Table of Contents

Introduction

Robotics is no longer confined to industrial floors. Collaborative robots move alongside humans in factories, mobile robots navigate warehouses and hospitals, and precision surgical devices perform complex procedures. At the heart of these machines lies a humble yet astonishing component: the planetary reducer. Also known as a planetary gearbox or epicyclic gear set, this mechanism multiplies torque while keeping footprints small, enabling robots to deliver powerful, precise motion in tight spaces.

Because planetary reducers support coaxial input and output shafts, they integrate neatly with servo motors, stepper motors and electric actuators, providing the mechanical advantage necessary to handle payloads or accelerate quickly. However, selecting and sourcing planetary gearboxes is not trivial, engineers must balance power density, efficiency, noise, backlash, cost and reliability, while ensuring vendors can deliver quality and transparency.

This guide explores how planetary reducers work, their advantages and limitations, types and variations, applications across robotics, and how to select and source them intelligently. Throughout, we weave in Yana Sourcing’s SMART + HEART philosophy, a combination of rigorous technical analysis and human-centred partnership that ensures clients obtain gearboxes that not only meet specifications but also align with project timelines, budgets and ethical sourcing standards.

How Planetary Reducers Work

Basic Mechanism

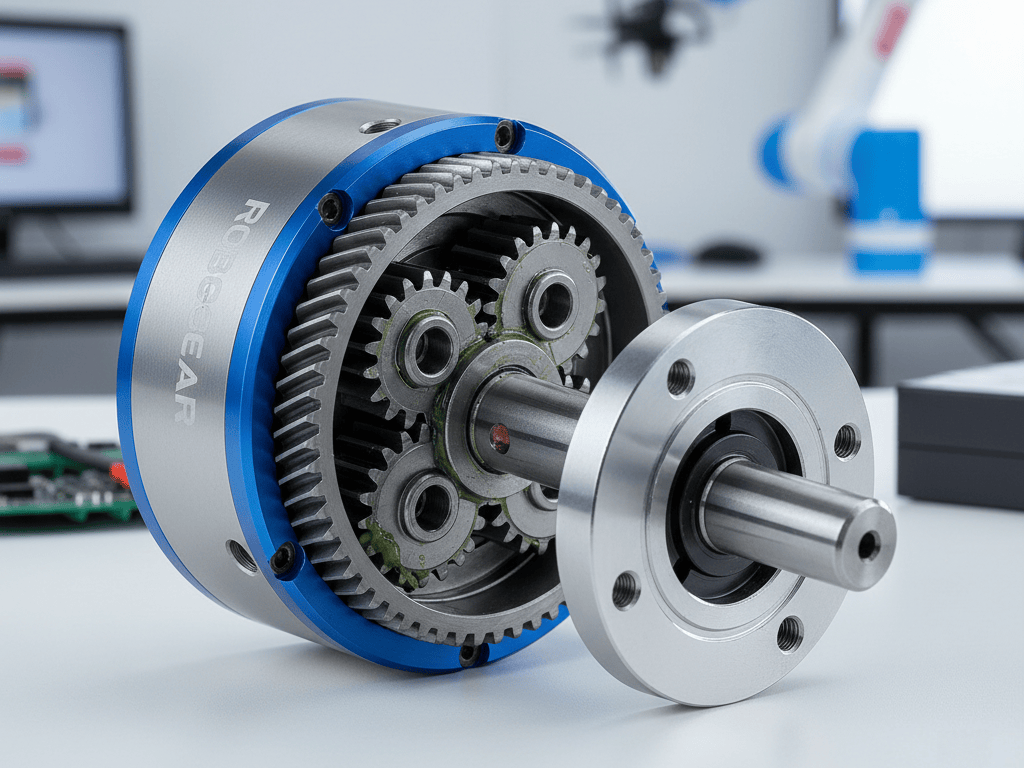

Planetary reducers consist of three core components: a sun gear at the center, several planet gears orbiting the sun, and a ring gear (also called the annulus) surrounding the planets. The planet gears are mounted on a planet carrier that holds them at fixed relative positions. When the sun gear is driven by an input shaft, the planet gears roll along the internal teeth of the stationary ring gear while rotating on their own axes. This rolling orbit (“epicyclic motion”) produces a speed reduction and a torque multiplication at the carrier, which acts as the output shaft. Because the sun, planets and ring remain coaxial, the design achieves large reduction ratios in a compact package.

Mathematically, the reduction ratio in a simple planetary set depends on the number of teeth on the ring gear (NR) and sun gear (NS):

{Reduction Ratio} = 1 + \frac{N_R}{N_S}

For example, if the ring has 80 teeth and the sun has 20 teeth, the ratio is 1 + 80/20 = 5:1. Higher ratios can be achieved by adding more stages. Each stage typically delivers 3:1–10:1 reduction with efficiencies around 97%. Multi‑stage gearboxes use two or three planetary sets in series to reach ratios of 100:1 or more without dramatically increasing size.

Load Distribution and Power Density

A key advantage of the planetary arrangement is symmetrical load distribution. Because the torque is shared among multiple planet gears that contact both the sun and ring gears simultaneously, stresses on individual teeth are lower than in simple spur gear trains. This load sharing allows planetary reducers to deliver high torque relative to their weight and size, resulting in exceptional power density, more power per kilogram than many alternatives. The coaxial alignment also eliminates bending moments, creating purely torsional reactions that simplify mounting and reduce vibration.

Coaxial Alignment and Space Efficiency

Conventional parallel-shaft gearboxes require offset shafts that increase length and complexity. In contrast, planetary gear sets maintain the input, output and ring gears on a common axis, allowing for a short axial length and a cylindrical envelope. This shape is ideal for robotic joints and wheels where space is at a premium. The diagram below illustrates a simplified planetary reducer (sun gear in blue, three planet gears in green, ring gear in black).

Advantages of Planetary Reducers

Planetary gearboxes are favoured in robotics not only for their compactness but also for a suite of performance characteristics that address the needs of precision motion control.

High Torque-to-Weight Ratio and Power Density

Because torque is transmitted through multiple planets simultaneously, planetary reducers can transmit high torque while keeping individual gear sizes small. This yields an exceptional torque-to-weight ratio, sometimes referred to as power density, which is crucial for robots that must lift or move heavy loads relative to their own mass. Load distribution also reduces gear tooth stresses, promoting longer life and enabling gearboxes to handle shock loads without catastrophic failure.

Compactness and Lightweight Design

The coaxial architecture means the input and output shafts share a common centreline, so the reducer’s diameter can be minimized and axial length kept short. This compactness allows engineers to fit gearboxes into tight joints of articulated arms, humanoid robots and exoskeletons. A smaller gearbox also reduces the overall weight of the robotic system, saving energy and making mobile robots more efficient.

High Efficiency

Planetary reducers typically achieve efficiencies of 96–97% per stage, with total efficiencies around 90–95% for two-stage gearboxes. The high efficiency results from rolling contact and well-distributed loads. Helical gear versions can further reduce vibration and increase torque capacity; though they introduce axial forces, proper bearing design mitigates this.

Low Backlash and High Precision

Backlash, the lost motion due to clearance between mating teeth, is critical in precision robotics. Traditional planetary gearboxes exhibit higher backlash than harmonic drives but deliver much higher torque. Modern designs have minimized backlash to just a few arc‑minutes (e.g., 5–20 arc‑min) by combining precision machining, preloaded bearings and spring compensation. Some zero‑backlash planetary gearheads use wear‑compensation mechanisms to maintain tight tolerances throughout life, enabling smooth servo control and accurate positioning.

Versatility of Reduction Ratios

Single-stage planetary reducers offer ratios from 3:1 to 10:1, while multi-stage versions achieve ratios exceeding 100:1 without severe drop in efficiency or footprint. Engineers can combine stages or vary tooth counts to tailor the ratio to application demands. Moreover, planetary sets can be configured for speed reduction (sun driving), speed increase (ring driving), differential action, or dual input–dual output arrangements, making them versatile building blocks for complex transmissions.

Smooth Operation and Long Life

Multiple points of contact reduce gear-tooth load, resulting in smoother torque transmission, lower noise, and less vibration compared with simple spur gear trains. The symmetrical layout also balances inertial forces, promoting stability at high speeds. Because loads are distributed, tooth wear is slower and gearboxes can achieve long service life with proper lubrication. Some designs use helical teeth to further smooth operation and reduce acoustic noise, though they require thrust bearings to absorb axial forces.

Flexibility and Modularity

Planetary gear systems offer numerous kinematic combinations. Engineers can lock or drive different components (sun, ring, carrier) to produce various outputs, speed reduction, speed increase or directional changes. Modular designs enable quick swapping of gear stages or mixing planetary sets with other reducers (e.g., cycloidal or harmonic) to achieve hybrid performance. The ability to stack stages without adding significant diameter allows planetary reducers to deliver high ratios while remaining compact.

Robustness and Durability

Planetary gearboxes are built from hardened alloy steels or advanced composites, with precision bearings and hardened tooth profiles. When paired with proper lubrication and sealing, they offer excellent resistance to wear, corrosion and contamination. Because torque is transmitted through multiple gears, a single tooth failure does not necessarily disable the gearbox, making planetary reducers inherently more fault tolerant than single-gear systems.

Disadvantages and Trade‑offs

Despite their many advantages, planetary reducers have limitations and trade‑offs that engineers must consider during design and sourcing.

Complex Design and Higher Cost

Manufacturing a planetary gearbox requires tight tolerances to ensure that the planet gears share load evenly. Misplacement or clearance differences can cause one planet to carry more load than others, leading to premature wear or failure. Precision machining, heat treatment and quality control drive up costs relative to simple spur gearboxes. The assembly process is also more complex because multiple planets must be timed correctly and bearings preloaded. High-performance zero‑backlash designs incorporate wear‑compensation mechanisms and special preload springs, further increasing cost.

Bearing Loads and Lubrication

Planet gears generate radial forces that produce high loads on carrier bearings and ring gear bushings. Heavy radial loads require robust bearings and stiff housings; otherwise, deflection leads to misalignment and uneven load sharing. Because the gears are enclosed, heat dissipation can be challenging. Continuous lubrication is essential to prevent overheating and wear. Compact, sealed designs may require oil circulation or grease that can handle high temperature and resist leakage.

Unequal Load Sharing and Torque Ripple

In practice, manufacturing tolerances and gear tooth profile errors can cause the planets to carry unequal torque. This results in torque ripple, variations in output torque, which may affect precision motion control. Sophisticated designs use preload springs, helical gearing or micro‑adjustments to equalize load distribution, but these solutions add complexity and cost.

Limited Reduction per Stage

While planetary reducers can achieve high overall ratios, each stage typically provides a moderate reduction (3:1–10:1). Achieving ratios above 100:1 requires multiple stages, which adds length, weight and cost. Engineers must balance the desired ratio against the number of stages and the resulting efficiency (each stage introduces ~3–4% power loss).

Noise, Vibration and Axial Forces

Straight‑cut spur gears generate gear mesh noise and vibration at high speeds. Switching to helical gears reduces noise and increases torque capacity but introduces axial thrust that must be absorbed by bearings. In servo applications, smooth, quiet operation is important to avoid exciting resonances in robotic arms. Therefore, high‑precision helical planetary gearheads are common in robotics despite their higher cost.

Types and Variations

Planetary gear technology is diverse, with variations optimized for different performance criteria. Below are some key types relevant to robotics.

Spur vs. Helical Planetary Gearboxes

Spur planetary gearboxes use straight teeth. They are simpler to manufacture and more efficient but generate more noise and vibration at high speeds. Helical planetary gearboxes employ angled teeth that gradually engage, which increases torque capacity and reduces noise; however, helical gears produce axial thrust forces requiring additional bearings. Robotics applications often prefer helical gearheads for smoother motion and higher torsional stiffness, especially in servo-driven joints.

Single-Stage and Multi-Stage Configurations

Single-stage planetary reducers offer modest ratios (e.g., 3:1–10:1) and high efficiency, suitable for applications needing low to moderate reduction. For higher reductions, gearboxes combine two or three planetary stages in series. Two-stage units achieve ratios up to ~100:1 with high efficiency, whereas three-stage gearboxes reach 175:1 or more.

High-Precision / Zero‑Backlash Designs

Modern planetary gearheads for robotics feature zero‑backlash mechanisms, such as dual gear trains with preloaded springs or torque couplings that eliminate clearance between teeth. These designs reduce lost motion to a few arc-minutes and maintain preload throughout the gearbox’s life. They deliver high torsional stiffness and repeatability required for robotic arms, machine tools and medical devices.

Right-Angle Planetary Gearboxes

Some applications require the output shaft to be at a right angle to the input. Right‑angle planetary reducers combine bevel gears or worm gears with a planetary set. These gearheads maintain high torque capacity while changing the axis of rotation.

Differential Planetary Sets

By driving different elements (sun, ring, carrier) simultaneously, planetary sets can produce differential outputs, enabling advanced functions like torque splitting, variable ratio and multi‑input mixing. Though less common in standard robotics, differential epicyclic trains are used in automotive transmissions and may find application in robotic vehicles and manipulators.

Micro and Integrated Planetary Gearboxes

Advances in micro‑machining and additive manufacturing have produced tiny planetary reducers for micro‑robots, medical devices and aerospace instruments. These gearboxes integrate motors, sensors and control electronics into a single module, offering plug‑and‑play actuation that saves space and simplifies system design.

Applications Across Robotics

Planetary reducers’ combination of compactness, power density and precision makes them ubiquitous in robotics and automation. Below we highlight key application domains.

Industrial Robots and Cobots

Articulated robot arms used in welding, assembly, packaging and painting require high torque to lift payloads and precise positioning to achieve repeatable accuracy. Low‑backlash helical planetary gearheads are paired with servo motors to drive each joint, providing the stiffness and responsiveness needed for dynamic tasks. Collaborative robots (cobots) also leverage planetary reducers because their compact joints need to fit within human-safe envelope while delivering sufficient torque.

Mobile Robots and AGVs

Autonomous mobile robots (AMRs), automated guided vehicles (AGVs), and robotic lawn mowers use planetary gearboxes in wheel drives and steering mechanisms. The gearheads provide the torque multiplication required to accelerate and climb slopes while maintaining a small, robust package. Precision gearboxes with low backlash enable smooth navigation and accurate odometry. Market analyses predict that the mobile robot segment will drive significant growth in the planetary precision gear market by 2026.

Humanoid Robots and Exoskeletons

Robotic humanoids and powered exoskeletons need actuation systems that fit within limb segments yet deliver human‑like force and speed. Planetary reducers combined with high-torque density motors allow designers to place actuators inside joints or along limbs without bulky protrusions. Zero‑backlash gearheads ensure the limbs respond precisely to control signals, enabling delicate manipulation or stable gait.

Medical and Laboratory Automation

Surgical robots, endoscopic devices and laboratory automation equipment demand high precision, sterility and smooth motion. Compact, sealed planetary gearboxes with stainless steel housings meet these requirements while delivering the torque necessary for cutting, gripping or transferring samples. Low-noise, low-backlash designs minimize disturbances that could affect sensitive procedures.

Aerospace and UAVs

Drones and satellite positioning systems require light weight, high reliability and precise control. Miniaturized planetary reducers drive gimbals, control surfaces and reaction wheels, offering high efficiency and robustness in harsh environments. Their coaxial design conserves space and mass, which is critical in aerospace applications.

Industrial Automation Equipment

Conveyors, packaging machines, printing presses and gantry systems employ planetary gear reducers to convert servo motor speeds into usable torque. Their long life and high efficiency help reduce maintenance downtime and energy consumption. By combining planetary gear sets with belt drives or harmonic reducers, engineers can tailor performance to specific tasks.

Selection Criteria and Considerations

Choosing the right planetary reducer requires evaluating both mechanical parameters and application context. Below is a checklist of key factors:

- Torque and Load: Determine peak and continuous torque requirements, including shock loads. Planetary reducers excel at high torque but must be sized correctly; oversizing reduces efficiency while undersizing causes overheating and wear.

- Speed and Ratio: Identify input speed and desired output speed. Single-stage gearboxes offer limited ratios; multiple stages increase ratio but add length and reduce efficiency.

- Backlash and Positioning Accuracy: For precision motion control, choose low- or zero-backlash gearheads. Consider the gearhead’s torsional stiffness and the servo motor’s control bandwidth.

- Efficiency and Heat Dissipation: High efficiency reduces energy consumption and heat generation. Check whether lubrication type (grease vs. oil) suits the duty cycle and ambient temperature.

- Size and Weight: Evaluate the gearhead’s length and diameter to ensure it fits within the robotic joint or chassis. Lightweight gearboxes improve dynamic response.

- Mounting and Interface: Ensure the gearbox’s input matches your motor’s shaft size, mounting flange and bolt pattern. Check output shaft style (solid, hollow, flange or spline) and whether right‑angle configurations are needed.

- Duty Cycle and Environment: Consider duty cycle (continuous vs. intermittent), ambient temperature, contamination, shock and vibration. Food, medical or cleanroom environments require special materials and sealing.

- Noise and Vibration: If human operators are nearby or if sensors require quiet operation, select helical gearheads or noise‑optimized designs.

- Cost and Availability: Balance performance with budget. Higher precision gearheads cost more but may be necessary for demanding tasks. Factor in lead times, minimum order quantities and supplier reliability.

- Supplier Support and Warranty: Ensure the vendor provides technical documentation, performance curves, life estimates and after‑sales support. A reliable supplier will offer quality certifications and traceability.

Sourcing, Manufacturing & Quality Strategy (Yana’s SMART + HEART Approach)

At Yana Sourcing, we believe that specifying a high-performance planetary gearbox is only half the battle; sourcing and quality assurance complete the picture. Our SMART + HEART philosophy reflects a blend of engineering rigour (SMART) and a partnership mentality that values transparency, communication and ethics (HEART). Here’s how we help clients procure the right gearboxes:

- Requirements Definition (SMART): We collaborate with your engineering team to understand torque, speed, backlash, life and environmental requirements. This ensures the specification matches the intended application, avoiding over- or under-design.

- Supplier Identification (SMART): Our database of vetted suppliers spans Asia, Europe and the Americas. We evaluate manufacturers based on technical capability, quality systems (ISO 9001/IATF 16949), material traceability and ability to customise gearboxes.

- Risk Assessment (SMART/HEART): We perform factory audits, financial evaluations and geopolitical risk analysis to ensure continuity of supply. Dual sourcing strategies are encouraged to mitigate disruptions.

- Quality Control (SMART): Yana’s inspectors monitor production processes, including heat treatment, gear grinding, assembly and preload calibration. We conduct dimensional and functional testing, measuring backlash, efficiency, noise and torque capacity, before shipping.

- Ethical Engagement (HEART): We foster long-term relationships with suppliers built on fair pricing, transparency and respect. Our team communicates regularly with clients and manufacturers to resolve issues early and align expectations.

- Logistics and After-Sales Support (HEART): We manage logistics and customs, ensuring gearboxes arrive on time and in optimal condition. After delivery, we assist with integration, provide maintenance guidelines and coordinate warranty claims.

By combining technical acuity with empathetic partnership, Yana reduces procurement risk and ensures that the planetary reducers you receive perform as promised in your robotic systems.

Future Trends & Innovations

Planetary reducer technology is evolving rapidly as robotics advances and the industrial landscape transforms. Several trends are shaping the future of these gearboxes:

Smart Gearboxes and Condition Monitoring

Integration of sensors into gearheads is enabling continuous monitoring of temperature, vibration, torque and lubricant quality. Built‑in accelerometers, thermistors and oil-quality probes feed data to control systems or cloud platforms. This data supports predictive maintenance, detecting early signs of wear or misalignment before failures occur.

The ZD Driver report highlights that sensors such as vibration and temperature probes are being embedded in gearboxes to enable condition monitoring and predictive maintenance. Combining sensor data with machine learning algorithms, manufacturers create digital twins—virtual models that simulate real-world performance and help predict failure scenarios or optimize efficiency.

Advanced Materials and Manufacturing

Improved steels, surface treatments and composite materials are increasing the load capacity and fatigue life of gear teeth while reducing weight. Additive manufacturing allows for novel gear geometries and rapid prototyping. For small robots, micro gearboxes fabricated with lithography or micromachining deliver precise torque in millimeter‑scale packages.

Hybrid Drives and Integrated Systems

Robots increasingly combine planetary reducers with other transmission technologies, such as harmonic drives (for zero backlash) or cycloidal reducers (for high shock load capacity), into hybrid gearheads that capitalise on the strengths of each mechanism. Designers can use a planetary stage for bulk reduction and a harmonic stage for fine positioning, achieving high torque and precision in one unit. Yana has sourced hybrid gearboxes for clients requiring both high torque and near-zero backlash.

AI-Driven Design and Control

Advances in AI and machine learning are improving gear design and control algorithms. Generative design tools can optimise gear tooth profiles for load distribution and noise reduction. Machine learning models use condition-monitoring data to predict remaining life and adjust control parameters in real time, improving efficiency and reliability. According to robotics trend analyses, integration of AI and advanced sensor technology will enhance predictive maintenance and real-time process optimisation in robotic systems.

Industry Growth and Market Dynamics

The robotics industry is expanding, with mobile robots driving significant demand for precision planetary gearboxes. As labour shortages and supply chain reconfigurations accelerate automation, more companies will invest in robots that rely on high-quality gearheads. In the meantime, zero‑backlash and high-torque planetary reducers will become mainstream, pushing manufacturers to refine designs and lower costs.

Conclusion

Planetary reducers are the compact powerhouses that enable modern robots to deliver smooth, powerful and precise motion. By distributing load across multiple planet gears, they achieve high torque-to-weight ratios, high efficiency and long life. Their coaxial architecture saves space, and modern designs minimize backlash to meet the demanding needs of robotics and automation. However, planetary gearboxes require careful design and sourcing: unequal load sharing, bearing loads and complex assembly call for precision manufacturing and rigorous quality control.

As robotics applications diversify, from industrial arms to mobile robots, surgical devices and exoskeletons, the versatility and reliability of planetary reducers will keep them at the forefront of motion control. Future innovations will embed sensors for predictive maintenance, adopt new materials and additive manufacturing, and integrate AI-driven design and control. Hybrid gearboxes combining planetary, harmonic and cycloidal stages will offer even better performance.

Yana Sourcing stands ready to help you navigate this landscape. Through our SMART + HEART approach, we deliver not only high-performance gearboxes but also the technical guidance, supplier validation and partnership needed to ensure your robotic systems succeed. Whether you’re designing a new cobot joint or retrofitting an AGV drive, reach out to our team to discuss how we can help you source planetary reducers that unlock the full potential of your technology.