Table of Contents

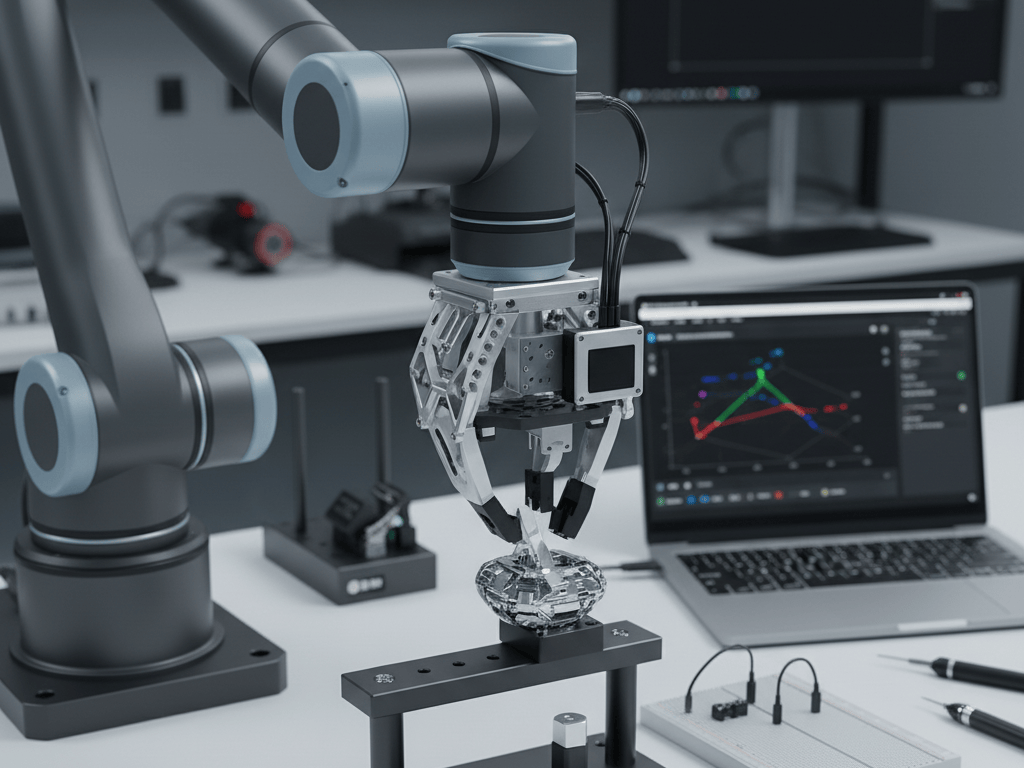

Robots are no longer blind, cage‑bound machines. Modern collaborative robots, surgical assistants and mobile manipulators can feel as well as move thanks to force–torque (F/T) sensors. These devices measure the forces and torques applied at a robot’s wrist or joint and convert them into electrical signals that a controller can use to adjust grip strength, regulate contact forces and detect unexpected impacts. By enabling tactile awareness, force–torque sensors make cobots safer around people, allow robots to polish or assemble components delicately and open new applications such as haptic tele‑operation and rehabilitation. This page explores how F/T sensors work, their key specifications and applications, and what to look for when sourcing these components.

Introduction: robots need a sense of touch

Imagine shaking a robot’s hand or working alongside a robot that pushes parts into place without crushing them. Such interactions require the robot to know how hard it is pressing and how much torque it is applying about its joints. Force–torque sensors give robots this sense of touch, making it possible to perform tasks that once required skilled human operators. Zurich‑based Bota Systems notes that force‑torque sensors let robots perform tasks that previously were only possible manually.

When integrated into collaborative robots (cobots), these sensors help monitor contact forces so that the robot can safely share workspaces with people; they are also used in industrial robots, humanoids and medical robots for welding, precision assembly and even minimally invasive surgery. Sensors that measure both forces and torques (three orthogonal force components and three torques) enable robots to interact with their environment intelligently and provide feedback for closed‑loop control. Without force–torque sensing, robots would be limited to preprogrammed movements and could not adjust to real‑world variations.

2 Working principles: how force–torque sensors measure forces and torques

2.1 What they measure

A six‑axis force–torque sensor simultaneously measures three orthogonal forces (Fx, Fy, Fz) and three torques (Tx, Ty, Tz). The ATI Multi‑Axis Force/Torque Sensor system illustrates the basics: it consists of a transducer, shielded high‑flex cable and data‑acquisition electronics and is used in applications ranging from robotic assembly and grinding to surgical robots and haptics. These sensors decouple the applied load into separate axes so that the robot’s controller knows both the magnitude and direction of contact forces. In research, a key performance challenge is balancing measurement range with minimal cross‑talk (interference between axes) and maintaining linearity and isotropy (equal response in all directions).

2.2 Transduction mechanisms

There are several transduction technologies for force–torque sensors:

- Resistive strain gauges (piezoresistive) – The most common approach. Strain gauges bonded to a deformable structure change resistance when deformed. Multiple gauges arranged in Wheatstone bridges on cross‑beams produce signals proportional to applied forces and torques. Silicon strain gauges produce higher signal‑to‑noise ratios than conventional foil gauges; for example, ATI’s sensors use silicon gauges and offer a signal 75 times stronger than foil gauges with near‑zero noise distortion. High‑strength structures (e.g., grade‑5 titanium or stainless steel) allow overload capacities many times the rated load.

- Piezoelectric sensors – Ceramic elements generate a voltage when stressed. They are highly sensitive and suited to dynamic measurements but have limitations for static loads.

- Capacitive sensors – Variations in capacitance between plates measure strain. They offer high sensitivity and can be miniaturized but may be sensitive to environmental conditions.

- Optoelectronic and optical fiber sensors – Changes in light transmission or interference caused by deformation measure forces. These offer high precision and immunity to electromagnetic noise but are more complex.

- MEMS and inductive sensors – Micro‑electro‑mechanical systems integrate sensor elements on silicon. Inductive sensing uses changes in inductance caused by movement and is an emerging alternative to strain gauges.

Researchers have explored these modalities to reduce cost, miniaturize force–torque sensors and improve fault tolerance. Strain‑gauge‑based sensors remain dominant in industry because they are robust, cost‑effective and provide high signal quality. Recent research has focused on improving the decoupling of forces and torques. For example, a novel strain gauge arrangement and error‑reduction techniques were proposed in 2019 to minimise crosstalk; the authors used a decoupling matrix and least‑squares calibration to improve sensitivity. Such work underscores that calibration and error compensation are integral to reliable force–torque sensing.

2.3 Mechanical design and decoupling

Most industrial F/T sensors use a cross‑beam or ring structure that deforms under load. Strain gauges are placed at strategic points to maximise sensitivity to a particular axis while minimising sensitivity to others. Decoupling cross‑talk is crucial; the design aims for each channel to respond primarily to its intended load component. High overload capability is achieved through materials like grade‑5 titanium and high‑yield-strength stainless steel; for example, ATI’s Nano17Ti force–torque sensors can handle overloads 4.9–19.6 times its rated capacity while maintaining high signal‑to‑noise ratio.

2.4 Calibration and error reduction

Force–torque sensors require careful calibration. Manufacturers supply calibration matrices that convert raw voltage readings into forces and torques. Calibration accounts for manufacturing tolerances, cross‑talk, nonlinearity and temperature effects. Modern sensors incorporate onboard microcontrollers to store calibration data, linearize outputs and apply temperature compensation. Research has proposed in situ calibration techniques (e.g., least‑squares estimation) and double parallel strain gauge arrangements to further reduce cross‑talk and improve sensitivity. For high‑precision applications (surgery, haptics), users may perform additional calibration and compensation using dead‑weight or multi‑load fixtures.

3 Applications of force–torque sensors in robotics

3.1 Collaborative robots and safety

One of the most transformative uses of force–torque sensors is in collaborative robots (cobots). Cobots operate near humans without cages, so they must continuously monitor forces to avoid injury. Force‑torque sensors allow cobots to adjust grip strength and motion speed; they detect unexpected contact and command the robot to stop or slow down, enabling safe human–robot collaboration. Sensodrive, a German torque‑sensor manufacturer, notes that its sensors underpin human‑robot collaboration by limiting forces in robot joints and enabling compliance according to ISO/TS 15066 safety standards. Bota Systems’ sensors for large cobots offer high sensitivity across the full payload range, enabling heavy palletizing and welding while maintaining safe interactions.

3.2 Industrial automation and manufacturing

In factories, F/T sensors enable robots to perform tasks that require precise force control: inserting parts, tightening screws, polishing surfaces and grinding. The sensors monitor contact forces and adjust motion to maintain consistent pressure, improving product quality and reducing wear. ATI’s Axia80 sensor, for instance, integrates the electronics inside the sensor body, connects directly via EtherCAT or Ethernet, and offers overload protection 5–20 times the sensing range, making it ideal for assembly, grinding and polishing. Force–torque sensors also support predictive maintenance, they can detect abnormal force patterns that indicate wear or misalignment, prompting maintenance before failure.

3.3 Medical robotics and rehabilitation

Force–torque sensing is critical in surgical robots and rehabilitation devices, where controlling the interaction force protects patients. F/T sensors allow minimally invasive surgical instruments to sense tissue resistance and provide haptic feedback to surgeons. In rehabilitation, exoskeletons use torque sensors at joints to measure user‑applied forces and adjust assistance; Sensodrive notes that its torque sensors are installed in exoskeletons to precisely measure supporting forces, enabling safe interaction between humans and machines. Their sensors also dampen vibrations in surgical microscopes and allow sensitive force feedback in medical devices.

3.4 Research manipulators, tele‑operation and haptics

In research laboratories, F/T sensors support haptic devices and tele‑operation. They measure forces exerted by users on manipulators, enabling kinesthetic teaching (hand‑guiding) and teleoperation with realistic force feedback. Bota Systems highlights that its sensors enable researchers to explore end‑to‑end learning and haptic feedback by attaching the sensor directly to a robot’s flange and connecting it internally to the robot’s Ethernet network. The integrated design eliminates external cables, exposes tool auxiliary connections and supports high‑quality data collection for AI and robotics research.

3.5 Wearables, exoskeletons and human augmentation

Force–torque sensors have migrated beyond industrial robots into consumer products and wearables. XJCSENSOR notes that force sensors are integrated into wearables to measure touch pressure and grip strength, providing more immersive experiences. Sensodrive’s force–torque sensors are installed in exoskeletons and automotive steer‑by‑wire systems, demonstrating their versatility. As force–torque sensors become smaller and more efficient, they will support human augmentation, prosthetics and consumer electronics.

4 Key technical specifications and selection criteria

When sourcing a force–torque sensor, several performance metrics must be considered. Table 1 summarises common parameters and typical values or considerations derived from manufacturer data and research articles.

| Parameter | What it means | Typical values/examples |

|---|---|---|

| Force/torque range | Maximum forces and torques that can be measured along each axis. Choose based on expected loads to avoid saturation. | ATI’s Nano17Ti sensors measure forces up to ~56 N and torques up to 200 N·mm, while large cobot sensors like Bota Systems’ SensONE T80 handle high payload ranges for palletizing and welding. |

| Resolution and noise | Smallest change in force/torque the sensor can detect; influenced by strain gauge quality and electronics. | High‑performance sensors achieve noise‑free resolution of 0.01 % of full scale and sampling rates up to 4 kHz as in Bota Systems’ PixONE sensor. ATI sensors employ silicon strain gauges with high signal‑to‑noise ratios. |

| Overload capacity | Ability to withstand loads beyond rated range without damage. Important to handle shock loads. | ATI sensors can withstand overloads 4–20 times rated capacity. Bota Systems’ PixONE offers 500 % overload protection. |

| Linearity and hysteresis | Deviation from proportional response; hysteresis is the difference between loading and unloading. | Sensodrive’s torque sensors are completely free of hysteresis and provide high precision even under disturbances. |

| Temperature drift | Output variation with temperature. Look for sensors with low drift and built‑in compensation. | Manufacturers provide temperature coefficients; Sensodrive integrates reliable temperature compensation and EMC measures. |

| Bandwidth | Frequency response; determines how fast the sensor can track changing forces. | Industrial force–torque sensors often support bandwidths from a few hundred hertz up to several kilohertz; Bota Systems’ PixONE sample rate is 4 kHz. |

| Size and weight | Important for integration in small wrists or end‑effectors. | ATI’s Nano17 sensor is one of the smallest 6‑axis sensors and fits into restricted spaces. Sensodrive’s disc‑shaped force–torque sensors add little weight. |

| Environmental sealing | Protection against dust, moisture or chemicals. | ATI offers IP65 and IP68 (4 m) versions of its sensors, enabling use in wet or underwater environments. |

| Output interface | Electrical interface and protocol for reading data. | Options include analog voltages, RS‑422/485, USB, CAN, EtherCAT, Ethernet or SPI. Bota Systems provides multi‑protocol communication (100 Mbps Ethernet, RS‑422/RS‑485, USB, EtherCAT in/out). Sensodrive offers BiSS C, SPI and analog interfaces. |

When comparing force–torque sensors, consider not only the raw specifications but also the integration effort (cables, connectors, drivers), manufacturer support and calibration services. Evaluate whether the sensor is pre‑calibrated, how calibration matrices are provided, and whether software drivers exist for your control stack (e.g., ROS 2, EtherCAT). Also assess the mechanical interface (bolt patterns, through‑holes) to ensure compatibility with your robot flange and end‑effector.

5 Integration and mounting considerations

Proper integration of a force–torque sensor is essential to obtain accurate measurements and reliable operation.

- Mounting position – The sensor is typically mounted between the robot wrist and the end‑effector. It should be aligned with the robot’s coordinate frame to simplify interpretation. Some force–torque sensors, such as Bota Systems’ units for Kinova Gen3 and Franka FR3 robots, attach directly to the robot’s flange and connect internally to the robot’s network; they expose all tool auxiliary connections so that no external cables are needed. This design reduces installation time and risk of cable damage.

- Mechanical alignment and balancing – Ensure that the sensor’s reference axes align with the robot’s axes. Balanced mounting minimizes bias forces and torques. Some force–torque sensors incorporate through‑holes to allow cables or pneumatic lines to pass through the centre, e.g., ATI’s Mini45 has a through‑hole for linkages or cables, and Bota Systems’ PixONE features a large hole for cable routing.

- Cable management – High‑flex cables must be routed to avoid snagging or fatigue. Integrated sensors with internal connections reduce external wiring.

- Calibration and software – Follow the manufacturer’s procedures for installing calibration matrices. Use built‑in controllers or interfaces such as EtherCAT or USB to simplify data acquisition. Bota Systems provides an open‑source

FTstackwith drivers for Python, ROS 2 and C++. - Environmental conditions – Choose force–torque sensors with appropriate IP ratings for dusty, wet or sterile environments. ATI offers IP65 and IP68 variants; Sensodrive sensors are designed to be maintenance‑free and robust under extreme conditions.

- Vibration isolation and filtering – In high‑vibration environments, mechanical isolation or filtering algorithms may be needed to separate true interaction forces from noise.

6 Sourcing and manufacturing insights

6.1 Materials and construction

Force–torque sensors are precision instruments. High‑quality sensors use grade‑5 titanium or high‑yield-strength stainless steel structures to maximise stiffness and overload capacity. Manufacturing techniques such as EDM wire cutting produce strong, decoupled structures. ATI’s sensors, for example, are wire‑cut from titanium or stainless steel, enabling overload capacities several times the rated load. The use of silicon strain gauges improves signal strength and reduces noise. For waterproof sensors, elastomeric seals and potting are used to achieve IP65 or IP68 protection.

6.2 Quality control and calibration

Manufacturers perform multi‑point calibration using dead weights and torque references, then supply calibration matrices. High‑end sensors come with detailed calibration certificates and error budgets. Sensodrive emphasises that their force–torque sensors are produced exclusively in Germany using the highest quality components and that each unit is tested to deliver high precision, low noise and long service. Chinese manufacturers such as XJCSENSOR and Hypersen offer more cost‑effective sensors; when sourcing from these suppliers, request calibration reports and check that overload protection and cross‑talk specifications meet your application requirements.

6.3 Supply chain and volumes

Sensodrive notes that torque‑controlled applications require customisation and that they specialise in medium to large quantities, whereas small volumes may be met with complete drive units. For startups and researchers needing only a few force–torque sensors, consider vendors with low minimum order quantities (MOQs) or distributors stocking popular models. When sourcing from overseas, factor in lead times, import duties and after‑sales support. Yana Sourcing can help vet suppliers, ensure quality control and manage logistics, especially when procuring from China.

7 Major manufacturers and their specialties

The global market for force–torque sensors includes both established players and emerging suppliers. Table 2 summarises representative companies and highlights their strengths.

| Manufacturer | Region | Notable features and products |

|---|---|---|

| ATI Industrial Automation | USA | Pioneer in multi‑axis F/T sensors; offers force–torque sensors in titanium and stainless steel with silicon strain gauges and high overload capability. Products like the Axia80 and Mini45 include integrated electronics, direct Ethernet/EtherCAT interfaces and overload protection 5–20× rated range. Variants with IP65/IP68 sealing enable use in wet or underwater environments. |

| Bota Systems | Switzerland | Provides digital 6‑axis force–torque sensors with built‑in electronics and multi‑protocol communication (Ethernet, RS‑422/485, USB, EtherCAT). Sensors attach directly to robot flanges and require no external cables. The PixONE and SensONE series offer noise‑free resolution (0.01 % FS), sampling rates up to 4 kHz and 500 % overload protection. Used for large cobots, human–machine interaction and AI research. |

| Sensodrive | Germany | Spin‑off of the German Aerospace Center; provides torque sensors and complete drives for cobots, medical robots, exoskeletons and steering systems. Sensors have high rigidity, are maintenance‑free and free of hysteresis; they compensate temperature and external disturbances. Disc‑shaped design allows easy integration. Certified safety for human‑robot collaboration (ISO/TS 15066). |

| FUTEK | USA | Supplies miniature load and torque cells with high precision. Known for robust, compact sensors used in aerospace, medical devices and test equipment. |

| Robotiq | Canada | Offers plug‑and‑play F/T sensors for Universal Robots and other cobots. Designed for easy integration and include on‑board processing for tasks like polishing and assembly. |

| OnRobot | Denmark | Provides sensors and grippers with built‑in force–torque measurement. Sensors interface seamlessly with many cobot brands, enabling force control tasks without extensive programming. |

| Bota Systems (Hypersen) | China | Domestic producers like Hypersen offer cost‑effective six‑axis sensors for research and light industrial use. These sensors often use strain‑gauge technology and can be customised for specific applications. |

8 Design trends and innovations

The force–torque sensor industry is evolving rapidly. Current trends include:

- Miniaturisation and integration – Force–torque sensors are becoming smaller and more integrated. ATI’s Nano17 and Mini45 provide high performance in a compact form factor, while Bota Systems’ PixONE features a through‑hole for cable routing and multiprotocol electronics integrated into the sensor.

- High bandwidth and overload protection – Modern force–torque sensors support higher sampling rates (up to 4 kHz) and greater overload margins (e.g., 500 % of rated load). This enables dynamic tasks and improves safety.

- Smart sensors with embedded processing – Many force–torque sensors now include microcontrollers that perform signal conditioning, cross‑talk compensation, temperature compensation and even basic force control. Some provide streaming interfaces over Ethernet or EtherCAT for real‑time integration.

- Advanced sensing technologies – Research is exploring inductive, optical and MEMS‑based six‑axis force–torque sensors. For example, new MEMS piezoresistive and capacitive sensors are being developed to reduce size and cost. A novel 6‑axis force–moment sensor proposed by Kebede et al. used 32 strain gauges and a decoupling matrix to minimize crosstalk and improve sensitivity. Optical sensors with low crosstalk and high resolution are also in development for legged robots.

- Multimodal sensing – Force–torque sensors are being combined with inertial measurement units (IMUs), vision and tactile arrays to provide richer data. Bota Systems emphasises capturing internal and external forces and tactile data to enhance machine learning and robot training.

- OEM‑specific kits and plug‑and‑play designs – Vendors now offer kits tailored for specific robot brands. Bota Systems provides kits for Kinova Gen3, Franka FR3 and other robots that include flange adapters and plug‑and‑play software. OnRobot and Robotiq also supply force–torque sensors that integrate directly with Universal Robots, simplifying deployment.

- Extended DOF sensors and tactile arrays – New force–torque sensors such as Bota Systems’ PixONE provide 12 degrees of freedom (force and torque combined with orientation and tactile channels) and are targeted at humanoids, surface finishing and legged locomotion. These devices offer high bandwidth, overload protection and a central hole for cable routing.

9 Comparative selection guide

Selecting a force–torque sensor involves balancing application requirements and budget. Table 3 suggests suitable sensor features for typical robotics scenarios.

| Application | Required features | Example sensor |

|---|---|---|

| Collaborative robot for assembly/pick‑and‑place | Moderate force range (~50 N), low hysteresis, plug‑and‑play interface, EtherCAT or USB connectivity | OnRobot HEX E or Robotiq FT 300 |

| Heavy industrial manipulator (welding, palletizing) | High overload capacity (>300 N), high sensitivity across full payload range, IP65 sealing, integrated electronics | Bota Systems SensONE T80 or ATI Axia80 |

| Precision polishing or grinding | High bandwidth (≥1 kHz), noise‑free resolution, integrated filters, robust mechanical design | ATI Axia80 or FUTEK High Bandwidth sensor |

| Surgical or medical robot | Compact, low range (1–20 N), minimal cross‑talk, sterile or IP67 rating, high resolution, low noise | ATI Nano17Ti or Sensodrive medical torque sensor |

| Exoskeleton or wearable | Lightweight, disc‑shaped design, free of hysteresis, robust under transverse loads, BiSS or SPI interface | Sensodrive torque sensor |

| Research haptics and teleoperation | High precision, low noise, integrated software (ROS 2 drivers), high sampling rate; easy flange mounting | Bota Systems MegaONE or PixONE |

10 Practical tips for sourcing force–torque sensors

- Define your load envelope – Determine the maximum and typical forces and torques in your application (including shock loads). Choose force–torque sensors with sufficient range and overload capacity to avoid damage.

- Check signal quality and resolution – For tasks like polishing or haptics, resolution and noise are critical. Look for sensors with high signal‑to‑noise ratios (silicon strain gauges) and noise‑free resolution like Bota Systems’ PixONE.

- Evaluate environmental requirements – If the robot works in a wet or dusty environment, select sensors with IP65/IP68 protection. For sterile or food applications, stainless steel housings and sealing are important.

- Consider integration and interface – Choose a sensor that matches your robot’s mechanical flange and provides a suitable electrical interface (EtherCAT, USB, CAN, SPI). Integrated sensors with internal wiring, as provided by Bota Systems, simplify installation and reduce cable fatigue.

- Demand calibration certificates and support – Ask suppliers for calibration matrices, error budgets and temperature coefficients. High‑quality sensors come with detailed documentation and support for calibration updates. Check whether the vendor provides drivers for your software stack (e.g., ROS 2). Sensodrive offers integration expertise and even free support for large orders.

- Assess supplier reliability – Evaluate the manufacturer’s track record, supply chain stability and after‑sales support. Sensodrive emphasises that its sensors are produced entirely in Germany with stable supply chains. When sourcing from emerging suppliers, vet their manufacturing processes and request sample units.

- Plan for future scalability – If your project might grow, choose a sensor family with multiple ranges or form factors. Some vendors offer customisation; Sensodrive’s sensors can be individually adapted and Bota Systems’ PixONE is designed for scalable production.

11 Summary: enabling intelligent interaction through force–torque sensing

Force–torque sensors are the muscles’ feedback in modern robots. They transform mechanical deformation into electrical signals, allowing robots to adjust their actions in real time. By measuring forces and torques along all six axes, these force–torque sensors enable collaborative robots to share workspaces safely with humans, allow industrial arms to perform delicate assembly and grinding, empower surgical robots and exoskeletons to provide precise assistan, and support haptic research and tele‑operation.

Advances in materials, transduction technologies and embedded electronics continue to improve resolution, bandwidth and overload capacity. As sensors become smarter and more integrated, robots will gain an even greater sense of touch, enabling applications from heavy industrial automation to wearable human augmentation. When sourcing these critical components, consider performance parameters, integration requirements and supplier quality. A carefully selected force–torque sensor not only protects your robot and operators but also unlocks new levels of precision and autonomy.

If you are exploring robotics components or building next‑generation cobots and exoskeletons, Yana Sourcing can assist with sourcing verified force–torque sensors, facilitating factory audits and ensuring quality control. Reach out to discuss your requirements and find the best sensor solution for your project.