Table of Contents

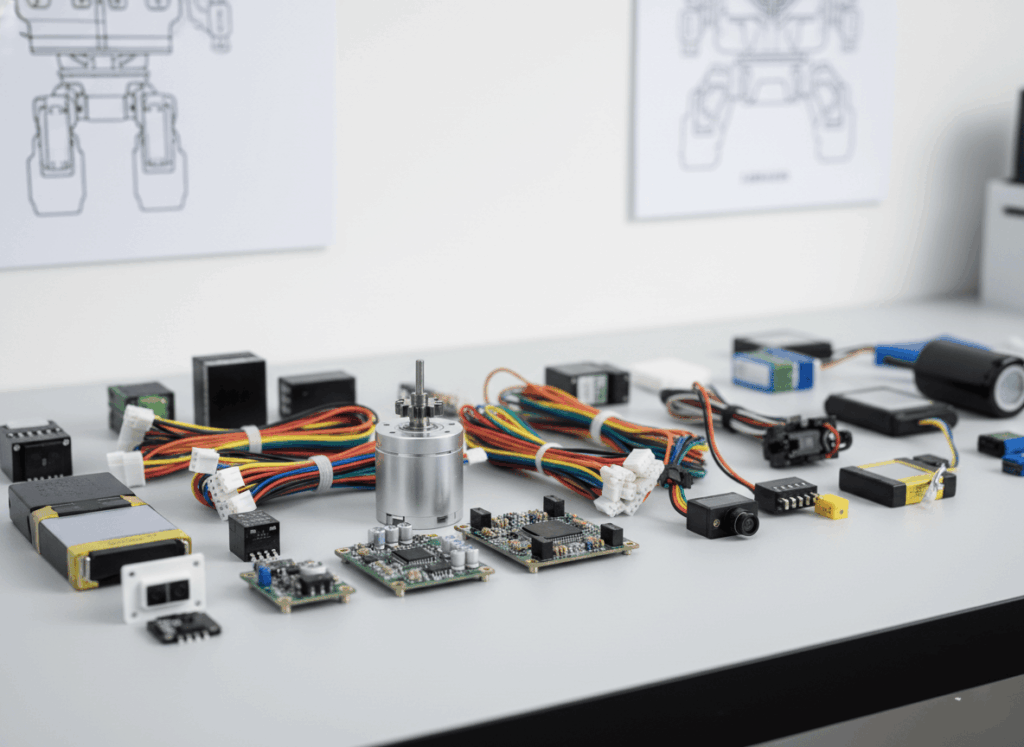

Electrical components form the skeleton and nervous system of every modern device. From the printed circuit board (PCB) hidden inside your smartphone to the power supply that keeps a factory running, electrical components are the foundation that translate ideas into reality.

For brands and engineers seeking to create world‑class products, sourcing these parts is not merely an exercise in procurement; it is a strategic decision that affects product quality, reliability, regulatory compliance and even brand reputation. In this comprehensive guide you will learn how to source electrical components effectively, understand their categories, and integrate them into your supply chain.

Along the way you will gain proven strategies and learn how Yana Sourcing can support your vision to build a higher‑dimensional business.

1. Why Electrical Components Matter in Modern Manufacturing

Electrical components are more than just parts; they are the building blocks that allow electronic systems to function. Inside a PCB, resistors regulate current, capacitors store and release energy, inductors filter signals, and semiconductors make logic operations possible. Researchers classify electrical components into passive, active and integrated circuits.

Passive components like resistors oppose current and control voltage; capacitors temporarily store electrical energy, filter noise and regulate voltage; inductors store energy in a magnetic field and help filter unwanted signals. Active components, including diodes and transistors, amplify signals or switch currents. Integrated circuits combine many active and passive elements into a single package, shrinking size and increasing functionality.

This classification matters because each category has different sourcing requirements. Passive components such as resistors and capacitors are standardised and available from a wide network of suppliers, whereas active components or integrated circuits may have limited suppliers and require closer relationships with original manufacturers.

Understanding the distinction helps you prioritise your procurement strategy and risk management. For example, sourcing capacitors may involve verifying tolerance values and dielectric materials, while sourcing integrated circuits requires navigating proprietary technologies, licensing restrictions and supply‑chain disruptions.

2. Key Categories of Electrical Components

To build a reliable product, you must understand the major categories of electrical components that go into it. This section focuses on four categories, PCBs, connectors, wiring harnesses and power supplies, along with examples, applications and sourcing considerations.

2.1 Printed Circuit Boards (PCBs)

A PCB is a rigid or flexible board that mechanically supports and electrically connects electrical components. Copper tracks on the board provide the pathways for signals and power, while soldered components perform specific functions. PCBs may be single‑sided, double‑sided or multi‑layer; the choice depends on complexity, space constraints and cost.

When sourcing PCBs, consider factors such as material type (FR‑4 vs. polyimide for flex boards), layer count, copper thickness, board thickness, surface finish and manufacturing tolerances. Multi‑layer boards require precise lamination and alignment, while flexible PCBs require materials that withstand bending and heat. Because PCBs underpin the functionality of your product, ensure suppliers have quality certifications (ISO 9001, UL) and consistent manufacturing processes.

2.2 Connectors and Interconnects

Connectors are the electrical structural components linking electronic devices and circuits. They serve as the bridge between disconnected or isolated circuits, ensuring smooth flow of current or signals. Without reliable connectors, signals degrade, power may be lost and products may fail prematurely. Connectors vary widely, from board‑to‑board connectors, USB connectors and coaxial connectors to high‑speed data connectors like HDMI or PCIe.

When sourcing connectors, consider current rating, voltage rating, contact resistance, mating cycles (durability), materials (gold plating vs. tin), operating temperature and environmental sealing (IP rating). For high‑speed applications, signal integrity and impedance control are essential. Because connectors physically join assemblies, mechanical robustness and design compatibility are as important as electrical specifications. Many failures in electronic products stem from connectors that degrade under vibration, moisture or wear; hence verifying test reports, certifications and sample evaluation is critical.

2.3 Wiring Harnesses

A wiring harness is a systematic assembly of multiple wires organised together to transmit signals or electrical power. Essentially, it is a bundle of cables with connectors that simplifies installation and ensures organised routing. Harnesses evolved from the 19th century’s early cable assemblies, expanding into the automotive and aerospace industries and then into household appliances and electronics. They are used to organise wires, provide mechanical protection, and improve space utilisation.

Wiring harness components include wires, connectors, terminals, sleeves and protective coverings. Manufacturing a harness involves planning wire lengths, cutting and stripping wires, crimping or soldering connectors, bundling and applying insulation. Quality control tests for continuity, insulation resistance and mechanical strength ensure reliability. Harnesses must meet industry standards (e.g., IPC/WHMA‑A‑620) and often require customised layouts for each product.

When sourcing harnesses, check whether suppliers offer prototyping, design support and adaptability to design changes. Because harnesses integrate many wires, errors or inconsistencies can cause system failures, making supplier quality control vital.

In recent years, harnesses have trended towards lightweight and compact designs and smart or integrated solutions. For example, automotive harnesses incorporate data cables and sensors, while aerospace harnesses emphasise weight savings and high reliability. Knowing these trends helps you anticipate future requirements and collaborate with innovative suppliers who can deliver next‑generation harness technology.

2.4 Power Supplies

A power supply is an electrical device that supplies electric power to a load. Its main purpose is to convert electric current from a source to the correct voltage, current and frequency to power the load. Functions can include current limiting, noise filtering, power factor correction, energy storage (as in uninterruptible power supplies), and safety measures. Power supplies range from small AC‑to‑DC converters used in chargers to sophisticated switching power supplies used in servers.

When sourcing power supplies, evaluate input range, output voltage and current, efficiency (how much energy is lost as heat), regulation (how stable the output remains under varying loads), protection features (over‑current, over‑voltage, short‑circuit), certifications (UL, CE, FCC) and form factor.

For products sold internationally, ensure compliance with regional safety standards. For industrial equipment, consider custom power supply modules that fit into your enclosure and support redundancy. Some industries require power supplies with medical‑grade isolation or military‑grade ruggedness. Because power supplies convert energy and dissipate heat, thermal management and efficiency directly impact product reliability.

3. The Chinese Supply Landscape for Electrical Components

China is the world’s largest manufacturing hub for electrical components. According to reports from 2024, China’s electronic information manufacturing sector delivered robust growth: the value‑added output of the electronic manufacturing industry rose by 11.8 percent compared with industrial growth as a whole.

The sector covers a wide array of products and components, ranging from integrated circuits to consumer electronics, and plays a significant role in economic growth and technological innovation. This growth is supported by government policies, an extensive supply chain network, and a skilled workforce. For companies looking to source electrical components, China offers unmatched breadth and scale.

Yet sourcing from China requires understanding the regional distribution of manufacturing hubs. Coastal provinces like Guangdong, Jiangsu and Zhejiang host numerous suppliers for PCBs, connectors and harnesses. Cities such as Shenzhen and Dongguan specialise in electronics assembly and are home to hundreds of contract manufacturers. Inland regions are growing in importance as manufacturers expand operations.

Prospective buyers should evaluate the local infrastructure, government incentives, labour costs and logistics capabilities of each region. In addition, geopolitical dynamics, tariffs and trade agreements can influence cost and lead times. Working with experienced sourcing partners based in China, such as Yana Sourcing, can help navigate this complex environment.

4. Quality Control & Compliance for Electrical Components

Quality control (QC) is the linchpin of successful electrical components sourcing. Components must meet specified electrical, mechanical and environmental requirements to ensure product safety and customer satisfaction. When selecting suppliers, confirm that they adhere to quality management systems (ISO 9001), environmental management (ISO 14001), and, where appropriate, automotive (IATF 16949) or aerospace (AS9100) standards. These systems ensure consistent process control and continuous improvement.

For PCBs, critical QC parameters include board thickness, copper thickness, hole diameter tolerance, surface finish quality (e.g., ENIG vs. HASL), solderability and cleanliness. Automated optical inspection (AOI), X‑ray testing and flying probe tests verify trace integrity and drilling accuracy. For connectors, QC involves verifying contact resistance, insulation resistance, vibration resistance and durability (mating cycles). For wiring harnesses, tests include continuity (checking for open circuits), insulation resistance, pull tests on crimped terminals, and high‑voltage testing.

Harnesses for automotive or aerospace applications must meet specific industry standards like UL 758 or MIL‑STD‑1344. Power supplies require load testing across the full operating range, burn‑in tests, ripple and noise measurement, and electromagnetic compatibility (EMC) compliance.

Compliance also extends to environmental regulations. Many markets require adherence to Restriction of Hazardous Substances (RoHS) directives, which limit the use of lead, mercury, cadmium and other toxic substances. Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulations require suppliers to disclose the presence of certain chemicals.

For lithium battery products, UN 38.3 certification ensures safe transport. Without compliance, your shipments may be held at customs or banned from certain regions. As supply chains globalise, verifying your suppliers’ certifications and test reports becomes non‑negotiable.

5. Cost Drivers & Logistics in Electrical Components Sourcing

Understanding cost drivers helps you forecast expenses and plan budgets. Key factors influencing the cost of electrical components include:

- Materials: The price of copper (used for PCB traces and wiring) and precious metals (gold plating on connectors) fluctuates with global commodity markets. Similarly, the cost of semiconductors depends on wafer supply and demand.

- Design Complexity: Multi‑layer PCBs, precision connectors and custom harnesses require more complex tooling and labour, increasing cost. Tight tolerances and special materials (e.g., high‑frequency laminate for RF PCBs) also raise prices.

- Labour and Automation: In China, labour costs vary by region. Complex harnesses with many manual steps may require semi‑automation to maintain competitiveness. Investing in automation can reduce long‑term costs but requires volume to justify the investment.

- Production Volume (MOQ): Suppliers often set minimum order quantities (MOQs). A larger order can reduce unit cost due to economies of scale, but tying up capital in inventory carries risk. Balancing MOQs with inventory strategy is crucial.

- Quality Requirements: Higher reliability components (e.g., automotive grade connectors, aerospace‑grade harnesses) cost more due to stricter materials, testing and certification requirements.

- Tariffs and Duties: Trade policies can add customs duties, anti‑dumping tariffs or value‑added tax (VAT). For example, exporting from China to the United States may involve import duties depending on the product code. Engaging a trade expert helps anticipate costs.

- Logistics and Shipping: Shipping costs depend on product weight, volume and shipping method (air, sea, rail). Lead times for sea freight can be 4–6 weeks, while air freight is faster but more expensive. Pandemic‑related disruptions have shown the importance of diversified logistics planning.

To manage these costs, consider multi‑sourcing (working with multiple suppliers to leverage competition), long‑term contracts, and supply chain resilience strategies. For critical electrical components with long lead times or constrained availability (such as chips or high‑reliability connectors), maintain strategic stock or negotiate supply guarantees. Working with a sourcing partner familiar with local market conditions helps you secure favourable pricing and avoid overpaying.

6. Integrating Electrical Components into Complete Solutions

An electronic product is more than a collection of individual parts; it is an integrated system. PCBs, connectors, wiring harnesses and power supplies must work seamlessly together. When designing a product, collaborate early with your suppliers and engineers to ensure compatibility. For example:

- Mechanical Fit: Connector footprints must match the PCB layout; harness lengths must match the enclosure design; power supply mounting holes must align with chassis supports.

- Electrical Compatibility: Voltage and current ratings across components must match system requirements. A mismatched power supply could cause undervoltage or overload conditions.

- Signal Integrity: High‑speed signals require controlled impedance across PCB traces, connectors and harnesses. Consider using differential pair routing and shielding to minimise crosstalk.

- Thermal Management: PCBs and power supplies generate heat. Thermal vias, heat sinks and proper airflow design maintain reliability.

- Regulatory Compliance: Ensure that the combination of components does not violate safety standards or EMC emissions limits.

By thinking in terms of systems rather than parts, you can reduce engineering changes later and avoid costly rework. Many design houses work closely with component suppliers to co‑design parts that meet performance, cost and manufacturability targets. Yana Sourcing supports this integration by connecting you with design‑capable suppliers and providing feedback during the product development cycle.

7. How Yana Sourcing Secures Your Electrical Components Supply Chain

At Yana Sourcing we believe that sourcing the future involves more than negotiation—it requires deep expertise, trust and empathy. We view sourcing as a partnership between our clients, our vetted suppliers and our engineering team. For electrical components, we provide the following value:

- Supplier Network: Our network includes ISO‑certified manufacturers of PCBs, connectors, harnesses and power supplies across China. We maintain a database of each supplier’s capabilities, certifications and performance history.

- Quality Assurance: We conduct factory audits, verify certifications and oversee production. Our quality inspectors perform on‑site checks, including sample testing, dimensional verification and functional tests.

- Design Support: For complex harnesses or custom connectors, we collaborate with engineering partners to optimise designs for manufacturability, reducing cost and lead times.

- Regulatory Compliance: We ensure suppliers meet international standards such as RoHS, REACH and UL. We assist with documentation and customs paperwork to smooth cross‑border logistics.

- Logistics & Consolidation: We manage shipping from multiple suppliers, consolidate shipments, and handle customs clearance. This reduces shipping cost and simplifies your supply chain.

- Risk Management: We monitor geopolitical developments, tariff changes and supply chain disruptions. We advise clients on alternative suppliers, diversification strategies and inventory buffers to ensure resilience.

- Heart‑Centred Partnership: Yana stands for “You Are Not Alone.” We approach every project with empathy, understanding that behind every electronic product there is a team of people with dreams. We aim to be not just the next‑level sourcing partner but a higher‑dimensional consultant who cares about your success.

8. Electrical Components Sourcing Checklist: 10 Steps to Success

To help you apply the insights from this guide, we offer the following checklist. Each step reinforces the importance of the focus keyword.

- Define Requirements: Clarify specifications for all electrical components, including electrical, mechanical, environmental and regulatory parameters.

- Identify Qualified Suppliers: Research and evaluate manufacturers of electrical components based on certifications, capabilities, location and communication responsiveness.

- Sample and Test: Request samples of electrical components and perform laboratory tests to verify performance and durability.

- Evaluate Costs: Analyse quotes for electrical components including material costs, labour, tooling, MOQs, packaging and logistics.

- Check Compliance: Ensure your electrical components supplier provides test reports and declarations of conformity (RoHS, REACH, UL, CE).

- Negotiate Contracts: Agree on pricing, payment terms, lead times, and quality obligations for each batch of electrical components.

- Plan Logistics: Determine shipping method and schedule to ensure timely delivery of electrical components; coordinate consolidation and packaging.

- Monitor Production: Use inspections and production monitoring to check that electrical components are manufactured to spec and on schedule.

- Manage Inventory: Balance safety stock and inventory turns to avoid shortages or excess of electrical components.

- Review and Improve: After each project, evaluate supplier performance and internal processes to continuously improve electrical components sourcing.

9. Conclusion: Sourcing with Heart and Intelligence

Sourcing electrical components is a journey that combines technical knowledge, market insight and human connection. By understanding the nature of different components, resistors and capacitors, connectors, wiring harnesses and power supplies, and by grasping the dynamics of the Chinese manufacturing landscape, you can make informed decisions. Quality control, compliance and cost management provide the technical backbone of sourcing, while integration thinking ensures that components come together into a cohesive system.

Yet the ultimate success of electrical components sourcing lies in building relationships. Yana Sourcing stands with you, bridging cultures, translating requirements, and advocating for your interests.

Whether you are a startup designing your first gadget, a mid‑market brand scaling production, or an enterprise launching an innovative product, contact us today, Yana Sourcing is ready to accompany you. Together we will source the future, one electrical component at a time.