Table of Contents

The Quiet Mechanics Behind Controlled Motion

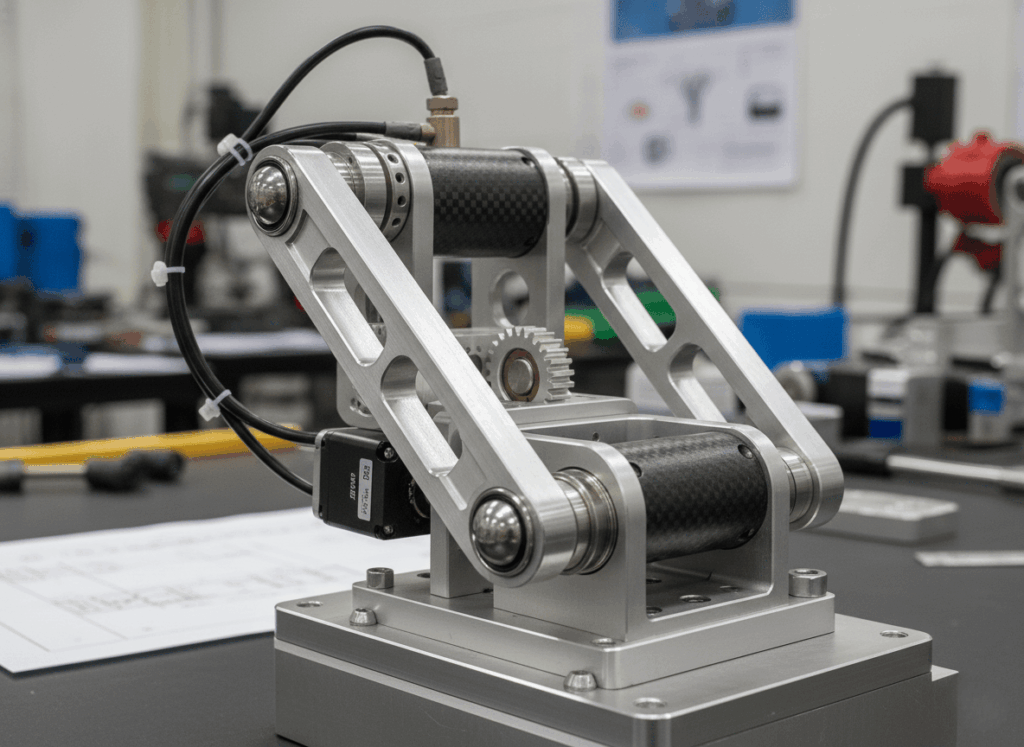

In the world of physical products, linkages are everywhere, yet they often go unnoticed. They sit inside the mechanisms we use daily, silently converting one type of motion into another. A linkage can transform rotation into straight‑line movement, amplify or reduce a distance, maintain a constant orientation, or synchronize multiple motions at once.

When engineered thoughtfully, linkages give a product its signature feel: the smooth arc of a door handle, the satisfying snap of a folding phone hinge, or the fluid stride of a robotic limb. When they are poorly chosen or badly made, those same linkages introduce slack, chatter, misalignment, and premature wear. This article explores linkages from the ground up: their types, their roles in reliable motion, how to select them, and how a high‑dimensional sourcing partner like Yana ensures that each linkage supports your product’s emotional and functional goals.

The Functional Role of Linkages in Product Development

The fundamental job of linkages is to transfer and transform motion. In its simplest form, a linkage is a system of rigid bars connected by joints that allow relative movement. That system may translate rotary motion into linear motion or vice versa, change the direction of movement, or amplify or reduce movement distances. For example, in an internal combustion engine, the slider‑crank linkage transforms the up‑and‑down motion of the piston into rotation of the crankshaft.

In a walking robot, linkages allow multiple legs to move in coordination, making the machine’s gait stable and natural. In every case, the way the linkage is designed and integrated influences the product’s feel. A sloppy, over‑flexible linkage results in wobble or backlash; a stiff, overly constrained linkage may make a mechanism feel brittle. Achieving the right balance requires understanding both the functional requirements and the user’s perception of quality.

Motion Transformation and Control

At the heart of many mechanisms is the need to change the type or magnitude of motion. Linkages accomplish this by combining simple joints into more complex structures. A common four‑bar linkage, for example, consists of four rigid rods connected to form a loop.

By carefully choosing the lengths and pivot points, designers can obtain a wide range of motion outputs. Some four‑bar linkages generate nearly straight lines, while others produce complex curves. These curves can be used to guide a tool precisely, open a lid in a controlled arc, or raise a platform smoothly. In all cases, the behavior of the linkage dictates how the product feels in the hand or responds to power.

Mechanical Advantage and Force Transmission

Beyond merely transferring motion, linkages can provide mechanical advantage. A lever is the simplest example of a linkage offering force multiplication. More elaborate lever systems, such as bell‑crank linkages, change the direction of force and can reduce or increase the distance traveled by an output.

In folding devices, for instance, a linkage might apply more force to compress a spring mechanism so that opening feels crisp yet easy. Designing with mechanical advantage ensures that the product user perceives the right level of resistance and responsiveness. High‑quality linkages maintain their ratios and do not flex under load, which is key to preserving product feel over time.

Repeatability and Precision

In robotics and automation, repeatability is essential. A positioning mechanism must return to the same point under the same conditions thousands or millions of times. Linkages are often chosen for their ability to provide repeatable motion paths without the complexity of expensive ball screws or linear guides.

For example, a parallel or pantograph linkage allows a gripper to travel in a straight line while keeping its orientation. Because the linkage is built from rigid bars and pivots, its kinematic behavior is deterministic. However, achieving high precision with linkages requires precise machining of joints, accurate assembly, and careful selection of materials to minimize wear. Designers must also consider backlash, the tiny gap in the joints that accumulates into noticeable play; this can be mitigated by using pre‑loaded bearings, plain bearings with interference fits, or by tuning the clearance in the joints.

Human Touch and Feel

Beyond their technical roles, linkages communicate quality through the way they feel. When you open a lid, adjust a seat, or operate a tool, your hand is sensitive to friction, vibration, and the weight of motion. A well‑crafted linkage will guide your movement smoothly and confidently. This matters across industries: in a surgical robot, the surgeon needs to feel exactly how the instrument responds; in a high‑end consumer appliance, the motion of the door or handle conveys luxury; in a piece of furniture, the folding mechanism signals sturdiness.

Creating a pleasant feel from a linkage involves carefully selecting pivot types, ensuring parallelism, avoiding misalignment, and controlling friction through materials, lubrication, and surface finishes. Yana’s sourcing philosophy embraces these subtleties because we know that users judge products not just by their function but by the sensations they generate.

Types of Linkages and Their Unique Behaviors

There are dozens of linkage types, each with specialized behaviors. Understanding the major families helps product developers select the right design for their application. In this section, we explore several common linkages, showing how they transform motion, where they excel, and what trade‑offs they involve.

Four‑Bar Linkages

The four‑bar linkage is one of the most fundamental and widely used configurations. It consists of four rigid links connected in a loop by four pivot joints. By selecting the lengths and relative positions of the links, designers can generate various motion paths. Some four‑bar linkages produce nearly straight motion, while others create complex curves. Their relative simplicity makes four‑bar linkages popular in robots, vehicles, and folding structures.

One classic application is the landing gear linkage in aircraft: during retraction, the four‑bar mechanism guides the wheel into the body, while in the deployed state, it locks the leg in a stable position. Another example is the four‑bar linkage in a car’s suspension, where the motion needs to be carefully controlled to maintain wheel alignment and ride quality. Because the motion path is defined purely by geometry, the four‑bar linkage is repeatable and deterministic, but achieving a perfect path requires careful machining and assembly to eliminate slop.

Slider‑Crank Mechanisms

The slider‑crank is another essential linkage, converting linear motion into rotation (or vice versa). It consists of a crank attached to a rotating shaft, a connecting rod, and a slider that moves in a straight line. The most common example is the internal combustion engine, where the piston’s up‑and‑down movement is transformed into the rotation of the crankshaft through the slider‑crank linkage. This configuration also appears in pumps, compressors, and many types of reciprocating machines.

The kinematics of a slider‑crank are straightforward, but to achieve smooth operation, the joint connecting the connecting rod to the crank pin must be accurately fitted, and the sliding contact must be well supported by bearings or guide rails. In robotics, slider‑crank linkages can drive linear motion stages with a wide range of travel lengths by adjusting the connecting rod’s length and the crank radius. However, the motion is not purely sinusoidal, so controllers often need to compensate for varying velocity and acceleration.

Bell‑Crank and Lever Systems

Bell‑crank linkages change the direction of force. A bell‑crank typically consists of an “L” or “T” shaped lever pivoting on a fixed axis, with input force applied at one end and output force at the other end, perpendicular to the input. This arrangement allows motion to turn corners and adapt to limited spaces.

For instance, in aircraft control systems, bell‑cranks transfer the pilot’s control inputs around obstacles and align them with the control surfaces. In mechanical keyboards, a bell‑crank converts the downward motion of a key into the horizontal motion of a switch slider. Because the angle between the input and output determines the mechanical advantage, designers can tune the ratio to achieve the desired feel or travel distance. A drawback of bell‑cranks is the potential for side loads, so careful selection of pivot type and proper alignment of forces are critical to avoid bending and premature wear.

Straight‑Line Mechanisms

Some linkages are designed to produce nearly straight‑line motion from rotational inputs. One celebrated example is the Watt’s linkage, used in the 18th century to guide the piston rod in steam engines. It consists of two equal-length rods connected by a joint that moves along an arc, approximating a straight line over a small range.

Another sophisticated design is the Peaucellier–Lipkin linkage, which uses an eight‑bar configuration to produce perfect straight‑line motion through geometrical constraints. Straight‑line mechanisms have practical applications in modern engineering: in suspension systems, they maintain wheel alignment by keeping the axle motion within a nearly horizontal plane; in robotics, they allow end‑effectors to move in straight lines without sliding guides. However, these linkages have limited stroke length and require careful setup to minimize deviation from the ideal path.

Parallel and Pantograph Linkages

Parallel linkages use multiple bars to maintain the orientation of an output platform, enabling precise positioning without rotation. The most familiar example is the parallel‑link robot, often called a delta robot or a Stewart platform. In a simpler form, a parallelogram linkage consists of two pairs of parallel bars connected at their ends, ensuring that opposite corners remain parallel.

This property is useful in pick‑and‑place machines, where the end effector must stay level while moving in the plane. A pantograph is a more elaborate parallel linkage that scales motion: two parallelograms share a common pivot, enabling the output to produce an enlarged or reduced copy of the input motion. Drawing pantographs are used by artists to scale up their sketches, while industrial pantographs create scaled motion for engraving or welding. Parallel linkages require precise construction; any asymmetry or play in the joints will cause errors in the output motion. Materials with low thermal expansion and high stiffness help maintain accuracy under varying loads and temperatures.

Variable‑Geometry Linkages

Designers sometimes need mechanisms that can change their geometry to adapt to different tasks or conditions. Variable‑geometry linkages accomplish this by providing more than one degree of freedom in their joints, allowing the effective length or angle between links to change under control. A simple example is the adjustable linkage in a folding ladder, which can lock into multiple positions to accommodate different heights. In robotics, variable‑geometry linkages enable legged robots to adjust stride length or adapt to uneven terrain.

In aerospace, morphing wings use linkages to change the shape of the aerofoil for different flight regimes. These advanced linkages often incorporate multiple actuators and sensors, making their control more complex, but they provide flexibility that static designs cannot match. Selecting materials for such linkages involves balancing stiffness for load carrying and compliance for smooth articulation.

Selecting Linkages for Optimal Performance and Feel

Choosing a linkage is about more than matching a diagram; it involves understanding the stresses, kinematics, and user expectations. In this section, we explore the design considerations and selection principles that help engineers pick the right linkage for their product.

Load and Speed Requirements

The first step in selecting linkages is to define the loads and speeds they will handle. A linkage for a heavy industrial press must support large forces without bending, whereas a linkage in a precision instrument might handle only light loads but require minimal friction and play. High‑speed applications, such as motorized mechanisms, may demand careful attention to dynamic balance and inertial effects to avoid vibration.

For high‑load linkages, designers often choose thicker links, use high‑strength alloys, and incorporate bearings to reduce friction. For lightweight applications, aluminum or composite materials may suffice, but designers should ensure that joints remain rigid and do not twist under acceleration. When loads are variable or unpredictable, such as in robotics or prosthetics, including adjustability or compliance in the linkage may enhance resilience and performance.

Stroke, Travel, and Range of Motion

Different linkages provide different ranges of motion. Slider‑crank and linear linkages produce long travel distances in straight lines, while four‑bar and parallel linkages may have constrained or cyclical motion paths. Determining the required stroke length helps decide whether a simple lever, a slider‑crank, or a more specialized linkage is appropriate.

One must also consider how the travel influences acceleration and deceleration: if the motion must be rapid near the start and finish, certain linkages with sinusoidal velocity profiles might not be suitable without additional control input. A careful review of the desired motion profile helps avoid resonance or overshoot problems that lead to noise, vibration, or user discomfort.

Misalignment Accommodation and Compliance

Real‑world products rarely align perfectly; shafts may be off‑axis by small angles or distances due to manufacturing tolerances and assembly variations. Many linkages incorporate flexibility to tolerate misalignments. For example, universal joints and CV joints handle angular misalignment, while flexible couplings absorb radial or axial misalignment. Even within linkages, small misalignments can cause binding or uneven wear; thus, designers must either specify high precision or choose a linkage design tolerant of error.

To achieve a pleasant feel, some compliance can be beneficial: a compliant linkage can absorb sudden loads, reducing vibration. However, too much compliance causes bounce or sluggishness, so the stiffness of the linkage should match the product’s intended feel. Yana considers these factors when sourcing linkages: we look not just at nominal dimensions but at how the components behave under real assembly conditions.

Tolerance, Fit, and Lubrication

The joints in linkages determine how they move. The clearance, or tiny gap, between joint components must be small enough to avoid slop yet large enough to prevent binding. Precision applications often use bearings with preload (an internal bias that removes play) or bushings with interference fits to eliminate backlash. Designers must also specify how the linkage will be lubricated: oil, grease, or even solid lubricants like PTFE.

Proper lubrication reduces friction and wear, extending the life of the linkage and preserving its feel. Some linkages are designed for dry operation, such as those in food processing equipment, where lubricants might contaminate the product; in these cases, materials with low friction coefficients (e.g., PEEK or PTFE) or advanced coatings (e.g., DLC) are used. Tolerancing and lubrication are not afterthoughts; they determine how the linkage behaves from day one and after years of use.

Materials and Manufacturing Processes

Selecting materials for linkages requires balancing strength, weight, corrosion resistance, cost, and manufacturability. Carbon steel offers high strength and fatigue resistance but may rust; stainless steel adds corrosion resistance but costs more. Aluminum provides low weight and ease of machining but may not handle high loads without thicker sections. Composites and titanium alloys offer excellent strength-to-weight ratios and good corrosion resistance but require specialized manufacturing.

For applications where electrical insulation is necessary (such as MRI-compatible robots), non‑metallic linkages using PEEK or carbon fiber can be ideal. Manufacturing methods also influence linkage quality: CNC machining yields precise, smooth surfaces, while investment casting can produce complex shapes. Yana partners with suppliers who understand these trade‑offs and can produce linkages to exact specifications while meeting cost targets.

Safety Factors and Redundancy

Because linkages are subjected to cyclic loads, fatigue failure is a concern. Designers should use appropriate safety factors, multipliers that ensure the linkage can handle loads beyond normal operating conditions without failing. In critical systems, such as aircraft control surfaces or surgical tools, redundancy may be built into the linkage design. Parallel load paths or dual linkages can continue to function if one element fails. While redundancy adds weight and cost, it is necessary when failure could lead to injuries or costly downtime. Selecting linkages with known fatigue life and working with suppliers that perform rigorous testing will reduce the risk of unexpected failure.

Yana’s Approach to Sourcing and Integrating Linkages

Linkages may seem simple on the surface, but the nuances of their design, materials, manufacture, and integration influence how they perform and how your product feels. As a sourcing and engineering partner, Yana brings a high‑dimensional perspective to linkages: we understand the interplay between the components, the user’s perception, and the economics. Here’s how we support our clients in selecting and integrating linkages.

Supplier Vetting for Precision and Consistency

Not all suppliers are capable of producing high‑precision linkages. We vet each supplier’s process capability: Do they machine or cast components? Are they capable of meeting the tolerances required? Do they inspect joints for concentricity and co-axiality? We look at their track record of delivering consistent batches over time. Our sourcing network includes specialists in precision CNC machining, investment casting, and composite layup. We also ensure that suppliers have quality systems (ISO certifications, traceability protocols) and provide material certificates. By selecting suppliers based on capability, not just price, we reduce the risk of variability that can degrade the feel and performance of your product.

Collaborative Design and Co‑Development

At Yana, sourcing begins with understanding your product’s intent and constraints. We work with your design team to choose or refine linkages. This may involve altering link lengths for a better motion path, adding compliance to absorb shock, or switching from plain bushings to pre‑loaded bearings.

We use kinematic simulations to verify the linkage behavior and iterate until we achieve the desired feel. Co‑development is especially beneficial for startups or SMEs that lack in‑house mechanical engineering; our team can bridge the gap between concept and manufacturability, ensuring that the linkage is robust and production‑ready. Because we’ve already vetted suppliers, we can propose design changes that align with a partner’s manufacturing capabilities, avoiding late-stage surprises.

Quality Control and Traceability

Our sourcing process includes thorough inspection and testing of linkages. We measure critical dimensions, joint clearances, and surface finishes. For high precision applications, we may run life cycle tests on sample linkages to assess wear and backlash growth. Traceability is essential: we record which batch and which material lot each linkage came from. If a problem emerges in the field, we can trace it back to the source and correct the process. This level of quality control protects your brand reputation and ensures that your products feel consistent from the first unit to the thousandth.

Logistics and Integration Support

Beyond sourcing, we handle logistics, consolidating linkages from multiple suppliers, managing inventories, and ensuring timely delivery. We also assist with integration: for example, preassembling linkages into subassemblies or providing kits with the necessary hardware and lubricants. In some cases, we deliver linkages with pre‑applied coatings or surface treatments to simplify your production. Our goal is to make the adoption of high-quality linkages seamless for your team.

Ethical and Sustainable Considerations

We believe that sourcing responsibly is part of product quality. We verify that suppliers adhere to fair labor practices, environmental regulations, and ethical standards. In high‑value products where sustainability is a selling point, we can source linkages made from recycled metals or sustainable polymers. We also consider the environmental impact of coatings and lubricants, proposing alternatives when possible. By aligning the sourcing of linkages with your brand’s values, we help you resonate with customers who care about how their products are made.

Integration with Other Components and Systems

Linkages do not exist in isolation. They interact with bearings, couplings, screws, motors, and control systems. Recognizing these interactions ensures that the final product behaves as intended.

Bearings and Linkages

Bearings support the rotating or sliding joints within linkages. In many cases, the bearing type and quality determine how the linkage feels. For instance, using pre‑loaded angular contact bearings in a four‑bar linkage can eliminate backlash and provide a stiff response, enhancing repeatability.

On the other hand, plain bushings may be acceptable for low‑load, slow‑speed linkages, reducing cost and simplifying maintenance. When selecting bearings for linkages, designers must consider load direction, speeds, lubrication requirements, and space constraints. Collaboration between the bearing supplier and linkage designer can lead to optimized joints that meet performance and cost targets.

Couplings and Shafts

Couplings transmit power and motion between shafts. When a linkage is connected to a motor or another rotating element, couplings ensure alignment and smooth force transfer. Misalignment between the linkage input and the motor can cause vibration, wear, and noise. Flexible couplings mitigate misalignment but add compliance; rigid couplings transmit force directly but require precise alignment. Choosing the right coupling is critical when a linkage must provide accurate positioning. As a sourcing partner, Yana helps match couplings to linkages based on the application’s tolerance for misalignment and the desired feel.

Screws, Ball Screws, and Linear Guides

In linear motion systems, linkages often work alongside screws, ball screws, or linear guides. A linkage might convert rotational motion into linear movement, but a screw can offer more precise control and increased load capacity. In a robotic arm, for example, a linkage could provide the gross motion path, while a ball screw fine-tunes the end effector’s position. Understanding when to use a linkage, when to use a screw, and when to combine both requires systems-level thinking. Yana collaborates with engineers to design multi-stage motion systems where linkages handle large travel distances and screws or linear guides provide high-resolution adjustment.

Control Systems and Sensors

Modern products increasingly rely on sensors to monitor their motion and control systems to adjust it in real time. Linkages can incorporate position sensors, strain gauges, or limit switches directly. For instance, a robot with a parallel linkage may have encoders on each joint to measure angles and calculate the end effector’s position.

Adding sensors to linkages introduces new requirements: space for sensor mounting, wiring or wireless communication, and protection from dust and vibration. By working with Yana, customers can design linkages that integrate sensors seamlessly, ensuring that the mechanical design supports accurate feedback without adding bulk or complexity.

Innovations and Future Directions in Linkage Design

While linkages may seem like simple classical mechanisms, they are still evolving. Innovations in materials, manufacturing, and computation are opening new possibilities for linkages.

Compliant Mechanisms and Soft Linkages

Traditional linkages use rigid bars and joints, but compliant mechanisms rely on the flexibility of the material itself to provide the needed motion. These mechanisms can replace complex joint assemblies with a single piece of material that bends to create motion. Compliant linkages can reduce part count, cost, and maintenance because there are no pins or bearings to wear out.

They’re already used in precision instruments like microgrippers and surgical tools. However, designing compliant linkages requires advanced analysis to ensure that the flexures can withstand repeated bending without fatigue. Materials such as spring steels, superelastic alloys, and engineering polymers are commonly used. In the future, compliant linkages might appear in consumer products like foldable devices, where smooth, reliable motion with minimal part count is desirable.

Topology Optimization and Additive Manufacturing

Additive manufacturing (3D printing) allows complex shapes that are impossible or expensive to machine. Designers can use topology optimization algorithms to shape linkages that are lighter and stronger than traditional designs. For instance, a topology-optimized bell‑crank linkage might have organic, lattice-like structures that maintain stiffness while reducing mass.

Additive manufacturing also enables the production of linkages as integrated assemblies, with joints already in place, reducing assembly time. Some 3D printing processes can embed sensors or circuitry directly into the linkage, creating smart linkages that report their state in real time. Yana works with manufacturing partners who specialize in additive manufacturing to develop advanced linkages that meet strict performance requirements.

Smart Materials and Shape Memory Linkages

Shape memory alloys (SMAs) are materials that change shape when heated or electrically stimulated. Designers can use SMAs to create linkages that alter their length or stiffness without motors or screws. A shape memory linkage might change the lift of a valve or adjust the angle of a wing automatically when the temperature rises. Piezoelectric materials offer another avenue: they change dimension when a voltage is applied, enabling fine motion control without conventional actuators.

Integrating smart materials into linkages could lead to robots that change gait on the fly or consumer products that adapt their motion to user preferences. The challenge lies in controlling the material precisely and ensuring that it remains reliable over many cycles. Yana keeps abreast of developments in smart materials to inform future linkage designs for clients.

Digital Twins and Motion Simulation

Designing linkages often involves trial and error, but digital twins allow engineers to simulate the behavior of linkages before production. A digital twin is a virtual model that represents the physical linkage, capturing its geometry, material properties, and joint behaviors. Engineers can use digital twins to test different linkage configurations, analyze stresses, and predict how the linkage will wear over time. Digital twins also help optimize control strategies: by simulating a robot’s linkage system, a developer can create motion profiles that minimize energy use or reduce vibration. Yana leverages digital twin technology to shorten development cycles, reduce risk, and ensure that the linkages we source perform as expected once integrated into your product.

Conclusion: Linkages as the Signature of Motion Quality

Linkages may not be glamorous, but they are essential to the quality and feel of mechanical products. Whether transforming motion, distributing forces, maintaining alignment, or amplifying travel, linkages shape the user’s experience at a fundamental level. Selecting and integrating the right linkage requires a nuanced understanding of kinematics, materials, manufacturing, and user perception.

As a sourcing partner, Yana brings a high‑dimensional perspective to linkages: we consider not only how a linkage moves but how it feels and how it fits into the larger system. Our approach combines engineering rigor with an appreciation for the emotional aspects of product design.

By working with Yana, you ensure that every motion in your product, whether a hinge, a handle, or a robot arm, feels intentional, confident, and crafted. When linkages are chosen with care, they become an invisible signature of quality. We invite you to reach out and let us help you build motion that feels right, lasts long, and reflects the future of mechanical intelligence.