Table of Contents

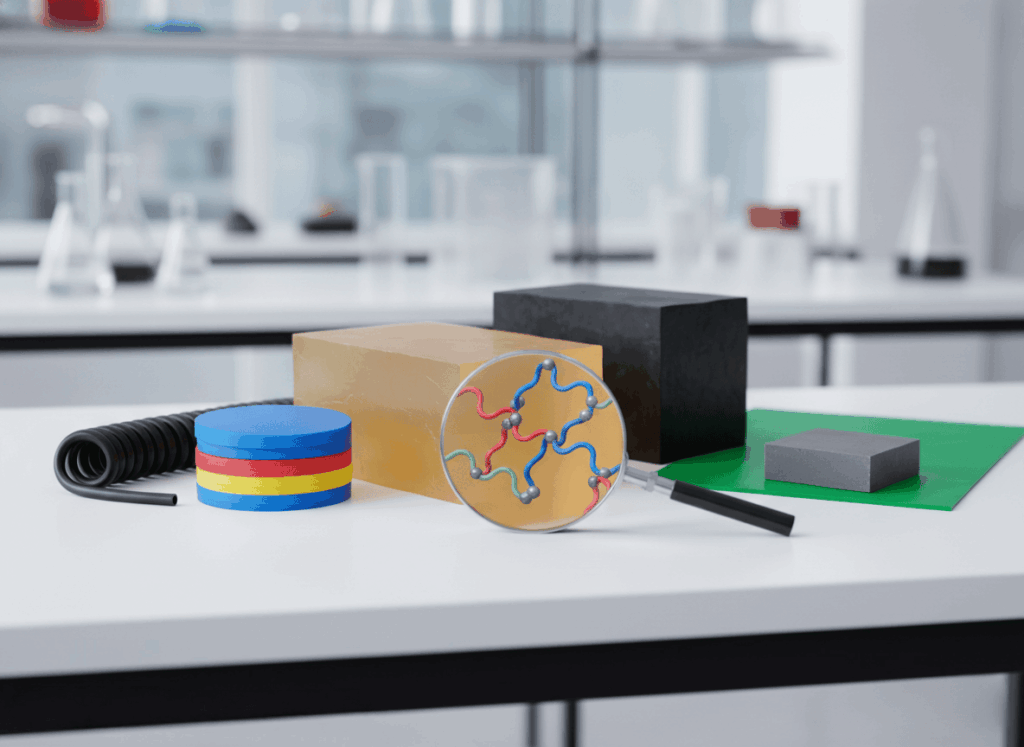

Engineering elastomers are the unsung heroes of motion, materials that flex, absorb, and recover where metals and plastics would fail.

From automotive seals to medical tubing, elastomers combine elasticity, durability, and environmental resistance in one continuous form.

They are the quiet backbone of mobility, comfort, and reliability, turning vibration into smoothness and impact into resilience.

At Yana Sourcing, we specialize in sourcing and customizing elastomer compounds, from silicone and EPDM to TPU and fluoroelastomers, engineered for precise performance, compliance, and lifecycle cost.

Key Properties of Engineering Elastomers

When designers talk about engineering elastomers, they’re referring to materials that behave like a paradox, soft yet strong, flexible yet precise.

Unlike rigid plastics or metals, elastomers store and release energy with every movement, making them essential wherever motion, vibration, or sealing defines product performance.

Their secret lies in cross-linked molecular chains, which stretch under stress and return to their original shape almost instantly.

The result is a class of materials that provide elasticity, comfort, vibration control, and long-term reliability across millions of cycles.

Below are the key engineering properties that define how elastomers outperform traditional materials.

Elastic Recovery and Fatigue Resistance

The hallmark of every engineering elastomer is its ability to deform and recover repeatedly without permanent damage.

While a metal spring might fatigue after thousands of cycles, elastomers can survive millions of compression and tension cycles with minimal loss of performance.

| Property | Typical Range | Materials with Best Performance |

|---|---|---|

| Elongation at Break | 200–1000% | Silicone, TPU |

| Tensile Strength | 5–35 MPa | NBR, FKM, TPU |

| Fatigue Life (cycles) | >10⁶ | EPDM, Silicone, TPU |

| Compression Set (70°C, 22h) | <20% | EPDM, FKM |

This resilience allows elastomers to absorb shocks, isolate vibrations, and maintain seals under dynamic pressure.

At Yana Sourcing, we help clients specify the correct compound hardness (measured in Shore A) to balance elasticity with dimensional stability, from soft gaskets (40A) to structural mounts (90A).

Temperature and Chemical Resistance

Different engineering elastomers thrive in different extremes.

Some, like silicone (VMQ), maintain flexibility down to -60°C and resist heat up to +230°C.

Others, such as fluoroelastomers (FKM), withstand aggressive fuels, oils, and solvents at continuous service temperatures exceeding 200°C.

| Material | Temperature Range (°C) | Chemical Resistance | Key Applications |

|---|---|---|---|

| Silicone (VMQ) | -60 → +230 | Excellent (inert) | Medical, aerospace |

| EPDM | -50 → +150 | Excellent vs. weather, ozone, water | Automotive seals, roofing |

| NBR | -30 → +120 | Excellent vs. oil, fuel | Hoses, gaskets |

| FKM (Viton®) | -20 → +250 | Superior vs. fuels, acids | Aerospace, engines |

| TPU | -40 → +100 | Moderate | Seals, rollers, consumer goods |

By mapping your product’s chemical and temperature exposure profile, Yana Sourcing ensures that elastomer compounds meet performance criteria under all operating conditions, verified to ASTM D573 (heat aging) and ISO 1817 (chemical immersion).

Compression Set and Hardness Control

One of the most critical properties for sealing elastomers is compression set, how much the material fails to recover after being squeezed.

Low compression set means better long-term sealing performance, especially in gaskets and O-rings exposed to constant load.

- EPDM and FKM offer compression set <15%, ensuring tight seals in automotive and chemical systems.

- Silicone maintains recovery over decades, ideal for medical and outdoor applications.

- Hardness is tuned via polymer formulation, fillers, and cross-link density.

At Yana Sourcing, we partner with compounders who can fine-tune hardness (30–95 Shore A) and rebound resilience (40–70%) based on real-use stress profiles, balancing grip, softness, and pressure retention.

Vibration Damping and Noise Reduction

Beyond sealing, engineering elastomers play a critical role in NVH management (Noise, Vibration, Harshness).

Their viscoelastic nature allows them to absorb and dissipate mechanical energy, converting vibration into heat.

This makes them indispensable in automotive mounts, robotics joints, HVAC isolators, and rail interiors.

| Damping Ratio (ζ) | Typical Materials |

|---|---|

| 0.05–0.15 | Silicone, TPU |

| 0.10–0.25 | EPDM, NBR |

| 0.20–0.40 | TPE blends, soft polyurethane |

Yana Sourcing’s elastomer sourcing includes dynamic mechanical analysis (DMA) testing to verify energy dissipation curves, ensuring your chosen material provides the right damping frequency for its intended system.

Major Types of Engineering Elastomers

While “rubber” once meant natural latex, today it refers to a broad family of engineering elastomers, each formulated to deliver precision resilience under specific mechanical, chemical, or environmental conditions.

From high-temperature silicone to oil-resistant nitrile, these materials define the tactile performance of industries in motion: mobility, energy, healthcare, and consumer technology.

Below are six elastomer families that dominate engineering and manufacturing today.

Silicone Rubber (VMQ)

Silicone is the most versatile of all engineering elastomers, prized for its temperature stability, purity, and biocompatibility.

Its unique Si–O–Si molecular backbone remains flexible where organic rubbers stiffen or degrade.

| Property | Typical Range | Remarks |

|---|---|---|

| Temperature Range | -60 → +230°C | Excellent low/high-temp resilience |

| Hardness (Shore A) | 30–80 | Adjustable with fillers |

| Compression Set (22h @175°C) | <25% | Retains sealing force |

| Elongation at Break | 200–700% | Highly elastic |

| Dielectric Strength | 20–25 kV/mm | Ideal for insulation |

Applications include medical tubing, gaskets, keypads, aerospace seals, and food-contact components.

Special grades, such as fluorosilicone (FVMQ), add resistance to fuels and oils.

Yana Sourcing offers FDA, USP Class VI, and ISO 10993-certified silicone compounds, sourced from verified producers in Japan, China, and Germany.

EPDM (Ethylene Propylene Diene Monomer)

EPDM is the weatherproof workhorse of engineering elastomers.

It withstands ozone, sunlight, and water better than nearly any other rubber, making it the default choice for outdoor and automotive sealing applications.

| Property | Typical Range | Key Strength |

|---|---|---|

| Temperature Range | -50 → +150°C | Maintains flexibility outdoors |

| Ozone Resistance | Excellent | Long-term weather sealing |

| Water / Steam Resistance | Excellent | Ideal for HVAC, roofs, vehicles |

| Oil Resistance | Poor | Avoid petroleum exposure |

EPDM’s structure prevents oxidation and maintains elasticity under UV exposure.

It is the foundation of automotive weatherstrips, radiator hoses, and roofing membranes.

Yana Sourcing provides EPDM compounds verified under ASTM D2000 and SAE J200, with hardness and curing systems optimized for extrusion or injection molding.

NBR (Nitrile Butadiene Rubber)

Nitrile rubber, or NBR, was developed for one purpose, resistance to oils and fuels.

It remains a cornerstone elastomer for industrial seals, hoses, and gaskets where hydrocarbons and lubricants are present.

| Property | Typical Range | Notes |

|---|---|---|

| Temperature Range | -30 → +120°C | Stable under oil exposure |

| Oil/Fuel Resistance | Excellent | Key advantage over EPDM |

| Tear Strength | 20–40 kN/m | Good mechanical strength |

| Compression Set (22h @100°C) | <25% | Reliable sealing performance |

NBR’s polarity gives it superior chemical compatibility with petroleum-based oils, diesel, and hydraulic fluids.

Yana Sourcing offers high-acrylonitrile (ACN) NBR grades for aggressive oils and low-ACN types for flexibility at low temperatures, both compliant with REACH and RoHS standards.

FKM (Viton® Fluoroelastomer)

When extreme heat and chemicals are the challenge, fluoroelastomers (FKM) deliver.

Their fluorinated structure resists fuels, solvents, and acids that degrade most rubbers.

| Property | Typical Range | Performance |

|---|---|---|

| Temperature Range | -20 → +250°C | Continuous high-temp sealing |

| Chemical Resistance | Outstanding | Fuels, solvents, acids |

| Compression Set (22h @200°C) | <20% | Excellent retention |

| Hardness (Shore A) | 60–90 | For high-pressure sealing |

FKM is standard in aerospace, chemical plants, fuel systems, and high-end automotive applications.

Variants like FEPM (Aflas) extend performance in steam and amines.

Yana Sourcing sources FKM from licensed producers (Viton®, Dai-El, and GBL) with certifications for ASTM D1418, D2000-M2HK, and AMS-R-83485.

TPU (Thermoplastic Polyurethane Elastomer)

TPU combines the elasticity of rubber with the processability of plastic, a hybrid elastomer perfect for cables, rollers, footwear, and flexible couplings.

Its microphase-separated structure provides toughness and wear resistance far superior to most rubbers.

| Property | Typical Range | Key Benefit |

|---|---|---|

| Hardness (Shore A/D) | 70A–75D | Wide range, tunable |

| Tensile Strength | 30–60 MPa | High strength |

| Abrasion Resistance | Excellent | Outperforms natural rubber |

| Temperature Range | -40 → +100°C | Stable for dynamic use |

TPU can be extruded, injection molded, or 3D printed, offering modern design flexibility.

Yana Sourcing partners with top TPU producers (BASF, Lubrizol, Wanhua) and can customize ester or ether-based grades depending on humidity, oil, or mechanical exposure.

TPE (Thermoplastic Elastomer Blends)

TPEs are polymer blends that behave like rubber but process like plastic, perfect for overmolded grips, soft-touch handles, and flexible seals.

They combine PP, SEBS, or TPU bases with elastomeric modifiers to tune flexibility, appearance, and cost.

| Property | Typical Range | Application |

|---|---|---|

| Hardness (Shore A) | 20–90 | Fully tunable |

| Elongation at Break | 300–700% | Soft yet strong |

| Service Temperature | -40 → +120°C | Moderate heat stability |

| Key Feature | Recyclable | 100% reprocessable |

TPEs bridge the gap between rubber and plastic, providing cost efficiency, aesthetic flexibility, and sustainable processing.

Yana Sourcing works with certified TPE compounders to adjust color, adhesion, and tactile feel for industrial and consumer markets alike.

Processing and Fabrication Considerations

Behind every high-performing elastomer part lies a process, a careful orchestration of mixing, molding, curing, and post-treatment that determines not only shape but long-term durability.

Unlike thermoplastics that melt and reset, most engineering elastomers rely on vulcanization: a chemical cross-linking process that locks molecules into elastic networks.

At Yana Sourcing, we view elastomer fabrication as a form of material engineering, where chemistry meets precision tooling.

Compression, Transfer, and Injection Molding

Different elastomers demand different molding techniques based on viscosity, cure rate, and part geometry.

| Process | Advantages | Typical Elastomers | Applications |

|---|---|---|---|

| Compression Molding | Low tooling cost, good for thick parts | EPDM, NBR, FKM | Seals, O-rings, gaskets |

| Transfer Molding | Better precision, less flash | Silicone, FKM | Medical seals, membranes |

| Injection Molding | High automation, fast cycle | Silicone (LSR), TPE, TPU | Keypads, soft-touch parts, tubing |

| Extrusion | Continuous profiles | EPDM, Silicone | Tubes, weatherstrips |

| Die-Cutting / Calendering | Flat sheets and films | EPDM, NBR | Gaskets, diaphragms |

Compression molding remains the most common for high-strength rubber seals, while liquid silicone rubber (LSR) injection molding dominates in medical and consumer applications for its cleanliness and precision.

Yana Sourcing matches each compound to its optimal process, verifying mold temperature, cure kinetics, and pressure profiles to ensure dimensional consistency across batches.

Mixing, Vulcanization, and Post-Curing

The elasticity of an engineering elastomer is born during vulcanization, the controlled creation of cross-links between polymer chains.

Different curing systems produce different thermal and chemical properties:

| Curing System | Key Chemistry | Typical Use | Remarks |

|---|---|---|---|

| Sulfur Cure | Sulfur bridges (S–S) | EPDM, NBR | Economical, good resilience |

| Peroxide Cure | Radical cross-links | Silicone, EPDM | High heat resistance |

| Platinum Cure (Addition Cure) | Hydrosilylation | Silicone (medical, LSR) | No byproducts, high purity |

| Fluorinated Cure Systems | Ionic/peroxide | FKM | Superior chemical durability |

After molding, post-curing at elevated temperature removes volatile residues, stabilizes mechanical properties, and enhances chemical resistance, especially for medical-grade silicone and FKM parts.

Yana Sourcing ensures every compound follows ISO 2393 (rubber compounding) and ASTM D412/D573 test procedures, verifying both formulation and cure quality.

Overmolding and Bonding to Plastics or Metals

The future of elastomer design lies in hybrid assemblies, where soft elastomers are permanently bonded to rigid substrates.

This combination improves ergonomics, vibration damping, and sealing integrity while simplifying assembly.

Common hybrid systems include:

- TPE or TPU overmolded onto PC/ABS or nylon for grips, seals, and housings.

- FKM bonded to steel in high-pressure valve seats.

- Silicone overmolded onto titanium or stainless steel in medical devices.

Successful bonding requires surface activation (plasma or primer), temperature control, and chemical adhesion promoters.

Yana Sourcing collaborates with adhesive formulators and tool designers to ensure consistent interfacial strength under cyclic load and temperature.

Testing and Certifications

Every batch of engineering elastomers must pass mechanical, thermal, and environmental testing to validate both compound formulation and production control.

| Standard | Test Description | Key Property |

|---|---|---|

| ASTM D412 / ISO 37 | Tensile and elongation | Strength and elasticity |

| ASTM D2240 | Shore hardness | Material stiffness |

| ASTM D573 | Heat aging | Retention after thermal exposure |

| ASTM D395 | Compression set | Sealing recovery |

| ASTM D471 / ISO 1817 | Fluid immersion | Chemical resistance |

| UL 157 / ISO 815 | Electrical and flame testing | Safety and dielectric performance |

Yana Sourcing audits suppliers to ensure all testing is conducted in ISO/IEC 17025-accredited labs, providing full Material Test Certificates (MTCs) for every batch.

Performance vs Cost: Selecting the Right Elastomer

Selecting the right engineering elastomer is a strategic balance between performance, processability, and price.

A compound that excels in the lab can fail in the field if not matched to the right environment, and conversely, a mid-range elastomer can outperform premium ones when chosen with context.

At Yana Sourcing, we turn this balancing act into a data-driven sourcing strategy: measuring not just material cost, but lifecycle value.

Mechanical vs Environmental Priorities

Each engineering elastomer serves a unique combination of mechanical and chemical demands, tear resistance, compression set, oil compatibility, and environmental aging.

Choosing the right one depends on where the stress comes from: movement, heat, fluid exposure, or weather.

| Property Focus | Recommended Elastomers | Key Industries |

|---|---|---|

| Heat Resistance | Silicone, FKM | Aerospace, engines, medical |

| Oil & Fuel Resistance | NBR, FKM | Automotive, hydraulic systems |

| Weather & Ozone Resistance | EPDM, Silicone | Construction, outdoor equipment |

| Wear & Tear Resistance | TPU, TPE | Robotics, footwear, consumer goods |

| Elasticity / Comfort | Silicone, TPE | Medical, wearable tech |

For example, EPDM excels outdoors but fails in contact with fuel; NBR thrives in oil but ages under ozone.

Yana Sourcing helps clients map operational stress profiles, defining real-world exposure scenarios, before committing to a specific compound.

Comparing Elastomers to Plastics and Rubbers

Engineering elastomers occupy the middle ground between traditional rubber and high-performance plastics.

Where plastics break under stress, elastomers flex and recover; where rubbers degrade, elastomers endure.

| Property | Thermoplastics | Elastomers | Traditional Rubber |

|---|---|---|---|

| Elastic Recovery | Low | Excellent | Good |

| Temperature Range (°C) | -20 → +100 | -60 → +250 | -30 → +120 |

| Chemical Resistance | Moderate | Excellent (selective) | Limited |

| Manufacturing Precision | Excellent | High (post-cure) | Moderate |

| Recyclability | High (TPE, TPU) | Moderate | Low |

| Cost (USD/kg) | 2–8 | 4–30 | 3–10 |

This makes elastomers ideal for hybrid components, where flexibility, sealing, and durability matter as much as shape or surface finish.

With materials like TPU and TPE, engineers can design parts that perform like rubber but assemble like plastic, reducing tooling complexity and energy use.

Regulatory and Safety Compliance

In elastomer sourcing, performance alone isn’t enough. Compliance defines access to markets.

Depending on industry, elastomers may need certification for biocompatibility, flame resistance, or environmental safety.

⚖️ Key Compliance Standards

- RoHS / REACH: Restrict heavy metals, PAHs, and phthalates in elastomer compounds.

- FDA 21 CFR 177 / USP Class VI: Required for food and medical-grade silicone, EPDM, and TPU.

- UL 94 / UL 157: Define flammability and dielectric performance.

- IATF 16949: Automotive-grade elastomer consistency certification.

- ISO 2230: Ensures proper storage and shelf-life control for rubber products.

Yana Sourcing audits supplier documentation and third-party test reports, ensuring compliance is verified before shipment, not after production.

This saves clients from costly requalification and ensures smooth integration into regulated markets.

Economic Tiering: Cost vs Performance Matrix

Every engineering elastomer falls within a performance-cost tier that helps guide procurement planning.

| Tier | Example Materials | Typical Cost (USD/kg) | Primary Advantage |

|---|---|---|---|

| Premium (High-Performance) | FKM, Silicone (medical), Fluorosilicone | 20–60 | Extreme temperature & chemical resistance |

| Mid-Performance | EPDM, NBR, Industrial Silicone | 6–15 | Balanced durability and processability |

| Value-Optimized | TPE, TPU blends | 3–8 | Cost-effective, recyclable, versatile |

In sourcing, price alone is deceptive, because processing yield, mold life, and part reliability can shift total cost dramatically.

Yana Sourcing performs Total Cost of Ownership (TCO) evaluations, factoring in tooling wear, scrap rate, and maintenance intervals to pinpoint true cost efficiency.

Real-World Applications and Case Studies

Elastomers are not just materials, they’re motion enablers.

Wherever parts bend, seal, or absorb shock, engineering elastomers deliver the combination of flexibility, fatigue life, and resilience that rigid materials can’t match.

Below are real-world case studies showing how smart material selection transformed product performance and production outcomes.

Case Study 1 — Automotive Seals and NVH Systems

Challenge:

A European OEM needed a sealing system for electric vehicles that could withstand UV, ozone, and temperature swings from –40°C to +120°C while maintaining noise and vibration isolation.

Conventional natural rubber aged prematurely, leading to leaks and cabin noise complaints.

Solution:

Yana Sourcing recommended EPDM with peroxide curing, enhanced with UV stabilizers and carbon-black fillers for longevity.

The compound was extruded into door and trunk seals, verified under ASTM D2000-M3CA standards.

Outcome:

- Service life extended by 3× (from 5 to 15 years).

- Cabin noise reduced by 12%.

- No degradation after 1,000-hour ozone test.

This success positioned EPDM as the benchmark for weather- and noise-control elastomer systems in EV platforms.

Case Study 2 — Medical Tubing and Device Interfaces

Challenge:

A U.S. medical-device company required biocompatible, sterilization-stable tubing for respiratory equipment.

PVC alternatives leached plasticizers under repeated autoclave sterilization, compromising patient safety.

Solution:

Yana Sourcing sourced platinum-cured medical-grade silicone (VMQ) with USP Class VI and ISO 10993 certifications.

Our team coordinated cleanroom extrusion and ensured traceability through batch-level test reports.

Outcome:

- Zero material degradation after 200 sterilization cycles.

- Oxygen permeability and softness maintained.

- Compliant with FDA 21 CFR 177.2600.

The switch to medical-grade silicone enabled safer, longer-lasting equipment — and simplified regulatory submission for CE and FDA approval.

Case Study 3 — Aerospace and Fuel System Seals

Challenge:

An aircraft engine supplier faced seal failures due to exposure to jet fuel, hydraulic fluids, and 200°C heat.

Standard nitrile rubber deformed and cracked after 500 flight hours.

Solution:

Yana Sourcing provided FKM (Viton®) fluoroelastomers with fluorinated curing systems, guaranteeing resistance to aromatic hydrocarbons and high-pressure cycling.

We validated compounds through AMS-R-83485 and ASTM D471 immersion testing.

Outcome:

- Seal life extended to 4,000 flight hours.

- No chemical swelling after 72-hour fuel immersion.

- Compression set under 15% at 200°C.

This project demonstrated how engineering elastomers can handle extreme aerospace environments where metal seals simply can’t flex.

Case Study 4 — Consumer Electronics and Soft-Touch Interfaces

Challenge:

A leading electronics brand wanted to replace painted plastic grips with soft-touch elastomer surfaces that resisted yellowing and peeling.

Durability and tactile feel were critical for product differentiation.

Solution:

Yana Sourcing delivered TPE-SEBS and TPU overmold compounds, matched for adhesion to PC/ABS housings.

We collaborated with an injection molder to fine-tune gate temperature and bonding layer formulation.

Outcome:

- Improved scratch resistance by 40%.

- Surface color retained after 1,000-hour UV exposure.

- Cycle time reduced by 18%.

This integration of design and sourcing helped the client lower cost and create a premium tactile experience with sustainable, recyclable materials.

Case Study 5 — Industrial Machinery and Robotics

Challenge:

A robotics integrator sought to reduce noise and wear in high-speed actuators, replacing bronze bushings with a material that could damp vibration while maintaining tight tolerances.

Solution:

Yana Sourcing supplied TPU and NBR-based damping inserts, CNC-machined to ±0.02 mm, combining elasticity with oil resistance.

We validated results using Dynamic Mechanical Analysis (DMA) and ISO 7628 vibration tests.

Outcome:

- Noise levels reduced by 8 dB.

- Maintenance interval doubled.

- Component weight reduced by 50%.

This case proved that when elastomers are engineered and sourced correctly, soft materials can deliver hard performance.

Conclusion — The Material of Movement

From automotive seals to surgical tubing and robotic joints, engineering elastomers form the unseen infrastructure of modern life.

They absorb impact, isolate vibration, seal fluids, and preserve motion, translating mechanical force into controlled flexibility.

No other class of materials captures the essence of resilience quite like elastomers: they bend, recover, and endure where metals fatigue and plastics crack.

As industries push toward electrification, miniaturization, and sustainability, elastomers are evolving too, becoming lighter, purer, and more recyclable through advances in TPE, TPU, and fluorosilicone chemistry.

They’re not just rubber anymore; they’re smart materials engineered to survive environments that never rest.

At Yana Sourcing, we see elastomers not as commodities, but as living materials, designed, mixed, and cured to match your system’s heartbeat.

We source with precision, audit with science, and deliver with traceability, ensuring that every seal, gasket, or membrane performs exactly as engineered.

Partner with Yana Sourcing for Certified Elastomer Solutions

Why Choose Us

- Technical Sourcing Expertise: We connect compound formulation, curing system, and application design.

- Global Certified Supply: Access verified manufacturers under ASTM D2000, ISO 9001, and IATF 16949.

- Custom Compounds: We tailor hardness, color, and additive systems to your functional and regulatory requirements.

Get Expert Support

Send us your component drawings or performance targets, and our team will match them to the optimal engineering elastomer compound, balancing durability, compliance, and cost efficiency.

We’ll help you source elastomers that meet ASTM, FDA, and UL standards across industries from automotive to medical.

📩 Contact Yana Sourcing today to build products that move, flex, and last, powered by the most advanced elastomer materials on Earth.