Table of Contents

Introduction

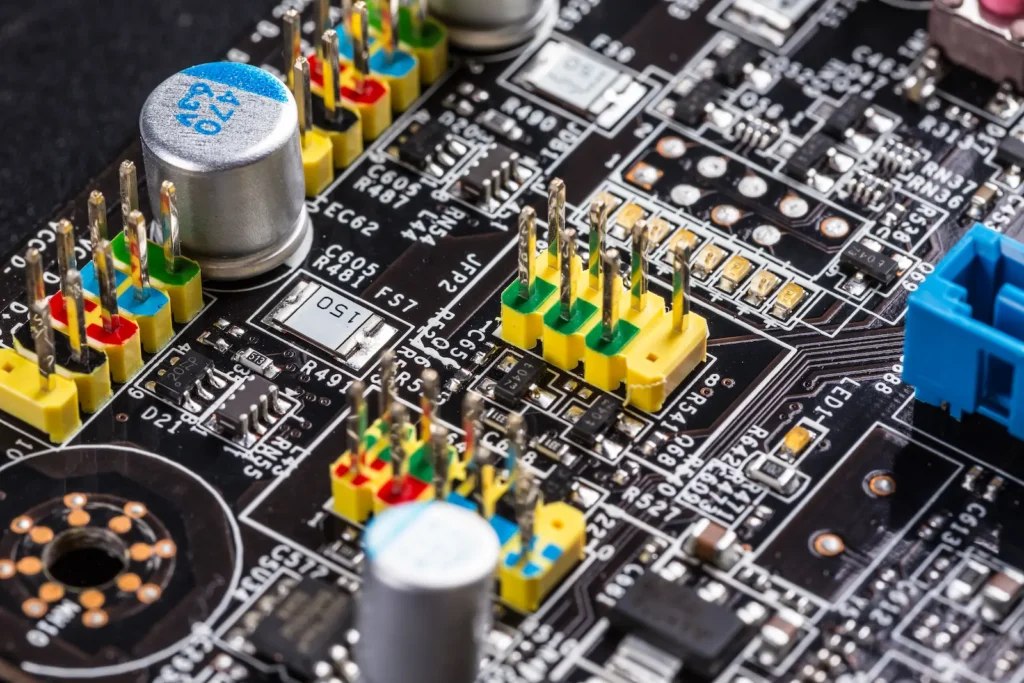

China is synonymous with electronics. From the smartphone in your pocket to the Bluetooth headphones on your desk, there is a good chance the products were made in Shenzhen or Dongguan. What started as low‑cost manufacturing has evolved into a high‑tech ecosystem offering everything from printed circuit board assembly (PCBA) and system integration to design support and after‑sales services. For startups, consumer electronics brands and IoT companies seeking a manufacturing partner, China Electronic Manufacturing Services are indispensable. But choosing the right partner is complex: you need to balance cost, quality, intellectual property (IP) protection, sustainability and scalability.

At Yana Sourcing, “You Are Not Alone” is more than a slogan; it reflects our belief that entrepreneurs deserve a partner who listens, understands and innovates with them. In this guide, we demystify the China Electronic Manufacturing Services (EMS) landscape and show you how to navigate China’s electronics manufacturing hubs. We explore why China dominates global Electronic Manufacturing Services, the different types of suppliers, how to vet partners, and what trends will shape manufacturing from 2025 onward. Throughout, we emphasise human‑centred manufacturing, ethical practices and the use of advanced technologies such as AI‑assisted quality control to deliver reliable products at scale.

Why This Guide Matters

- Safety and compliance – regulatory requirements are tightening. Electronics need certifications like CE (EU), FCC (US) and RoHS. Missteps in documentation or misclassification of HS codes can cause costly delays and penalties.

- Intellectual property – innovations can be copied quickly if protections aren’t in place. Selecting a partner with robust IP safeguards is critical.

- Sustainability – as consumers and regulators push for greener electronics, China Electronic Manufacturing Services (EMS) partners must reduce waste, manage hazardous materials and consider carbon footprints.

- Future‑ready – AI, automation and Industry 4.0 are reshaping manufacturing. Choosing a partner that invests in these technologies ensures longevity and competitiveness.

By the end of this guide, you will know how to choose the right China Electronic Manufacturing Services (EMS) partner, understand the costs and risks, and prepare for the future of electronics manufacturing.

Why China Dominates Global EMS

China has become the undisputed leader in contract electronics manufacturing. Several factors contribute to this dominance:

Integrated supply chains and clusters

Major industrial clusters like Shenzhen (Guangdong Province), Dongguan, Suzhou and Chengdu offer dense networks of component suppliers, PCB manufacturers, assembly houses, test labs and logistics providers. This concentration reduces lead times, lowers costs and supports rapid prototyping. Shenzhen’s electronics ecosystem emerged from the special economic zone policies of the 1980s and now includes thousands of component vendors and specialist contract manufacturers.

Understanding the landscape of China Electronic Manufacturing Services is crucial for any business looking to thrive in the competitive electronics market.

Skilled workforce

China invests heavily in vocational and engineering education. Millions of workers in Guangdong, Jiangsu and Zhejiang provinces specialise in electronics assembly, precision machining and quality control. Coupled with experienced management, this workforce can handle complex products such as smartphones, wearables and automotive electronics.

Government support

Policies like Made in China 2025 promote high‑value manufacturing and encourage investment in robotics, AI and new materials. The government offers tax incentives and funding for R&D, helping China Electronic Manufacturing Services (EMS) companies upgrade technologies and meet international standards.

Cost competitiveness and scalability

Although labour costs have risen, China’s efficiency, infrastructure and economies of scale keep total costs competitive. Factories can ramp from prototypes to millions of units with relative ease. Low minimum order quantities (MOQs) are available in pilot runs, allowing startups to test products without massive capital commitments.

Regulatory compliance and quality management

Many China Electronic Manufacturing Services (EMS) firms have adopted quality management systems like ISO 9001, ISO 13485 (medical), IATF 16949 (automotive) and ISO 14001 (environmental). Forward‑thinking factories also undergo environmental, social and governance (ESG) audits and deploy AI‑assisted quality control systems to meet rising standards.

Major China Electronic Manufacturing Services (EMS) Hubs

Shenzhen – The Silicon Valley of Hardware

Shenzhen is the epicentre of electronics manufacturing. The city’s Huaqiangbei district features markets where developers can source components, sensors and modules quickly. Beyond component availability, Shenzhen hosts full‑service China Electronic Manufacturing Services (EMS) providers offering design, prototyping, PCBA, testing and assembly. Many companies specialise in consumer devices, IoT, networking equipment and drones.

Strengths: Fast turnaround, small‑batch capability, access to innovation hubs. Potential challenges: intense competition and limited capacity for high‑mix, low‑volume orders during peak periods.

Dongguan – Precision and PCBA expertise

Located between Shenzhen and Guangzhou, Dongguan hosts many PCBA specialists. Factories here offer surface‑mount technology (SMT), through‑hole assembly, conformal coating and functional testing. Dongguan is also known for high‑quality enclosures, injection moulding and metalwork.

Strengths: Strong supply chain for electronic components, advanced test facilities, and skilled labour. Challenges: Some factories focus on large volumes; low‑volume orders may face longer lead times.

Suzhou and the Yangtze River Delta

Suzhou, Wuxi and the Yangtze River Delta form another China Electronic Manufacturing Services (EMS) cluster. These cities have well‑developed infrastructure, excellent transportation links and proximity to Shanghai. They attract foreign‑owned and joint‑venture China Electronic Manufacturing Services (EMS) providers serving medical, industrial and automotive sectors.

Strengths: Access to high‑end components and clean‑room facilities, strong IP protection, and stable quality systems. Challenges: Higher costs than Guangdong and potential communication barriers with smaller factories.

Other notable regions

- Chengdu & Chongqing – emerging hubs for automotive electronics and industrial controls.

- Qingdao & Tianjin – focus on consumer appliances and telecom equipment.

- Ningbo & Hangzhou – integrate EMS with e‑commerce supply chains.

Types of China Electronic Manufacturing Services (EMS) Providers

Selecting the right type of partner depends on your product complexity, order volume and business goals. Below are the main categories:

PCB Assembly (PCBA) specialists

PCBA specialists focus on mounting components onto printed circuit boards and testing finished boards. They offer:

- Surface‑mount technology (SMT) lines for high‑density boards.

- Through‑hole and mixed technology for boards requiring strong mechanical connections.

- Conformal coating and potting to protect against moisture and vibration.

- Functional and in‑circuit testing to ensure reliability.

These suppliers are ideal for companies that design their own boards but need a partner for assembly and testing. They often provide quick‑turn prototypes and can handle volumes from dozens to hundreds of thousands.

Full‑service China Electronic Manufacturing Services (EMS) providers

Full‑service providers manage the entire product lifecycle, from design and component sourcing to assembly, testing, packaging and logistics. They offer:

- Design for manufacturability (DFM) – suggestions to optimise your design for production.

- Bill of materials (BOM) management – sourcing components, negotiating prices and avoiding counterfeits.

- System integration and final assembly – combining PCBs, mechanical parts and firmware into finished products.

- After‑sales services – repairing returned units, upgrading firmware and supporting end users.

Full‑service China Electronic Manufacturing Services (EMS) is suited to startups and brands that require assistance with design and supply chain management. Because they manage so many steps, they often have higher MOQs but can be more cost‑effective at scale.

Niche China Electronic Manufacturing Services (EMS) providers (automotive, medical, IoT)

Some China Electronic Manufacturing Services (EMS) companies specialise in industry‑specific standards or technologies:

- Automotive electronics – certified to IATF 16949 and ISO 26262. They handle high‑reliability components, safety systems and thermal management.

- Medical devices – certified to ISO 13485, comply with FDA and MDR regulations, and maintain traceability and clean‑room environments.

- Industrial & IoT – produce ruggedised devices, sensors, industrial controllers and edge computing modules. These providers often support custom enclosures and robust connectivity tests.

Selecting a niche provider ensures compliance with regulatory requirements and industry‑specific quality standards.

How to Choose the Right China Electronic Manufacturing Services (EMS) Partner

1. Certification and quality standards

Ensure the factory holds relevant certifications:

- ISO 9001 for quality management (minimum requirement for all EMS). Factories without this certification may deliver inconsistent quality.

- ISO 13485 for medical devices – mandatory for healthcare products.

- IATF 16949 for automotive electronics – emphasises continuous improvement and defect prevention.

- ISO 14001 for environmental management – shows commitment to reducing waste.

- RoHS and REACH compliance – ensures products are free from hazardous substances.

Also look for factories that adopt ESG audits and invest in AI‑assisted quality control. These indicate a forward‑looking approach and alignment with global sustainability expectations.

2. Intellectual property protection

Protecting your design and firmware is crucial. Check that:

- The factory signs non‑disclosure agreements (NDAs) and respects IP laws.

- They maintain separate areas or lines for customers with sensitive designs.

- They avoid unauthorised subcontracting. Hidden subcontractors can leak IP or deliver inferior quality.

- They have a documented procedure for disposing of defective boards (to prevent scavenging of your product).

3. Production capacity and scalability

Assess whether the factory can handle your current volume and scale up. Ask about:

- Minimum order quantities (MOQs) – high MOQs may lock you into inventory you cannot sell. Many small China Electronic Manufacturing Services (EMS) providers accept small runs; confirm if they can combine orders or allocate dedicated lines.

- Lead times – how long from order to shipment? Faster isn’t always better; unrealistic timelines can result in quality issues.

- Flexibility – can they adjust to design changes or accelerated schedules? A strong partner will communicate proactively and plan for contingencies.

4. Supply chain management

An EMS’s strength lies in its ability to source quality components and avoid counterfeit parts. Evaluate:

- Supplier vetting processes – do they audit component suppliers? Lack of due diligence leads to substandard products and missed deadlines.

- Inventory management – do they carry buffer stocks? Are they transparent about shortages and substitutions?

- Pricing transparency – good China Electronic Manufacturing Services (EMS) partners share cost structures and negotiate fairly. Hidden mark‑ups can inflate total cost.

5. Communication and culture

Clear communication reduces misinterpretations and costly mistakes. Look for:

- English‑speaking account managers and engineers.

- Multiple communication channels (email, WeChat, video calls). Response times should be within hours, not days.

- Willingness to collaborate on design improvements. A factory that only follows instructions may miss opportunities to optimise your product.

Also recognise cultural differences. In China, maintaining harmony and “saving face” can cause suppliers to hide issues. Build trust through regular visits, open discussions and respect for hierarchy.

6. Ethics and sustainability

Quality now includes ethical labour practices and environmental impact. Investigate whether the China Electronic Manufacturing Services (EMS) partner:

- Follows local labour laws and provides fair wages and safe working conditions.

- Manages waste responsibly and complies with environmental regulations (e.g., ISO 14001). Factories embracing ESG audits demonstrate commitment.

- Supports sustainable materials and processes. For example, using recyclable aluminium or bio‑based plastics can reduce carbon footprints.

Pricing, Lead Times and Risk Factors

Cost breakdown

Pricing in China Electronic Manufacturing Services (EMS) depends on multiple factors:

- Component costs – influenced by BOM complexity, sourcing channels, tariffs and currency fluctuations.

- Manufacturing costs – labour, equipment amortisation, overhead and profit margins.

- Testing and certification – compliance tests, test jig development and certification fees.

- Packaging and logistics – includes custom packaging, labelling and freight (air or sea).

Tip: Request detailed quotes with line items. Compare multiple factories to ensure costs are fair. Cheaper quotes may exclude quality control, leading to defects and rework.

Lead times

Lead times vary by product and order size. A typical timeline:

- Prototype & DFM – 2–4 weeks.

- Component sourcing – 2–6 weeks (longer if using custom chips or components facing shortages).

- PCB fabrication and PCBA – 1–3 weeks depending on complexity and volumes.

- System integration and testing – 1–2 weeks.

- Packaging & shipping – 1 week for air, 3–6 weeks for sea freight.

For fast‑turn prototypes, some China Electronic Manufacturing Services (EMS) providers can compress steps, but don’t compromise testing.

Risk factors and mitigation

- Component shortages – diversify supplier base and consider alternate components.

- Quality issues – invest in regular inspections and emphasise detection and prevention. Forward‑thinking factories use AI‑assisted quality control to reduce defects.

- IP leakage – avoid factories known for side projects. Limit documentation exposure and use NDAs.

- Geopolitical risks – tariffs and export controls may affect components (e.g., semiconductors). Plan for multi‑country sourcing (China + 1 strategy).

- Currency fluctuations – negotiate quotes in your preferred currency or hedge exposure.

Future Trends in China Electronic Manufacturing Services (EMS)

The next five years will reshape electronics manufacturing. Keep an eye on these trends:

AI and machine vision

AI‑driven inspection systems are now common in leading Chinese factories. Computer vision and deep learning analyse solder joints, component placement and surface finish with exceptional speed and accuracy. Predictive algorithms forecast equipment failures, optimise reflow profiles and reduce human error.

Industry 4.0 and smart factories

Factories are implementing Industry 4.0 principles: sensors, data analytics, robotics and cloud connectivity. Digital twins replicate production environments to simulate processes and identify inefficiencies. Real‑time dashboards allow remote monitoring and decision‑making. The integration of sensors and IoT devices enables factories to operate autonomously and adapt to demand fluctuations.

Green electronics and circular design

Environmental regulations like the EU’s Circular Economy Action Plan are pushing manufacturers to reduce waste, design products for repairability and use recycled materials. China Electronic Manufacturing Services (EMS) providers will need to adopt eco‑design principles, such as modular architectures and recyclable enclosures. Some are developing closed‑loop recycling systems to reuse metals and plastics.

Advanced materials and technologies

New materials like graphene, silicon carbide and flexible substrates will open opportunities for thinner, lighter and more efficient devices. Additive manufacturing (3D printing) could enable custom circuits and enclosures. Quantum computing and 6G connectivity may require entirely new manufacturing processes.

ESG and social responsibility

Brands and investors demand transparency. ESG audits evaluate environmental impact, labour practices and governance. Chinese factories that embrace ESG and undergo third‑party audits will stand out. Consumers increasingly choose products that align with their values, so manufacturers must show how they minimise carbon footprints, treat workers fairly and recycle materials.

Yana’s Role in Connecting You with Reliable China Electronic Manufacturing Services (EMS) Partners

Choosing a China Electronic Manufacturing Services (EMS) partner can be overwhelming. Yana makes it easy:

- We listen first – we understand your product, values and goals before recommending partners.

- We vet and verify – through rigorous supplier verification, we ensure factories meet your criteria. Poor due diligence often leads to substandard products and reputational damage.

- We negotiate MOQs and pricing – our relationships allow us to secure low MOQs for prototypes and competitive prices for production.

- We manage quality control – from pre‑production sampling to in‑process and final inspections, we use both human inspectors and cutting‑edge tools like AI vision systems. We catch problems early and work with factories to fix them.

- We champion ethics and sustainability – we favour factories that adopt ESG audits, reduce waste and treat workers fairly. This ensures your products align with modern values.

- We provide transparency – we communicate clearly and provide reports, photos and videos, so you know what’s happening at every stage.

- We scale with you – from small pilots to mass production, we ensure continuity and consistency. Our network includes PCBA specialists, full‑service providers and niche manufacturers.

Frequently Asked Questions (FAQ)

What is the difference between EMS and ODM?

EMS (electronic manufacturing services) assemble products designed by clients. ODM (original design manufacturers) design and manufacture products that clients can rebrand. Many Chinese firms offer both services; some can modify their existing designs to suit your requirements.

How do I verify a China Electronic Manufacturing Services (EMS) provider?

Start by checking business licences, certifications and references. Visit the factory if possible. Conduct audits or work with a partner like Yana to evaluate facilities, production processes, workforce and supply chain practices. Due diligence prevents costly mistakes and counterfeit goods.

Can I start with small MOQs?

Yes. Many China Electronic Manufacturing Services (EMS) providers offer low MOQs for pilot runs, especially in Shenzhen and Dongguan. They may group orders from multiple clients to meet minimum component orders. Be clear about your forecast and roadmap so the factory can plan capacity.

What are the typical payment terms?

For new clients, factories may require a deposit (30–50 %) with the balance due before shipment. After building trust, it may be possible to negotiate longer terms or post‑shipment payment. Always structure payments around milestones (e.g., after successful PSI inspection, before shipping). Avoid paying the full amount upfront.

How long does it take to certify a new electronics product?

Certification timelines vary. EMI/EMC, safety and environmental tests can take 2–6 weeks. Plan certification concurrently with production to avoid delays. Certification labs may require sample units, so coordinate with your China Electronic Manufacturing Services (EMS) partner to ensure prototypes meet test requirements.

How do I protect my IP?

Use NDAs and non‑compete agreements. Select factories with good reputations and avoid those known for copycat products. Work with local legal counsel to register patents in China if necessary. Limit access to your design documents and consider splitting production across multiple suppliers to minimise risk.

How do I ensure products are ethically made?

Choose China Electronic Manufacturing Services (EMS) partners that undergo ESG audits and maintain certifications like SA8000 (social accountability). Conduct your own audits or engage third‑party inspectors. Ensure workers have safe conditions, fair pay and reasonable hours. Ask suppliers about waste management and environmental initiatives.

What happens if defects are found during PSI inspection?

The next steps depend on defect severity and agreement terms. Minor defects may be repaired or replaced immediately. Major issues may require reworking the entire batch or renegotiating compensation. Having clear acceptance criteria and documentation (e.g., AQL standards) helps resolve disputes.

Can I diversify my supply chain while working with China?

Yes. Many brands adopt a China + 1 strategy by sourcing some components or assemblies from other countries (e.g., Vietnam, Thailand, Mexico) to reduce risk. Yana helps evaluate and coordinate multi‑country production while maintaining quality and consistency.

Conclusion: Your Roadmap to Electronic Manufacturing Success

Choosing the right electronic manufacturing services partner in China can define your product’s success. From understanding major hubs like Shenzhen, Dongguan and Suzhou to discerning the differences between PCBA specialists, full‑service providers and niche China Electronic Manufacturing Services (EMS), you need a strategy that balances price, quality, IP protection and sustainability. Staying informed about certifications, supply chain management and cultural dynamics helps you avoid common pitfalls.

The future of China Electronic Manufacturing Services (EMS) is exciting: AI‑assisted inspection, Industry 4.0, green electronics and circular design will transform how products are made and recycled. At the same time, consumers and investors demand transparency and ethical manufacturing practices. By partnering with Yana, you gain a trusted ally on the ground who integrates human‑centred values with advanced technology. We handle the complexities of vetting factories, managing production, ensuring quality and navigating logistics, so you can focus on innovation and growth.

Whether you are a hardware startup building the next wearable device, a global brand launching an IoT platform or an entrepreneur creating sustainable electronics, remember: You Are Not Alone. Yana Sourcing helps you bring your vision to life, reliably, ethically and with a human touch.

Leave a Reply