Engineering polymers have quietly replaced metal in thousands of applications, from aerospace interiors to EV battery housings.

They offer the impossible balance of light weight, high strength, electrical insulation, and corrosion resistance, making them the building blocks of a new material age.

Far beyond conventional plastics, these polymers are engineered for precision, designed to perform under heat, pressure, and chemical exposure.

At Yana Sourcing, we connect manufacturers with certified polymer producers and compounders, helping clients choose the right formulation for every design, budget, and sustainability goal.

Key Properties of Engineering Polymers

In the language of modern manufacturing, engineering polymers speak the dialect of balance, strength with lightness, flexibility with precision, insulation with resilience.

Unlike commodity plastics used in packaging, these materials are designed to perform where metal once ruled: in motors, gears, housings, and medical instruments.

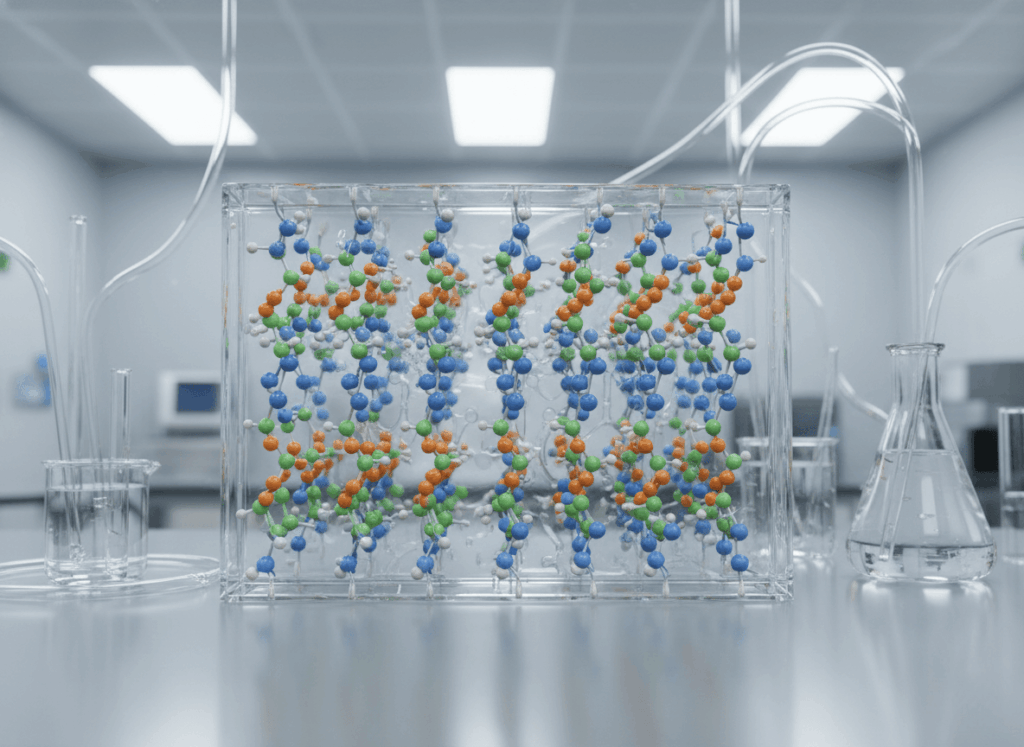

Their versatility lies in chemistry. By tailoring polymer chains and additives, engineers can tune properties to achieve the exact mix of mechanical, thermal, and electrical performance needed for each application.

Below are the core attributes that make engineering polymers indispensable to every industry driving toward efficiency and sustainability.

Strength-to-Weight Advantage

The defining value of engineering polymers is their ability to replace metal without compromising mechanical integrity.

With densities between 1.0–1.5 g/cm³, polymers are roughly six times lighter than steel and half the weight of aluminum, yet reinforced grades can reach tensile strengths up to 200 MPa.

- Glass-filled nylons (PA6-GF30) and carbon-reinforced PEEK exhibit stiffness comparable to light alloys.

- Their low inertia improves motion efficiency in rotating systems like fans, gears, and actuators.

- Lighter components reduce energy consumption and overall system weight, a key advantage in EVs and aerospace.

This combination of mechanical performance and mass efficiency defines why engineering polymers are often called “structural plastics”.

At Yana Sourcing, we help clients identify the right reinforcement ratio, balancing weight, rigidity, and moldability for optimal cost-performance.

Thermal and Chemical Resistance

Many engineering polymers perform comfortably in environments that would degrade ordinary plastics within minutes.

High-performance families such as PEEK, PPS, and PTFE can endure continuous service temperatures above 200°C and resist aggressive solvents, fuels, and hydraulic fluids.

| Polymer | Continuous Use Temp (°C) | Chemical Resistance | Key Application |

|---|---|---|---|

| PEEK | 250 | Excellent to acids and hydrocarbons | Aerospace, medical |

| PPS | 220 | Excellent, including strong bases | Automotive, electrical |

| PTFE | 260 | Universal, almost inert | Seals, chemical handling |

| PA 6/6 (Nylon) | 120 | Good to oils and fuels | Mechanical parts |

| PC (Polycarbonate) | 115 | Moderate, limited vs solvents | Lenses, housings |

For applications exposed to thermal cycling or chemical stress, such as under-hood components, valves, or heat shields, Yana Sourcing supplies compound formulations with stabilizers and fillers that maintain structure over long-term exposure.

Dimensional Stability and Machinability

Precision is where engineering polymers distinguish themselves.

Unlike commodity plastics, they can be machined, milled, or molded with tolerances within ±0.05 mm, even for small components.

Their low creep, high modulus, and controlled shrinkage make them ideal for gears, bearings, and valves that require long-term dimensional reliability.

Key aspects include:

- Low moisture absorption: PA12 and POM maintain accuracy under humidity.

- Low thermal expansion: PPS and PEEK remain stable across 200°C temperature ranges.

- High wear resistance: PTFE and POM provide natural lubrication, extending lifespan.

Yana Sourcing partners with precision molders and CNC machinists specialized in tight-tolerance polymer fabrication, ensuring every component fits both mechanically and economically.

Electrical Insulation and Flame Retardancy

Beyond mechanical strength, engineering polymers are powerful insulators.

Their high dielectric strength, low dissipation factor, and resistance to tracking make them essential in electronics, power systems, and EV battery assemblies.

| Property | Typical Value | Key Polymers |

|---|---|---|

| Dielectric Strength (kV/mm) | 15–35 | PC, PPS, PA, PEEK |

| Surface Resistivity (Ω/sq) | >10¹⁴ | POM, PTFE |

| Flame Rating (UL94) | V-0 / V-2 | FR-PC, FR-PBT, PPS |

With proper flame-retardant additives (halogen-free or phosphorus-based), polymers can meet UL94 V-0 and IEC 60695 safety ratings while maintaining mechanical strength.

For critical applications like connectors, housings, and insulators, Yana Sourcing ensures materials are UL-listed and RoHS-compliant, simplifying both production and certification.

Major Types of Engineering Polymers

Every engineering polymer tells a different story. Some were born from the aerospace industry’s need for high-temperature stability; others from the automotive world’s pursuit of lightweight precision.

Together, they form the structural and functional foundation of modern products, balancing performance, cost, and manufacturability.

Below are the seven polymer families that dominate industrial design, manufacturing, and sourcing today.

Polyamide (PA, Nylon 6, Nylon 6/6, Nylon 12)

Polyamides, known commercially as Nylon, are the most common engineering polymers in mechanical design.

They combine strength, toughness, and self-lubricating properties that make them ideal for gears, bearings, and under-hood automotive components.

| Property | Value Range | Remarks |

|---|---|---|

| Tensile Strength | 70–90 MPa | Comparable to cast aluminum |

| Continuous Use Temp | 100–130°C | Higher with glass filling |

| Water Absorption | 1–2% | Controlled via stabilizers |

| Density | 1.13 g/cm³ | Lightweight yet strong |

Nylon 6/6 (PA66) offers the best mechanical balance, while Nylon 12 (PA12) provides low moisture uptake and superior chemical resistance.

Glass-filled versions (PA66-GF30) deliver rigidity near aluminum levels, making them excellent for mounting brackets and structural housings.

Yana Sourcing helps clients choose stabilized or reinforced PA compounds, verifying certifications like UL94, ISO 1043, and ASTM D4066 for consistency across suppliers.

Polycarbonate (PC)

Polycarbonate is the go-to transparent engineering polymer for impact resistance.

It offers glass-like clarity combined with extraordinary toughness, making it ideal for lighting covers, enclosures, and protective shields.

- Impact strength: up to 900 J/m (20× higher than acrylic).

- Glass transition temperature: 145°C.

- Dielectric strength: 15–20 kV/mm.

PC is easy to mold and thermoform, allowing freedom of design.

When blended with ABS (PC/ABS), it achieves better heat and dimensional stability while maintaining excellent surface finish, common in automotive interiors and electronic housings.

Yana Sourcing ensures all PC grades are UV-stabilized, flame-retardant, and RoHS-certified, suitable for both indoor and outdoor applications.

Polyoxymethylene (POM, Acetal)

Also called Acetal, POM is the precision engineer’s plastic — a polymer made for mechanical parts, gears, valves, and bearings where metal once dominated.

Its low friction coefficient and dimensional accuracy make it a staple in machinery, automotive, and consumer products.

| Property | Typical Value | Note |

|---|---|---|

| Density | 1.41 g/cm³ | Medium weight |

| Tensile Strength | 70–100 MPa | High stiffness |

| Friction Coefficient | 0.2–0.3 | Self-lubricating |

| Water Absorption | <0.5% | Highly stable |

Available in homopolymer (POM-H) and copolymer (POM-C) versions, Acetal provides excellent creep resistance, machinability, and fatigue life.

For sourcing, Yana Sourcing supplies FDA-compliant and wear-modified POM for industrial and food-contact applications.

Polyetheretherketone (PEEK)

PEEK is the superstar of high-performance engineering polymers, capable of replacing metal in extreme conditions.

With tensile strength up to 100 MPa, melting point near 343°C, and chemical resistance rivaling PTFE, PEEK performs in aerospace, oil & gas, medical, and semiconductor environments.

- Retains 85% of mechanical strength up to 250°C.

- Resists most solvents, acids, and radiation.

- Exhibits extremely low wear and outgassing.

Reinforced grades with carbon fiber (CF-PEEK) or glass fiber (GF-PEEK) enhance stiffness and conductivity, making them ideal for robotic joints, compressor parts, and insulative spacers.

Yana Sourcing partners with licensed manufacturers providing ASTM D6262 / ISO 10931 certified PEEK with guaranteed lot traceability.

Polytetrafluoroethylene (PTFE)

Better known as Teflon, PTFE is famous for its frictionless surface and chemical inertness.

It is the most chemically resistant polymer known, unaffected by nearly all acids, solvents, and bases.

| Property | Typical Value |

|---|---|

| Service Temperature | -200 to +260°C |

| Friction Coefficient | 0.04 |

| Water Absorption | <0.01% |

| Dielectric Strength | 60 kV/mm |

These properties make PTFE indispensable in chemical processing, seals, gaskets, valves, and insulation.

Though difficult to process (non-melt-flowing), PTFE can be compression molded, skived, or sintered into precision shapes.

Yana Sourcing ensures PTFE sourcing from ISO 9001-certified mills, offering FDA, CE, and food-grade versions for specialized markets.

Polyphenylene Sulfide (PPS)

PPS bridges the gap between medium and high-performance engineering polymers, providing excellent heat and chemical resistance with stable electrical properties.

It can be injection molded, extruded, or reinforced with glass or carbon fiber.

- Heat deflection temperature: 260°C.

- Excellent dimensional stability and stiffness.

- UL94 V-0 flame rating without additives.

Used in automotive sensors, electronic connectors, and pump housings, PPS offers consistent performance even in corrosive fluids or prolonged thermal exposure.

Yana Sourcing supplies UL-listed and glass-filled PPS compounds optimized for both mechanical and dielectric performance.

Thermoplastic Polyurethane (TPU)

TPU combines elasticity with abrasion resistance, bridging the gap between rubber and plastic.

It remains flexible in cold temperatures and resilient under repeated stress, ideal for cables, seals, rollers, and wearable components.

| Property | Typical Value | Note |

|---|---|---|

| Hardness (Shore A/D) | 70A–75D | Customizable |

| Elongation at Break | 400–600% | Excellent resilience |

| Abrasion Resistance | Superior | Outlasts rubber 5× |

| Temperature Range | -50 to +100°C | Flexible yet stable |

Yana Sourcing offers ester-based TPU for mechanical toughness and ether-based TPU for hydrolysis resistance.

Both types can be extruded, overmolded, or 3D printed, enabling modern design flexibility.

Processing and Fabrication Considerations

How a polymer is processed defines its final performance as much as its chemistry.

Two components made from the same engineering polymer can behave completely differently if one was dried poorly or molded under the wrong conditions.

In a world shifting from metal machining to polymer precision, understanding fabrication is not optional, it’s essential.

At Yana Sourcing, we work with verified processors and compounders who treat polymers like what they are: engineered materials, not commodities.

Injection Molding, Extrusion, and Machining

Most engineering polymers are thermoplastics, which means they soften with heat and can be reshaped repeatedly, but only if thermal history is carefully controlled.

| Process | Suitable Polymers | Key Control Factors | Common Uses |

|---|---|---|---|

| Injection Molding | PA, PC, POM, PPS, TPU | Melt temperature, pressure, cooling rate | Gears, housings, connectors |

| Extrusion | PA, PC, PTFE, TPU | Melt uniformity, die temperature | Tubes, films, wire coatings |

| Machining | POM, PTFE, PEEK | Tool geometry, chip removal, feed rate | Bushings, spacers, custom prototypes |

| Compression / Transfer Molding | PTFE, PPS | Pressure and dwell time | Seals, gaskets, insulators |

Injection molding dominates for volume manufacturing. Its cycle control defines surface quality, dimensional accuracy, and mechanical consistency.

For high-temperature polymers like PEEK or PPS, specialized tooling and mold steels are required to handle melting points above 300°C.

Machining remains vital for prototyping, medical, and small-lot precision parts, especially where tolerances are tighter than ±0.05 mm.

Yana Sourcing collaborates with ISO 13485 and IATF 16949-certified molders, ensuring that process stability aligns with global quality standards.

Drying, Crystallization, and Annealing

Many engineering polymers are hygroscopic, they absorb moisture, which can degrade molecular weight during processing and weaken the final product.

Proper drying is the simplest yet most overlooked form of quality control.

| Polymer | Pre-Drying Temp (°C) | Time (hrs) | Notes |

|---|---|---|---|

| PA6 / PA66 | 80 | 4–6 | Must be dry to <0.2% moisture |

| PC | 120 | 3–4 | Prevent hydrolytic degradation |

| POM | 100 | 2 | Prevent surface pitting |

| PEEK | 150 | 2–3 | Use vacuum or desiccant dryer |

| TPU | 90 | 2–4 | Avoid bubbles and voids |

Crystallization defines rigidity and shrinkage.

Semi-crystalline polymers (like POM, PPS, PEEK) gain stiffness through controlled cooling, while amorphous types (PC, PMMA) depend on slow cooling to minimize warping.

Annealing, post-heating below the melting point, relieves internal stresses, improving dimensional stability and fatigue resistance.

Yana Sourcing verifies supplier process charts for drying, molding, and annealing, preventing invisible issues that would otherwise emerge in later testing or field use.

Reinforced Polymers (Glass Fiber, Carbon Fiber, and Additives)

To push polymers into new performance zones, manufacturers add reinforcements or modifiers that transform baseline materials into structural-grade solutions.

| Reinforcement | Function | Typical % | Example Polymer |

|---|---|---|---|

| Glass Fiber (GF) | Stiffness, heat resistance | 20–40% | PA6-GF30, PPS-GF40 |

| Carbon Fiber (CF) | Strength, conductivity, wear resistance | 10–30% | PEEK-CF30 |

| PTFE Fillers | Low friction | 5–15% | POM + PTFE |

| Mineral / Talc | Dimensional stability | 10–40% | PP-Talc, PA-Mineral |

| Flame Retardants | Fire safety (UL94 V-0) | Varies | FR-PC, FR-PBT |

| Impact Modifiers | Toughness, cold resistance | 5–15% | ABS, PC/ABS |

The challenge is that every filler affects flow, shrinkage, surface finish, and machining behavior.

Yana Sourcing helps clients interpret compound data sheets and rheology curves, choosing reinforcement levels that maintain both performance and manufacturability.

Tolerance Control and Shrinkage Management

Polymers expand and contract far more than metals.

A PA6-GF30 bracket and an aluminum alloy part may fit perfectly at room temperature, but diverge by several millimeters after heat exposure.

To ensure fit and function, every engineering polymer must be modeled with its shrinkage and thermal expansion coefficients.

| Polymer | Typical Shrinkage (%) | Linear Expansion (×10⁻⁵/°C) |

|---|---|---|

| POM | 2.0 | 10–12 |

| PA6-GF30 | 0.8 | 5–8 |

| PC/ABS | 0.6 | 7–10 |

| PEEK-CF30 | 0.3 | 3–4 |

| TPU | 1.2 | 15–20 |

Simulation tools like Moldflow and Ansys are used to predict shrinkage and warp before tooling begins.

Yana Sourcing integrates these data into the sourcing phase, aligning design tolerances with supplier capabilities to minimize rework and assembly misfits.

Performance vs Cost: Selecting the Right Polymer

Choosing the right engineering polymer is as much a business decision as it is a technical one.

A material that seems expensive per kilogram may cut total cost once tooling, assembly, and lifecycle savings are factored in.

At Yana Sourcing, we help clients navigate this equation, matching each polymer’s performance tier to real-world cost and sustainability goals.

Mechanical vs Thermal Priorities

The starting point is always understanding what matters more: mechanical strength, thermal resistance, or chemical stability.

No single engineering polymer excels at everything, each represents a trade-off between stiffness, toughness, and processability.

| Polymer | Key Strength | Limitation | Ideal Use |

|---|---|---|---|

| PA6/PA66 | Strength, fatigue resistance | Moisture absorption | Mechanical parts, gears |

| PC | Impact resistance, clarity | Sensitive to solvents | Lighting, electronics |

| POM | Precision, low friction | Poor UV stability | Bearings, gears, valves |

| PPS | Chemical and thermal stability | Brittle in thin walls | Electrical housings |

| PEEK | Extreme temperature resistance | High cost | Aerospace, medical |

| PTFE | Chemical inertness, low friction | Difficult to process | Seals, gaskets, coatings |

| TPU | Elasticity, abrasion resistance | Limited high-temp strength | Cables, seals, footwear |

The right polymer depends on failure mode, whether a component will crack, soften, creep, or erode.

Yana Sourcing uses failure-mapping tools that correlate stress, strain, and environment, helping teams select materials with quantified risk margins.

Comparing Engineering Polymers to Metals

One of the most strategic uses of engineering polymers is as a replacement for metal, not to imitate it, but to outperform it where it matters.

| Property | Aluminum | Steel | Engineering Polymers (Reinforced) |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.8 | 1.2–1.6 |

| Yield Strength (MPa) | 150–400 | 250–800 | 100–200 (reinforced) |

| Thermal Conductivity (W/m·K) | 205 | 50 | 0.3–0.4 |

| Corrosion Resistance | Good | Moderate | Excellent |

| Machinability | Good | Moderate | Excellent (POM, PA, PEEK) |

| Electrical Insulation | Poor | Poor | Excellent |

| Recyclability | High | High | Increasing (select polymers) |

While metals dominate in stiffness and thermal conductivity, engineering polymers win in mass efficiency, corrosion resistance, and design freedom.

Replacing aluminum or steel with glass-filled polymers can yield 30–60% weight reduction and simplify multi-part assemblies into single molded components.

Yana Sourcing evaluates these trade-offs holistically, comparing cost per part, energy efficiency, and supply risk to guide strategic material substitution.

Environmental and Regulatory Considerations

Sustainability is now a defining metric in polymer sourcing.

Clients increasingly require materials that meet both performance and environmental compliance, reducing carbon footprint without sacrificing durability.

♻️ Sustainability and Recyclability

- Recycled Engineering Polymers (rPA, rPC, rPBT): Offer up to 40% carbon reduction with mechanical properties near virgin grades.

- Bio-based Polymers (PA11, PLA blends): Derived from renewable feedstocks like castor oil or corn starch.

- Closed-Loop Supply Chains: Post-industrial scrap reprocessed into new technical parts.

⚖️ Regulatory Compliance

Every engineering polymer sourced for global markets must meet strict certification:

- RoHS / REACH: Restrict hazardous substances and ensure traceability.

- UL94 / IEC 60695: Define flame-retardant classifications (V-0, HB).

- ISO 10993 / FDA: Regulate biocompatibility for medical polymers.

- IATF 16949: Ensures consistency in automotive polymer components.

Yana Sourcing verifies material test certificates (MTCs) and sustainability documentation, integrating compliance directly into the sourcing workflow so clients can pass audits without delay.

Economic Tiering: Cost vs Performance Matrix

| Polymer Tier | Example Materials | Typical Cost (USD/kg) | Core Benefit |

|---|---|---|---|

| High-Performance | PEEK, PPS, LCP | 25–80 | Replaces metal in aerospace & medical |

| Mid-Performance | PA66, POM, PC/ABS | 5–10 | Mechanical and electrical balance |

| Value-Optimized | PP, ABS, rPA | 2–5 | Durable, low-cost structural plastics |

A PEEK bracket might cost 10× more than an aluminum one per kilogram, but weigh half as much, assemble faster, and last twice as long.

That’s the type of system-level efficiency Yana Sourcing quantifies when helping clients make material decisions.

Real-World Applications and Case Studies

The impact of engineering polymers is everywhere, in vehicles that weigh less, planes that fly farther, devices that last longer.

Each success story begins not with replacing metal for the sake of cost, but with rethinking what materials can achieve.

At Yana Sourcing, we turn this rethinking into sourcing action, matching polymers, processes, and performance metrics to your product vision.

Case Study 1 — Automotive and EV Components

Challenge:

A European EV startup sought to reduce vehicle weight without compromising safety in under-hood assemblies and interior parts.

Aluminum brackets added cost, corrosion risk, and excess mass.

Solution:

Yana Sourcing sourced PA66-GF30 and PPS-GF40 compounds certified under IATF 16949.

Both materials provided the necessary rigidity and heat stability, replacing multiple metal parts with single molded components.

We validated all grades with UL94 V-0 flame tests and ISO 527 tensile reports.

Outcome:

- Weight reduced by 38%.

- Assembly time cut by 25%.

- Production cost down by 12%.

The client later extended polymer conversion to battery tray housings and HVAC systems, proving the scalability of engineering polymers in EV manufacturing.

Case Study 2 — Aerospace Interiors and Structural Components

Challenge:

An aircraft interior manufacturer required high-temperature, low-toxicity polymers for cabin brackets and duct connectors.

Traditional thermosets lacked flexibility, while metal parts added unnecessary mass.

Solution:

Yana Sourcing introduced carbon fiber–reinforced PEEK (PEEK-CF30) and flame-retardant PPS formulations compliant with FAR 25.853 flammability standards.

We coordinated prototype runs with an aerospace-certified injection molder.

Outcome:

- Weight savings: 42% vs aluminum.

- Thermal stability: maintained up to 250°C.

- Toxic gas emission: <0.05% in fire tests.

These results allowed certification under EN 45545-2, confirming that high-performance polymers can meet aviation-grade safety and performance simultaneously.

Case Study 3 — Electronics and Energy Systems

Challenge:

An electronics OEM in Korea needed a flame-retardant housing material for 48V converters.

PC/ABS blends failed to meet the target UL94 V-0 rating at thin walls (<1.5 mm).

Solution:

Yana Sourcing recommended glass-filled PPS with halogen-free flame retardants.

We ensured compliance with RoHS 3, REACH SVHC, and IEC 60695 glow-wire testing.

Final molding was completed using hot-runner tools to maintain surface finish.

Outcome:

- Passed UL94 V-0 at 1.2 mm thickness.

- Thermal stability up to 230°C.

- Improved assembly yield by 18%.

The project validated the role of engineering polymers in thermal management and electrical safety, a key advantage in EV and renewable energy systems.

Case Study 4 — Medical Devices and Surgical Equipment

Challenge:

A U.S. medical startup required biocompatible, sterilization-resistant polymer components for handheld surgical tools.

Standard PC/ABS blends failed repeated autoclave cycles.

Solution:

Yana Sourcing sourced medical-grade PEEK (ASTM F2026, ISO 10993), and coordinated FDA 510(k) material traceability documentation.

We verified sterilization resistance under steam (134°C), gamma, and EtO conditions.

Outcome:

- Zero degradation after 100 sterilization cycles.

- Reduced device mass by 35%.

- Passed FDA submission on first review.

By enabling medical compliance and precision, this case showed how engineering polymers merge technology and trust in healthcare manufacturing.

Case Study 5 — Industrial Machinery and Automation

Challenge:

A German robotics integrator wanted to replace machined brass bushings and aluminum spacers in robotic joints to reduce inertia and wear.

Solution:

Yana Sourcing delivered PTFE- and POM-based wear-resistant compounds, CNC-machined to ±0.02 mm tolerance.

These materials provided low friction without lubrication and stable performance across temperature ranges.

Outcome:

- Energy efficiency +9%.

- Maintenance interval doubled.

- Cost reduction of 28% over 2 years.

The project demonstrated how engineering polymers can extend mechanical lifespan and simplify assembly in motion systems.

Conclusion — The Plastic That Outperforms Metal

In an age where every gram, watt, and degree counts, engineering polymers have emerged as the quiet revolution in material science.

They are no longer “plastic parts,” but precision materials, designed, tested, and trusted across the world’s most demanding industries.

From the torque of an EV motor to the sterility of surgical tools, these polymers prove that lightness can be strong, flexible can be durable, and sustainable can be profitable.

Each polymer, nylon, PEEK, PPS, PTFE, or TPU, represents a different kind of intelligence: the ability to adapt form and function without compromise.

They enable a generation of designers and engineers to rethink structures, reduce waste, and build the future lighter, cleaner, and faster.

At Yana Sourcing, we don’t just find suppliers, we translate material data into strategy.

We connect your specifications with certified compounders and molders across China, Europe, and Japan, ensuring your chosen polymer meets ASTM, ISO, and UL standards from prototype to mass production.

Partner with Yana Sourcing for Certified Polymer Solutions

Why Work With Us

- Engineering-Led Sourcing: We match material performance to your real-world product demands, not just datasheets.

- Certified Supply Chain: Every compounder verified under ISO 9001, IATF 16949, and RoHS/REACH.

- From Prototype to Scale: We support injection molding, CNC machining, and additive manufacturing partners worldwide.

Get Expert Material Support

Send us your part drawings, application environment, and volume estimates, and we’ll recommend the right engineering polymer and compound formulation, balancing performance, compliance, and cost.

📩 Contact Yana Sourcing today to discover how high-performance polymers can strengthen your products while lightening your production load.