Table of Contents

Introduction — Why Voice Coil Motors Matter in Robotics

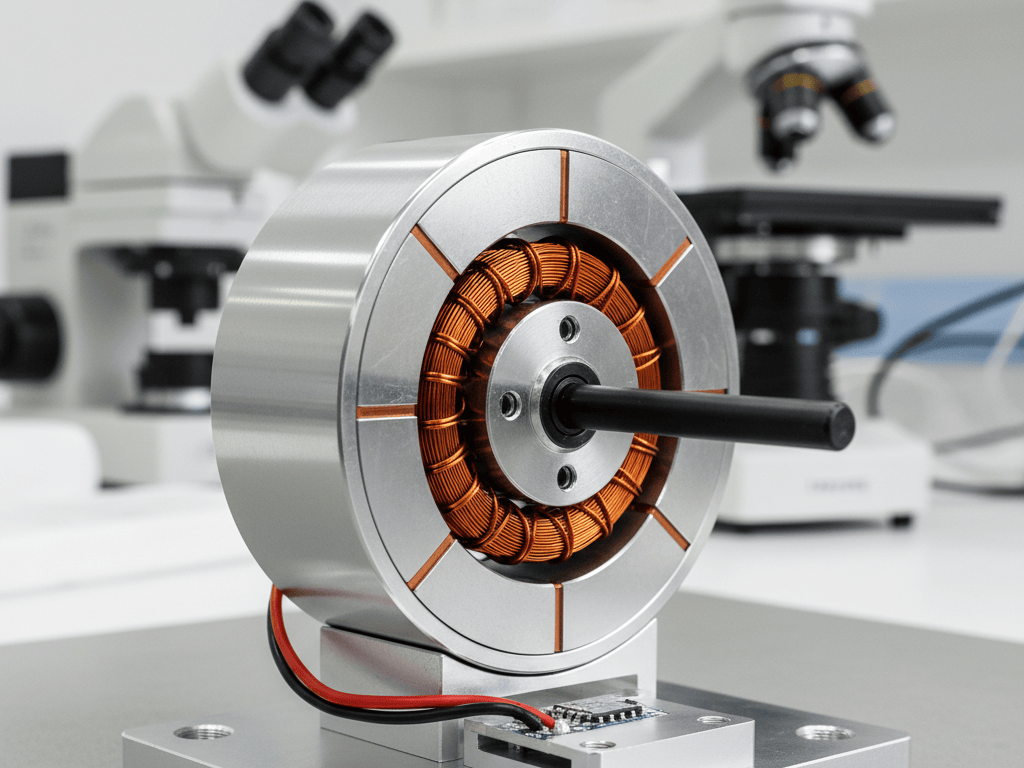

Robotics is no longer limited to industrial arms and assembly lines. Modern robots perform delicate surgical tasks, finely adjust optics in semiconductor lithography systems, provide tactile feedback in haptic devices, and precisely position sensors in autonomous vehicles. All of these micro‑motion tasks require actuators that deliver fast, smooth and silent control. That is where voice coil motors (VCMs) come in. A voice coil motor is the simplest form of electric motor: it has only two main parts, a magnetic housing and a coil. Applying a voltage across the terminals generates a magnetic field that pushes the coil in one direction, while reversing the polarity moves it in the opposite direction. Because the motor’s force is proportional to current, the output force is nearly constant over the entire stroke range.

Voice coil motors are brushless and non‑commutated, which means there are no brushes to wear out and no commutation electronics to generate ripple. This simplicity yields extremely smooth motion, high reliability and zero cogging. Their structural stability supports high positioning resolution when combined with external position sensors and motion controllers. Unlike rotary motors that rotate continuously or linear motors that travel long distances, voice coil motors specialize in short‑stroke, high‑precision linear motion. They excel in small‑range positioning applications such as focusing lenses, oscillatory scanning systems, micro‑valve control and miniature positioning stages. Because they deliver force directly and have low moving mass, voice coil motors can accelerate extremely quickly, enabling rapid step responses and high bandwidth. These characteristics make voice coil motors indispensable for robotics at all levels, especially when tasks demand fast response, precise positioning and silent operation.

Working Principle of Voice Coil Motors

Voice coil motors operate on the Lorentz force principle, which states that a current‑carrying conductor in a magnetic field experiences a force that is proportional to the current and the magnetic flux density. In a typical VCM, the conductor is a coil of wire, and the magnetic field is provided by permanent magnets. A simple linear voice coil motor consists of a tubular coil of wire situated inside a cylindrical magnetic field produced by permanent magnets. The permanent magnets are arranged so that the side of the magnets facing the ferromagnetic cylinder has the same polarity as the cylinder. When current passes through the coil, the magnetic field generated by the coil interacts with the field from the permanent magnets, producing a force that moves the coil linearly along a fixed path. The direction of motion depends on the polarity of the current, and the magnitude of the force is proportional to the current, yielding direct control over force and position.

Voice coil actuators can be configured as moving‑coil devices, where the coil moves within a fixed magnetic field, or moving‑magnet devices, where the magnet assembly moves and the coil remains stationary. Because there is no ferromagnetic core in the moving coil, voice coil motors have very low inductance and therefore exhibit fast electrical time constants, allowing rapid current changes and extremely high bandwidth. They also have low hysteresis and no cogging, because there are no teeth or commutation structures in the magnetic circuit. The force generated is linear with current, so the relationship between the command signal and the mechanical output is very predictable. VCMs are inherently bidirectional, providing equal force in both directions simply by reversing the current. Because there are no mechanical contact points, no gears, belts or lead screws, there is essentially zero friction and backlash.

The stroke length of a voice coil motor is limited by the physical travel of the coil relative to the magnet assembly. Most voice coil actuators can travel anywhere from a few millimetres to several centimetres, and some specialized designs can achieve strokes up to 5 inches. The absence of mechanical couplings makes voice coil motors extremely quiet. However, because they rely on the interaction of magnetic fields, the moving coil or magnet requires a guiding mechanism, typically a bearing, flexure or air bearing, to constrain its motion. Customers must design this guidance mechanism and ensure proper alignment for optimal performance. In open‑loop applications, a voice coil motor acts as a force generator proportional to current; in closed‑loop systems, feedback from a position sensor allows precise control of position, velocity and force.

Performance Characteristics & Control

Voice coil motors deliver a unique combination of performance attributes that set them apart from other motor types. First, they offer very high acceleration and fast response times because the moving mass is limited to the coil and the coil holder. Custom devices can achieve accelerations exceeding 500g. The low electrical inductance allows current to change rapidly, giving voice coil motors bandwidths up to several kilohertz. Second, they exhibit smooth, cog‑free force output. Unlike stepper or brushless motors, there are no teeth or commutation phases; the coil moves in a continuous magnetic field, so the force is uniform over the stroke. Third, VCMs have zero backlash and minimal hysteresis, making them ideal for closed‑loop control tasks requiring nanometre or micrometre positioning accuracy. Fourth, they are bidirectional: reversing the current reverses the force, providing equal performance in both directions. Fifth, voice coil motors are simple; they have no commutation electronics, no gearboxes and no brushes, so reliability and lifetime are high. Finally, because there are no rotating shafts, they operate silently, a critical requirement for laboratory instruments and medical devices.

Control of a voice coil motor can be open‑loop or closed‑loop. In open‑loop operation, the current directly determines the force. This is useful for force control or vibration generation. In closed‑loop position control, a linear encoder or high‑resolution resolver measures the position of the moving element, and a servo controller adjusts the current to reach the desired position. Closed‑loop systems deliver micrometre‑scale accuracy and repeatability when properly tuned.

To illustrate how voice coil motors compare with other robotic actuators, the following table summarises key performance parameters:

| Parameter | Voice Coil Motor | Linear Motor | Servo Motor | Stepper Motor |

|---|---|---|---|---|

| Motion type | Short‑stroke linear | Long‑stroke linear | Continuous rotary | Discrete rotary |

| Response speed | Ultra‑fast (≈2 ms) | Fast (10–20 ms) | Moderate | Slow |

| Backlash / Friction | None | Minimal | Depends on geartrain | Depends on lead screw |

| Stroke range | 1–50 mm (typical) | Up to 2 m | 360° | 360° discrete |

| Precision | Nanometre–micrometre | Micrometre | High (with encoder) | Moderate |

| Cooling method | Natural or liquid | Passive or active | Fan or liquid | Passive |

| Cogging / Commutation ripple | None | Low | Possible | Significant |

This comparison underscores that voice coil motors excel in fast, frictionless and precise micro‑motion tasks. While linear motors handle long strokes, and servo and stepper motors provide continuous rotation, VCMs dominate applications that need short, highly responsive linear motion without mechanical wear or noise.

Integration in Robotic Systems

VCMs are used across all four levels of robotics—from simple manipulators to advanced autonomous systems, because their characteristics translate directly into improved precision and responsiveness.

L1 (Basic Automation): At the most fundamental level, voice coil motors are ideal for tasks that require oscillatory or vibratory motion. In test equipment, VCMs provide the shaking force in shakers and vibrators. In small positioning stages, VCMs deliver fine adjustments with sub‑micrometre resolution. VCMs also actuate micro‑pumps and syringe drives in laboratory robots, providing smooth and silent motion that does not introduce vibrations into sensitive experiments.

L2 (Collaborative and Service Robotics): Many collaborative robots and service robots incorporate vision systems and sensor suites that require precise focusing and alignment. Voice coil motors drive autofocus mechanisms in camera systems and optical microscopes, enabling clear images even when the robot is moving. In medical devices and diagnostic equipment, VCMs actuate surgical instruments and micro‑valves with high precision and gentle force. Because VCMs are silent and produce no cogging, they do not interfere with audio sensors or create vibrations that would disturb patients.

L3 (Adaptive Robotics): High‑performance robotic platforms, such as semiconductor wafer handling systems or precision pick‑and‑place machines, rely on VCMs for rapid, accurate linear motion. A key application is in fine positioning stages used in photonics and laser alignment systems, where voice coil motors adjust lens positions or mirror angles with nanometre accuracy. In active vibration isolation systems, VCMs generate counterforces to cancel out disturbances and keep optical tables or sensors stable. Because VCMs have low moving mass, they can accelerate quickly and settle rapidly, reducing cycle times in manufacturing.

L4 (Humanoid and Autonomous Systems): At the cutting edge, voice coil motors are integrated into haptic feedback devices and tactile interfaces for humanoid robots. In wearable robotics and prosthetics, VCMs provide fine control of finger joints or tactile actuators, giving users precise and responsive feedback. In advanced vehicles, VCMs adjust LiDAR mirrors or camera gimbals to stabilize sensors against vibrations. These micro‑motion tasks require silent operation, zero backlash and extremely high responsiveness, all hallmarks of voice coil technology.

Design Considerations — Size, Cooling, Noise, Weight

Designing with voice coil motors requires careful attention to packaging, thermal management and integration. Because VCMs are often used in tight spaces, selecting the right form factor, cylindrical, flat or custom, is critical. Stroke length and required force dictate the length of the coil and the size of the magnet assembly. VCMs generate heat when current flows through the coil; although the copper coil is air‑cooled in low‑duty applications, higher continuous forces may require liquid cooling via water jackets or heat sinks integrated into the housing. Noise levels are minimal because there are no gears or mechanical contacts; however, proper bearing selection and isolation are needed to maintain silence in sensitive instruments.

The moving mass of the coil influences acceleration and bandwidth. To achieve the fastest response times, designers minimize coil mass and optimize the coil support structure. The coil must be supported by a linear bearing, air bearing or flexure to guide its motion. Flexures provide frictionless guidance but have limited travel; bearings allow longer strokes but add some friction. Proper cable management is essential to prevent the coil’s wire leads from adding stiffness or generating noise as the coil moves.

Integration Challenges and Proven Solutions

Despite their advantages, voice coil motors pose specific integration challenges.

• Limited stroke — VCMs typically offer strokes of 1–50 mm. If a longer travel is required, designers can combine two voice coil stages or integrate a lever or flexure‑amplification mechanism. In some systems, a dual‑stage actuator couples a coarse linear motor (for long travel) with a voice coil (for fine positioning), delivering long stroke and nanometre precision.

• Thermal management — Continuous high‑force operation generates heat that can demagnetize the permanent magnets or damage the coil. Liquid cooling jackets and thermal sensors integrated into the housing maintain coil temperature. Choosing magnets with high temperature ratings (e.g., samarium–cobalt) improves thermal robustness.

• Alignment sensitivity — The coil must move precisely within the magnetic gap. Misalignment increases cogging or reduces force constant. Precision machining and automated assembly ensure concentricity between coil and magnet. Some suppliers provide pre‑aligned, integrated modules that include bearings and sensors.

• Bearing or guidance selection — Traditional ball bearings introduce friction and noise, while flexures limit travel. Air bearings or cross‑roller bearings offer smooth motion over moderate strokes; flexures are ideal for ultra‑precision motion.

• Control tuning — VCMs have low inductance, so servo amplifiers must provide high peak currents and fast slew rates. Feed‑forward control and adaptive algorithms improve dynamic response and minimize overshoot.

By addressing these challenges through careful design and by selecting high‑quality components, engineers can fully exploit the advantages of voice coil motors in robotic systems.

Manufacturing & Sourcing Insights

VCMs rely on high‑quality permanent magnets and precision manufacturing. Common magnet materials include neodymium‑iron‑boron (NdFeB), samarium–cobalt (SmCo) and alnico. VCM suppliers often customize the shape, dimensions and grade of the magnets to achieve desired force constants and thermal performance. A typical voice coil motor kit includes the magnet housing and coil; customers integrate bearings, sensors and mechanical mounts. Suppliers in Asia, particularly China and Japan, dominate high‑volume production thanks to mature rare‑earth magnet supply chains and cost advantages. Japanese manufacturers produce miniature voice coil actuators for smartphone cameras and medical devices, while Chinese suppliers offer low‑cost VCMs for consumer electronics and entry‑level robotics. European companies (Germany, Switzerland) and U.S. firms focus on precision, high‑force and custom VCMs for scientific and industrial markets.

The supply chain for voice coil motors can be sensitive to global events. During the COVID‑19 pandemic, manufacturing centers for electronics were temporarily shut down, leading to a shortage of raw materials, components and final goods. This disruption highlighted the importance of diversified sourcing and regional redundancy. Despite these challenges, demand for voice coil motors increased in industries such as automotive, semiconductors and healthcare, and manufacturers continued to invest in new products.

Minimum order quantities (MOQ) vary by supplier but are typically low for standard designs, often a few hundred units, and higher for custom coils. Lead times range from 4 to 12 weeks depending on magnet availability and customization. Because VCMs are used in precision equipment, quality and traceability are paramount. Suppliers provide material certifications, magnet batch data and coil resistance measurements. Advanced manufacturers offer clean‑room assembly for medical and semiconductor applications.

Quality Control Checklist

Yana’s sourcing framework emphasizes rigorous quality control for voice coil motors. A typical QC checklist includes:

- Force constant (Kf) measurement — Verify that the motor produces the specified force per ampere across the stroke, using calibrated load cells and current sources.

- Back‑EMF and hysteresis tests — Measure the coil’s back‑electromotive force to ensure consistent magnetic circuit performance; evaluate hysteresis by cycling the motor and checking for force repeatability.

- Stroke uniformity and linearity — Use laser interferometers or high‑precision encoders to confirm that force output remains uniform across the travel range and that the coil travels linearly without tilt.

- Magnet assembly balance and centering — Inspect the magnet housing for concentricity; unbalanced magnets can cause radial forces and reduce bearing life.

- Thermal cycling and endurance tests — Run the motor through temperature extremes and long‑duration cycles to check for coil insulation breakdown or magnet demagnetization.

- Sensor calibration — Verify linear encoder or Hall sensor alignment and resolution to ensure accurate feedback.

Yana’s inspectors witness tests, collect data and compare results against specifications. Failing units are quarantined and root‑cause analysis is performed to prevent recurrence.

Risk Factors

Sourcing voice coil motors involves several risks:

- Magnet demagnetization — High temperatures or incorrect magnet grades can reduce the magnetic field and force output. Suppliers must use magnets with appropriate temperature ratings and provide demagnetization curves.

- Coil delamination — Poor adhesive quality or manufacturing defects can cause the coil wire to separate from the bobbin, reducing reliability.

- Counterfeit materials — Some low‑cost suppliers may substitute lower‑grade magnets or copper‑clad aluminum wire, leading to inconsistent performance. Supplier audits and material certifications mitigate this risk.

- Alignment drift — Misalignment between coil and magnet can occur during shipping or assembly, degrading performance. Integrated modules with pre‑aligned components reduce this risk.

- Supply disruptions — As the pandemic illustrated, reliance on a single region can expose the supply chain to shutdowns and transportation delays. Yana advocates dual sourcing and inventory buffers.

By understanding these risks and partnering with vetted suppliers, companies can secure high‑quality voice coil motors and maintain consistent production.

Emerging Innovations & Future Trends

Although voice coil motors have existed since the early days of loudspeakers, recent advances are driving a renaissance in micro‑motion technology. Here are six innovations propelling VCM performance and expanding their applicability:

- AI‑tuned VCM Drivers — Machine‑learning algorithms embedded in motor controllers automatically adjust control parameters in response to changing loads and environmental conditions. Self‑learning PID loops reduce overshoot, improve settling times and compensate for aging or temperature variation. In robotic systems where loads vary unpredictably, AI‑tuned drivers help maintain nanometre precision.

- Dual‑Stage Voice Coil Modules — Combining a coarse actuator (such as a voice coil paired with a long‑stroke linear motor) with a fine‑stage voice coil enables wide travel ranges with nanometre resolution. These dual‑stage modules are increasingly used in semiconductor lithography, wafer inspection, and precision metrology to deliver both speed and accuracy.

- Integrated Sensors and Smart Modules — Modern voice coil motors incorporate integrated position sensors, temperature sensors and sometimes force sensors. Onboard electronics monitor the health of the motor and communicate with the controller for predictive maintenance. Smart VCMs reduce wiring complexity and simplify system integration.

- Low‑Voltage Micro‑VCMs — Advances in coil and magnet design have enabled high‑performance voice coil actuators that operate at safe low voltages (<24 V). These micro‑VCMs power wearable haptic devices, tactile feedback systems and compact medical instruments, allowing direct battery operation without complex high‑voltage converters.

- Hybrid Voice Coil Modules — Combining voice coil technology with piezoelectric or electromagnetic actuators provides large stroke and ultra‑fine resolution. In microscopy and optical instruments, hybrid modules enable scanning over millimetres while achieving sub‑nanometre positioning, bridging the gap between micro‑ and nano‑scale actuation.

- Rare‑Earth Optimization and Alternative Materials — As rare‑earth supply volatility and environmental concerns grow, manufacturers are developing magnet compositions that reduce dependence on neodymium. New magnetic materials and magnet assembly techniques improve thermal stability and cost efficiency, broadening the operational temperature range of VCMs and reducing supply chain risk.

These trends show that voice coil motors are far from mature technology; instead, they are evolving rapidly to meet the demands of precision robotics, automation, medical technology and consumer electronics. Yana monitors these innovations to help clients stay ahead of the curve.

Choosing the Right Voice Coil Motor for Your Robot

Selecting a VCM for a robotic application requires balancing multiple criteria:

- Force requirements — Determine the peak and continuous force needed. Peak force drives acceleration; continuous force determines the ability to hold loads without overheating. For force control applications, the voice coil’s force constant should match the controller’s current output range.

- Stroke length — Choose a stroke that covers the required motion plus margin. Longer strokes require larger magnets and coils, increasing mass; smaller strokes provide faster response.

- Bandwidth and response — High‑bandwidth applications such as active vibration control or high‑speed focusing require low inductance and minimal moving mass. Check the coil inductance and mass to estimate response time.

- Cooling and duty cycle — If the application demands continuous high force, select a VCM with integrated liquid cooling or ensure that the system can dissipate heat. For intermittent or low‑duty tasks, natural convection may suffice.

- Mounting and orientation — Consider whether the coil or magnet should move, the available mounting space, and the orientation (horizontal or vertical). Moving‑magnet designs keep the coil stationary to simplify wiring; moving‑coil designs offer lower moving mass.

- Sensor integration — Decide whether you need an integrated position sensor. VCMs are often paired with optical encoders, linear Hall sensors or capacitive gauges. Integrated sensors simplify wiring and reduce alignment efforts.

- Cost versus performance — Evaluate the total cost, including coil, magnet assembly, bearings, sensors and control electronics. Lower‑cost VCMs may use aluminum wire or lower‑grade magnets, which can reduce performance. Consider lifetime costs and maintenance when selecting a supplier.

Example Scenarios — Where Voice Coil Motors Excel

- Optics and Laser Alignment: In semiconductor lithography and laser scanning systems, VCMs adjust mirrors, lenses and objective positions. Their nanometre‑level precision and high bandwidth ensure sharp images and accurate alignment.

- Medical Devices: In syringe pumps, infusion pumps and surgical robots, voice coil actuators provide smooth, noise‑free motion. Sub‑millimetre accuracy and rapid response allow doctors to perform delicate procedures and control flow rates precisely.

- Haptic Interfaces and Wearables: VCMs deliver tactile feedback in virtual reality devices and prosthetics. Because they can vibrate at high frequencies without mechanical wear, they provide realistic sensations and long life.

- Semiconductor Handling: In wafer steppers and inspection tools, dual‑stage VCMs provide coarse and fine positioning to align wafers with masks or sensors. The ability to settle quickly reduces cycle times and increases throughput.

- Speakers and Audio Transducers: While not a robotic application, the origins of voice coil technology lie in loudspeakers. The same principle used to move a speaker cone produces high‑fidelity sound, proving the versatility of VCMs.

These scenarios illustrate how voice coil motors deliver unmatched performance in tasks that require rapid, precise and silent movement.

Sourcing Verified Voice Coil Motors with Yana

At Yana Sourcing, we believe that sourcing critical components is about more than finding the lowest price. It’s about securing quality, reliability and trust across the entire supply chain. Our SMART + HEART framework ensures that every voice coil motor we source meets both technical and human expectations.

- SMART means we perform comprehensive technical due diligence. We audit factories, verify magnet compositions, measure force constants and inspect assembly processes. We ensure that suppliers provide material certificates and meet international standards. Our on‑site engineers witness quality tests, from force constant measurements to thermal cycling, ensuring that the motors perform as specified.

- HEART reflects our commitment to long‑term relationships and ethical sourcing. We build partnerships with suppliers who share our values, fair labor practices, environmental stewardship and transparent communication. We understand cultural differences and bridge them to create successful collaborations. Our clients trust us not just to deliver parts, but to protect their intellectual property and ensure a sustainable supply chain.

Partnering with Yana provides peace of mind that your robotic projects will benefit from verified voice coil motor suppliers. We handle everything from supplier qualification and price negotiation to quality control and logistics. Our global network enables us to offer multiple sourcing options, mitigating risks from regional disruptions and ensuring continuity of supply.

Ready to advance your robotics project? Contact Yana Sourcing to secure high‑performance, verified voice coil motors and experience the precision, speed and silence that our customers rely on.