Table of Contents

Where Motion Becomes Intentional Movement

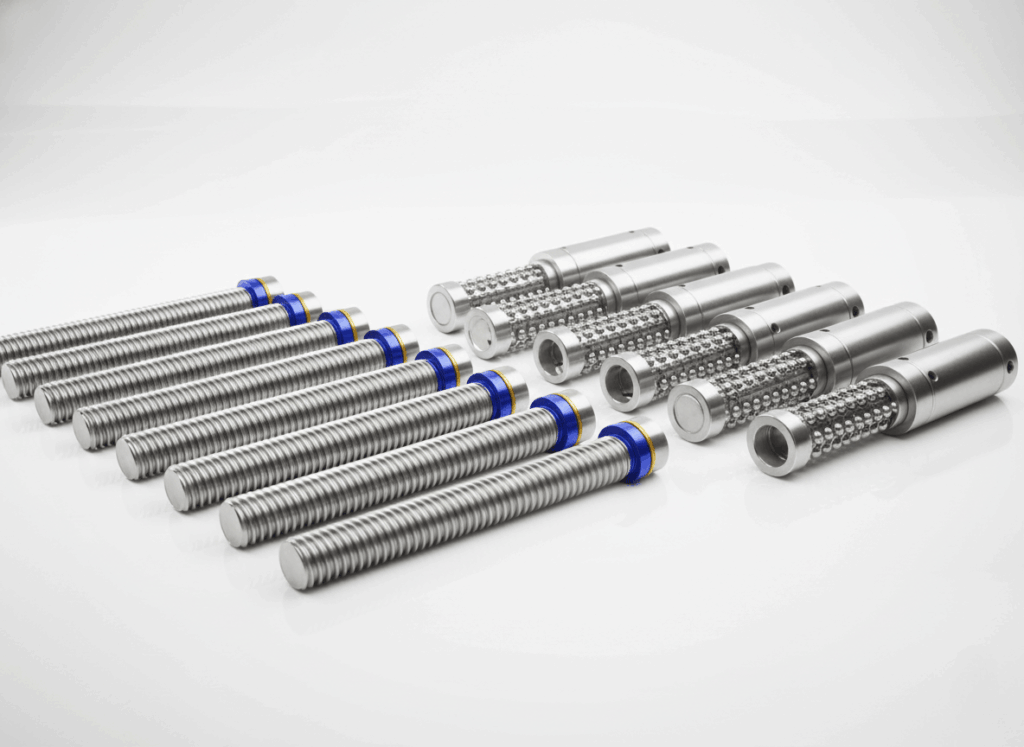

Screws and ballscrews are the quiet engineers behind every precision mechanism. When founders talk about how smooth a product feels, they’re often celebrating the careful selection and integration of screws and ballscrews. From robotics and automation to consumer electronics and medical devices, screws and ballscrews transform rotary motion into linear translation, clamp parts together with confidence, and maintain alignment across thousands of cycles. Understanding screws and ballscrews gives designers the power to translate ideas into reality and to control movement with grace. Each thread carries intent; each ball track holds a promise. By appreciating the importance of screws and ballscrews early in the design process, innovators can build products that feel right and last long.

Why Screws and Ballscrews Matter in Product Design

When people think about mechanical components, they might imagine motors and gears, but screws and ballscrews rarely get the spotlight. Yet screws and ballscrews are fundamental in turning rotary motion into controlled linear movement, a function that lies at the heart of CNC machines, 3D printers, and robotic arms. A well-chosen combination of screws and ballscrews ensures that a machine moves not just accurately but effortlessly, translating torque into force with minimal backlash and wear.

In product development, screws and ballscrews bridge the gap between conceptual geometry and real-world motion, making them essential for repeatability and reliability. Screws and ballscrews also hold parts together, resisting vibrations and dynamic loads. Their material, thread pitch, and lubrication determine how long they will last and how smooth the product will feel over time. Whether they are used in prototypes or final assemblies, screws and ballscrews matter more than many realize.

Types of Screws and Ballscrews

Not all screws and ballscrews are the same. When engineers talk about screws and ballscrews, they’re describing a family of devices that share the same basic principle, converting rotational input into linear output, but differ in construction, efficiency, and load capacity.

- Machine Screws: These screws and ballscrews variants are used to fasten components together, often into threaded holes or with nuts. They come in a variety of head styles (flat, pan, socket) and are used when repeatable assembly and serviceability are important.

- Lead Screws: A more robust type of screw, lead screws and ballscrews are typically found in drives where linear motion is required. Lead screws use sliding contact between the screw and nut threads and provide good load capacity, though with higher friction than ball screws. They’re simple, cost-effective, and can be self-locking, meaning they hold their position without external power.

- Acme & Trapezoidal Screws: These screws and ballscrews have distinct thread profiles. The Acme screw is common in the United States, while trapezoidal screws follow a metric profile. They offer high strength and are widely used in heavy-duty applications.

- Ball Screws: These are the stars of the screws and ballscrews family when it comes to efficiency and accuracy. Ball screws use recirculating balls between the screw and nut, reducing friction to very low levels. Ball screws can convert motion with efficiencies above 90%, making them suitable for high-speed and high-precision machinery.

- Rolled vs Ground Ball Screws: Rolled ball screws are cost-effective and good for general applications, while ground ball screws and ballscrews offer tighter tolerances and smoother operation, albeit at higher cost. Ground ball screws are produced by grinding, ensuring minimal friction and improved accuracy.

- Miniature Screws & Custom Screw Drives: In medical devices and precision instruments, miniature screws and ballscrews handle delicate positioning. Custom screw drives might integrate coatings or unusual pitches to suit specific performance requirements.

Understanding the differences among these screws and ballscrews helps engineers choose the right one for their project’s requirements. Each type of screw serves a specific purpose, and using the wrong screws and ballscrews can introduce backlash, wear, or inefficiency that compromise the entire system.

Material and Coating Options

The performance of screws and ballscrews depends not only on their geometry and design but also on the materials and coatings used. Most screws and ballscrews are made from various steels, but each alloy brings different properties. High-carbon steel screws and ballscrews deliver excellent strength and wear resistance, making them suitable for high-load applications. Stainless steel screws and ballscrews offer corrosion resistance in humid or chemically aggressive environments, though they may sacrifice some hardness compared to carbon steel. For applications requiring exceptional stiffness and low thermal expansion, engineers might choose alloy steels or titanium screws and ballscrews.

Coatings play another crucial role in extending the life of screws and ballscrews. Black oxide coatings add mild corrosion resistance and reduce glare. Zinc plating provides moderate protection against moisture but may be unsuitable for high-load scenarios that wear through the coating. Hard chrome plating or nickel plating increases surface hardness and reduces friction, prolonging the life of screws and ballscrews used in high-speed environments. In some high-end bearings and ball screws, ceramic or hybrid materials are introduced to reduce weight and increase speed capability, but these are more common in ball screws than standard screws and ballscrews.

Choosing the right material and finish ensures that screws and ballscrews remain reliable in the intended environment. Yana’s expertise in sourcing extends to the metallurgical level, ensuring screws and ballscrews won’t corrode prematurely or deform under load. Reliable screws and ballscrews start with appropriate material selection and protective coatings.

Engineering Considerations for Screws and Ballscrews

Selecting screws and ballscrews isn’t just about picking a size or thread pitch. Engineers must consider multiple variables to make sure screws and ballscrews match the application’s demands.

Load Capacity and Duty Cycle: Screws and ballscrews need to handle static and dynamic loads without deforming. Ball screws have rolling contact with ball bearings, enabling them to manage high loads while maintaining low friction. Lead screws are better for heavy loads at low speeds but may introduce more friction and heat. The duty cycle, how often and for how long the system will run, also influences the choice of screws and ballscrews. Constantly moving components require screws and ballscrews with durable materials, accurate lubrication, and robust bearing support to prevent premature wear.

Pitch and Lead: The pitch of the thread determines how far a nut travels along the screws and ballscrews per rotation. Smaller pitch values offer finer positioning, while larger pitches provide faster travel. Engineers choose the lead of screws and ballscrews based on desired balance between speed and resolution. Ball screws offer high repeatability and low friction, making them ideal for precise positioning systems.

Backlash and Preload: Backlash is the lost motion between the screw and nut due to clearance in the threads or recirculating ball bearings. For high-precision applications such as CNC machines or medical devices, screws and ballscrews must minimize or eliminate backlash. Ball screws often incorporate preloading by using oversized balls or double nuts to remove free play. Lead screws can also be preloaded by using split nuts or adjustable nuts. Precise preload eliminates backlash but increases friction, so screws and ballscrews must be balanced for performance and efficiency.

Lubrication and Maintenance: Every interface where metal contacts metal needs lubrication. The lubrication of screws and ballscrews reduces friction, dissipates heat, and prevents wear. Oil or grease are common choices; oil flows through channels in ball screws, whereas grease packs into lead screw assemblies. Over-lubricating screws and ballscrews can attract dust and debris, while under-lubricating leads to premature wear. Regular maintenance schedules for screws and ballscrews ensure longevity and prevent failure in critical systems.

Alignment and Support Bearings: Even the best screws and ballscrews fail if the assembly isn’t properly aligned. Support bearings at both ends of screws and ballscrews maintain axial and radial alignment, preventing bending and vibration. Misaligned screws and ballscrews can bind, introducing uneven wear or causing the assembly to jam. A straight, well-supported screw is crucial for smooth operation.

These engineering considerations shape how screws and ballscrews perform and how long they last. Proper planning results in a system that moves confidently, quietly, and predictably.

Screws versus Ballscrews – Pros and Cons

Understanding the difference between standard lead screws and ball screws helps engineers choose the right screws and ballscrews for their application. Each type has its advantages and trade-offs.

Lead Screws are simpler in design and have a sliding contact between the nut and screw. They tend to be self-locking, which means the screws and ballscrews (specifically lead screws) hold position without power. Lead screws are quieter than ball screws at low speeds and can be more forgiving to misalignment. However, lead screws are less efficient because sliding friction converts more input energy into heat. The higher friction of these screws and ballscrews means they require more torque to move under load. They’re ideal when precise positioning isn’t as critical or when cost is a concern.

Ball Screws, on the other hand, use ball bearings to create rolling contact between the nut and screw. This reduces friction dramatically, yielding efficiencies above 90%. Ball screws can travel faster than lead screws and deliver higher positional accuracy. They’re also less prone to wear under high loads. However, ball screws can back-drive easily; they don’t self-lock, meaning they need a brake or motor resistance to hold position. Ball screws also tend to be more expensive due to their complex manufacturing. But for high-end robotics, CNC equipment, or any application that demands repeatable precision, ball screws are the superior screws and ballscrews choice.

Ultimately, the decision between lead screws and ball screws depends on the priorities of the design, whether it’s cost, efficiency, noise, accuracy, or self-locking behavior. Each of these screws and ballscrews plays an essential role in different contexts, and knowing the pros and cons is critical to successful product development.

Integration of Screws and Ballscrews in Systems

Integration is the stage where screws and ballscrews transform from discrete parts into functional subsystems. Screws and ballscrews must align with the frame, bearings, and actuators in a machine. For example, a CNC machine’s table may use ball screws to translate the motion of stepper or servo motors into a precise linear stroke. The ball screw housing must fit precisely into linear bearings, and couplings must connect the ball screw to the motor without introducing eccentricity.

In robotics arms, screws and ballscrews are used in joints and axes for stable, repeatable movement. When integrated correctly, these screws and ballscrews ensure that the end effector moves smoothly and holds its position accurately. Improper integration can cause bending or misalignment, leading to backlash or vibration.

Engineers also need to consider the thermal environment in which screws and ballscrews operate. Heat expansion can cause a slight increase in length, changing backlash or preload. Using appropriate materials and compensating structures can minimize thermal growth. For ball screws, thermal expansion can cause a change in ball diameters, leading to pitch error.

Integration decisions also include how to manage the noise from screws and ballscrews. Low-noise applications, like home automation devices, require screws and ballscrews that operate quietly. Vibration dampers or rubber mounts might be introduced to reduce noise transmission.

Another integration factor is accessibility for maintenance. Screws and ballscrews require periodic lubrication or adjustments. Designing a chassis with accessible lubrication ports and removable covers ensures that screws and ballscrews can be serviced without disassembling the entire system.

Yana’s Approach to Sourcing Screws and Ballscrews

Sourcing screws and ballscrews might seem like a simple procurement task, but in reality, it requires deep understanding of mechanical systems, supplier capabilities, and quality assurance methods. Yana’s approach is grounded in years of working on high-impact products where screws and ballscrews make or break the user experience.

Comprehensive Supplier Vetting: Yana collaborates with manufacturers who specialize in screws and ballscrews, checking not just catalog data but real-world output. We look at process control, machining capabilities, heat treatment, and inspection procedures. Our suppliers must demonstrate consistency in thread profiles and ball raceways, as well as capacity for surface finishing and anti-corrosion treatments.

Application-Specific Engineering: We don’t simply pick screws and ballscrews off the shelf. Yana looks at the application and matches the right screws and ballscrews to the load, speed, environment, and desired feel. If a customer’s product needs silent operation in an office environment, we’ll choose screws and ballscrews with specific coatings or ball circuits that minimize noise. If the design needs to survive shock loads, we’ll integrate heavier wall thickness or dual-nut ball screws for added stiffness.

Quality Verification: Our process includes rigorous verification of screws and ballscrews. We check pitch, straightness, run-out, and preload values for ball screws. We test thread integrity, strength, and hardness for lead screws. Our documentation includes material certificates and batch traceability, ensuring that every set of screws and ballscrews can be traced back to its production run.

Continuous Improvement: Sourcing screws and ballscrews is not a one-time event. As projects scale, Yana adjusts specifications to optimize cost, lead time, and performance. Feedback from end users influences how we refine future choices of screws and ballscrews.

Through this combination of engineering, quality control, and supplier collaboration, Yana ensures that screws and ballscrews align with the project’s goals. Our calm precision extends to everything we do, from selecting materials to documenting dimensions. Screws and ballscrews sourced through Yana form the backbone of reliable product development.

Future Directions in Screws and Ballscrews

The screws and ballscrews industry continues to innovate, enabling higher performance and new applications. One emerging trend is the integration of sensors directly into screws and ballscrews. These smart screws can monitor temperature, vibration, and load in real time, feeding data back to control systems for predictive maintenance. When a ball screw begins to wear, it can alert the system, minimizing downtime and preventing catastrophic failures.

Coatings and materials are also evolving. Low-friction coatings based on advanced polymers or diamond-like carbon (DLC) reduce friction and wear, extending the lifespan of screws and ballscrews. Hybrid ball screws that incorporate ceramic balls allow for higher speeds due to lower rolling resistance and reduced thermal expansion.

Additive manufacturing is another technology that could influence the screws and ballscrews space. 3D printing of screw components with internal channels for lubrication or cooling opens new design possibilities. The ability to rapidly prototype custom screws and ballscrews enables faster iteration cycles.

Sustainability considerations are shaping material choices. Recyclable materials, as well as processes to refurbish or recycle worn screws and ballscrews, are increasingly important. Designers and engineers should consider the lifecycle of screws and ballscrews in their sustainability planning.

As the world moves toward more automated and connected systems, screws and ballscrews will remain integral to mechanical motion. Advances in manufacturing and materials promise further improvements in precision, durability, and efficiency. Yet even the smartest screw remains grounded in the fundamentals: a spiral path that translates rotation into linear progress.

Conclusion

Screws and ballscrews may be small compared to motors and actuators, but their impact on product quality is immense. They are the fulcrum on which precision motion balances. When screws and ballscrews are selected with care, assembled with precision, and maintained thoughtfully, they deliver smooth movement, repeatable positioning, and a long service life. From simple lead screws to high-end ball screws, these components embody the craft of performance.

As you develop products that move with confidence, remember that screws and ballscrews are not commodities; they are the heart of mechanical synergy. They decide whether your product hums quietly or rattles, whether it delivers the same feel after the thousandth cycle as it did the first. Partnering with Yana means you gain access to deep knowledge of screws and ballscrews, a curated supply network, and a calm, thoughtful sourcing process.

In a world where innovation moves at an ever-accelerating pace, you can choose to rush or you can choose to move right. Start with the basics, choose the right screws and ballscrews, and let that foundation lead to a product that feels right, works right, and lasts. Yana invites you to take this journey with us, crafting products where screws and ballscrews do more than turn threads; they turn possibilities into reality.