Table of Contents

Introduction — Why RV Reducers Matter in Modern Robotics

Robotic systems thrive on precise motion and high torque. Motors produce rotational energy, while actuators convert that energy into movement. Between them sits the gear reducer—the component that balances speed and torque so a robot can lift heavy loads or position its end effector accurately. Among the many reducer families, RV (rotary vector) reducers, also called cycloidal gearboxes, stand out for their ability to combine extraordinary torque density, shock resistance, and minimal backlash. These reducers power the largest joints in industrial robots, the bases of collaborative arms, and the heavy‑duty axes of gantry systems. They provide the dependable, high‑precision motion that industries from automotive manufacturing to defense demand.

This guide explores the design, performance, and sourcing of RV reducers. It builds on the content of our actuators and motors pages, focusing on how RV reducers translate motor output into high‑torque, low‑speed rotation. You’ll learn how they work, what makes them different from harmonic drives or planetary reducers, how to choose the right model, and why Yana’s SMART + HEART sourcing philosophy is crucial for successful integration. Whether you’re an engineer designing a robot or a sourcing professional evaluating suppliers, this comprehensive guide will empower you to make informed decisions.

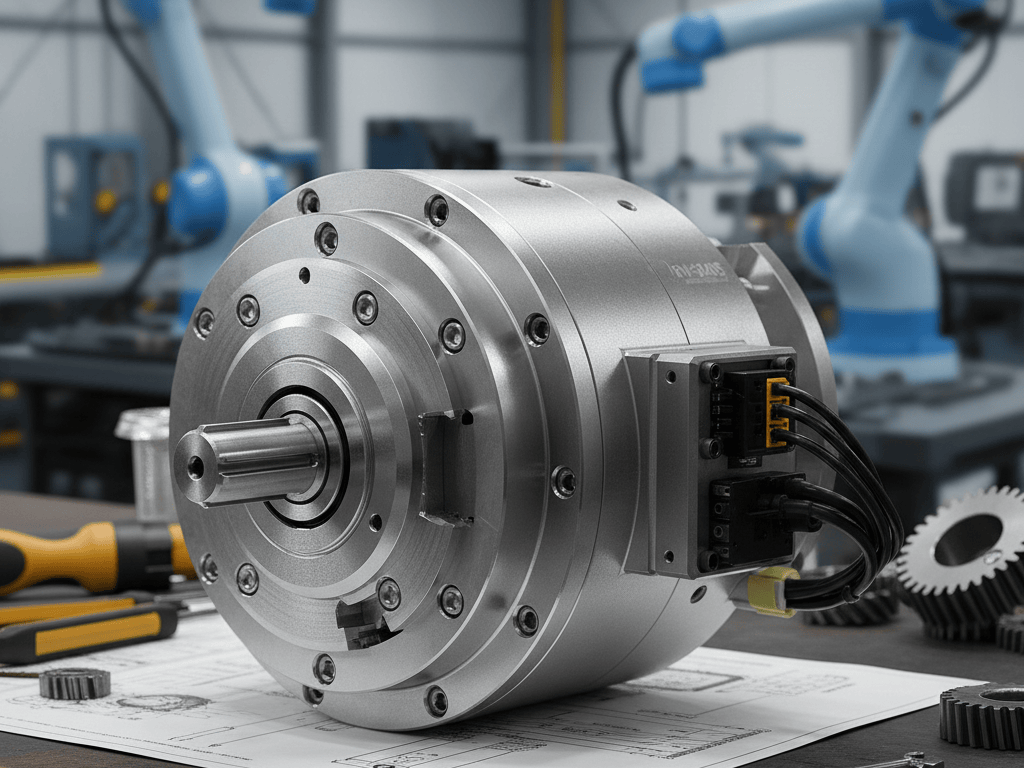

What Are RV Reducers? Working Principle & Components

Cycloidal Mechanism and Two‑Stage Reduction

Unlike traditional gearboxes that rely on involute gear teeth, RV reducers use a cycloidal motion. At their core lies an eccentric cam (or cycloid disc) connected to the input shaft. As this cam rotates, it creates a wobbly cycloidal path that drives a set of roller pins. The cycloidal disc’s motion is converted back into pure rotation at the output, yielding very high reduction ratios. Nabtesco, a leading manufacturer, highlights that their RV reducers employ a two‑stage reduction: a spur gear stage couples the motor to a set of planetary gears, which drive crankshafts connected to the cycloidal cams. This two‑stage design reduces vibration, distributes force evenly across multiple contact points, and enhances shock resistance.

In a typical RV reducer, almost all the teeth are engaged simultaneously because the cam has one eccentric lobe fewer than the ring’s number of pins. Each full rotation of the cam advances the output by only one or two pins, achieving reduction ratios of 30:1 to over 300:1. The two‑stage system combines a planetary pre‑gear with the cycloidal disc, allowing the design to handle high input speeds and offering a wide choice of ratios.

Key Components and Layout

Although vendors use slightly different architectures, most RV reducers consist of the following parts:

- Input shaft and pinion: Coupled directly to the motor (often a servo motor or torque motor). A small spur gear or pinion drives the planetary pre‑gear.

- Planetary gear set: A conventional sun–planet–ring system reduces speed and increases torque before the cycloidal stage. This first stage also helps isolate the cycloidal disc from motor vibrations.

- Cycloidal cam (disc): An eccentric disc with lobes that interacts with pins or rollers in the ring. Its cycloidal path converts input rotation into a reduced output.

- Ring gear with pins/rollers: A fixed outer ring lined with pins or rollers. The cam’s lobes engage these pins, distributing load over a large contact area. Some modern designs replace fixed pins with curved tracks to simplify assembly and allow for miniaturization.

- Output shaft: Often connected via a crankshaft or carrier that collects the motion from the cycloidal disc and transmits it to the robot joint. Many RV reducers integrate angular contact or cross‑roller bearings to support axial, radial and moment loads.

- Housing and lubrication: A sealed housing containing grease or oil ensures longevity and quiet operation. Some models include a hollow shaft through which cables or hoses can pass.

This architecture delivers true zero backlash because the cycloidal cam is preloaded against the ring pins; there is always some elastic deformation but no clearance. Many designs achieve hysteresis (lost motion) under one arc‑minute, making them extremely precise.

Why Choose RV Reducers? Key Advantages

High Torque Density and Shock Resistance

RV reducers excel at transmitting very high torque in a compact volume. Nabtesco specifies rated torques up to 28,000 Nm, with the ability to survive five times the rated torque in emergency stop conditions. The reason lies in the large contact area: more than 30 % of the cycloidal disc engages pins simultaneously, spreading load and reducing stress. This makes RV reducers ideal for heavy‑duty robot joints, lifting axes, turntables and other high‑load applications.

The robust mechanical construction also gives RV reducers excellent shock load capacity and vibration resistance. Where a harmonic drive might fail due to its thin flexspline, the solid steel parts of an RV reducer can absorb repeated shocks without permanent deformation. This resilience is invaluable in industrial settings where robots frequently start, stop or collide with unpredictable loads.

Extreme Precision with Low Backlash

Cycloidal reducers are virtually backlash‑free. Nabtesco’s precision series achieves pure backlash of 0.1–0.2 arc minutes, while hysteresis (lost motion) is less than one arc minute. This level of precision rivals harmonic drives and significantly outperforms standard planetary gears. Zero backlash is essential in applications like welding, painting, assembly, or pick‑and‑place, where even tiny positional errors accumulate at the robot’s end effector.

High Stiffness and Load Capacity

RV reducers feature integrated bearings that absorb axial, radial and moment loads, eliminating the need for external support bearings in many joints. This leads to high torsional and tilting stiffness, critical for maintaining tool orientation under heavy loads. Cycloidal reducers can transmit two to three times more torque than similarly sized harmonic drives. Their large rolling elements yield higher axial and radial load capacity, lower input inertia and greater reliability.

Durability and Long Service Life

Because force is spread across many contact points, wear is minimal and the gears have a long service life. Cycloidal drives use rolling contact rather than sliding contact, reducing friction and heat generation. Nabtesco’s design claims “extremely low wear” and a long maintenance‑free life. As a result, RV reducers maintain accuracy over time better than harmonic drives, whose flexsplines gradually lose stiffness and backlash increases.

Compact, Coaxial Design

Despite their heavy‑duty capability, RV reducers are compact and lightweight. The two‑stage reduction allows a large speed reduction in a small envelope. Many models offer a hollow shaft to route cables, hoses or drive shafts through the reducer, simplifying system integration and saving space. This makes them suitable for collaborative robots where every millimetre and gram count.

High Efficiency (in the Right Conditions)

Cycloidal reducers achieve peak efficiencies comparable to planetary gears. The review of compact gearboxes notes efficiency around 87 %, although it depends on operating speed and torque. Efficiency tends to drop at very low or high speeds due to friction losses. Proper lubrication and selecting the right size for the load help maximize efficiency.

Performance & Design Parameters

When selecting an RV reducer, consider these parameters to balance performance, cost and reliability.

Reduction Ratio & Speed Matching

- Ratio range: Single‑stage cycloidal reducers offer ratios from about 30:1 to 190:1. Two‑stage designs with planetary pre‑gears can reach over 300:1. Choose a ratio that allows your motor to run near its optimal speed while delivering the required torque.

- Input speed limits: Cycloidal reducers tolerate moderate input speeds, but high speeds can cause vibration and heat due to the eccentric rotating mass. Modern designs use dual cam stages shifted 180 degrees to cancel imbalances and allow speeds up to 8,500 rpm, although typical RV reducers operate at lower speeds for longevity. Consult the manufacturer’s ratings.

Torque & Load Handling

- Continuous vs peak torque: Determine the continuous torque required for normal operation and the peak torque during acceleration or collision. Many RV reducers can withstand 5 × rated torque for short durations. Avoid oversizing by matching the reducer’s rating to actual needs.

- Axial & radial loads: Integrated bearings handle significant axial and radial loads; check the manufacturer’s load charts. If your application imposes large external moments (for example, a long arm with a heavy payload), ensure the reducer’s tilting stiffness is adequate.

Backlash & Hysteresis

- Backlash: The clearance between output and input in reversing direction. RV reducers achieve near‑zero backlash (0.1–0.2 arc min). Verify this parameter if your robot requires sub‑arc‑minute precision.

- Hysteresis: The difference between commanded and actual output when reversing direction, due to elastic deformation. Even if backlash is zero, hysteresis can degrade accuracy. Look for specifications below 1 arc minute.

Stiffness & Natural Frequency

- Torsional stiffness: High stiffness reduces torsional deflection under load and increases servo bandwidth. Cycloidal gearboxes exhibit some of the highest torsional rigidity among compact gearboxes.

- Moment stiffness: Because the gear and bearing stage is integrated, RV reducers resist bending and tilting moments, critical for robot arms and positioning devices.

Efficiency & Thermal Considerations

- Efficiency: As mentioned, RV reducers have efficiencies around 87 %. Efficiency depends on speed and lubrication; too low a load or speed can increase friction losses. Choose lubricants specified by the manufacturer.

- Temperature: High load or speed increases heat. Ensure the reducer’s temperature rating matches your environment. Some applications require custom lubricants for vacuum or clean‑room environments.

Size & Weight

- Outer diameter & length: RV reducers are larger than harmonic drives but smaller than some planetary gearboxes. Check the dimensions to ensure it fits within your joint geometry.

- Hollow bore: If routing cables or fluid lines through the reducer, verify the hollow shaft diameter.

Life & Reliability

- Fatigue life: The cycloidal disc and pins must withstand repeated high loads. High‑quality materials and manufacturing ensure long life. The literature notes that cycloid drives require less maintenance and maintain accuracy better than strain‑wave drives.

- Lubrication: Many RV reducers are sealed and lubricated for life, but some require periodic lubrication, especially in harsh environments. Choose models with maintenance intervals that match your operational plans.

Cost & Weight Trade‑offs

RV reducers deliver outstanding performance but are more expensive and heavier than harmonic drives or standard planetary gearboxes. Manufacturing complexity, precision machining of cams, pins and bearings, requires large investments in production equipment. When cost is a primary constraint and load or precision demands are moderate, harmonic or planetary gears may be more economical. However, for heavy‑duty, high‑precision applications, the investment in RV reducers often pays off through longer life and lower maintenance.

Tradeoffs, Limitations & Mitigation

Larger Size and Weight

Compared to harmonic drives, RV reducers are bulkier and heavier. Their robust construction and integrated bearings increase mass, which can affect robot dynamics, especially in distal joints. To mitigate weight, choose the smallest reducer that meets your torque needs and consider placing RV reducers in proximal joints (base, shoulder, upper arm) while using lighter harmonic or planetary drives in the wrist and hand.

Manufacturing Complexity and Cost

The cycloidal disc, pins and high‑precision bearings require tight tolerances. As the review notes, making RV reducers more compact is challenging because smaller components require extreme manufacturing precision. This complexity translates into higher cost and longer lead times. Mitigate by choosing standard sizes when possible and working with suppliers experienced in large‑volume production.

High Input Speed Limitations and Torque Ripple

The eccentric cam’s mass limits input speed. High speeds can cause vibrations and torque ripple, periodic variations in output torque due to the cycloidal motion. Pre‑gearing with a planetary stage helps, but if your application demands very high input speeds, consider using direct‑drive motors or harmonic drives, or select RV reducers specifically designed for high‑speed operation. Some manufacturers use dual cams to balance inertial forces and reduce ripple. Additionally, control algorithms can compensate for torque ripple, and proper preload can minimize its effects.

Sensitivity to Manufacturing Errors

Cycloidal drives are sensitive to centre distance errors between the cam and ring, which can increase torque ripple and reduce efficiency. To mitigate, choose suppliers with rigorous quality control and testing. Some designs adopt non‑involute tooth profiles or involute teeth with reduced pressure angles to reduce sensitivity to misalignment.

Operating Environment

RV reducers are robust but still need protection from contamination and extreme temperatures. If your robot operates in food processing, vacuum, underwater or clean‑room environments, select versions with appropriate seals and lubricants. For outdoor or defence applications subject to temperature extremes, choose models rated for those conditions.

Applications & Real‑World Use Cases

The unique blend of strength, precision and durability makes RV reducers indispensable across many industries. Here are some notable application areas:

Industrial Robots & Automation

RV reducers dominate in articulated industrial robots. They occupy the base, shoulder and elbow joints, positions subject to high torque and moment loads. Their shock resistance ensures robots can handle sudden starts and stops without backlash or damage. In gantry robots and Cartesian robots, they provide stable axes for heavy payloads. RV reducers also power welding positioners, painting robots, packaging machines, and automated assembly lines where precision and long life are paramount.

Collaborative & Service Robots

In collaborative robots (cobots), high torque density allows manufacturers to design slender arms with integrated force sensing. RV reducers can be paired with torque sensors to create compliant joints that are strong yet safe for human interaction. Their reliability suits service robots operating in hospitals, warehouses and retail spaces.

CNC & Machine Tools

Cycloidal reducers maintain precise rotary positioning in CNC milling heads, grinding machines, and rotary tables. Low vibration and high stiffness deliver accurate cuts and improved surface finish. RV reducers are also used in tool changers and pallet changers, ensuring repeatable alignment when swapping tools or workpieces.

Medical Equipment

Medical devices demand quiet, sterile operation. Cycloidal reducers provide precise positioning with low noise, supporting dental milling machines, surgical robots and imaging equipment. They maintain accuracy over thousands of cycles and are available with lubricants suitable for clean rooms.

Defence, Aerospace & Security

Applications include pan‑tilt units for surveillance cameras, weapon station positioning, radar systems, and aerial gimbals. Cycloidal reducers resist vibration and maintain position in harsh conditions. They handle rapid acceleration, shock loading and extreme temperatures; special lubricants extend the operating range. Their high rigidity ensures targeting accuracy and reliability under recoil and wind loads.

Heavy Machinery & Industrials

In conveyor systems, mining equipment, and wind turbines, RV reducers deliver high torque with minimal maintenance. They power heavy duty winches, excavators, and drilling rigs where durability and efficiency matter. The ability to handle high loads without failure reduces downtime and maintenance costs.

Automotive & Electric Vehicles

Some electric vehicles employ cycloidal drives in differentials and transmissions. Their compact size and high torque capacity help convert high‑speed motor rotation into wheel torque. They’re also used in power steering systems and automated manufacturing processes.

Aerospace & Defence Aviation

Aircraft actuators, landing gear systems and satellite attitude control rely on cycloidal reducers for high reliability and low backlash. NASA originally used strain‑wave gears, but modern spacecraft increasingly adopt cycloidal reducers because of their shock resistance and load capacity.

Integration & System Design Considerations

Motor Coupling & Inertia Matching

Like any gearbox, an RV reducer must be matched to the motor. Check that the input pinion and mounting flange fit your motor’s shaft and bolt pattern. Ensure the reflected inertia (output inertia divided by the square of the gear ratio) is within the motor’s capabilities; a high gear ratio reduces reflected inertia, allowing smaller motors to move larger loads.

Bearing Integration & Structural Support

RV reducers often integrate angular ball or cross‑roller bearings, enabling them to support radial, axial and bending loads without additional external bearings. This simplifies the joint structure and reduces assembly time. When designing the joint, ensure proper preload on the bearings and avoid misalignment that could induce radial loads on the cycloidal disc.

Lubrication & Sealing

Select reducers with lubrication suited to the operating environment. Standard models use grease or oil sealed within the housing. For high‑vacuum or food‑grade environments, choose special lubricants. Make sure seals are adequate for dust, debris or moisture; a failure of the seal can lead to contamination and premature wear.

Control & Dynamics

The eccentric motion of the cycloidal disc introduces torque ripple and inertia variations. Control algorithms must compensate for these effects to achieve smooth motion. Many servo drives offer feed‑forward torque compensation. Additionally, the natural frequency of the reducer–motor system should lie outside the servo control bandwidth. Use dynamic models and simulation to tune your control loops accordingly.

Hybrid Systems & Mixed Gear Trains

For multi‑axis systems, combining gear types can yield optimal performance. For instance, use RV reducers on proximal joints requiring high torque and stiffness, and harmonic drives or planetary reducers on distal joints where weight and size are critical. This hybrid approach balances cost, weight and performance across the robot’s kinematic chain.

Sourcing, Manufacturing & Quality Strategy

Global Manufacturing Landscape

RV reducers originated in Germany during the 1920s but gained prominence when Japanese companies like Nabtesco and Sumitomo industrialized the technology. Today, Japan remains the leader in high‑precision cycloidal reducers, providing products with zero backlash, extreme rigidity and long life. China has developed manufacturing capacity to meet the soaring demand for industrial robots; quality varies widely, from world‑class producers to low‑cost but inconsistent suppliers. Europe, South Korea and the United States also produce specialty RV reducers tailored to niche markets.

Quality Control & Inspection

Building a reliable RV reducer requires stringent quality control:

- Materials & Heat Treatment: High‑strength steels and proper heat treatment ensure the cycloidal disc and pins resist fatigue and wear. Request material certificates and verify heat treatment records.

- Machining Precision: The cycloidal cam profile and pin diameter must meet tight tolerances to minimize torque ripple and ensure smooth rolling contact. Inspect gear profiles using coordinate measuring machines.

- Bearing Preload & Assembly: Integrated bearings must be preloaded correctly; too much preload increases friction and heat, while too little reduces stiffness and increases backlash. Choose suppliers with robust assembly processes.

- Performance Testing: Evaluate backlash, hysteresis, torque ripple, efficiency and temperature rise under load. Accept only units that meet specification.

Supply Chain & Risk Management

Reliance on single suppliers or regions exposes projects to risk (e.g., geopolitical issues, pandemics, raw material shortages). Mitigate by:

- Dual Sourcing: Qualify multiple suppliers across different geographies. Standardize reducer interfaces (bolt patterns, shaft dimensions) to allow interchangeable components.

- Inventory Buffers: Maintain safety stock or schedule deliveries to avoid production stoppages. Balance inventory costs against lead time risk.

- Supplier Audits: Conduct regular on‑site or virtual audits to verify quality systems and ethical practices. Assess both the hard metrics (quality, capacity, certifications) and soft factors (communication, responsiveness) using Yana’s SMART + HEART methodology.

- Contractual Protections: Ensure your contracts include warranties, liability clauses, and explicit definitions of performance metrics (backlash, efficiency, life) to support after‑sales claims.

Yana’s SMART + HEART Sourcing Framework

At Yana Sourcing, we evaluate suppliers using a rigorous framework:

- SMART (Scientific, Market, Assurance, Risk, Transparency): We inspect technical capability, financial health, adherence to standards, risk management practices and transparency. Only suppliers who excel across these metrics are considered.

- HEART (History, Execution, Agility, Reliability, Trust): We assess the supplier’s track record, ability to execute orders accurately, agility in handling changes, reliability in meeting deadlines, and trustworthiness. The HEART component ensures human factors like ethics and communication are weighed alongside technical metrics.

By blending quantitative and qualitative assessment, Yana ensures that every RV reducer in your supply chain is both technically sound and ethically sourced.

Future Trends & Innovations

Hybrid Gear Designs

To overcome limitations like torque ripple and inertia, manufacturers are developing hybrid gearboxes that combine cycloidal and planetary stages more seamlessly. By integrating both stages within a single housing and optimizing the tooth geometry, these designs aim to deliver higher efficiency, smoother output and compactness. The review notes that such cycloid–planetary hybrids now command over 60 % of the robotic gearbox market.

Lightweight Materials & Miniaturization

New alloys and composite materials offer opportunities to reduce the weight of cycloidal drives without compromising strength. Research is exploring carbon‑fibre reinforced cams and ceramic bearings. At the same time, engineers are developing miniature RV reducers to power small exoskeletons, wearable robots and micro‑industrial systems. Miniaturization is challenging because tolerances shrink, but innovations like curved tracks replacing fixed pins simplify assembly and allow smaller, lighter designs.

Integrated Sensors & Smart Diagnostics

Following the trends in motors and actuators, RV reducers will soon feature embedded temperature, vibration, and torque sensors. Real‑time data enables predictive maintenance: the reducer can warn of lubrication degradation, misalignment or fatigue before failure. Integration with edge computing and AI will allow reducers to adapt their preload or lubricant distribution dynamically, extending life and optimizing performance.

Digital Twins & AI‑Driven Design

Designers are embracing digital twin technology, modelling gear kinematics, materials and loads virtually before building physical prototypes. Combined with AI algorithms, designers can optimize cam profiles, tooth shapes and bearing configurations to reduce torque ripple and increase efficiency. AI also predicts supply chain disruptions and helps choose suppliers with lower risk profiles.

Sustainable Manufacturing & Lifecycle

Sustainability will shape the future of RV reducers. Manufacturers are exploring recyclable lubricants, low‑emission heat treatments, and remanufacturable gearboxes. Customers increasingly demand lifecycle analyses and transparent environmental reporting. RV reducer suppliers who adopt circular economy principles will gain a competitive edge.

Yana’s Approach & Conclusion

RV reducers provide the heavy‑duty backbone of modern robotics. With exceptional torque density, shock resistance, stiffness and precision, they excel where harmonic drives and planetary gears fall short. Their unique cycloidal mechanism ensures extremely low backlash and long service life, enabling robots to perform dynamic, precise operations across industries from manufacturing and medicine to defence and energy. Yet their strengths come with challenges: higher cost, greater weight and sensitivity to manufacturing precision.

Selecting the right RV reducer demands a holistic view: understand your load, speed, precision and environmental requirements; weigh the trade‑offs against alternative gear types; and ensure your supplier can deliver consistent quality. At Yana Sourcing, we blend technical expertise with human judgment. Our SMART + HEART framework evaluates suppliers not just on product metrics but on ethics, communication and reliability. We maintain global networks across Japan, Europe, China and the Americas to source the best RV reducers, ensuring that your robots perform with precision, power and peace of mind.

By incorporating RV reducers into your robotic designs, you unlock a world of possibilities: stronger joints, higher payloads, smoother motion and longer life. Combined with Yana’s high‑dimensional sourcing, your next generation of robots will operate with the confidence, resilience and agility needed to dominate their tasks. Let us guide you through this journey, because precision motion requires precision sourcing.