages maintain end effector orientation and require precision bearings and balanced counterweights. As with servo drive control loops that must coordinate multiple axes, mechanical linkages must balance forces across joints to prevent localised wear or slip.

Gears and transmissions

Gears and transmissions convert speed and torque. Planetary gearboxes provide high reduction ratios in compact packages; spur gears transmit power at high efficiency but may produce noise; harmonic drives offer zero backlash and compactness; cycloidal drives provide high torque and rigidity. The choice of gear type influences mechanical backlash, efficiency, positioning accuracy and resilience to shock.

Modern innovations in gear technology mirror the innovations in servo driver electronics: new materials (e.g., high‑strength plastics, heat‑treated steels) and manufacturing methods (hobbing, grinding, additive manufacturing) are enabling high torque density and low noise. Designers must consider gear ratio, service factor, thermal rating, torsional stiffness and dynamic response.

How to Select the Right Mechanical Components

Technical selection factors

Choosing precision mechanical components begins with understanding technical requirements. For bearings, consider radial and axial loads, speed, tolerance class (e.g., P0, P4, P2), lubrication and preload. For screws and ball screws, evaluate lead accuracy, preload, nut type (single or double), pitch diameter and critical speed. Coupling selection involves torsional rigidity, misalignment tolerance and moment of inertia.

Linkage design must account for workspace geometry, joint limits, acceleration and dynamic forces. Gears and transmissions require analysis of ratio, efficiency, backlash, torque capability, lubrication method and noise. Each of these parameters has analogues in control systems: the stiffness of a bearing influences servo loop stability, just as overshoot in a PID loop can cause mechanical resonance.

Environmental and duty cycle considerations

Mechanical components operate within specific environments and duty cycles. Exposure to dust, moisture, chemicals, temperature extremes and radiation can degrade materials and lubricants. Bearings may require stainless steel or ceramic construction; screws may need protective bellows; couplings and linkages may need protective boots or shielding.

High duty cycles demand continuous lubrication and precision alignment; shock loading requires high static load capacity. Designers should evaluate worst‑case scenarios: start‑stop cycles, acceleration spikes, vibration frequencies, misalignment changes and thermal gradients. As with integrated servo drives that read torque sensors and adjust via communication buses like EtherCAT, mechanical systems need feedback (e.g., using sensors or wear indicators) to detect emerging failures.

Tolerance, precision and quality standards

Quality standards differentiate commodity parts from precision mechanical components for reliable product development. Bearings are classified by ISO tolerances (ISO 492) and ABEC ratings (ABEC 1–9); ball screws are graded by ISO 3408 accuracy classes (C0–C10); gears adhere to AGMA quality grades (Q0–Q15). Higher grades require tighter manufacturing tolerances, surface finishes and heat treatments.

These standards directly impact performance: a higher ABEC class bearing reduces runout and noise, a lower backlash gear box improves positioning accuracy, a precision ball screw ensures linearity. Failing to specify these metrics leads to hidden performance problems analogous to the way poorly designed motion control boards cause jerky movements and errors. When evaluating suppliers, demand certifications, test reports and sample measurements to confirm compliance.

Supply Chain & Manufacturing Context

Regional production clusters

China is the manufacturing powerhouse for many precision mechanical components. Bearings are produced in clusters around Wafangdian (Liaoning), Cixi (Zhejiang) and Luoyang (Henan); ball screws and linear guides often come from Guangdong and Jiangsu provinces; precision gearboxes are a speciality in Shenzhen, Ningbo and Suzhou.

Each region has its strengths, such as high‑volume production, flexible customisation or advanced heat treatment. Understanding regional capabilities helps match your quality targets and lead times. For example, one supplier may excel at low‑cost bearings for consumer devices, while another specialises in high‑accuracy cross‑roller bearings for industrial robots. Without this context, you risk ordering from a factory that cannot meet your tolerance requirements.

Price vs performance tradeoffs

Mechanical components range from mass‑market commodity to aerospace‑grade. Price is influenced by material costs, tolerance grade, production volume, brand reputation and after‑sales support. In some cases, selecting a mid‑grade bearing or gear results in acceptable performance at lower cost; in others, only top‑grade parts ensure reliability.

Startups often start with lower cost components and then upgrade once the design is proven. A good sourcing partner helps you balance these tradeoffs, just as unified motion controllers reduce cost by integrating machine logic and robot control. Avoid focusing solely on unit price; consider total cost of ownership, including the cost of field failures, warranty returns and brand reputation.

Customisation, MOQ and lead times

Customisation can differentiate your product but also increases cost and complexity. For screws, you may specify a unique lead pitch; for couplings, a specific bore diameter; for bearings, a custom preload and seal. Minimum order quantities (MOQs) and lead times vary; some factories require thousands of pieces, others accept small orders with higher per‑unit prices. Tooling costs may be amortised over large orders. Lead times range from weeks to months depending on production capacity, material availability and processing steps (e.g., heat treatment, grinding). Plan accordingly and build relationships with suppliers who can scale with you.

QC, testing and traceability

Quality control (QC) begins at the supplier’s facility. Good suppliers perform incoming material inspection, heat treatment verification, machining tolerance checks, assembly run‑in and final inspection. For bearings, measurement tools like coordinate measuring machines (CMMs) and vibration analysers ensure consistency.

For ball screws, laser interferometers check lead error. For gears, tooth profile scanners verify involute accuracy. Some suppliers provide individual serial numbers and test reports for traceability. When selecting precision mechanical components, request QC data and inspect parts upon arrival. Poor QC is often hidden until the component is installed, causing failure analogous to separate PLC and robot controllers causing communication issues.

Work with Yana

Calm precision, no drama

Working with Yana means taking the guesswork out of precision mechanical components. We listen to your vision, determine the feel and performance you seek, and help specify the right parts. We don’t chase the lowest unit price; we aim for reliability, repeatability and feel. Our engineers understand the interplay between mechanical elements and control systems, and they guide you through the tradeoffs that will shape your product’s character. As with servo drivers that use PID control to maintain accuracy and stability, our selection process balances stiffness, damping and precision.

Honest specs and real samples

When you work with us, you see actual data – tolerances, preload values, material certificates and test reports. We facilitate sample evaluations so you can experience the feel yourself. We understand that engineering is as much about tactile sensation as spreadsheets, which is why we focus on precision mechanical components rather than commodity catalogue parts. Our network spans factories known for high quality and customisation flexibility; we negotiate MOQs and lead times to match your programme schedule. We believe transparency builds trust, and we share our supplier assessments with you.

Long‑term reliability beats short‑term cost

Choosing precision mechanical components is an investment. While a cheaper bearing might save pennies upfront, the cost of a product recall, service visit or tarnished reputation is far greater. Our approach aligns with the philosophy that unified motion controllers reduce complexity and improve reliability; likewise, selecting the right mechanical components reduces system complexity by preventing hidden failure points.

We advocate designing for serviceability and longevity: specifying bearings with greasing ports, screws with easy preload adjustment, couplings that can be replaced without disassembly, and gearboxes that allow modular upgrades. This long‑term view is how Yana helps you build products that feel as good on day 1000 as they did on day 1.

Conclusion

Mechanical components define the soul of your product. From the whisper‑quiet spin of a precision bearing to the deliberate click of a backlash‑free gear drive, every tactile impression is a reflection of the precision mechanical components you choose.

In this article we explored the major families – bearings, screws and ball screws, couplings, linkages, and gears and transmissions – and showed how their selection affects feel, stability and longevity. We examined selection principles, environmental considerations, quality standards, supply chain factors and long‑term reliability. Throughout we drew parallels with servo drivers and control systems, highlighting how integrated design and high‑quality components lead to predictable, delightful hardware.

As you embark on your next product, remember that mechanical components are not interchangeable afterthoughts; they are purposeful decisions that signal your values. By working with Yana you gain a partner who balances tactile craft with engineering rigour, guiding you to select precision mechanical components that align with your vision. Let’s build systems that feel right, perform reliably and last – not because they must, but because they can.