Table of Contents

The Role of Motors Across L1–L4 Robotics

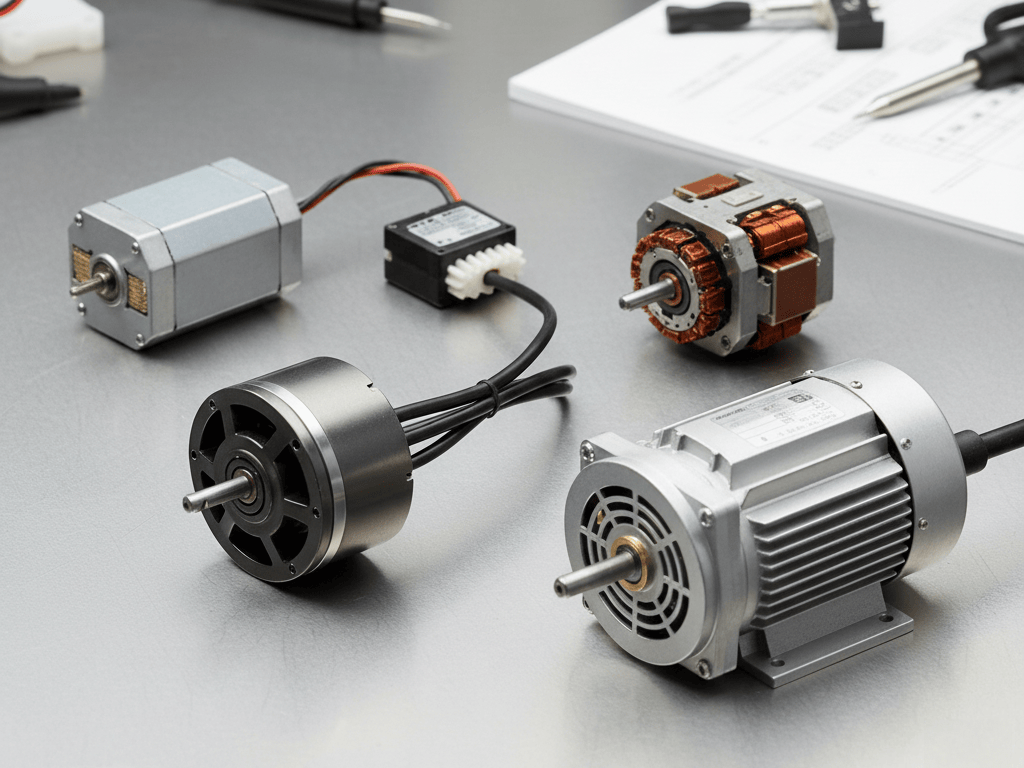

Motors convert electrical energy into mechanical motion. Without them robots would lack the torque, speed and positioning required to interact with the physical world. In robotics, motors drive rotary joints, linear stages and wheeled or tracked vehicles. At the most basic level (L1), motors supply the force for simple pick‑and‑place arms and conveyor drives. As systems progress to L2–L3, multiple axes of motion are coordinated for collaborative arms or mobile platforms, while at L4 motors must support humanoid gait, dexterous manipulation and soft interaction. Motors differ from actuators by focusing on energy conversion; actuators integrate sensors, transmissions and structure to produce complete motion modules. Because motors operate as the power core of intelligent robots, understanding their types and performance metrics is essential for engineers and buyers alike.

Core Motor Families and Their Applications

Modern robotics employs a range of motor types. Choosing the right one depends on desired torque, speed, precision and cost. Below are the principal motor families and how they serve robotic systems.

Servo Motors — The Precision Intelligence

Servo motors are the brains of motion. They integrate a permanent‑magnet motor (either DC or AC), a feedback device and a control drive into a closed‑loop system that commands position, speed and torque. The feedback (encoder or resolver) continuously measures rotor position and velocity, while the drive adjusts voltage and current to correct any deviation from the desired trajectory. Servos deliver high accuracy, quick acceleration and high torque density, making them indispensable for robotic joints, gimbals and precision stages. They come in several flavours:

- DC servo motors: Historically common in hobbyist and low‑cost systems, these units pair a brushed DC motor with an encoder and use pulse‑width modulation for control. They offer high starting torque but require maintenance due to brush wear and electrical noise.

- AC servo motors (permanent‑magnet synchronous motors): These brushless servos use rare‑earth magnets and provide high power density, wide speed range and long life. They form the backbone of industrial robots, CNC machines and automated assembly lines. AC servos deliver peak torque across the speed range, making them excellent for high throughput tasks.

- Brushless servo motors: A subset of BLDC motors equipped with encoders and sophisticated drives, these units provide precise positioning and high speeds while eliminating brushes. Frameless brushless servos allow designers to embed rotor‑stator sets directly into robot joints to minimize weight and inertia.

- Hybrid servo motors: Also known as closed‑loop stepper systems, they blend the high torque of stepper motors at low speeds with servo feedback for closed‑loop operation. Hybrid servos maintain position without hunting thanks to detent torque, handle large load inertia mismatch and offer cost‑effective precision for belts and lead screws.

Servo motors are linked to the servo motors page, where each subclass is explored in depth. When selecting a servo, Yana considers feedback type, torque constant, inertia ratio, and drive compatibility to ensure optimal performance and long‑term reliability.

BLDC Motors — The Brushless Efficiency Backbone

Brushless DC (BLDC) motors eliminate mechanical commutators by replacing brushes with solid‑state electronic commutation. Their stators contain multiple phase windings, while the rotors feature permanent magnets. A controller switches currents sequentially to create a rotating magnetic field that the rotor follows. This design provides high efficiency, long life, low noise and a high torque‑to‑weight ratio. BLDC motors dominate battery‑powered robots (drones, AGVs), fans, pumps and compressors. They are more efficient than brushed DC motors, maintenance‑free and capable of high rotational speeds. Sensorless variants rely on back‑EMF detection and offer cost savings; sensor‑based drives use Hall sensors or encoders for precise control. A full discussion of BLDC motors—including control methods (trapezoidal vs sinusoidal), outrunner vs inrunner designs, and integration into robotic joints, can be found on the BLDC Motors page.

Stepper Motors — Precision in Discrete Steps

Stepper motors divide a full rotation into hundreds or thousands of equal increments. By sequentially energizing stator coils, the rotor moves in fixed step angles, enabling open‑loop positioning without feedback. Steppers hold their position when stationary due to detent torque, making them ideal for applications like 3D printers, CNC routers, camera sliders and small robots where cost and simplicity are priorities. They deliver high torque at low speeds but lose torque rapidly at higher RPMs and cannot achieve continuous peak torque like servos. Microstepping techniques improve resolution but reduce available torque. For in‑depth exploration of stepper types (variable reluctance, permanent‑magnet and hybrid steppers), microstepping, and control strategies, see the Stepper Motors page.

Torque & Frameless Motors — Direct‑Drive Power for Next‑Gen Robots

Torque motors are brushless, permanent‑magnet machines designed to deliver very high torque at low speeds without the need for gearboxes. They are frameless (no housing or bearings) and integrate directly into the mechanical structure of the robot. With many magnetic poles and large diameters, torque motors achieve high torque per volume and weight. They power direct‑drive joints in collaborative robots, haptic devices, gimbals, steering systems and simulators. Their large hollow shafts allow cables, cooling lines and other components to pass through the motor. Since torque motors are frameless, manufacturers supply stator and rotor kits that the robot builder integrates with bearings, encoders and housing. See the torque motors page for details on direct‑drive benefits, sizing, cooling strategies and innovations.

Frameless motors refer to rotor‑stator kits (usually BLDC or servo architectures) sold without housings or bearings. They allow designers to embed the motor into a joint or stage, optimizing mechanical integration and reducing weight. Frameless motors provide high torque density, design flexibility and often a large clear aperture for cable routing or optics. The frameless motors page covers integration techniques, thermal considerations and sourcing tips.

Linear & Voice Coil Motors — Frictionless Linear Motion

While most motors produce rotation, some act directly in a straight line. Linear motors are essentially unrolled rotary motors: the stator and forcer slide past each other to create a linear force. They deliver high acceleration, fast settling, and sub‑micron positioning because there are no mechanical conversions (like lead screws) introducing backlash or friction. Linear motors come in iron‑core, ironless and slotless variants, each with different force densities and cogging characteristics. They power SCARA robots, pick‑and‑place systems, gantries and semiconductor inspection equipment. For a deep dive into linear motor topologies, control strategies and integration, see the linear motors page.

Voice coil motors (VCMs) are short‑stroke linear actuators based on the Lorentz force. By passing current through a coil in a magnetic field, VCMs generate bidirectional force proportional to current. They offer extremely smooth, fast and precise motion, perfect for focusing systems, haptic devices and medical instruments. Although their stroke is limited (often 10–50 mm), VCMs excel at micro‑positioning and rapid accelerations. Learn more on the voice coil motors page, including details on moving‑coil vs moving‑magnet designs, force curves and integration challenges.

Planetary Gear & Hybrid Motors — Compact, Adaptive Solutions

Motors often require gear reduction to amplify torque and match load inertia. Planetary gear motors integrate a motor (commonly BLDC or DC) with a planetary gearbox—a compact, coaxial transmission that uses a sun gear, multiple planet gears and a ring gear to achieve high torque multiplication in a small package. Planetary gear systems distribute load across multiple gear contacts, increasing durability and load capacity. They are ideal for space‑constrained robotic joints, AGV drive wheels, small arms and industrial automation modules. Yana’s planetary gear motors page explores gear ratios, efficiency, backlash, noise and lubrication considerations.

Hybrid motors combine design principles from two or more motor families to deliver unique performance. For example, closed‑loop hybrid stepper motors merge detent torque with servo feedback, while hybrid torque‑linear actuators pair rotary and linear motion in one package. Hybrid motors often incorporate AI‑based tuning, smart sensors and modular structures to adapt dynamically to varied tasks. Explore hybrid innovation and sourcing strategies on the hybrid motors page.

Performance Metrics: Torque, Speed, Efficiency and Control

Selecting the right motor requires evaluating key performance metrics.

- Torque and Speed – Motors convert electrical power into rotational force (torque) and angular velocity (speed). DC motors offer high starting torque and wide speed range; servo motors provide high peak torque and high speeds due to rare‑earth magnets; stepper motors deliver high holding torque at zero speed but lose torque as speed increases; BLDC motors can produce high torque at low speeds with low friction; torque motors maximize torque at low speeds for direct drive.

- Accuracy and Resolution – Servo motors achieve ±0.02 ° accuracy, while stepper motors achieve ±0.005 °. Hybrid servos can deliver high accuracy without hunting due to detent torque. Encoders and feedback sensors increase precision, essential for pick‑and‑place and machine tools.

- Control and Feedback – Servo and brushless motors operate in closed loop with encoders, delivering precise speed and torque control. Stepper motors usually run open loop but can include encoders for improved accuracy. DC and AC motors typically use simple voltage/frequency control; servo drives add current regulation, field‑oriented control and tuning.

- Efficiency and Thermal Management – BLDC motors are more efficient than brushed DC motors because electronic commutation eliminates brush losses. DC motors generate more heat at high load, requiring heat sinks. Servo motors maintain high efficiency due to rare‑earth magnets and optimized stators. Torque motors dissipate heat through large diameter housings or liquid cooling.

- Cost and Complexity – Brushed DC and stepper motors are inexpensive and simple to control. Servo and brushless motors cost more but offer higher performance. Torque motors and linear motors require specialized drives and mechanical integration, increasing cost but eliminating gearboxes or screws.

Comparative Table

| Parameter | Brushed DC | Stepper Motor | Servo Motor | BLDC Motor | Torque Motor | Linear Motor |

|---|---|---|---|---|---|---|

| Control | Open loop (voltage) | Open loop pulses | Closed loop with encoder | Closed loop or speed control | Closed loop | Closed loop |

| Starting Torque | High | High at low speed | High peak and continuous | High low‑speed torque | Very high at low speed | Force output rather than torque |

| Speed Range | Wide | Low‑medium | High | High | Low‑medium | High |

| Accuracy | Moderate | ±0.005 ° | ±0.02 ° | Depends on feedback | High with encoder | Sub‑micron with encoder |

| Maintenance | Brush wear | Low | Low | Low | Low | Low |

| Typical Applications | Low‑cost robotics, toys | 3D printers, CNC stages | Robot joints, machine tools | Drones, drives | Precision joints, simulators | Pick‑and‑place, transport |

Motor Integration in Robotic Systems

Motors are integrated differently depending on robotic level and application.

L1: Core Motion

At the simplest level, motors provide basic motion for pick‑and‑place arms, conveyors and small robots. Stepper motors offer precise incremental moves without feedback; DC motors power wheeled bases. Servo motors pair with gearboxes and linear actuators to convert rotational motion into linear travel for pick‑and‑place stations.

L2: Modular Arms and Grippers

For collaborative arms or service robots, servo and brushless motors deliver the speed, torque and precision to move payloads smoothly. Each joint may contain a servo motor with an encoder, gearbox and sometimes a brake. Brushless servos allow compact designs and high‑speed motion. Hybrid servos provide high torque at low speeds and handle dynamic loads without retuning. Grippers often employ small servo or stepper motors for finger actuation.

L3: Industrial Manipulators and Mobile Platforms

Industrial robots require motors capable of high continuous torque, precise positioning and long life. Servo motors with rare‑earth magnets and high‑resolution encoders meet these demands. Direct‑drive torque motors eliminate gearboxes in precision joints, reducing backlash and maintenance. AGVs and AMRs (autonomous mobile robots) use BLDC or DC motors for traction; brushless motors improve efficiency and battery life.

L4: Humanoids and High‑Degree‑of‑Freedom Robots

Humanoid robots, exoskeletons and dexterous manipulators require motors that combine high torque density, compliance and low inertia. Frameless torque motors integrated directly into joints provide high torque with minimal weight. Servo motors with harmonic drives deliver compact high‑ratio gearing. Linear motors enable high‑speed vertical lifts or telescoping limbs. Hybrid and AI‑tuned motors adapt stiffness and damping in real time for safe interaction. Designs consider cable routing, cooling, compliance and mounting for human‑scale proportions.

Design Considerations: Size, Cooling, Noise and Weight

- Size and Weight – Frameless motors remove housings and bearings, reducing weight and allowing integration into structural elements.

- Cooling – Motors dissipate heat through fins, housings or liquid channels. Torque motors often require water‑cooled jackets for continuous high torque. BLDC and servo motors rely on efficient stator design and forced air cooling.

- Noise and Vibration – Brushless and servo motors operate quietly; steppers can produce resonance at certain speeds; torque motors minimize vibrations by eliminating gear backlash.

- Cable Management – Motors integrated into joints must route power, feedback and cooling lines through hollow shafts.

Integration Challenges and Proven Solutions

| Challenge | Root Cause | Solution |

|---|---|---|

| Thermal buildup | Continuous high current | Use liquid or forced‑air cooling; derate duty cycle |

| Backlash & mechanical wear | Gearboxes & couplings | Employ direct‑drive torque motors or harmonic drives |

| Accuracy drift | Sensor misalignment | Calibrate encoders; use absolute encoders |

| Torque ripple & resonance | Coil switching & structural modes | Use skewed rotor poles, micro‑stepping, or FOC (field‑oriented control) |

| Cable routing in joints | Limited space | Design hollow shafts and slip rings |

Manufacturing & Sourcing Insights

Global Production Regions

Robotics motors are produced worldwide.

- China dominates high‑volume production of DC motors, stepper motors and cost‑effective servos and brushless units. Many suppliers offer integrated joint modules and cobot actuators.

- Japan is renowned for precision micro‑motors and high‑reliability servos used in electronics assembly and medical robots.

- Europe (Germany, Switzerland) produces premium servo and torque motors, linear stages and frameless sets for aerospace and industrial automation.

- USA specializes in custom high‑performance torque motors, high‑power BLDC drives and advanced servo systems for aerospace, defense and research.

Cost and Lead Times

Standard brushed DC, stepper and small BLDC motors have low minimum order quantities (100–500 units) and short lead times (6–8 weeks). Servo and brushless motors with custom windings or integrated gearboxes require higher minimums (often 500–1,000 units) and lead times of 8–12 weeks. Torque motors and linear motors involve custom sizing and integration; expect lead times of 10–16 weeks.

Quality Control Checklist

- Torque Constant & Back EMF – Verify rated torque and voltage constant under load.

- Encoder Calibration – Check accuracy and repeatability; absolute encoders should retain position after power loss.

- Rotor & Stator Balance – Ensure minimal vibration; inspect magnet placement and lamination roundness.

- Insulation & Wiring – Test for proper insulation resistance and robust cable assemblies.

- Thermal Cycle Testing – Run motors through full load cycles to detect early failures.

- Noise & Vibration – Measure acoustic and mechanical noise to ensure smooth operation.

Risk Factors

- Magnet Supply Chain – Rare‑earth magnets (NdFeB, SmCo) are subject to geopolitical risk; diversification and recycling are key.

- Counterfeit Components – Low‑cost suppliers may use inferior magnets or windings; audits and materials verification mitigate this risk.

- Thermal & Mechanical Stress – Overloading motors can demagnetize rotors or degrade insulation.

- Control Electronics – Low‑quality drivers can cause current ripple and instability.

- Compliance & Certifications – Medical and aerospace applications require ISO, UL and CE certification; ensure suppliers meet standards.

Emerging Trends & Future Innovations

The robotics motor landscape is evolving rapidly. Key trends include:

- High‑Torque‑Density Materials – Use of amorphous metal laminations, silicon steel grades and optimized windings to increase torque per weight. Torque motors achieve unprecedented torque density for humanoid joints and exoskeletons.

- Integrated Sensors & Electronics – Smart motors incorporate temperature, current and vibration sensors with embedded electronics for predictive maintenance and self‑tuning. Absolute encoders retain position through power cycles.

- AI‑Based Control & Tuning – Machine learning algorithms optimize PID gains and adapt to changing loads in real time. Hybrid motors adjust stiffness and damping to comply with human interaction.

- Rare‑Earth Alternative Magnets – Ferrite and alnico composites reduce dependence on rare‑earth supply.

- Modular & Frameless Designs – Frameless motors allow tight integration into mechanical structures, reducing weight and volume. Direct‑drive torque modules with integrated drives simplify joint design.

- Regenerative Drives – Electric drives recover braking energy and feed it back to batteries, enhancing efficiency in mobile robots.

- Ultra‑Fast Linear & Voice‑Coil Motors – Linear motors and voice‑coil actuators deliver micro‑second response for haptic feedback, medical imaging and semiconductor inspection.

Selecting the Right Motor for Your Robot

Choosing a motor involves balancing technical requirements, cost and risk.

- Define Load Requirements – Determine torque, speed, force and duty cycle. High‑start torque or heavy payloads may favor servo or torque motors; light loads and precise stepping may use steppers.

- Establish Positioning Needs – Accuracy and repeatability requirements dictate the need for encoders or open loop operation. Stepper motors offer 0.005 ° resolution; servo motors provide 0.02 ° but can move faster.

- Assess Speed & Response – Servo and BLDC motors handle high speeds; torque motors and steppers suit low‑speed or stationary holding tasks.

- Consider Environment – Temperature extremes, vacuum, moisture and EMI influence motor selection. Industrial environments may require IP‑rated housings.

- Evaluate Integration & Form Factor – Determine whether a frameless motor (embedded in structure) or housed unit is appropriate. Hollow‑shaft torque motors enable cable routing.

- Plan for Control Strategy – Decide between open loop (simple but less robust) and closed loop (requires encoders and drives).

- Budget & Lifecycle Costs – Balance initial cost with efficiency, maintenance and lifespan. Stepper and DC motors cost less; servo and torque motors cost more but offer higher performance and longevity.

Example Scenarios

- 3D Printers & CNC Machines – Stepper motors excel in low‑speed, high‑precision positioning of print heads and tool stages. Hybrid steppers add closed‑loop control to handle load variations.

- Collaborative Robot Arms – Servo motors with harmonic drives provide the smooth motion and high torque density needed for six‑axis arms. Torque motors reduce backlash in direct‑drive wrists and shoulders.

- Autonomous Mobile Robots (AMRs) – BLDC motors power wheels and actuators due to high efficiency and long life. Regenerative drives recapture braking energy.

- Humanoids & Exoskeletons – Frameless torque motors embedded in joints deliver high torque with minimal weight, enabling human‑like motion. Linear actuators provide vertical lifts or telescopic limbs.

- Medical Robots & Precision Instruments – Brushless servo motors and voice‑coil actuators offer ultra‑smooth, silent motion with nanometer accuracy. Motors with absolute encoders ensure safe operation and recovery after power loss.

Sourcing Verified Robotics Motors with Yana

Yana Sourcing bridges the gap between innovative robotics designers and reliable motor manufacturers. Our SMART + HEART framework combines rigorous technical validation with human‑centric relationships. We audit factories for quality systems, verify magnet materials and winding processes, and perform torque, noise and endurance testing on sample motors. We also emphasize ethical sourcing and long‑term partnerships, ensuring that our clients receive not only a product but a trustworthy supply chain.

Whether you need high‑volume DC motors, precision servo and torque motors, custom frameless kits or cutting‑edge linear and hybrid motors, Yana Sourcing delivers zero‑risk procurement and lifecycle support.

Partner with Yana Sourcing to secure verified robotics motor suppliers and power the intelligent motion behind your next‑generation robots.