Table of Contents

Understanding Control Boards in Robotics

Introduction: Why Control Boards Are the Brainstem of Robotic Controllers

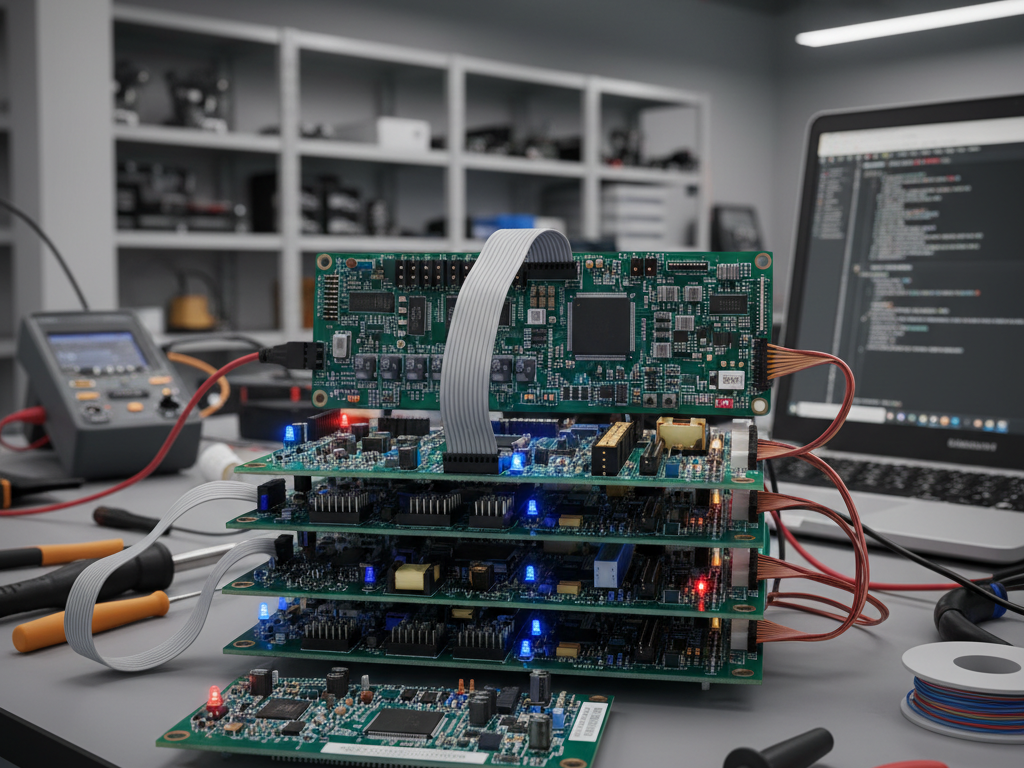

Modern intelligent machines rely on electronic control boards to translate high‑level commands into precise actions. In a mechanical sense, motors and reducers provide movement, but without control boards the motion would be erratic and imprecise. Control boards sit at the intersection of hardware and software, interpreting signals from sensors, applying complex algorithms, and sending voltage commands to servo drivers and actuators.

They are the brainstem of robotic controllers, always listening, calculating, and coordinating. Unlike simple relay circuits or generic microcontroller boards, robotics control boards integrate specialized microprocessors, feedback processing, communication networks and safety functions. This article explores what control boards are, how they differ from general servo controllers, and why they are indispensable to building high‑margin, higher‑dimensional robotic solutions.

To illustrate, consider a robotic arm handling delicate components on a production line. Commands originate from the host PLC or PC and pass through the control boards, which generate precise pulse‑width modulation (PWM) signals to the servo drivers. The control boards monitor encoders, torque sensors and limit switches, adjusting trajectories in real time.

If a deviation occurs, algorithms like proportional‑integral‑derivative (PID) instantly correct the error. Without such control boards, the arm might overshoot, vibrate or stall. For businesses building high‑value products, whether in electronics, medical devices or luxury goods, precision and repeatability are non‑negotiable. Proper control boards ensure the machine’s movement aligns with the design intent and protects margins by reducing waste.

What Are Control Boards? Definitions and Core Roles

At their core, control boards are printed circuit boards (PCBs) that integrate a microcontroller or processor, power electronics, sensor interfaces and communication ports to manage electromechanical systems. In robotics, control boards perform several essential roles: generating motor commands, processing feedback, regulating speed and position, planning trajectories, and maintaining safe operation. These boards differ from general servo drives; a servo drive (or motor driver) amplifies commands into current for the motor, whereas the control boards compute those commands and coordinate multiple axes.

The AnyPCBA motion control article explains that robot motion control boards convert high‑level commands into PWM signals for motors, integrating microcontrollers, motor drivers, feedback sensors and communication interfaces. It notes that these boards are “essential for real‑time control,” enabling precise positioning, velocity regulation and trajectory planning.

Poorly designed boards cause jerky movement and positioning errors, while well‑engineered boards yield smooth, energy‑efficient motion. This underscores that control boards aren’t optional accessories but critical components that directly dictate robot performance. In a high‑margin manufacturing context, where quality and consistency impact profits, such control boards must be carefully selected and integrated.

Anatomy of a Control Board: Microcontrollers, Communication and Power Logic

A typical robotics control board consists of several layers of functionality. At the heart lies a microcontroller or microprocessor that executes firmware routines: reading sensor data, calculating control algorithms and issuing drive commands. Surrounding the processor are signal conditioning circuits, voltage dividers, filters and amplifiers, that prepare analog sensor signals for digital processing. Power electronics manage the distribution of DC power across the board and may include gate drivers to control external transistors or MOSFETs driving motors.

A rich set of communication ports (EtherCAT, CAN, RS‑485, USB) enables the control boards to interact with higher‑level PLCs, human–machine interfaces and other subsystems. Finally, safety circuits implement features like safe torque off (STO) or emergency stop, ensuring the system shuts down gracefully when faults occur.

Many high‑end control boards incorporate field‑programmable gate arrays (FPGAs) or digital signal processors (DSPs) to accelerate real‑time calculations. For example, industrial controllers may implement model predictive control (MPC) loops that anticipate future states and adjust actions accordingly. Others embed artificial intelligence (AI) co‑processors for vision and perception tasks.

While generic microcontrollers can drive simple hobby robots, advanced control boards integrate specialized hardware to support multi‑axis synchronization, high‑bandwidth communications and safety compliance. Yana’s sourcing team maintains a database of control board architectures, from compact single‑axis boards for startups to rack‑mount boards with redundant processors for aerospace systems. Understanding this anatomy helps clients choose the right board for their project.

Types of Control Boards: Motion, Vision, AI and Hybrid Systems

Robotics applications vary widely, so manufacturers design different types of control boards to match requirements. Motion control boards focus on precise control of motors and actuators. They implement servo loops, generate PWM or pulse‑direction commands and handle feedback from encoders and load cells. Vision control boards integrate camera interfaces, image processors and neural network accelerators to handle perception tasks like object detection or pose estimation.

AI control boards take this further, combining CPUs, GPUs or dedicated AI chips with software stacks for machine learning and reinforcement learning algorithms. Hybrid systems blend motion and vision, enabling tasks like pick‑and‑place using camera feedback. A careful selection of control boards ensures the right balance of functionality, computing power and cost.

For instance, collaborative robots (cobots) often use integrated controllers that merge safety functions, servo control and communication into a single board. This reduces wiring complexity and improves reliability. The Ingenia article explains that embedding servo controllers into robot joints, rather than using separate modules, improves torque feedback and safety through features like Safe Torque Off (STO) implemented via custom interface boards.

Similarly, controllers for autonomous mobile robots combine motor control, navigation sensors and LiDAR processing on one board, enabling compact designs. As robotics becomes more complex, the ability to mix and match control functions while maintaining stability becomes a competitive differentiator. Yana works with manufacturers to source custom hybrid boards that align with a client’s unique use case, whether it’s low‑latency vision control for surgical robots or robust motion control for heavy machinery.

Control Boards vs PLCs: Choosing the Right Architecture for Robotics

Many industrial machines have historically relied on programmable logic controllers (PLCs) for sequencing operations. However, robotics demands more than simple on/off control; it requires high‑frequency feedback and complex kinematics. A Control Engineering article highlights the challenges of using separate PLCs and robot controllers. It notes that when using conventional robot control systems, machine builders often need to add encoders and extra hardware to link the robot controller with the PLC, which increases cost and development complexity. In addition, communication latencies between PLC and robot can reduce performance and make troubleshooting harder.

The same article describes an alternative: a single motion‑centric controller that integrates machine logic and robotic kinematic control. By using such unified control boards, the machine and robot share one controller and programming environment. According to the article, these controllers coordinate machine cycles and robots, eliminating separate robot controllers and communication issues; as a result, development time is reduced, long‑term reliability is improved, and machines become more productive. This evidence illustrates that integrated control architectures deliver significant business benefits, fewer parts, lower maintenance and easier upgrades. Yana advocates for this unified approach when designing new robotic cells because it simplifies the supply chain and improves margins.

Performance, Design and Engineering Principles

Electrical Design and Layer Architecture: How Control Boards Manage Motion

Electrical design lies at the heart of control boards. At the most basic level, boards must route power effectively while isolating sensitive signal lines. For motion control, the board generates voltage or current commands that drive servo amplifiers; it must also measure feedback signals accurately. Designers often use multilayer PCBs with dedicated ground planes and shielded traces to minimize electromagnetic interference (EMI). High‑frequency switching can induce noise on sensor lines, so analog and digital sections are separated. Heat dissipation is a major concern; components such as microprocessors and FETs must be placed near copper pours or thermal vias to spread heat. Without careful layout, controllers may overheat or drift, causing performance issues.

Beyond board layout, firmware is critical. Control algorithms like PID loops tune the motor response to achieve quick settling with minimal overshoot. The proportional coefficient sets how aggressively the loop reacts to error, while integral and derivative coefficients correct steady‑state error and anticipate future error respectively. Real‑time operating systems (RTOS) enable deterministic task scheduling, ensuring that sensor readings and control outputs occur at precise intervals. As robotics applications require sub‑millisecond response times, the interplay between hardware layout and software scheduling on control boards is fundamental to achieving smooth motion. Yana works with manufacturers who validate these designs through simulation and real‑world testing to guarantee reliability.

Communication Protocols: EtherCAT, CAN, Modbus and RS‑485

For control boards to orchestrate complex machines, they must communicate effectively with other devices. Common communication protocols in robotics include EtherCAT, CAN bus, Modbus and RS‑485. EtherCAT is a deterministic Ethernet‑based fieldbus that enables high‑speed, low‑latency communication with multiple servos and sensors. Its distributed clock mechanism ensures precise synchronization across axes. CAN bus is widely used in automotive and mobile robots; it supports robust communication over twisted‑pair cables and includes error detection mechanisms. Modbus (RTU/TCP) provides a simple master‑slave protocol suitable for linking controllers with PLCs or human‑machine interfaces. RS‑485 is a differential serial interface used in industrial networks for long‑distance communication.

Networked servo controllers rely on these buses to share information. Motion control boards integrate communication interfaces to link with robot CPU. When designing a robotics cell, Yana’s engineers ensure that the selected control boards support the required protocols. For example, an AGV may require CANopen for drive units and EtherCAT for lifting modules. Standardizing on one bus may simplify wiring, but using multiple can optimize performance and cost. The choice of protocol impacts the board’s microcontroller selection, firmware complexity and overall cost. Yana leverages supplier expertise to balance these factors and ensure a future‑proof solution.

Processing Power and Latency: The Silent Factor Behind Precision

Robotic movement often appears smooth from the outside, but under the hood the system performs thousands of calculations per second. A control board must execute control laws quickly enough so that mechanical parts respond before new disturbances arise. If the controller is too slow, the robot may vibrate, overshoot or fail to follow a trajectory. Conversely, an overly powerful processor may waste energy and cost. Determining the right processing power is a balancing act.

Well‑designed motion control boards ensure high precision, rapid response and smooth movement, whereas poorly designed boards lead to jerky motion and energy inefficiency. Achieving high precision requires both hardware (fast processors) and software (optimized algorithms). For example, multi‑axis interpolation demands simultaneous updates to multiple motors; a unified controller that integrates machine logic and robot control can handle these tasks with low latency. Unified controllers reduce communication delays and simplify adaptation to production changes. When Yana selects control boards, we analyze processor benchmarks, real‑time capabilities and upgrade roadmaps to ensure the board will meet current needs and scale with new features.

Safety, EMI and Thermal Design Considerations

Safety is paramount in industrial robotics. Control boards implement safety through hardware and firmware. Features like Safe Torque Off (STO) cut power to servo drives when triggered, preventing unintended movement. Watchdog timers monitor processor health and reset the board if it becomes unresponsive. Voltage and current sensors detect overloads, while temperature sensors track thermal stress. Standard safety certifications (ISO 13849, IEC 61508) require redundant channels and self‑diagnostics.

EMI mitigation and thermal design are equally important. Motors and switching circuits generate electromagnetic noise that can corrupt sensor readings. Board designers use ground planes, decoupling capacitors and shielded cables to protect signals. Thermal management involves selecting components with appropriate thermal coefficients, placing heat‑generating parts near copper pours, and using heat sinks or fans. The Innovations such as non‑silicon transistors and gate driver technology that improve power density and heat dissipation. Sourcing control boards with such innovations helps maximize power efficiency and reliability, which is crucial for heavy‑duty robots or battery‑powered systems. Yana evaluates suppliers’ adherence to design guidelines and thermal testing results before recommending a board to clients.

The Rise of Modular Control Boards: Scalability in Intelligent Motion

As robotics systems grow in complexity, modular control boards provide a flexible architecture. Instead of a monolithic board controlling every axis, modular boards allow developers to add or remove channels as needed. For example, a base board may provide three axes of control and a communications interface, and additional daughter cards add more axes or peripherals. Such modularity simplifies maintenance and upgrades; if one axis fails, the others remain operational, and replacement is inexpensive.

Unified controllers that integrate machine logic and robot kinematic control adopt this modular concept. Integrating machine logic with robot control in a single controller eliminates communication issues, reduces development time and lowers costs. Modular control boards complement this approach by allowing incremental expansion without redesigning the entire controller. They also align with Yana’s philosophy of higher‑dimensional design, building systems that adapt to market changes and product variations with minimal downtime. In addition, modular boards can be configured for redundancy in safety‑critical applications, where two controllers run in parallel to ensure fail‑safe operation.

Multi‑Axis Synchronization: Where Control Boards Prove Their Worth

Coordinating multiple axes is one of the most challenging tasks for control boards. For example, a pick‑and‑place robot may require five or six axes to move simultaneously along complex trajectories. If the axes are not synchronized, the robot may collide with itself or drop a payload. High‑performance control boards handle multi‑axis interpolation and path planning, updating each motor at microsecond intervals. They use trajectory tables or spline interpolation to generate smooth paths, ensuring that acceleration and deceleration profiles do not exceed mechanical limits. Multi‑axis synchronization demonstrates how control boards unify mechanical, electrical and computational design, without them, a robot is merely a pile of motors.

Real‑Time Processing vs Buffered Commands: Trade‑Offs Explained

Two common approaches exist for executing motion commands: real‑time streaming and buffered programs. Real‑time streaming updates the control loop in sync with sensor feedback, providing maximum responsiveness but requiring high CPU bandwidth. Buffered programs store sequences of commands on the control boards and execute them step by step, reducing communication overhead. The choice depends on the application; high‑speed machining demands real‑time control, while pick‑and‑place tasks may benefit from buffered routines. Yana’s experts evaluate these trade‑offs during controller selection, considering the design goal, budget and production environment.

Case Example: Upgrading from PLC to Custom Control Board

A mid‑size manufacturer producing precision instruments was experiencing inconsistent positioning accuracy using a PLC‑based robot controller. The PLC and robot controller communicated via analog signals; delays caused overshoot and wasted parts. After analysis, Yana recommended replacing the PLC with a custom multi‑axis control board integrated with servo drivers. The new board executed control loops at 2 kHz, implemented PID algorithms and shared data via EtherCAT. Immediately, the machine achieved smoother motion, improved accuracy and reduced cycle time. The change underscored the importance of unified control architectures. By moving to an integrated control board design, the manufacturer increased yield, saved energy and freed maintenance staff from endless tuning.

Manufacturing and Sourcing Landscape

Where the World’s Best Control Boards Are Made

Production of sophisticated control boards involves advanced electronics manufacturing, precise PCB fabrication and stringent quality control. While some robotics OEMs design boards in‑house, many rely on specialist suppliers. China remains a global hub for control board manufacturing, offering clusters of PCB fabricators, electronic component distributors, assembly houses and testing labs. Regions like Shenzhen and Dongguan have matured from simple assembly plants to full‑fledged design and manufacturing ecosystems. Their factories manufacture boards for global robotics leaders, offering competitive pricing without sacrificing quality.

However, not all suppliers are equal. Low‑cost factories may cut corners on copper thickness, solder quality or component authenticity, leading to failures in the field. Yana’s sourcing experts vet suppliers by inspecting their facilities, reviewing ISO 9001 and IPC standards compliance, and assessing their supply chain transparency. Our teams conduct audits to ensure that boards are produced on modern lines with automated optical inspection (AOI) and X‑ray inspection. The goal is to secure control boards that meet or exceed international safety and quality standards, boards that will survive the stresses of robotics, not just consumer electronics.

PCB Fabrication Ecosystems in China: Precision Meets Scale

China’s dominance in electronics manufacturing stems from an ecosystem of PCB fabricators offering a full range of services. Large producers run state‑of‑the‑art factories capable of building multi‑layer boards with high-density interconnect (HDI) features, blind vias and controlled impedance. Meanwhile, smaller PCB shops specialize in quick‑turn prototypes and low‑volume production. Many of these facilities are located near component markets like Huaqiangbei, allowing rapid procurement of parts.

Choosing the right PCB partner is crucial for robotics. For example, control boards often require high current traces to drive power stages, requiring thicker copper. They also may need rigid‑flex sections for tight installations inside robot arms. Yana’s procurement teams match each client’s needs with appropriate fabricators, one board may require a 12‑layer stackup with buried vias, while another may use a simple four‑layer design. When the product requires high reliability, we ensure that the fabricator offers 100% electrical testing, ionic contamination testing and high‑temperature reliability testing. In high‑margin industries such as aerospace or medical robotics, these extra steps protect brand reputation and safety.

Component Sourcing and Assembly Challenges in Robotics

Even the best PCB design fails without quality components and assembly. Semiconductor shortages, counterfeit parts and supply chain disruptions can derail projects. Control boards typically include microcontrollers, FPGAs, memory chips, analog–to–digital converters, sensors, connectors and passive components. Each part must come from reliable sources with traceable documentation. Counterfeit microcontrollers may contain recycled silicon that fails under load; substandard connectors may cause intermittent signals.

Assembly quality matters too. Poor soldering can create cold joints that fail under vibration. Temperature profiles must be tuned for lead‑free solder to avoid tombstoning components. Robotics control boards often incorporate connectors rated for many insertion cycles; a cheap connector may wear out and cause downtime. Yana’s sourcing process includes traceability checks to confirm part authenticity and quality audits of assembly houses. We also ensure that manufacturing partners perform functional testing on the assembled control boards, a final step that verifies firmware, sensors and communications before shipping.

Testing, Certification and Compliance: CE, UL, ISO and Beyond

Robotics products serve industries with strict regulatory requirements. Medical devices must meet IEC 60601 standards; industrial machines must conform to EN 60204 and UL 508. Control boards play a critical role in achieving these certifications. For example, safe torque off circuits must be validated to meet SIL 3 or PL d requirements. Boards must demonstrate electromagnetic compatibility (EMC) compliance under CISPR 11. Flame retardancy of PCBs is tested according to UL 94 V‑0.

Yana works with testing laboratories and certification bodies to ensure that sourced control boards come with appropriate certificates and test reports. We manage compliance documentation for clients, saving them time and ensuring they can pass final product audits. In high‑margin markets, regulatory approval is not just a requirement; it is a competitive advantage. By proactively sourcing boards with built‑in compliance features, Yana helps clients accelerate time to market.

Sourcing Control Boards the Yana Way: Transparent, Smart and Strategic

Yana’s approach to sourcing control boards goes beyond price negotiations. We begin by understanding the client’s product vision and margin targets. We then create a supply map, identifying potential board types (motion, vision, AI or hybrid) and the appropriate manufacturing geographies. We evaluate suppliers for technical capability, supply chain resilience and sustainability practices. When selecting boards, we consider the machine’s lifecycle, how will the control board be serviced? Can it be updated with new firmware? What is the mean time between failures (MTBF)? These questions ensure that the chosen board supports long‑term profitability.

Because we value transparency, we provide clients with supplier inspection reports, test data and cost breakdowns. Our higher‑dimensional sourcing philosophy treats control boards not just as components but as strategic investments. A reliable board reduces downtime, improves throughput and protects margin. A cheap but unreliable board does the opposite, jeopardizing brand reputation and profit. With access to both large contract manufacturers and boutique PCB shops, we tailor solutions to companies of any size, from startups launching their first product to enterprises optimizing global supply chains.

The Supply Chain Advantage: Why Shenzhen Still Leads the World

Shenzhen’s electronics ecosystem is unmatched. Component distributors, PCB plants, assembly houses and logistic hubs sit within a short radius. This proximity reduces lead times for prototypes and production orders. While other regions like Southeast Asia and Eastern Europe are growing in electronics manufacturing, Shenzhen still offers unmatched speed and scale. For control boards that need rapid iteration, such as those in robotics startups or pilot lines, Shenzhen’s ecosystem saves time and cost. However, for high‑margin sectors requiring strict intellectual property protection, Yana may recommend partners in Taiwan or Europe. The flexibility to choose across regions is part of our value.

Balancing Cost, Quality and Lead Time in Control Board Procurement

Supply chain management always involves trade‑offs. Shorter lead times may require paying more for capacity; the highest quality may mean longer wait times if a factory is busy. Yana helps clients balance these factors based on their business priorities. If a product launch is time‑sensitive, we expedite by working with partners known for quick turnaround. If quality is paramount, we allocate longer lead times and schedule reliability tests. Our deep supplier relationships allow us to negotiate favourable terms even for smaller clients. For high‑margin robotics, choosing reliability often yields greater lifetime profitability than chasing the lowest unit cost.

Hidden Pitfalls in OEM Board Orders—and How to Avoid Them

Ordering control boards from original equipment manufacturers (OEMs) can hide pitfalls. Some OEMs limit access to firmware, preventing upgrades or modifications; this can lock the client into a single vendor. Others use proprietary connectors or chips that become obsolete. To avoid these pitfalls, Yana negotiates for firmware source code or at least a defined upgrade path. We ensure that connectors and chips are standard or available from multiple suppliers. We also insist on clear contracts covering intellectual property, liability and warranty. By anticipating issues, we protect our clients from supply chain shocks and technical dead ends.

Integration and Applications

Integrating Control Boards with Servo Drivers, Sensors and Software

Control boards do not operate in isolation; they anchor the entire robot ecosystem. They must interface with servo drivers, sensors and high‑level software. Servo drivers amplify commands from control boards into current or voltage for motors; sensors provide feedback on position, speed, torque and environment; software orchestrates tasks and coordinates human interaction. A well‑designed control board features connectors and firmware that simplify integration. For example, a board may include connectors for incremental and absolute encoders, analog inputs for force sensors and digital inputs for limit switches. It may support plug‑and‑play servo drivers over EtherCAT, reducing wiring complexity.

Software integration is equally important. Many robotics control boards support standard communication protocols like ROS (Robot Operating System), OPC UA or EtherNet/IP. These protocols allow high‑level applications to send commands and receive feedback in a structured way. When control boards expose a robust API, developers can write custom applications or integrate with enterprise systems. Yana ensures that boards come with documentation, sample code and long‑term firmware support so that clients can build systems without being tied to proprietary tools. Integration is not just technical—it’s also strategic, because the ease of integration affects time to market and product flexibility.

Control Boards in Cobots, AGVs and Industrial Arms

Control board requirements vary by robot type. Collaborative robots (cobots) work alongside humans, requiring advanced safety functions such as power and force limiting. Their control boards integrate torque sensors and complex algorithms to monitor external forces and stop motion safely. Servo drives integrated into robot joints leverage torque feedback to ensure safety and implement features like STO. For cobots, the board may also implement machine learning routines to adapt to human interaction over time.

Automated guided vehicles (AGVs) need control boards capable of handling drive units, navigation sensors, battery management and wireless communication. These boards integrate inertial measurement units (IMUs), LiDAR, cameras and encoders. High‑bandwidth communication ensures real‑time path planning and obstacle avoidance. Industrial arms often require more axes and higher power, so their control boards must manage heat and provide robust fault detection. In heavy industry or hazardous environments, boards may include protective coatings and reinforced connectors. Yana sources board designs tailored to each robot class, combining safety, performance and cost considerations.

The Role of Control Boards in Machine Vision and Edge AI

As robots take on more complex tasks, they need to perceive their environment. Machine vision, using cameras and AI algorithms, is integral to tasks like part picking, assembly verification and quality inspection. Traditional setups process vision data on an external PC, but integrating the vision pipeline directly on control boards reduces latency and improves synchronization with motion.

Vision‑enabled control boards include image sensors, FPGAs, GPUs or AI accelerators, along with memory and high‑speed interfaces. They run perception algorithms that detect objects, measure distances or identify anomalies. By fusing vision and motion control on one board, robots can perform closed‑loop adjustments, for example, adjusting trajectory based on object orientation in real time.

Edge AI pushes computation closer to the source of data. Rather than sending data to a cloud server, the AI inference runs on the board itself. This reduces latency and ensures privacy. In quality control, a vision board can detect defects and trigger immediate rejections. In warehouse robots, it can read barcodes and navigate aisles. For such applications, selecting control boards with sufficient computing headroom and energy efficiency is crucial. Yana monitors trends in AI hardware (like neural processing units and GPUs) and ensures suppliers can integrate them into control boards when clients need advanced perception.

Control Boards for Next‑Gen Robotics Startups and D2C Automation Brands

Not all robotics companies are industrial giants; many are startups or direct‑to‑consumer (D2C) brands building innovative products. These companies need control boards that are affordable yet scalable. For example, a startup designing a desktop robot arm for makers may require a board that supports stepper motors, simple encoders and a USB interface for PC control.

As the product matures, the board should be upgradable to support servo drives and network protocols. Similarly, a D2C brand selling smart home robots may need integrated Wi‑Fi and Bluetooth along with motor control. Yana identifies board suppliers that offer roadmap support, ensuring clients can start with a minimal viable product and add features as demand grows.

Open‑Source vs Proprietary Firmware: Which Strategy Scales Better?

Choosing between open‑source firmware and proprietary firmware affects long‑term flexibility. Open‑source firmware, such as those based on ROS or Arduino, allows developers to modify and extend functionality. It fosters a community that contributes new features and bug fixes. However, maintaining open‑source code requires engineering expertise.

Proprietary firmware, provided by board manufacturers, may be more stable and optimized but can lock customers into specific vendors. Yana’s stance depends on the client’s strategy: if they have internal engineers and need maximum flexibility, open‑source may be best. If they need turnkey solutions, proprietary may be acceptable. In both cases, our contract negotiations ensure that clients retain rights to update or migrate firmware when needed.

Case Study: A Multi‑Axis Control Board for a Pick‑and‑Place Robot

To illustrate integration, consider an electronics manufacturer building a pick‑and‑place robot for circuit assembly. The robot must move across three axes to pick components and place them accurately on a PCB. The original design used three separate motor controllers and a PLC; communication issues caused jitter and frequent misplacements. Yana recommended a unified control board that integrated three servo channels, encoder feedback and EtherCAT communication.

We worked with a Shenzhen supplier to customize the board with high‑precision ADCs and a dual‑core processor. After integration, the robot achieved 30% faster cycle times and reduced placement errors by half. The board’s built‑in safety functions allowed the machine to meet CE certification without additional hardware. This case shows how control board selection shapes performance, quality and regulatory compliance.

Innovation, Intelligence and the Future

Smart Control Boards: AI Co‑processors and Predictive Maintenance

The future of control boards lies in embedding intelligence at the edge. Smart boards integrate AI co‑processors, dedicated chips for neural network inference. These chips can run algorithms for anomaly detection, predictive maintenance or adaptive control. For example, a board may monitor vibration data from motors and predict bearing wear, enabling proactive maintenance rather than reactive repairs. AI co‑processors also enable adaptive motion control: algorithms can adjust PID parameters on the fly to optimize for efficiency or precision. In high‑margin industries like medical robotics, these capabilities reduce downtime and enhance safety.

Unified Systems: Where Control Boards and Software Merge

In the long term, the distinction between hardware and software is blurring. Integrated systems combine physical boards with virtual control layers, enabling remote updates and centralized monitoring. A unified system may consist of smart servo drivers with onboard processors, a central control board handling coordination, and software that orchestrates tasks and analytics. The Motion Control & Motor Association article we referenced earlier suggests that unified control architectures face challenges due to proprietary systems, but open platforms are emerging that allow easy integration of controllers and software. Yana watches these developments and partners with suppliers building open, interoperable control ecosystems. Our mission is to help clients adopt unified architectures that reduce vendor lock‑in and foster innovation.

Sustainability in Electronics: Repairability, Efficiency and Lifecycle Value

Sustainability is becoming a major consideration in robotics. Control boards contribute to e‑waste when they cannot be repaired or recycled. Designing boards for repairability, such as by using through‑hole components where possible, socketed chips or modular design, extends their life. High efficiency reduces energy consumption, important for battery‑powered robots and green initiatives. Yana encourages suppliers to use eco‑friendly materials, comply with RoHS and REACH directives, and provide takeback programs. For high‑margin products, emphasizing sustainability may also appeal to customers and investors.

Embedded Intelligence: Control Boards that Learn from Motion

Embedded intelligence refers to control boards that adapt to their environment. Through machine learning algorithms, boards can optimize trajectories, identify anomalies or adjust control parameters. For example, a board controlling a packaging robot might learn the typical weight distribution of packages and adjust acceleration profiles to reduce wear. Over time, the board builds a model of the system and tunes itself. This reduces manual tuning and maintenance. While still emerging, Yana is already working with suppliers exploring these capabilities. For clients with long product cycles, investing in intelligent control boards yields benefits for years.

Cloud‑Linked Robotics: Secure Data Feedback from Edge to Enterprise

Although edge computing grows, cloud connectivity remains important for fleet management, analytics and remote updates. Modern control boards include secure communication modules, enabling encrypted data transfer to cloud platforms. This connectivity allows manufacturers to monitor machine health across factories, deploy firmware updates and analyze performance trends. However, connectivity introduces cybersecurity risks. Control boards must implement secure boot, encryption and access control to prevent unauthorized access. Yana guides clients through these considerations, selecting boards with robust security features and aligning with international cybersecurity standards.

Conclusion

Control Boards as the Quiet Power Behind Higher‑Dimensional Robotics

Control boards may be hidden inside enclosures, but they embody the intelligence, agility and reliability that define modern robotics. By translating high‑level intent into precise motion, they connect the mechanical world with digital logic. They unify motion control, safety, sensing and communication into one cohesive architecture. When designed and sourced properly, control boards enhance precision, reduce downtime and enable high‑margin products that stand apart in competitive markets. When overlooked, they become bottlenecks that erode quality and profit.

Yana Sourcing’s mission is to help innovators select and integrate control boards that align with their vision and business goals. We bring together engineering insight, supply chain expertise and a commitment to transparency. Whether you are a startup building your first robot or an enterprise optimizing a global manufacturing network, our higher‑dimensional sourcing approach ensures that your control boards, and your entire system, are built for the future.

Ready to elevate your robotics design? Let’s build the nerve center of your next innovation together. Contact us today and discover how smart sourcing and intelligent design make all the difference.