Table of Contents

In your robotics stack, motors generate rotational power, actuators integrate motors with sensors and control electronics to create useful motion, and reducers convert that motion into the speed and torque required by joints. While motors and actuators are covered elsewhere, this page explains the gearboxes that bridge them. A reducer slows down a motor’s high‑speed rotation and multiplies its torque so the robot can lift, hold and position loads precisely. Choosing the right reducer is critical for achieving accuracy, efficiency and longevity.

The Hidden Backbone of Robotic Motion

Reducers are the mechanical backbone of robotic joints. They transmit power from motors to arms and wheels, amplify torque and ensure smooth positioning. Without the right gearbox, even the most advanced servo motor will stall or lose precision. Industrial robots rely on zero‑backlash reducers to maintain repeatability and stiffness. In collaborative robots, compact strain‑wave gears allow slim wrists and elbows; heavy industrial arms use robust cycloidal drives in base joints; and general‑purpose robots often employ planetary gearboxes for balanced performance. Understanding these options helps you select the best solution for each axis.

Basic Principle: Trade Speed for Torque

A reducer uses gear meshes to lower speed and increase torque. A small pinion driving a larger gear slows the output speed according to the gear ratio. For example, a 20‑tooth pinion driving a 100‑tooth gear yields a 5:1 ratio. Robotics often requires ratios above 50:1 to match high‑speed motors to slow‑moving joints, so designers turn to special mechanisms: harmonic drives, cycloidal RV reducers and planetary gearboxes.

Comparing the Main Types of Robotic Reducers

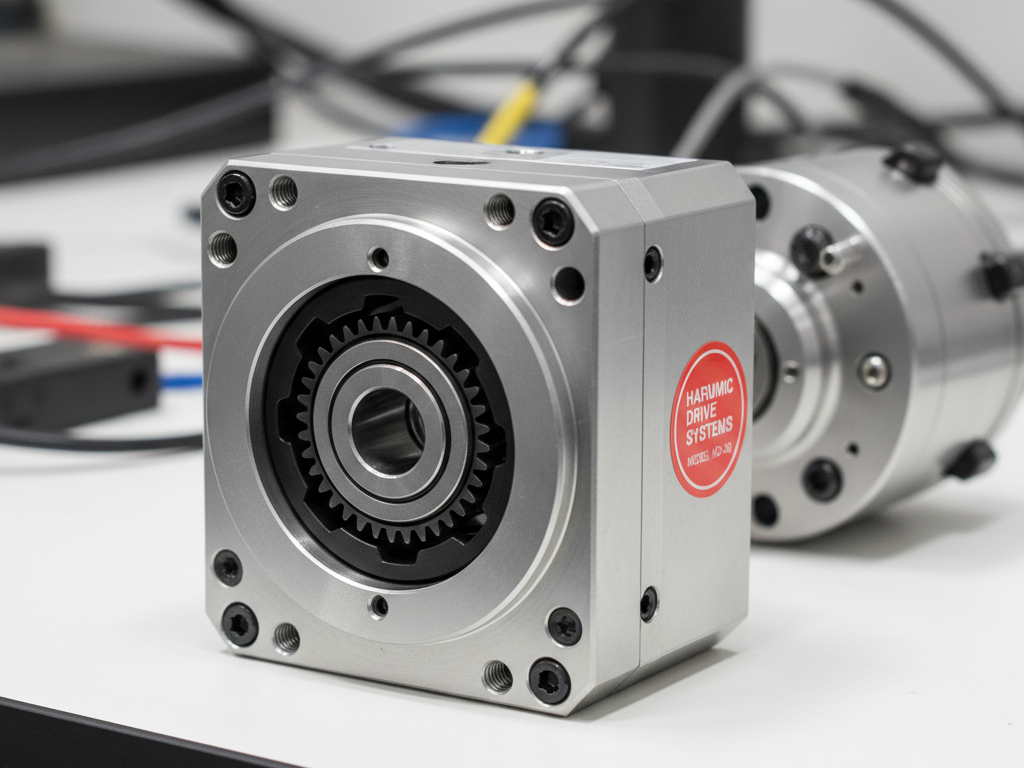

Harmonic Drives — Zero‑Backlash Precision

Harmonic drives, also known as strain‑wave gears, consist of three parts: an elliptical wave generator, a flexible cup‑shaped flexspline and a rigid circular spline. As the wave generator rotates, it deforms the flexspline so its teeth engage with the circular spline at opposite sides. Because the flexspline has fewer teeth (typically two fewer) than the circular spline, each revolution of the wave generator results in a slight relative motion between the two gears, producing high reduction ratios up to 320:1.

Why choose harmonic drives? They offer unmatched compactness and zero backlash. Nearly one‑third of the teeth are engaged at once, yielding high torque density and very precise motion. This makes them ideal for collaborative robot arms, surgical robots and gimbals where space and accuracy are critical. Because the output is completely preloaded, there is no play, enabling robots to maintain position even under small external forces.

Tradeoffs. The thin flexspline must flex with every rotation. Under high shock or continuous heavy load, it can fatigue or deform; cycloidal drives are better suited for those conditions. Harmonic gears also have moderate mechanical efficiency, so they may generate heat at high duty cycles.

RV (Cycloidal) Reducers — Industrial Strength and Rigidity

Cycloidal or RV reducers use cam disks driven by an eccentric shaft and rolling pins in the housing. The eccentric motion of the disks causes slow rotation of the output shaft, while rolling elements distribute load evenl. This architecture provides very high torque capacity and torsional rigidity. An RV gearbox can transmit two to three times more torque than a similar‑sized harmonic drive.

Why choose RV reducers? They withstand heavy loads and shocks, and their rigid structure offers long life. Industrial robots use RV drives in base and shoulder joints that carry the largest torques. They maintain low backlash (around 1 arc‑minute) and handle axial and radial loads thanks to integrated bearings. RV drives are the workhorses of manufacturing robots that weld, palletize or machine parts.

Tradeoffs. RV reducers are heavier and bulkier than harmonic drives, and their eccentric mechanism introduces slight torque ripple. They require precise machining, robust lubrication and come at a higher cost. For applications that value compactness or light weight, planetary or harmonic reducers may be preferable.

Planetary Reducers — Balance and Versatility

A planetary reducer contains a central sun gear, multiple planet gears and an outer ring gear. The planets rotate around the sun and mesh with the ring, distributing torque across multiple gear contacts. Planetary reducers achieve ratios from about 3:1 to 200:1 by stacking stages. The load sharing results in high torque density relative to size, and efficiencies often exceed 95 %.

Why choose planetary gearboxes? They offer a good compromise among size, efficiency, cost and precision. Precision planetary gearboxes can achieve backlash as low as 1–5 arc‑minutes, sufficient for most motion control tasks. Their coaxial design makes them easy to integrate with servo motors, and many vendors offer off‑the‑shelf combinations. Planetary drives are common in servo axes, linear modules, mobile robots and small industrial arms.

Tradeoffs. Planetary gearboxes cannot achieve true zero backlash because a small clearance is required for lubrication. For extreme precision or very high reduction ratios, harmonic drives may be better. Planetary gearboxes also have lower shock tolerance than RV reducers.

Quick Comparison

| Feature | Harmonic | RV (Cycloidal) | Planetary |

|---|---|---|---|

| Ratio range | 30–320:1 | 50–300:1 | 3–200:1 |

| Backlash | Zero | ~1 arc‑min | 1–5 arc‑min |

| Torque density | High | Highest | Medium |

| Weight | Lightest | Heaviest | Moderate |

| Shock load capacity | Low to medium | High | Medium |

| Efficiency | 80–90 % | 85–90 % | 90–97 % |

| Typical uses | Collaborative robots, gimbals | Industrial robot bases | General robotics, AGVs |

Selection and Design Guidelines

Matching a reducer to your application requires balancing torque, speed, precision, weight, efficiency and cost. The following guidelines summarise the most important factors.

1. Evaluate Torque and Speed

Calculate the continuous and peak torque that the joint must deliver. Continuous torque keeps the robot moving under steady loads; peak torque covers acceleration and shock. Gearbox ratings must exceed both. Check the required output speed and choose a reduction ratio that allows the motor to run at its efficient speed range. Oversizing the ratio will cause the motor to operate at high RPM and generate heat, while undersizing may leave insufficient torque.

2. Choose the Right Precision

Backlash defines how much play exists at the output. For pick‑and‑place or machining robots, near‑zero backlash is essential; harmonic and RV drives excel here. For applications with position feedback or compliance compensation, planetary gearboxes with low backlash may suffice. Also consider torsional stiffness, as a flexible gearbox can degrade servo performance.

3. Consider Efficiency and Duty Cycle

Efficiency influences energy consumption and heat. Planetary gearboxes typically offer the highest efficiency, followed by RV and then harmonic drives. For continuous operation at high power, a low‑efficiency gear may overheat. Duty cycle also impacts lifespan: harmonic flexsplines fatigue faster under constant load than cycloidal or planetary gears. When planning high duty cycles, verify manufacturer life ratings.

4. Account for Environment and Integration

Consider temperature, dust, vibration and mounting orientation. Sealed gearboxes are necessary for dirty or wet environments. Check whether the reducer can support radial and axial loads; RV and planetary gearboxes typically incorporate bearings, while harmonic drives may require external support. Align the reducer’s mounting interface with your actuator and frame; mismatch can cause misalignment and premature wear.

5. Synchronize With Motor and Actuator

Reducers reflect load inertia back to the motor. To achieve stable servo control, the ratio of load inertia to motor inertia should be within recommended limits. Integrated servo actuators that combine motor, reducer and encoder simplify selection and reduce alignment errors. For bespoke designs, ensure the reducer’s input shaft and mounting pattern match your motor.

Sourcing & Quality Considerations

Key Manufacturing Regions

- Japan: Leading manufacturer of premium harmonic and RV gearboxes. Offers high precision and reliability but at higher cost.

- China: Major producer of standard gearboxes, including harmonic and planetary types. Quality varies; rigorous supplier evaluation is necessary.

- Europe & USA: Provide specialized, high‑performance reducers for aerospace, defense and research.

Quality Checklist

- Materials and Heat Treatment: Use appropriate steels and surface hardening to prevent wear.

- Machining Accuracy: Tight tolerances reduce vibration and backlash.

- Assembly: Preload bearings correctly and ensure gear concentricity. Poor assembly can ruin otherwise good components.

- Lubrication: Verify grease or oil systems suited to your environment. Inadequate lubrication causes premature failure.

- Testing & Certification: Request performance data and certifications (e.g., ISO 9001). Auditing suppliers or using a trusted sourcing partner reduces risk.

Risk Mitigation

Multi‑sourcing reduces supply chain risks but increases complexity. Standardize interface dimensions and ratios to interchange gearboxes from different suppliers. Maintain buffer stock and long‑term contracts, and audit suppliers regularly—practices aligned with Yana’s SMART + HEART philosophy.

Future Directions & Innovations

Gearbox technology is evolving quickly to meet robotics’ demands for smaller, smarter and more sustainable mechanisms.

- Higher Torque Density and Miniaturization: Advanced alloys, optimized tooth profiles and finite‑element analysis are enabling more torque in smaller packages. Compact gearboxes are empowering exoskeletons and portable robots.

- Hybrid Mechanisms: Combinations of strain‑wave and planetary stages deliver higher ratios, strength and stiffness. Harmonic drives with specially shaped “S‑tooth” profiles reduce stress concentration.

- Smart Reducers: Sensors embedded inside gearboxes monitor temperature, vibration and torque for predictive maintenance. Some designs integrate torque sensors or electronics for adaptive control.

- Sustainable Materials and Manufacturing: Recycled alloys, composite housings and additive manufacturing reduce weight and environmental impact. Greaseless or sealed‑for‑life lubricants minimize maintenance and waste.

The Yana Edge: SMART + HEART in Sourcing

Yana Sourcing advocates the SMART + HEART framework: Sourcing, Manufacturing, Auditing, Risk management and Technology plus Honesty, Ethics, Accountability, Reliability and Trust. Apply it by evaluating multiple suppliers, auditing manufacturing processes, planning for supply disruptions and adopting the latest technologies where appropriate. Treat suppliers as partners, share expectations openly and build long‑term relationships. In doing so you not only reduce risk but also foster innovation and trust.

Conclusion: Powering the Next Generation of Robots

Reducers convert a motor’s speed into the torque and precision required for robotic movement. Choosing between harmonic, RV and planetary gearboxes, and tuning their ratios, sizes and quality, determines whether your robot moves smoothly, accurately and reliably. Harmonic drives offer compactness and zero backlash for precise joints. RV drives provide strength and stiffness for industrial robots. Planetary drives strike a balance of efficiency, cost and flexibility. By following the guidelines in this page and leveraging Yana’s SMART + HEART sourcing philosophy, you can build robust robots that meet your performance, budget and sustainability goals.

Understanding Dynamics and Servo Control

Reducers don’t only reduce speed; they also influence the dynamic behaviour of a servo system. A gearbox adds inertia and compliance, which affect how quickly the joint can accelerate and respond to commands. When designing the control system for a robotic joint, pay attention to the reflected inertia, the load inertia as seen by the motor through the gear ratio.

High gear ratios decrease the reflected inertia, making the motor easier to control; low ratios can result in high inertias that cause sluggish response. A general rule is to maintain a load‑to‑motor inertia ratio below 10:1 for stable servo tuning. Harmonic and RV reducers, with their high ratios, often simplify control because they reduce reflected inertia. Planetary gearboxes with lower ratios may require more careful tuning.

Natural frequency and resonance also matter. Gearbox compliance introduces a resonance frequency in the drive train. If the resonance is near the control bandwidth, the servo may oscillate or become unstable. High‑stiffness reducers, such as RV drives, push the resonance higher, allowing faster control loops. Lower stiffness reducers may require notch filters or torque observers to maintain stability. When selecting a reducer, check the torsional rigidity specification and ensure it aligns with your motion profile.

Examples of Reducer Selection in Real Robots

Collaborative Robot Joint

Consider a lightweight collaborative robot arm used for assembly tasks. It needs compact joints, high accuracy and low weight to minimize inertial forces and ensure safe human‑robot interaction. A harmonic drive is often the best choice. For instance, a wrist joint that must deliver 20 Nm continuous torque and rotate at up to 60 rpm could use a harmonic reducer with a ratio of 100:1. Paired with a brushless servo motor, this combination yields a small, light joint with zero backlash. The control system can use absolute encoders and torque sensing for safe, compliant motion. The harmonic reducer’s low backlash ensures that when the robot stops, the tool tip does not drift, an essential requirement for precision pick‑and‑place.

Industrial Robot Base Joint

In a six‑axis industrial robot used for welding, the base joint may see torques of several thousand Newton‑metres while supporting the entire arm. Durability and rigidity are paramount. An RV reducer with a ratio of around 80:1 delivers the necessary torque capacity and stiffness. Its cycloidal mechanism can withstand shock loads and high duty cycles common in welding or material handling operations. Because RV gearboxes are heavier, they are typically placed in lower joints where weight has less impact on dynamic performance. Pairing an RV reducer with a high‑power AC servo motor creates a robust joint that maintains calibration over millions of cycles.

Mobile Robot Drive

For an autonomous mobile robot or AGV (Automated Guided Vehicle) driving wheels, the requirements are different. Speed and efficiency are critical for long battery life, and the load is relatively moderate. A planetary gearbox with a ratio between 10:1 and 20:1, integrated with a BLDC motor, provides adequate torque for wheel traction while maintaining high efficiency. The small backlash is acceptable because wheel positioning is controlled by feedback sensors. Some designs use a two‑stage planetary reducer to achieve a compact form factor with enough torque for climbing inclines or carrying payloads.

These examples illustrate how different applications prioritize different reducer characteristics. Collaborative robots value precision and low inertia; industrial robots emphasize strength and durability; mobile robots need efficiency and moderate precision. Your design should reflect the unique requirements of the intended use case.

Integration with Motors and Actuators

Reducers are not standalone devices; they must integrate seamlessly with motors, encoders, brakes and sometimes controllers. When you choose a reducer, verify that its input shaft type (keyed, splined or hollow) matches your motor. Align the mounting flange and bolt circle with your actuator housing. Mismatched interfaces can cause run‑out and misalignment, leading to vibration and wear. Many manufacturers offer reducers with direct motor adapters or integrated servo actuators that combine motor, reducer and feedback sensor in one package. These integrated units simplify design, minimize alignment issues and reduce overall length. They also come factory preloaded and lubricated, ensuring consistent performance over their service life.

In modular robotics or multi‑axis systems, standardizing on a common interface size allows you to mix and match motor and gearbox suppliers, which supports the multi‑sourcing strategy advocated by Yana Sourcing. Consider using frameless motors (discussed in the motors section) inside a custom reducer housing to create ultra‑compact actuators. Frameless motors and harmonic drives are a popular combination for humanoid robots and exoskeletons because they deliver high torque density in minimal space.

Global Supply Chain and Material Considerations

The global supply chain for gear reducers depends on access to high‑strength steels and well‑trained manufacturing talent. Regional disruptions or material shortages can delay production or increase costs. Sourcing components from different regions (Asia, Europe, Americas) helps mitigate risk. Quality control and specification compliance vary widely: in China dozens of factories produce harmonic and planetary reducers, some deliver world‑class products while others cut corners. Japan remains the benchmark for premium precision gearboxes, particularly for harmonic and RV types, though lead times are longer and prices higher.

Quality assurance is vital. Request sample gearboxes for evaluation and perform incoming inspections under representative loads. Monitor parameters such as backlash, torque ripple, efficiency and temperature rise. Audit suppliers’ manufacturing processes and be prepared to invest in tooling or fixture modifications if you plan to reassign production across different suppliers.

Smart Control and Predictive Maintenance

Modern reducers are becoming smart devices. Integrated sensors measure temperature, vibration and load. This data feeds predictive algorithms that identify wear before it causes a breakdown. A cycloidal reducer equipped with a vibration sensor can detect early signs of bearing damage so maintenance can be scheduled proactively. Some premium servo actuators embed torque sensors between the motor and gearbox, enabling force‑controlled assembly or safe human‑robot interaction. These smart reducers also support adaptive motion control, adjusting speed and stiffness based on load. As you design future robots, plan for gearboxes that transmit torque and also provide useful data.

Applying SMART + HEART in Practice

The SMART + HEART philosophy guides how you select and manage reducer suppliers. Put simply:

• Source widely and wisely – Identify multiple suppliers and evaluate them on capability and innovation, not just price. Understand how they machine gears and assemble gearboxes so you can interpret quality data.

• Audit and plan for risk – Visit factories or commission inspections, verify certifications and map your supply chain. Maintain contingency plans and safety stocks for critical components.

• Adopt technology and build trust – Encourage suppliers to integrate smart sensors and improved materials. Communicate openly about requirements and forecasts. Ethical, long‑term relationships foster reliability and success.

When you bring heart into sourcing, you respect the people and companies who provide your parts. This fosters trust and ultimately improves the quality of your robots.