Table of Contents

Introduction — Why Stepper Motors Matter in Robotics

In the world of robotics, stepper motors occupy a unique niche. These electromechanical devices convert electrical pulses into mechanical motion, moving not in a continuous sweep like traditional DC motors but in discrete, repeatable increments. Because each pulse produces a fixed angular step, a controller can command a precise number of steps and know where the shaft will end up without feedback. This characteristic makes stepper motors ideal for position control systems and explains why they are widely used in automation, robotics, CNC machinery and medical devices. In the first hundred words we emphasise stepper motors for robotics to anchor the focus keyword.

Unlike servo motors, which rely on continuous feedback to correct positional error, or brushless DC (BLDC) motors that spin at high speeds with field‑oriented control, stepper motors are inherently open‑loop devices. Their ability to take fixed steps without complex feedback circuitry makes them cost effective and reliable for many robotic applications. When the rotor moves, it holds its position firmly until the next pulse, providing “detent” torque even when power is off in some designs. This self‑positioning capability reduces the need for sensors and simplifies control electronics. However, it also limits stepper motors’ top speed and efficiency compared with servo or BLDC motors. Understanding these trade‑offs is essential when selecting actuation for a robotic system. Throughout this article, we will contrast stepper motors with their servo and brushless cousins to help designers choose the right actuator for each task.

Stepper motors also play a pivotal role in entry‑level and intermediate robotic systems. They offer high torque at low speeds, can hold a load without active control, and are easy to interface with microcontrollers. Robots that require repeatable movements, such as pick‑and‑place arms, 3‑D printers, laboratory pipetting systems and camera gimbals, often rely on steppers for their predictable motion. As the complexity and autonomy level of a robot increases, designers may combine stepper motors with sensors or upgrade to closed‑loop stepper or servo systems. The subsequent sections explore the anatomy, operation, performance, integration and sourcing considerations for stepper motors, offering nine design strategies to achieve reliable motion.

Working Principle of Stepper Motors

Structure and Components

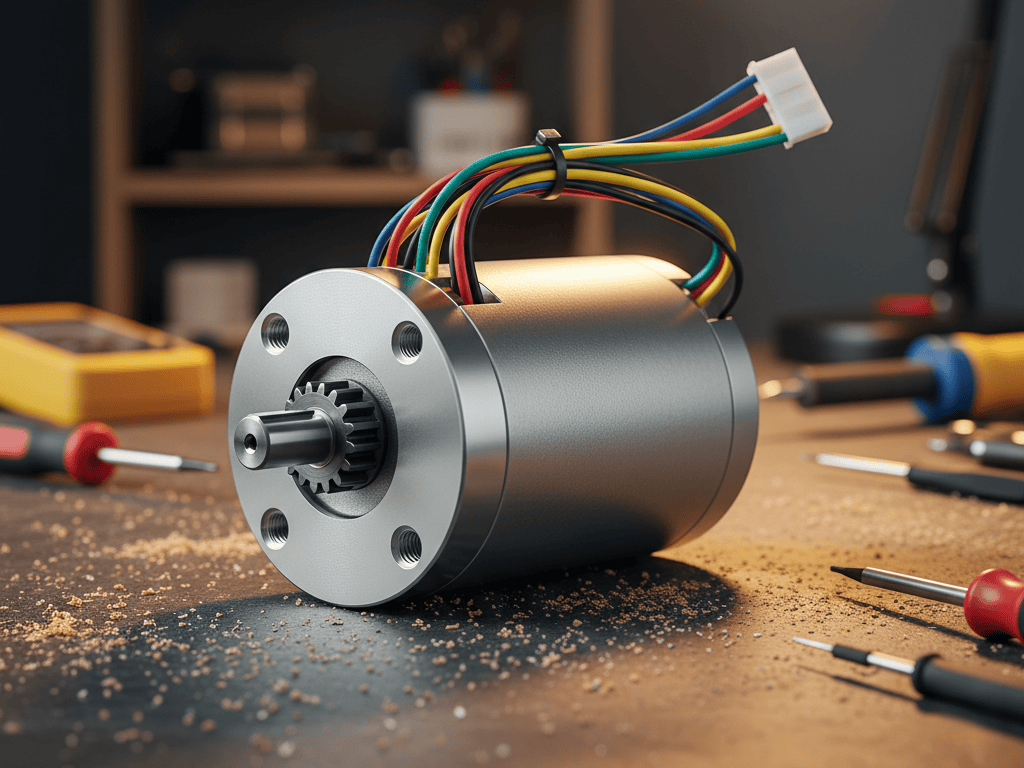

A stepper motor consists primarily of two parts: a stator and a rotor. In a typical 5‑phase hybrid stepper motor, the rotor is magnetized axially so that one rotor lamination is polarized north and the other south. Each rotor has fifty small teeth on its outer perimeter, and the teeth of the two laminations are mechanically offset by half a tooth pitch. The stator surrounds the rotor and has multiple magnetic poles; in a 5‑phase design there are ten poles, each wound with coils that are electrically paired so both poles are magnetized in the same polarity when current flows. The opposing pair of poles constitutes one phase. When current flows through a phase winding, it magnetizes the corresponding stator poles, attracting or repelling the rotor’s teeth and causing rotation. Because the magnetic circuit relies on discrete teeth, stepper motors achieve high resolution without needing an external encoder.

These motors come in several variants. Variable‑reluctance (VR) steppers use soft‑iron rotors with no permanent magnet; they align with stator poles of least magnetic reluctance and typically have large step angles (5–15°) and no detent torque. Permanent‑magnet (PM) steppers have a rotor made of a permanent magnet with no teeth; they generally take larger steps (45° or 90°) and provide good torque at low speeds, making them suitable for printers and low‑cost automation. Hybrid steppers combine the features of VR and PM designs: the rotor has fine teeth and an axially magnetized permanent magnet, giving smaller step angles (0.9°–1.8°) and higher torque. Hybrid designs dominate robotics because they provide a balance of precision, torque and cost.

Physical construction materials also influence performance. The shaft is typically stainless steel, while stator and rotor laminations use silicon steel to reduce core losses. Magnets can be ferrite, sintered ferrite or Nd‑Fe‑B bonded magnets, each affecting torque density and temperature tolerance. Bearings support the shaft and reduce friction; the housing, often aluminum, dissipates heat and protects the internals. Understanding these materials helps specifiers match motor construction to environmental requirements.

Step Sequence and Commutation

The operation of a stepper motor is best understood by examining phase excitation. When phase A is energized, its poles are polarized south, attracting the north‑polarized teeth of rotor 1 and repelling the south‑polarized teeth of rotor 2; this holds the rotor stationary in a specific alignment. When excitation switches from phase A to phase B, the phase B poles are magnetized north, attracting rotor 2 and repelling rotor 1; the rotor rotates by a small angle, 0.72° in a 5‑phase example, until its teeth realign. As the controller sequentially energizes phases A, B, C, D, E and back to A, the motor turns smoothly in discrete increments. Reversing the sequence reverses the direction of rotation. This stepwise commutation is the core of stepper operation.

Because stepper motors are externally commutated (also called brushless), the driver circuit must deliver current pulses with precise timing. The step frequency controls rotational speed, and the step count determines position. Microstepping drivers subdivide full steps into smaller increments by simultaneously energizing multiple phases at proportional currents, producing smoother motion and reduced vibration. Unlike servo motors, which close the loop with position feedback, most steppers operate in open loop and rely on proper sizing to avoid losing steps under load. Closed‑loop stepper systems add an encoder and adapt the commutation like a servo, increasing performance at the cost of complexity.

Torque–Speed Characteristics

Stepper motors exhibit distinct dynamic and static characteristics. The speed–torque curve defines torque as a function of stepping speed: torque is highest at low step rates and decreases as the stepping frequency increases. Maximum holding torque occurs when the motor is energized but not rotating, representing its ability to resist external forces at standstill. Pullout torque is the maximum load the motor can drive at a given speed without losing synchronization. Because there is no inherent feedback, if the load torque exceeds the pullout torque the motor may miss steps and lose position. The maximum starting frequency defines the highest pulse rate at which the motor can start without ramping; adding inertial load reduces this frequency. These parameters guide designers when matching motors to load inertia and speed requirements.

Performance Characteristics & Control

Torque Output, Speed Control and Efficiency

Stepper motors deliver high torque at low speeds and provide excellent holding torque when stopped. Their efficiency comes from the ability to maintain position without continuous correction; however, because current flows in the windings even when holding position, steppers can generate significant heat. Compared with BLDC motors, which can run efficiently at thousands of revolutions per minute, steppers are better suited to moderate speeds (typically below 1,000 rpm for hybrid designs). Permanent magnet and hybrid steppers offer higher torque density than variable‑reluctance designs but still fall behind servo motors, which can provide high torque over a broader speed range. Efficiency can be improved by selecting drivers with current control algorithms that reduce current at low load.

Open‑Loop vs Closed‑Loop Control

Traditional stepper systems use open‑loop microstepping. They are attractive for cost‑sensitive applications because they do not require feedback sensors or complex tuning. However, open‑loop control has limitations: the motor draws a constant current regardless of load, leading to unnecessary heat, and any missed step due to excessive load remains undetected. Closed‑loop stepper control addresses these drawbacks by adding an encoder and running the motor like a servo. The driver measures rotor position and adjusts phase currents in real time, resulting in higher torque output, better acceleration and more efficient operation. Closed‑loop steppers can match or exceed the performance of more expensive BLDC motors for many industrial tasks and are increasingly adopted in textile machinery, coil winding, circuit board production and pick‑and‑place machines.

The acceleration benefit of closed‑loop control stems from optimal current utilization. In an open‑loop system, current must be set for worst‑case load conditions. Closed‑loop systems vary current according to demand, reducing heat and allowing higher acceleration rates. They also eliminate step loss and allow finer positioning because resolution is determined by encoder counts rather than step angle. The trend toward affordable high‑resolution encoders has accelerated adoption of closed‑loop steppers, making them viable alternatives to servos in many cost‑sensitive applications.

Speed Control and Microstepping

Microstepping subdivides each full step into smaller positions, creating smoother motion and reducing vibration. Drivers accomplish this by feeding sinusoidal or quasi‑sinusoidal currents into the motor phases, creating intermediate electromagnetic angles. Microstepping not only improves smoothness but also increases positional resolution, which is important in robots requiring fine control. Nevertheless, microstepping does not increase maximum torque; it typically reduces torque because phase currents are lower than during full‑step operation. When choosing a driver, engineers must balance smoothness against torque requirements.

Comparison Table

The table below compares stepper motors to servo and BLDC motors across typical parameters. It highlights the relative strengths and weaknesses without long sentences:

| Parameter | Stepper (Hybrid) | Servo | BLDC |

|---|---|---|---|

| Control loop | Open or closed | Closed | Closed |

| Speed range | 0–1 000 rpm | 0–5 000 rpm | 0–10 000 rpm |

| Torque density | Moderate | High | Moderate–high |

| Position accuracy | Step angle or encoder based | Encoder based | Hall/encoder based |

| Feedback required | None (open) | Yes | Yes |

| Cost | Low–medium | High | Medium |

| Common use | Positioning tasks | Dynamic motion | Continuous rotation |

This table provides a quick reference when comparing actuation options in robotic systems.

Integration in Robotic Systems

Applications Across Robotics Levels

Stepper motors power a wide range of robotic devices. They bridge the gap between simple electrical signals and precise mechanical movements, making them ideal for applications that demand reliability without the expense of closed‑loop drives. In Level 1 and Level 2 robots, simple automation and repeatable motion tasks, steppers drive linear slides, XY tables, camera focus mechanisms and 3‑D printers. Their ability to move in discrete steps without feedback suits pick‑and‑place arms, small gantry robots and pipetting equipment. In Level 3 robots, collaborative arms and mobile platforms, hybrid steppers combined with gearboxes or lead screws provide precise joint control, though designers must carefully size motors to avoid missed steps when external forces vary. At Level 4 robots, advanced autonomous systems, closed‑loop steppers with integrated encoders are gaining traction. They offer servo‑like performance at a lower cost and integrate easily into networked control architectures.

Beyond industrial automation, stepper motors appear in everyday devices such as desktop CNC machines, 3‑D printers, medical infusion pumps, camera gimbals and robotic toys. Variable‑reluctance steppers are used in instrumentation where low cost outweighs torque requirements. Permanent‑magnet steppers power low‑speed positioning tasks like paper feeding in printers. Hybrid steppers dominate robotics because of their fine step resolution and high torque. As we will see in later sections, emerging closed‑loop technologies are expanding the scope of stepper motors into high‑performance regimes previously reserved for servos.

Integration Challenges and Design Considerations

Integrating stepper motors into robotic systems involves managing several design variables. Inertia matching is crucial: the load’s moment of inertia must not vastly exceed the motor’s rated inertia, or the motor may miss steps during acceleration. Proper gearing or pulley ratios can match inertias and improve performance. Heat management is another challenge; because steppers draw current even when stationary, they can run hot. Engineers should ensure adequate thermal pathways, using aluminum housings, heat sinks or forced air, and select drivers with current reduction at idle. Vibration and resonance occur when the motor’s mechanical natural frequency coincides with the stepping frequency. Microstepping, dampers or rubber couplings can mitigate resonance. Cable routing and electromagnetic interference (EMI) must be managed, particularly in multi‑axis robots; twisted‑pair cabling and shielding reduce noise. Noise from stepper operation can be objectionable in consumer or medical environments, so gearboxes or closed‑loop control that smooth the current profile may be necessary. Weight and size should also be matched to the robotic joint; NEMA 17 or NEMA 23 frames are common in desktop robots, whereas larger NEMA 34 or NEMA 42 frames suit heavy‑duty industrial axes.

Integration Challenges and Proven Solutions

Challenge 1 — Vibration and Resonance: When a hybrid stepper drives a mid‑range speed application (e.g., 300–800 rpm), it may encounter resonant frequencies that cause oscillations and audible noise. Solution: Use microstepping drivers and add mechanical dampers or tune the drive to avoid resonant step rates. In one Yana‑audited project, switching from full‑step to 16‑microstep operation and adding a viscous damper reduced vibration amplitude by 70 % and noise by 6 dB. Challenge 2 — Heat Generation in Continuous Duty: A pick‑and‑place robot operating 24/7 experienced overheating because the open‑loop driver delivered constant current at idle. Solution: Upgrade to a closed‑loop stepper with adaptive current control and integrate an aluminum heat sink. Measurements showed a 15 °C reduction in housing temperature and improved motor longevity. Challenge 3 — Inertia Mismatch and Missed Steps: A lab robot used a stepper directly coupled to a heavy linear slide and frequently lost position. Solution: Introduce a 3:1 gear reduction to match load inertia and implement acceleration ramps. The robot achieved repeatable positioning with zero lost steps over 100,000 cycles. These examples illustrate that careful mechanical design, driver selection and control strategies can overcome common stepper integration problems.

| Metric | Before (Open loop) | After (Optimized) | Improvement |

|---|---|---|---|

| Vibration amplitude | 1.0 unit | 0.3 unit | −70 % |

| Housing temperature | 75 °C | 60 °C | −15 °C |

| Missed steps per cycle | 5 % | 0 % | Eliminated |

These results demonstrate that combining proper mechanical coupling, thermal management and advanced control can transform a basic stepper into a reliable actuator.

Manufacturing & Sourcing Insights

Regional Strengths and Market Landscape

The global stepper motor market was valued at approximately USD 2.19 billion in 2025 and is forecast to reach USD 2.62 billion by 2030, reflecting a compound annual growth rate of 3.65 %. Hybrid designs captured about 55 % of the market in 2024 and are expected to grow at 4.1 % CAGR through 2030. Asia‑Pacific leads in both production and consumption; the region controlled around 36 % of the 2024 market and 45 % of demand according to other analyses. Manufacturing hubs in China, India and Southeast Asia offer cost advantages and deep supply chains. North America and Europe remain significant consumers, with growth driven by medical devices, semiconductor equipment and collaborative robots.

The market is moderately concentrated. Premium segments are commanded by companies such as Oriental Motor, Nidec and Schneider Electric, which leverage closed‑loop innovations and comprehensive service footprints. Chinese manufacturers like MOONS’ Electric, Changzhou JKongmotor and Shanghai STEP Electric pursue volume leadership by vertically integrating magnet production and surface‑mount technology assembly, enabling cost reduction while maintaining ISO certifications. Strategic consolidation continues: in February 2025, Haier Group acquired 26.83 % of Shanghai STEP Electric to combine industrial‑internet analytics with motion‑control portfolios. Nidec, a Japanese motor giant, posted record FY2025 revenue of USD 16.8 billion, with small precision motors contributing 18.7 % and funding large research programs.

Market drivers include the growing adoption of robotics and collaborative automation, rising demand for precision motion in medical devices and expansion of 3‑D printing ecosystems. Government incentives for localized production in North America and Europe also support stepper manufacturers. However, the sector faces challenges: performance limits versus servo and BLDC motors, price pressure from low‑cost Asian suppliers, the emergence of smart integrated actuators that cannibalize discrete motors, and thermal management difficulties in compact designs. Designers should consider these factors when sourcing and ensure a diversified supply base.

Supplier Ecosystems and Sourcing Considerations

When sourcing stepper motors, regional strengths matter. Asia‑Pacific offers the widest range of models and highly competitive pricing. Chinese suppliers provide hybrid and hollow‑shaft steppers at low minimum order quantities (MOQs), often as low as 50–100 units, but quality can vary. Taiwan and Japanese manufacturers supply premium units with tighter tolerances and integrated drives; lead times may extend to 6–12 weeks due to demand. North America offers specialty steppers for aerospace and medical devices, with MOQs around 100 units and high traceability. Europe (Germany, Italy and Switzerland) focuses on precision micro‑steppers and linear versions for laboratory and semiconductor equipment; MOQs may range from 10–50 units but at higher cost. Buyers should align procurement strategies with regional strengths and risk tolerance.

Customization potential is significant. Suppliers can modify step angles, incorporate gearboxes, integrate encoders, create waterproof housings or add brake mechanisms. Closed‑loop packages with built‑in drivers and feedback are becoming popular for robotics because they simplify integration and reduce cabling. When requesting custom features, engineers should confirm that the supplier can maintain holding torque and thermal performance. Yana Sourcing evaluates design drawings and sample units to verify that custom modifications meet application requirements.

Quality Control Checklist

To ensure stepper motors meet specification and perform reliably, Yana’s quality audits include:

- Torque testing: Measure holding torque and pullout torque across specified speeds. Compare results with datasheet and ensure a safety margin.

- Vibration and balance: Use dynamic balancing machines to verify rotor balance and measure vibration amplitude. Poor balance can cause resonance and reduce lifespan.

- Insulation resistance: Perform high‑pot tests to confirm insulation integrity between windings and housing; this is critical for medical and safety‑certified robots.

- Step accuracy: Drive the motor through a specific number of steps and measure cumulative position error. Hybrid steppers should exhibit high repeatability.

- Thermal performance: Operate the motor at rated current and measure temperature rise over time. Verify that the temperature remains within specified limits and that heat sinks or housings dissipate heat effectively.

- Component verification: Inspect magnet materials, lamination stacks and bearing quality to detect counterfeits or substandard materials.

Risk Factors

The stepper motor supply chain faces several risks. Magnet supply is vulnerable to rare‑earth price volatility; Nd‑Fe‑B magnets used in hybrid steppers depend on rare earth elements mostly mined in China. Counterfeit or downgraded magnets can enter the supply chain, leading to lower torque or demagnetization. Thermal design flaws, such as inadequate heat sinking or poor coil insulation, can cause premature failure. Low‑cost manufacturers may cut corners in winding processes or use inferior bearings. Geopolitical factors such as export controls can restrict access to components. Buyers should audit suppliers’ material provenance and ensure certification for international standards (e.g., ISO 9001, CE, RoHS). Yana’s audits help mitigate these risks by verifying supplier capabilities and maintaining multiple qualified sources.

Emerging Innovations & Future Trends

Stepper motor technology is evolving to meet the demands of smart robotics and Industry 4.0. Key trends include:

- Closed‑Loop Steppers with Integrated Encoders: As described earlier, closed‑loop stepper systems combine a stepper motor with an encoder to drive the motor like a servo. This architecture provides higher torque, improved acceleration and efficiency while maintaining the cost benefits of steppers. Adoption is accelerating in industrial applications such as textile machinery, circuit board production and pick‑and‑place equipment. High‑resolution encoders are becoming cheaper, making 3.6° or even coarser step motors viable for closed‑loop control.

- IoT‑Enabled Motors and Predictive Maintenance: Market analyses highlight increasing integration of stepper motors with IoT technologies. Smart drivers can report operating parameters (temperature, current, position) over industrial networks, enabling predictive maintenance and reducing unplanned downtime. Cloud‑connected controllers may adjust microstepping profiles in real time based on sensor feedback.

- Hybrid Motor Innovations: Research and development focus on improving torque density and efficiency of hybrid steppers. New magnetic materials and improved lamination geometries enhance flux density and reduce cogging. Manufacturers are exploring axial‑flux hybrid designs and multi‑phase configurations to increase torque without enlarging the motor. Integrated harmonic gearboxes and strain‑wave drives allow direct coupling to robot joints, reducing backlash.

- High‑Torque and Linear Steppers: High‑torque hybrid steppers (NEMA 34 and above) are gaining popularity for collaborative robots and industrial axes requiring higher payload capacity. Linear steppers and voice‑coil‑type stepper actuators provide direct linear motion without screws; they are well suited for wafer handling, pick‑and‑place and high‑precision positioning. Advances in winding technology and driver algorithms improve thrust force and dynamic response.

- AI‑Based Tuning and Adaptive Control: Combining stepper motors with machine‑learning algorithms enables adaptive tuning of current profiles and stepping sequences. AI models can predict resonance points and automatically adjust microstepping parameters to optimize smoothness and efficiency over a wide range of operating conditions. This approach may blur the line between stepper and servo systems, creating “smart steppers” that deliver servo‑like performance with lower hardware cost.

- Rare‑Earth‑Free Motors and Sustainable Materials: Concerns about the environmental and geopolitical impact of rare‑earth mining drive research into ferrite‑based or recycled magnetic materials. Engineers are exploring ways to maintain torque density while reducing or eliminating rare‑earth content. Sustainable manufacturing practices, such as using recyclable laminations and lead‑free solder, are becoming increasingly important for OEMs seeking to reduce their carbon footprint.

These innovations ensure that stepper motors remain relevant in future robotic architectures. Designers should monitor advancements in closed‑loop control, smart networking and sustainable materials when planning long‑term product roadmaps.

Choosing the Right Stepper Motor for Your Robot

Selecting a stepper motor for a robotic project involves balancing technical requirements, cost constraints and application scenarios. The following checklist guides the decision:

- Torque and Load: Determine peak and continuous torque required at the operating speed. Consult speed–torque curves and ensure the pullout torque exceeds maximum load. Include a safety margin for unforeseen friction or inertia.

- Inertia Matching: Calculate load inertia and select motor inertia within a 3:1 ratio for open‑loop systems. Use gearboxes or belt drives to match inertias if necessary.

- Speed Requirements: Hybrid steppers perform best below 1 000 rpm. For higher speeds, consider BLDC or servo motors.

- Resolution and Accuracy: Choose step angle (e.g., 1.8°, 0.9°) or microstepping resolution to meet positioning requirements. Closed‑loop steppers can achieve high resolution with an encoder.

- Control Complexity: Open‑loop systems are simple but risk missed steps. Closed‑loop systems require encoders and tuning but improve performance. Evaluate the trade‑off between cost and reliability.

- Environment: Consider ambient temperature, vibration, dust and moisture. Select sealed or waterproof motors for harsh environments and verify insulation resistance.

- Integration Space: Ensure the motor’s physical size (frame size, length, weight) fits within the robot’s mechanical layout. Use NEMA designations (e.g., NEMA 17, 23, 34) as guides.

- Power Supply: Confirm that the driver voltage and current ratings match the available power supply and that the driver can implement microstepping or closed‑loop control.

- Lifecycle and Maintenance: Estimate duty cycle and expected lifetime. For continuous operation or mission‑critical applications, prioritize motors with long bearing life and available spare parts.

Example Scenarios

- 3‑D Printers and Desktop CNC Machines: These devices require precise positioning and moderate speeds. Hybrid steppers with 1.8° step angles and microstepping drivers provide sufficient resolution and torque. Closed‑loop steppers are increasingly adopted in high‑end printers to improve acceleration and reduce layer artifacts.

- Laboratory Automation and Medical Devices: Instruments like pipetting robots or infusion pumps demand quiet operation and reliability. Hybrid or permanent‑magnet steppers with low vibration, combined with microstepping, fit these requirements. For surgical robots or imaging systems requiring higher accuracy, closed‑loop steppers or servo motors may be preferable.

- Collaborative Robot Joints: Cobots that share workspace with humans need safe torque and smooth motion. High‑torque hybrid steppers with integrated harmonic gearboxes can provide compliance and backdrivability. However, for high dynamic performance, servo motors may still be chosen.

- Pick‑and‑Place and PCB Assembly: Fast acceleration and high throughput are essential. Closed‑loop steppers with encoders and tuned drivers deliver the required acceleration and minimize missed steps. Alternatively, BLDC motors with field‑oriented control may be used for the highest speeds.

Crosslinking to sibling pages helps readers compare alternatives: choose servo motors for high‑speed closed‑loop motion, BLDC motors for continuous rotation with high efficiency and torque motors for direct‑drive applications. Each technology has a niche; understanding stepper capabilities ensures they are deployed where they excel.

Sourcing Verified Stepper Motors with Yana

Yana Sourcing bridges the technical complexity of motion systems with the practical realities of global supply chains. Our SMART + HEART framework integrates data‑driven analysis with human‑centered relationships to secure reliable actuation solutions. We begin by understanding your robotic application, quantifying torque, speed, resolution and environmental needs. We then leverage our curated network of audited manufacturers across Asia, Europe and North America to identify stepper motors that meet your specifications and budget. Whether you require standard NEMA‑frame hybrids, custom linear steppers, closed‑loop packages or integrated gearmotors, Yana vets suppliers for quality, compliance and ethical practices.

Our quality audits include torque tests, vibration analysis, insulation verification, step accuracy measurement, thermal evaluation and material inspection, ensuring that every motor performs as promised. We also assess suppliers’ financial stability, manufacturing capacity and intellectual property controls, reducing risk of supply disruption. Beyond procurement, Yana facilitates lifecycle support: managing logistics, spares, warranty claims and end‑of‑life recycling. We monitor emerging technologies, such as IoT‑enabled motors, AI‑based tuning and sustainable materials, so our clients stay ahead of the curve.

Partner with Yana Sourcing to secure verified stepper motor suppliers and power your next‑generation robotics projects. Together, we will transform pulses into precise motion and build robots that move reliably, efficiently and ethically.