Table of Contents

Introduction — Why Harmonic Reducers Matter in Robotics

In modern robotics, precision is everything. Robots must position arms with sub‑millimetre accuracy, move gracefully at variable speeds, and handle loads without shaking or slipping. To achieve this, designers pair powerful motors with sophisticated actuators and gear reducers. Among these reducers, the harmonic reducer (also called a strain‑wave gear) is revered for its ability to deliver zero backlash, ultra‑high reduction ratios, and compact form factors. Put simply, harmonic reducers unlock the next level of motion control, enabling collaborative robots, humanoids, surgical arms, and space mechanisms to perform with uncanny smoothness and precision.

This page dives deep into harmonic reducers: their working principle, performance metrics, design considerations, tradeoffs, applications, sourcing strategies, and future trends. Whether you’re an engineer selecting components for a new robot or a sourcing professional evaluating suppliers, this comprehensive guide will help you make informed decisions, and show how Yana Sourcing’s SMART + HEART framework elevates every reducer project to a higher dimension.

What Are Harmonic Reducers? Working Principle & Components

The Strain‑Wave Gear Architecture

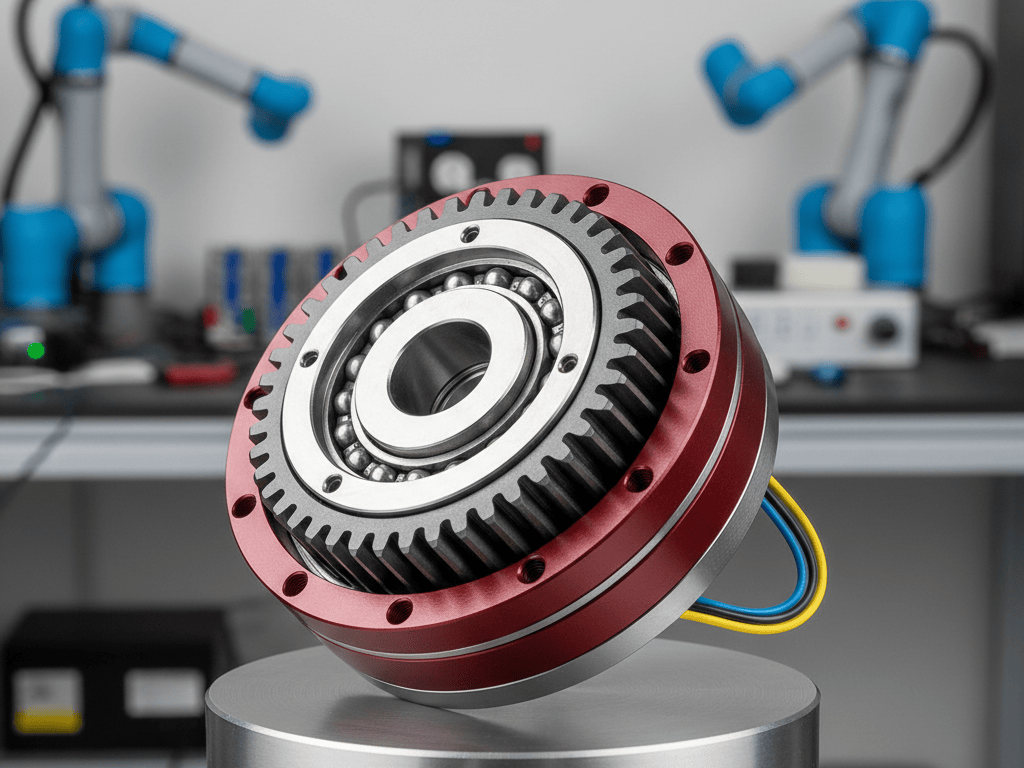

A harmonic reducer consists of three key parts:

- Wave Generator – An elliptical disk with an integrated bearing. It connects to the input motor shaft and forces the flexspline to deform elliptically.

- Flexspline – A thin‑walled, cup‑shaped steel component with external teeth. It fits over the wave generator and flexes to match the wave generator’s elliptical shape.

- Circular Spline – A rigid ring with internal teeth. It surrounds the flexspline and remains stationary during operation.

These components work in harmony. As the motor rotates the wave generator, the flexspline deforms and its teeth mesh with the circular spline at two diametrically opposite points. Crucially, the flexspline has fewer teeth than the circular spline (often two fewer), so each rotation of the wave generator causes the flexspline to lag slightly behind. If the circular spline has 200 teeth and the flexspline has 198, each full rotation of the wave generator advances the flexspline by two teeth, creating a reduction ratio of 100:1. This design yields extremely high ratios in a single stage, something impossible with conventional spur gears.

How It Achieves Zero Backlash

Because the flexspline and circular spline remain in constant engagement across broad contact regions (about one‑third of their circumferences), there is no clearance between teeth. This absence of play is why harmonic drives are also called “zero‑backlash gears.” Torque transmission is continuous and smooth, without oscillations or dead zones. The preload created by the flexspline’s elastic deformation maintains contact even under reversing loads, ensuring repeatable positioning.

Compact, Coaxial Design

Harmonic reducers are coaxial, input and output shafts align along the same axis. This eliminates offset angles and bulky couplings, reducing mechanical footprint and weight. Many models feature a hollow shaft at the centre, allowing cables, fluid lines, or other drive shafts to pass through. This property simplifies integration in robotic joints, gimbals, and instruments where space is at a premium.

High Torque Capability

Despite their light weight, harmonic reducers can transmit significant torque. The large contact area and constant tooth engagement distribute forces evenly, enabling the reducer to handle loads far greater than its size suggest. This high torque density empowers small motors to move heavy arms or payloads.

Why Choose Harmonic Reducers? Key Advantages

Harmonic reducers are beloved for several reasons:

- Zero Backlash & High Accuracy – The elastic preload ensures play‑free motion. Precision and repeatability remain high across the reducer’s lif. Robots using harmonic drives can position end effectors within microns, making them ideal for assembly, surgery, and semiconductor manufacturing.

- Compact & Lightweight – Single‑stage reduction ratios up to 320:1 are achievable without stacking multiple gear sets. This reduces volume and mass, enabling slender robot wrists and elbows.

- High Torsional Stiffness – The flexspline’s steel structure and broad contact area deliver excellent torsional rigidity. Stiffness reduces deflection under load, improving servo stability and control bandwidth.

- High Torque Density – Even though the components are thin, harmonic reducers can transmit significant torque, making them suitable for heavy duty in a compact package.

- Coaxial & Hollow‑shaft Integration – Perfect alignment with the motor shaft and optional hollow bores simplify wiring and piping, reducing design complexity.

- Versatile Applications – Beyond robotics, harmonic reducers power medical imaging devices, aerospace control systems, satellite antennas, CNC tool changers, flight simulators, and more.

With these strengths, harmonic reducers have become a de facto choice for precision rotary joints. But their benefits come with tradeoffs that must be considered.

Performance & Design Parameters

Selecting and designing with harmonic reducers requires careful evaluation of several parameters:

Reduction Ratio & Speed

- Ratio Range – Typical single‑stage harmonic reducers offer ratios from 30:1 to 320:1. Higher ratios provide more torque amplification but slow output speed. Choose a ratio that allows your motor to operate near its peak efficiency and delivers the required torque.

- Motor Speed Matching – Too high a ratio may force the motor to spin at very high RPM, generating heat and reducing life. Too low a ratio reduces torque, risking stall. Analyse load inertia, acceleration, and duty cycle to find a balance.

Torque Capacity & Load

- Continuous vs Peak Torque – Determine both the continuous torque needed for normal operation and the peak torque during acceleration or shock. Ensure the reducer’s rated torque covers both; oversizing provides safety but increases weight and cost.

- Radial & Axial Loads – Harmonic reducers transmit torque through the flexspline. They handle axial loads well but have limited radial load capability. For joints with high side loads, use external bearings or cross‑roller bearings integrated in some models.

Backlash & Accuracy

- Zero Backlash – Harmonic reducers inherently eliminate backlash. However, elastically loaded designs can exhibit hysteresis (lag between input and output when reversing). Choose models with low hysteresis if bidirectional precision is critical.

- Resolution & Repeatability – The reducer’s resolution is limited by the tooth count; more teeth yield finer motion increments. Consider the encoder resolution and controller performance to achieve the desired joint precision.

Stiffness & Natural Frequency

- Torsional Stiffness – High stiffness suppresses torsional deflection under load. Check stiffness values and ensure the reducer does not introduce resonance near the control loop’s bandwidth. Stiffer reducers support higher servo gains.

- Compliance & Resonance – The flexspline’s elasticity introduces compliance, which can reduce the natural frequency of the system. Engineers must design control algorithms and select couplings that avoid exciting these frequencies.

Efficiency & Heat

- Mechanical Efficiency – Harmonic reducers typically achieve 80–90 % efficiency. Some energy is lost through friction in the flexspline and bearings. Lower efficiency means more heat and higher motor power required. Use proper lubrication and consider cooling if the application demands continuous high torque.

- Temperature Limitations – High ambient temperatures or continuous operation raise internal heat. Check the reducer’s temperature ratings and consider thermal management strategies.

Size & Weight

- Outer Diameter & Length – Harmonic reducers are compact compared to planetary or cycloidal gears but still vary across models. Evaluate your space constraints and choose a reducer that fits the joint design without compromising strength.

- Hollow Shaft Diameter – If you need to route cables or shafts, ensure the hollow bore size meets your requirements.

Life & Reliability

- Fatigue Life – The flexspline is the most stressed component; its thin wall cycles through deformation each revolution. While proper heat treatment ensures long life, overloading or shock can cause fatigue cracks. Select quality materials and sizes appropriate for the duty cycle.

- Maintenance – Harmonic reducers are often sealed and lubricated for life. However, the flexspline can wear and may require replacement in severe applications. Design for accessibility if future service is expected.

Tradeoffs, Limitations & Mitigation

Although harmonic reducers shine in precision robotics, designers must be aware of their limitations:

- Flexspline Wear & Fatigue – As noted, the flexspline can degrade over time. Regular maintenance or periodic replacement is needed in high‑duty environments. Using stainless or specialized alloys and ensuring proper preload reduces wear.

- Shock & Overload Sensitivity – Exceeding torque ratings can deform the flexspline or cause tooth fracture. Harmonic drives are not ideal for heavy shock loads. Mitigate by adding torque limits in the control system, using torque sensors, or selecting a larger reducer.

- Torque Ripple & Hysteresis – Elastic deformation leads to slight torque ripple; although small, it may affect ultra‑smooth motion. High‑precision tasks can incorporate filters or oversizing to minimize ripple.

- Limited Radial Load Capability – Because the flexspline does not support high radial forces, a separate bearing system is often required. Integrated cross‑roller bearings or external bearings provide radial stiffness.

- Cost & Supply – Harmonic reducers are typically more expensive than planetary gears due to their specialized manufacturing. Lead times may be longer, especially for high‑precision or custom models. Supply chain strategies (discussed below) are essential.

By understanding these challenges and designing accordingly, engineers can harness harmonic reducers’ strengths while avoiding potential failures.

Applications & Real‑World Use Cases

Harmonic reducers enable numerous robotic and industrial systems:

Robotics Arms & Collaborative Robots

In industrial and collaborative arms, harmonic drives are frequently used for wrist, elbow, and shoulder joints. Their compactness and zero backlash allow multi‑degree‑of‑freedom motion in a small envelope. Collaborative robots (cobots) benefit from harmonic reducers’ low weight and high torque density, delivering strong yet responsive joints.

Medical & Surgical Devices

Precise movement and sterility requirements make harmonic reducers ideal for surgical robots and medical imaging equipment. They ensure smooth, controlled movements of instruments and reduce vibrations that could affect imaging quality.

Aerospace & Space Exploration

Originally conceived by Walton Musser in 1955 for space applications, harmonic drives continue to fly beyond our planet. They operate in satellite pointing mechanisms, antenna positioning, flight simulators, and control surfaces in aircraft. NASA and ESA missions rely on strain‑wave gear’s reliability and precision.

Semiconductors & Machine Tools

Zero backlash and high stiffness are crucial in semiconductor wafer handlers and CNC tool changers. Harmonic reducers deliver precise indexing and positioning, improving manufacturing yields and surface finishes. They are also used in coordinate measuring machines and metrology equipment.

Automotive & Consumer Products

Emerging applications include electric power steering, active suspension systems, camera gimbals, and drones. These systems value the harmonic reducer’s high torque density and lightweight properties.

By choosing the right harmonic reducer, designers unlock performance across a multitude of industries. Yana’s cross‑domain expertise ensures you select the correct model for each specific case.

Integration & System Design Considerations

Coupling with Motors & Actuators

The reducer must match the motor physically and dynamically:

- Input Interface – Verify shaft types (key, spline, hollow) and mounting flanges. Many harmonic reducers come with direct servo motor adapters or integrated servomotors.

- Inertia Matching – The reflected inertia seen by the motor through the reducer should be within safe ratios (typically less than 10:1). Higher gear ratios help reduce reflected inertia, making control easier.

- Damping & Compliance – The flexspline introduces compliance. Control algorithms may need to account for elasticity to maintain servo stability. Use torsionally stiff couplings and tune servo gains carefully.

Mounting & Bearings

Harmonic reducers transmit torque but do not inherently support high radial loads. Integrate cross‑roller bearings at the output or use external bearings to handle radial and axial loads. Ensure accurate alignment between the reducer and the joint structure to prevent side loads that could damage the flexspline.

Lubrication & Sealing

Quality harmonic reducers are pre‑lubricated with grease or oil for life. However, ensure compatibility with your operating environment (e.g., food grade for medical, vacuum compatible for aerospace). Sealed housings prevent contamination and maintain lubrication. If you plan to operate in extreme temperatures or vacuums, consult the manufacturer for special lubricants.

Sensors & Feedback

Harmonic reducers pair well with absolute encoders or resolver sensors mounted directly on the motor shaft or reducer output. High‑resolution feedback allows precise control of output position and velocity. Some integrated harmonic servos embed torque sensors to enable force control and haptic feedback.

Dynamics & Control

Pay attention to the joint’s natural frequency. The compliance of the flexspline lowers the resonance frequency; design the control system to avoid exciting this resonance. Use filters or notch filters when necessary. When designing for collaborative robots, incorporate force/torque sensing and limit torque to ensure safety.

Sourcing, Manufacturing & Quality Strategy

Global Manufacturing Landscape

Harmonic reducers require meticulous machining and heat treatment. The leading manufacturers are concentrated in Japan, where companies like Harmonic Drive Systems and Nidec produce high‑quality, high‑precision gearboxes. Japanese products are renowned for their zero backlash, long life, and consistent quality, albeit at premium prices. Meanwhile, China hosts numerous suppliers offering more affordable options; quality ranges from world‑class to inconsistent. South Korea, Germany, and the United States also produce specialty harmonic drives and custom solutions.

Quality Control & Inspection Points

- Materials & Heat Treatment – Use high‑strength alloys and proper heat treatment to resist fatigue. Request material certificates and heat treat records.

- Tooth Profile & Gear Cutting – Precision gear cutting and grinding ensure accurate tooth geometry and mesh. Inspect gear flanks for surface finish and pitch accuracy.

- Flexspline Integrity – Test flexspline thickness, hardness, and uniformity. Microcracks can lead to early failure.

- Assembly & Preload – Proper bearing preload and alignment are vital. Oversized preload leads to heat and wear; insufficient preload results in backlash.

- Performance Testing – Evaluate backlash (or hysteresis), torque ripple, efficiency, and temperature rise under load. Request test reports or perform acceptance testing.

Supply Chain & Risk Management

Supply chain disruptions, currency fluctuations, or material shortages (such as high‑strength steels) can delay deliveries and increase costs. Yana’s risk strategies recommend:

- Multi‑Sourcing – Qualify multiple suppliers across different regions to reduce dependency on a single factory.

- Standardization – Standardize reducer interfaces (flanges, ratios) to allow interchangeability between suppliers.

- Inventory Buffer – Maintain safety stock for critical components to handle delays. Balance inventory costs with lead time risks.

- Supplier Audits – Conduct periodic audits and inspect manufacturing processes. Align suppliers with ethical practices and quality management systems.

- Intellectual Property Protection – Ensure that proprietary designs and know‑how are protected through NDAs and manufacturing contracts.

Yana’s SMART + HEART Sourcing

Our sourcing philosophy ensures technical rigour and human trust. The SMART test assesses suppliers on their Basics, Market & Financials, Assurance & Certifications, References & Case Studies, and Transparency & ESG metrics. The HEART test evaluates their History, Execution, Agility, Reliability, and Trustworthiness. Only suppliers who excel in both hard metrics and soft factors earn Yana’s partnership. Our global presence and long‑standing relationships give us insights into each supplier’s true capabilities and cultural fit.

Future Trends & Innovations

Miniaturization & Lightweight Materials

Next‑generation harmonic reducers will be smaller and lighter, thanks to advanced alloys and composite materials. Research is exploring flexsplines made from carbon fibre composites to reduce mass while maintaining strength. Miniaturized gears will enable compact exoskeletons, wearable robotics, and portable equipment.

Integrated Sensors & Smart Gearboxes

Manufacturers are embedding temperature, vibration, and torque sensors directly into gearboxes. These smart reducers monitor their own health and feed data to predictive maintenance systems. Future harmonic reducers may include microcontrollers that adjust preload or lubrication based on load conditions. This self‑adaptation will improve reliability and reduce unplanned downtime.

Hybrid & Double‑Stage Designs

To further increase reduction ratios and stiffness without increasing size, engineers are developing hybrid gearboxes combining harmonic and planetary stages or using double‑flexspline configurations. Novel tooth profiles (e.g., S‑tooth designs) reduce stress concentration and prolong flexspline life.

Sustainable Manufacturing & Recyclability

Environmental pressures are prompting producers to adopt low‑impact manufacturing and recyclable materials. Coatings that eliminate harmful lubricants, lubricants with bio‑based oils, and remanufacturable gearboxes are under development. Customers increasingly demand lifecycle assessments and transparent environmental reporting.

Digital Twins & AI‑Driven Design

Combining digital twin technology with AI allows engineers to simulate reducer performance under varied conditions. AI can optimize tooth geometry, flexspline thickness, and preload to achieve specific performance targets. Yana embraces these tools to predict supply chain disruptions and market trends years in advance, keeping our clients ahead of the curve.

Yana’s Approach & Conclusion

Harmonic reducers are the cornerstone of precision robotics. They deliver zero backlash, high torque density, and compact integration, enabling robots to perform delicate tasks with confidence. Yet their complex design demands meticulous engineering and reliable sourcing. The flexspline’s elasticity, while empowering, imposes fatigue and shock limits. Selecting the right ratio, size, and supplier is essential for long‑term success.

At Yana Sourcing, we apply higher‑dimensional perception to every project. We evaluate suppliers with our SMART + HEART framework, balancing quantitative performance metrics with human factors. We anticipate market trends, identify hidden risks, and architect ecosystems of trust. We don’t just find parts; we unlock possibilities.

In summary, harmonic reducers offer unmatched performance for precision robotics, if chosen and managed wisely. When integrated with appropriate motors and actuators, and sourced from trusted partners, they empower your robots to move with the grace, strength, and accuracy of living organisms. Reach out to Yana’s team to explore how we can elevate your next generation of robots. Together, we transform motion into mastery.