Table of Contents

Introduction: From Motion to Perception

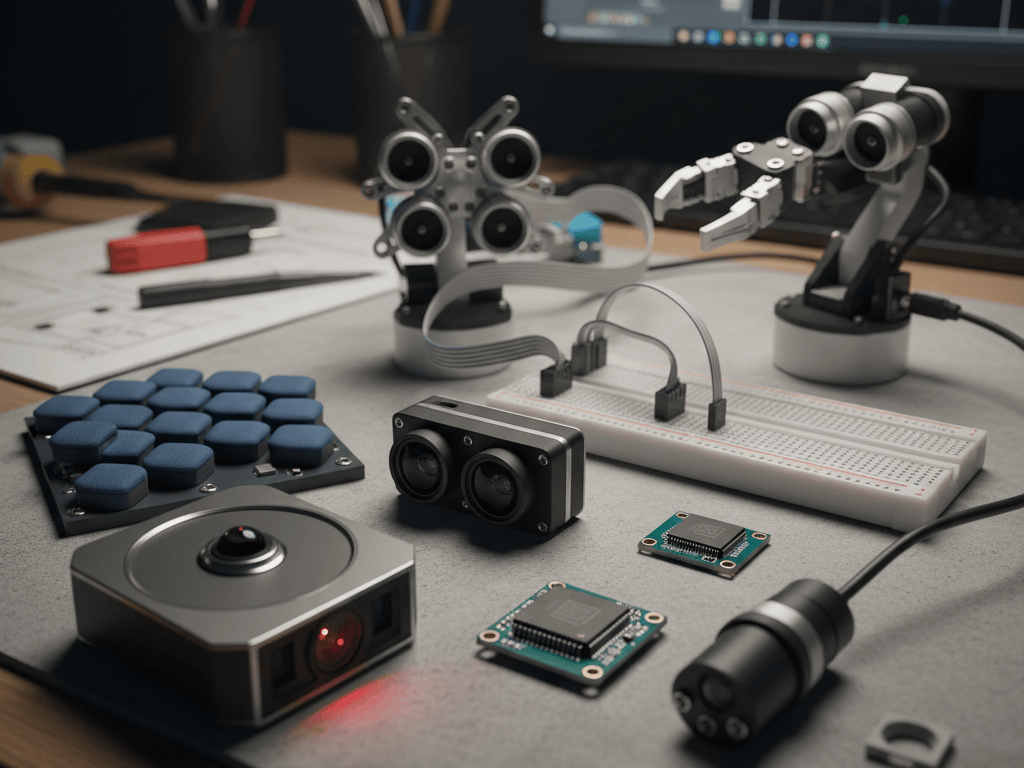

Robots rely on powerful actuation and control systems, but without robotics sensors they would be blind and deaf to the world around them. From joint position to external forces, these sensors convert physical phenomena into data that closes the loop between motion and perception. As the next logical step after actuators, motors, and reducers, robotics sensors provide the feedback that enables precision, safety, and adaptability. Understanding these sensors is essential for anyone designing or sourcing intelligent machines.

The evolution of robotics sensors parallels the journey from simple mechanization to embodied intelligence. Early machines moved in open loop, but modern robots depend on these sensors for real-time feedback. Whether you are optimizing industrial manipulators or designing collaborative robots for human environments, robotics sensors form the foundation of responsiveness and autonomy. In this article we explore the types, specifications, sourcing considerations, and future trends of sensors so that you can make informed decisions for your next project.

The Role of Sensors in Robotics Systems

Every mechatronic system uses robotics sensors to measure physical variables such as position, velocity, acceleration, force, and light. In closed-loop control, sensors provide data that the controller uses to correct deviations and maintain performance. For example, position encoders measure joint angles so that motor controllers can adjust torque to reach the desired setpoint. Without robotic sensors, a robot cannot detect errors, compensate for load changes, or interact safely with its environment.

Safety and collaboration depend heavily on robotic sensors. Force–torque sensors detect contact and protect both humans and machines, while vision and proximity sensors prevent collisions. In calibration and self‑monitoring, sensors track drift, aging, and mechanical wear, allowing predictive maintenance and sustained accuracy. Autonomy also arises from robotic sensors: inertial measurement units (IMUs) and vision sensors support navigation, mapping, and machine learning. The interplay between actuators and sensors defines the agility and intelligence of modern robots.

Feedback and Control

At the heart of every control loop are robotic sensors that provide timely and precise feedback. Encoders measure position and speed, while current sensors estimate torque. By comparing sensor data to setpoints, the controller adjusts motor signals to minimize error. High-performance robots rely on high-resolution sensors to achieve millimeter‑scale accuracy and smooth motion. In dynamic tasks like walking or balancing, inertial robotic sensors measure acceleration and angular rates to maintain stability.

Safety and Collaboration

Collaborative robots operate safely around humans by using robotic sensors that sense contact and proximity. Force–torque sensors detect unexpected loads and trigger compliance, while vision sensors identify obstacles and adjust paths. These sensors enable robots to work alongside people without cages, unlocking new applications in healthcare, logistics, and service industries. Safety regulations often require specific robotic sensors to meet standards such as ISO 10218, demonstrating their critical role.

Calibration and Self-Monitoring

Over time, mechanical components can wear or shift, affecting accuracy. Robotic sensors monitor these changes and allow automatic calibration. Encoders can measure backlash or slippage, while torque sensors detect gear wear. IMUs track bias drift that arises from temperature changes. With continuous feedback from sensors, robots can schedule maintenance and adjust parameters before significant errors occur. This self‑monitoring extends the lifetime of machines and reduces downtime.

Autonomy and Perception

Beyond control and safety, robotic sensors enable robots to understand and navigate their environment. Vision sensors provide images and depth maps for object recognition and path planning. IMUs measure motion for localization and mapping. Tactile and proximity sensors feel surfaces and detect edges. Fusing data from multiple sensors allows robots to build a model of the world and interact intelligently. Without robust perception from robotic sensors, autonomy would remain out of reach.

For a deeper technical exploration of robotic sensors in indoor autonomous mobile robots, covering localization, mapping and sensor fusion, see Liu et al. (2024).

Classification of Robotic Sensors

There are many types of robotic sensors, but they can be broadly categorized based on what they measure and how they are used. Internal sensors measure the robot’s own state, while external sensors perceive the environment. Smart sensors combine measurement with processing to deliver usable information. Selecting the right robotic sensors depends on understanding these categories and matching them to your application.

| Category | Measures | Example | Main Use |

|---|---|---|---|

| Internal Sensors | Position, velocity, torque, acceleration | Encoders, IMUs, torque sensors | Control, stability |

| External Sensors | Force, contact, distance, light, sound | Force–torque, vision, lidar | Perception, safety |

| Smart/Integrated Sensors | Measurement + processing | Embedded sensors in actuators | Predictive control |

Each row summarizes key robotic sensors categories without lengthy sentences. Internal sensors like encoders and IMUs provide essential feedback for motion control. External robotic sensors such as cameras and lidar map the robot’s surroundings. Smart sensors embed computation to pre‑process data and deliver high‑level information, reducing load on the controller.

Understanding these categories helps you decide which robotic sensors to integrate. For instance, a mobile robot might use internal sensors to track wheel speed, external robotic sensors to avoid obstacles, and smart sensors to perform local SLAM (Simultaneous Localization and Mapping). The following sections examine specific types of robotic sensors in more detail.

Key Technical Parameters for Sensor Selection

Selecting the right robotic sensors requires balancing multiple parameters such as resolution, accuracy, latency, range, and robustness. Each parameter influences performance and cost, and the priorities depend on the application. For instance, a pick‑and‑place robot needs high-resolution encoders, while a warehouse robot may prioritize low-latency vision sensors. Let’s explore the key criteria you should consider when sourcing robotic sensors.

Resolution and Precision

Resolution refers to the smallest change a sensor can detect, while precision describes how repeatable the measurement is. For position encoders, resolution is typically given in pulses per revolution or bits. High-resolution robotic sensors enable fine control, but may be more expensive and produce larger data volumes. Precision ensures that measurements are consistent across trials; high precision is critical when sensors feed back into control loops.

Accuracy and Drift

Accuracy describes how close a measurement is to the true value, and drift refers to gradual changes in sensor output over time. Robotic sensors must be accurate enough to meet application requirements; inaccurate sensors lead to systematic errors. Drift can result from temperature variations, mechanical wear, or aging of materials. Good robotic sensors minimize drift through design and compensation. Selecting robotic sensors with specified accuracy and drift helps maintain performance.

Latency and Bandwidth

Latency is the delay between the physical event and the output of the sensor, while bandwidth describes the range of frequencies the sensor can respond to. Robotic sensors with low latency are necessary for fast control loops, especially in dynamic systems. For instance, an IMU must output inertial data quickly to maintain balance. Bandwidth is important for capturing rapid motions or vibrations. When sourcing robotic sensors, check that the latency and bandwidth match your control system’s requirements.

Range and Sensitivity

Range is the maximum and minimum values a sensor can measure, and sensitivity is the ratio of output change to input change. Force–torque sensors, for example, have specified load ranges; exceeding them may damage the sensor. Sensitivity indicates how responsive a sensor is to small changes. Choosing robotic sensors with appropriate range and sensitivity prevents saturation or noise issues. Many suppliers of sensors offer multiple ranges to fit different loads and tasks.

Robustness and Environmental Tolerance

Robots often operate in harsh environments, so robotic sensors must withstand vibration, dust, moisture, and extreme temperatures. IP ratings indicate protection against solids and liquids, and certifications like CE or RoHS ensure compliance. Robust sensors may use sealed housings, shock‑resistant mounts, or temperature‑compensated electronics. When selecting sensors, consider the expected environment and choose sensors built to survive it.

Interface and Compatibility

Robotic sensors communicate via interfaces such as analog voltage, PWM, I²C, SPI, CAN, RS‑485, or fieldbus protocols like EtherCAT and CANopen. Make sure the chosen robotic sensors have outputs compatible with your controller’s inputs. Some robotic sensors offer multiple interfaces or configurable outputs. Consider also whether the sensor requires external signal conditioning or has integrated processing. Standardized interfaces simplify integration and maintenance.

Manufacturing and Sourcing Considerations

The performance of robotic sensors depends not only on design but also on manufacturing quality and supplier reliability. Sourcing sensors from reputable manufacturers ensures that specifications are met and that sensors are calibrated and tested. When vetting suppliers, consider factors such as quality control processes, material selection, and certification.

Quality and Calibration

High-quality robotic sensors undergo rigorous calibration and testing to ensure that they meet the specified accuracy and precision. Calibration may involve traceable standards and multiple temperature cycles. When sourcing sensors, request calibration certificates and test reports. Poor calibration can lead to inconsistent measurements and control instability, so choose suppliers who demonstrate thorough quality assurance.

Material and Assembly

The materials used in robotic sensors affect their durability and performance. For instance, strain gauges in force–torque sensors require high-strength steel or titanium; optical encoders use precision glass scales and high‑quality photodiodes. Assembly processes must maintain alignment and ensure protection against contamination. When evaluating robotic sensors, ask about material specifications and assembly tolerances.

Testing and Certification

Many industries require robotic sensors to meet specific standards, such as ISO 9001 for quality management or ISO 13849 for safety. Look for certifications like CE, UL, and RoHS, which indicate compliance with safety and environmental regulations. For force–torque sensors, IP ratings confirm protection against dust and fluids. Testing for shock, vibration, and temperature extremes verifies that these sensors can withstand real‑world conditions.

Supplier Vetting

Choosing a supplier for robotic sensors requires assessing their manufacturing capabilities, reliability, and support. Suppliers should be able to provide consistent quality across batches, and they should be responsive to technical inquiries. Long-term partnerships with trusted suppliers of sensors help ensure supply continuity and allow for customization. Evaluate supplier track records, customer reviews, and sample performance.

MOQ and Cost Trade-Offs

Minimum order quantities (MOQs) and pricing can influence the selection of robotic sensors. Some high-performance sensors have higher MOQs due to specialized production processes. Balancing cost against precision and reliability is key. For startups or small runs, find suppliers who offer low-MOQ sensors or consider integrating off-the-shelf modules. While cost reduction is important, compromising on sensor quality can lead to greater expenses down the line.

Major Sensor Categories

The following sections introduce the primary categories of robotic sensors in more detail: force–torque sensors, encoders, and IMU & vision sensors. Each plays a distinct role in giving robots the sense of touch, position, and perception.

Force–Torque Sensors: Enabling Safe and Sensitive Interaction

Force–torque (F/T) sensors measure the forces and moments applied to a robot’s end-effector. In robotic sensors taxonomy, these are external sensors that detect contact interactions. Common technologies include strain gauge, capacitive, piezoelectric, and optical measurement. The sensor typically has six degrees of measurement: three forces (Fx, Fy, Fz) and three torques (Tx, Ty, Tz). F/T sensors enable compliant behaviors in collaborative robots, polishing tasks, assembly, and medical robots.

Key specifications for F/T robotic sensors include resolution (how small a force they can detect), overload capacity (the maximum load before damage), stiffness (resistance to deformation), and drift (stability over time). Integration requires proper mounting, signal conditioning, and calibration. Many F/T sensors support interfaces like Ethernet, CAN, or EtherCAT. Suppliers include ATI Industrial Automation, OnRobot, Robotiq, FUTEK, and several Chinese manufacturers. Recently, integrated F/T sensors within actuators and soft sensors have emerged, providing compact and lightweight solutions.

Encoders: Precision Feedback for Motion and Control

Encoders are robotic sensors that measure rotational or linear position. They are essential internal sensors for every joint and wheel in a robot. Encoders can be classified into rotary and linear types, and into absolute and incremental encoding. Technologies include optical discs, magnetic sensors, capacitive pick‑ups, and inductive systems. By converting movement into digital pulses or codes, encoders provide the precise feedback necessary for position and speed control.

The main performance metrics for encoder robotic sensors are resolution (pulses per revolution or bits), accuracy, repeatability, and maximum speed. Incremental encoders output pulses relative to motion, requiring a reference to determine absolute position; absolute encoders output a unique code for each position, useful for homing-free operation. Integration factors include mounting (shaft vs. hollow shaft), coupling to the shaft, and communication protocol (TTL, RS‑422, SSI, BiSS, CANopen, EtherCAT). Renishaw, Heidenhain, Baumer, CUI Devices, and domestic suppliers offer a range of encoder robotic sensors, while integrated encoders in brushless motors (BLDC) reduce wiring and improve compactness. Recent trends include single-chip magnetic encoders and AI-enhanced calibration methods.

IMU and Vision Sensors — The Foundations of Spatial Awareness

Inertial measurement units (IMUs) and vision sensors are external robotic sensors that give robots the ability to sense their movement and environment. An IMU typically combines accelerometers, gyroscopes, and sometimes magnetometers to measure linear acceleration and angular rate along three axes. IMUs provide essential data for balancing, pose estimation, and dead-reckoning. Key specifications include bias stability (drift over time), noise density, dynamic range, and sampling rate. MEMS-based IMU robotic sensors are widely available from Bosch Sensortec, STMicroelectronics, Invensense, and others. Proper calibration and filtering are crucial to mitigate drift and noise.

Vision sensors encompass 2D cameras, depth cameras (stereo, time-of-flight, or structured light), and emerging event cameras. These robotic sensors capture images or depth information for object recognition, obstacle avoidance, and navigation. Important parameters include resolution, frame rate, field of view, dynamic range, and interface (USB, MIPI, Ethernet, GigE). Sourcing vision robotic sensors involves consideration of lens quality, imaging sensor sensitivity, and onboard processing (such as ISP for color correction). Notable suppliers are Intel RealSense, Basler, Luxonis (OAK), and numerous OEM modules. The fusion of IMU and vision data, known as visual-inertial odometry (VIO), provides robust localization and mapping for autonomous robots.

Sensor Fusion and Integration

Modern robots combine multiple robotic sensors to improve robustness and accuracy. Sensor fusion involves aligning data in time and space, calibrating sensor offsets, and merging outputs to estimate state. Combining encoder data with IMU measurements yields better velocity estimates; combining IMU with vision sensors enables SLAM (Simultaneous Localization and Mapping). Integrating force–torque sensors with position feedback allows compliant control. Effective sensor fusion requires precise time synchronization, stable interfaces, and algorithms to handle noise and outliers. Implementations often run on microcontrollers, FPGAs, or embedded computers, with frameworks like ROS 2 offering drivers and synchronization tools.

Integration and Control Architecture

To benefit from robotic sensors, a system architecture must handle data acquisition, processing, and control. Integration begins with mechanical mounting of the sensors in suitable locations, followed by electrical connection and communication with the control electronics. In multi-axis robots, each joint may have an encoder, and end-effectors include F/T sensors. IMUs are positioned near the center of mass or on moving limbs.

Data from robotic sensors flows into a control unit, often through fieldbus networks like EtherCAT, CANopen, or industrial Ethernet. High-speed buses ensure that feedback arrives within the control cycle, typically 1–2 kHz for motion control. The control software reads sensor values, computes errors relative to desired trajectories, and sends commands to actuators. Integration must also manage sampling rates, filtering, and synchronization. For vision sensors, image data may go through dedicated processing pipelines or AI accelerators.

Software frameworks such as ROS (Robot Operating System) provide abstractions and drivers for many robotic sensors. ROS 2, the modern real-time version, supports time synchronization (TSN), QoS settings, and composition of sensor nodes. In distributed systems, it is crucial that all robotic sensors share a common clock or timestamping mechanism to avoid drift. Firmware updates and diagnostics for robotic sensors can be handled over the network, simplifying maintenance.

Emerging Trends in Robotics Sensing

The field of robotic sensors continues to evolve rapidly. Advances in materials, microelectronics, and artificial intelligence drive new capabilities and applications. Here are some of the trends shaping the next generation of robotic sensors:

Embedded Sensors and Smart Actuation

Manufacturers are embedding robotic sensors directly into actuators and reducers, creating compact modules with integrated feedback. For example, harmonic drives with built-in torque sensors or BLDC motors with integrated encoders. This integration reduces wiring, improves reliability, and facilitates plug-and-play design. Smart actuators with embedded robotic sensors can report health status and support predictive maintenance.

Soft Sensors and Tactile Perception

Soft robotics is influencing the design of robotic sensors. Flexible and stretchable sensors made from conductive elastomers can conform to curved surfaces and detect distributed pressure. These soft robotic sensors enable robotic hands to feel texture and shape, providing new levels of dexterity. They also open possibilities for wearable sensors and human–robot interfaces.

AI-Based Sensing and Edge Processing

Machine learning is being applied to robotic sensors for enhanced perception and anomaly detection. AI can filter sensor noise, detect patterns in IMU data, or classify scenes from vision sensors. With edge computing hardware, robotic sensors can preprocess data locally, reducing communication loads and enabling fast response. For instance, AI-enhanced cameras can detect objects and send only metadata to the controller.

Neuromorphic and Event-Based Sensors

Event cameras and neuromorphic sensors represent a novel class of robotic sensors inspired by biological systems. Instead of capturing frames at fixed intervals, event cameras output asynchronous pixel events when brightness changes. These robotic sensors offer ultra-fast response and high dynamic range, ideal for high-speed robotics. Neuromorphic sensors mimic neural processing, capturing temporal patterns. Though emerging, such robotic sensors promise breakthroughs in motion prediction and energy efficiency.

Sustainability and Miniaturization

As sustainability becomes a priority, robotic sensors are being developed with low power consumption, recyclable materials, and eco-friendly manufacturing. MEMS technology allows miniaturization, enabling robotic sensors to be integrated into small drones, wearables, and micro-robots. Reducing size and weight improves energy efficiency and opens new application domains.

Conclusion

Robotic sensors are the nervous system of intelligent machines. They transform mechanical structures into responsive and adaptable robots by providing continuous feedback on position, force, motion, and environment. From force–torque sensors that enable safe interaction to encoders that deliver precise position data, and from IMUs that monitor motion to vision systems that perceive the world, robotic sensors underpin every aspect of autonomy and control.

As you design or source robots, pay careful attention to the choice and integration of robotic sensors. Consider parameters like resolution, accuracy, latency, and robustness, and work with suppliers who offer reliable calibration and support. Explore emerging trends such as embedded sensing, soft tactile sensors, and AI-enhanced perception to stay ahead of the curve. By understanding and leveraging robotic sensors, you can build robots that are not only powerful but also intelligent, safe, and future-ready.

Ready to Source Robotic Sensors with Confidence?

Yana Sourcing helps brands and innovators find reliable manufacturers for high-precision robotic sensors, from force–torque transducers to encoders and IMUs. Whether you need verified suppliers, low-MOQ production, or quality-controlled delivery, our sourcing experts in China can help you bring your designs to life.

👉 Contact Us Now to start your robotics sensor sourcing journey, from concept to shipment.