Table of Contents

Introduction — Why Servo Motors Matter in Robotics

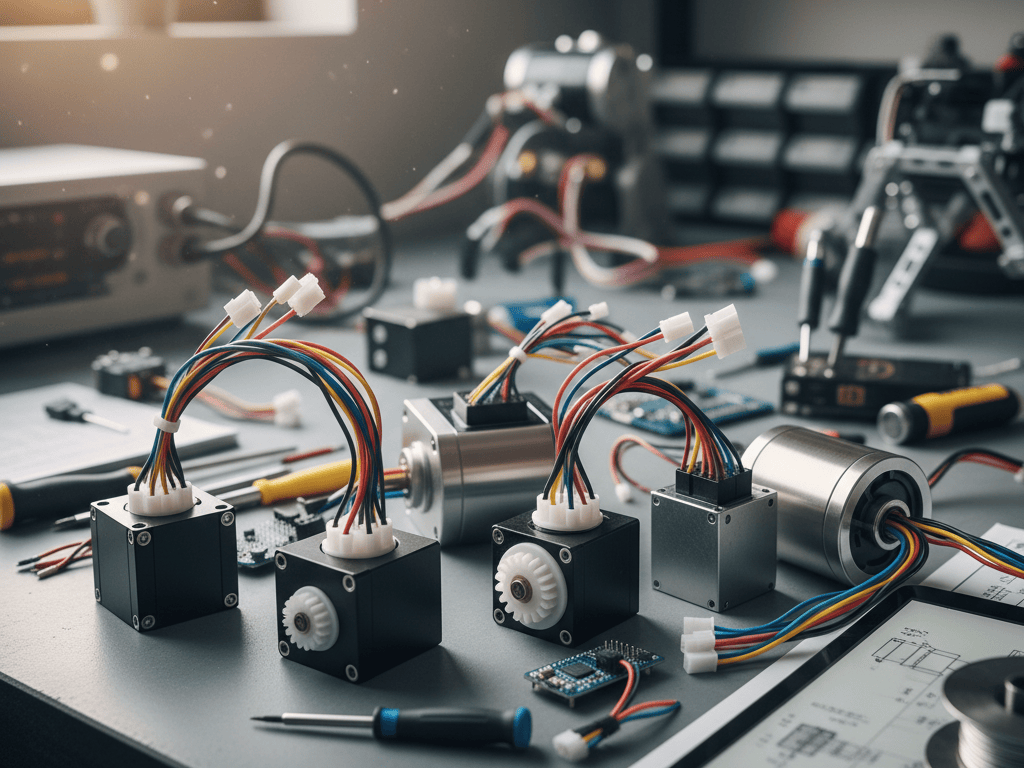

In the modern robotics landscape, servo motors are the intelligent engines that bridge computation and motion. A servo motor is not just a standard motor that spins when voltage is applied; rather, it is a closed‑loop actuator that continuously compares its output with a command signal and corrects any deviations. This real‑time feedback mechanism gives servo systems the ability to precisely control position, speed and torque, making them indispensable in robot arms, humanoid joints, autonomous vehicles, medical devices and aerospace systems. Servo motors differ fundamentally from open‑loop drives like basic DC motors or steppers; instead of simply receiving power and spinning freely, servos monitor their position through sensors and adjust power to maintain the desired state. By embedding sensors, control circuitry and gearing into a compact housing, servo motors deliver accurate, repeatable motion that can be finely tuned, stopped or held in place, capabilities that are critical for robots operating in dynamic and uncertain environments. Throughout this article, we explore how servos work, what makes them different, and why they are central to the future of intelligent automation.

Working Principle of Servo Motors

At the heart of a servo system is a closed‑loop control architecture. A servo motor consists of several key elements: a rotary electric motor (which can be AC or DC), a feedback device such as an encoder or resolver, a control circuit and a gear train for torque amplification. The control circuitry receives a command signal from a higher‑level controller (such as a programmable logic controller or robot control unit), then drives the motor to rotate the shaft. As the shaft turns, the encoder measures its position and sends that information back to the control circuit. If there is a difference between the commanded position and the actual position, the control circuitry adjusts the motor’s voltage and current to correct the error. This closed loop repeats continuously, allowing the servo to achieve and maintain the desired position or speed.

Servo motors can be either AC or DC. AC servo motors are typically synchronous permanent‑magnet machines whose rotors are magnetized by rare‑earth magnets; they offer high torque density, high efficiency and operate at synchronous speed without slip. DC servos (often called brushed servos) use a brushed DC motor with a feedback loop; they provide quick response and high torque at low speeds but have lower efficiency and require maintenance due to brush wear. Modern robotics mostly employs brushless AC servo motors because they combine high torque and speed with maintenance‑free operation and low noise.

A typical servo motor includes an embedded gearbox that multiplies torque and reduces speed, allowing small motors to move heavy loads. The gear train also produces a phenomenon known as detent torque, the ability to hold a position without constant power, which is valuable for maintaining a robot’s posture. Attached to the output shaft is an encoder or resolver that measures angular position. Encoders can be incremental (measuring relative change) or absolute (reporting an exact position), and high‑precision encoders can provide positional accuracy down to arc‑minutes or even arc‑seconds. The servo drive, sometimes called an amplifier, regulates the motor’s voltage and current and performs the real‑time control calculations.

The relationship between torque and speed in a servo motor is defined by the motor’s construction and control scheme. Generally, servo motors are designed to provide high torque across a broad speed range, and they can deliver significant peak torque for short durations to accelerate loads or overcome static friction. The torque–speed curve is usually flat up to a certain rated speed, after which torque begins to drop due to back electromotive force and thermal limits. By operating within the continuous torque region and respecting duty cycle limits, engineers can ensure reliability and longevity.

Performance Characteristics & Control

Servo motors are prized for their combination of precision, responsiveness and power. Key performance attributes include:

- Position accuracy: With high‑resolution encoders and finely tuned control loops, servo motors can position loads with angular accuracy measured in arc‑minutes or better. This precision is vital for tasks such as robotic welding, pick‑and‑place, surgical robotics and semiconductor manufacturing.

- High torque at low speeds: Servos maintain high torque even at low rotational speeds. DC servos are known for producing high torque at low RPM, while AC servos deliver high torque density across a wide speed range. This torque capability allows robots to accelerate quickly, handle variable loads and perform force‑controlled tasks.

- Speed control and dynamic response: Servo systems have a fast response time because feedback operates in real time, adjusting voltage and current to follow command changes. Controllers can tune bandwidth (the frequency at which the system can respond) to match application requirements. High bandwidth enables precise tracking of complex motion profiles without overshoot or lag.

- Efficiency and thermal management: Brushless AC servos operate with high efficiency due to permanent‑magnet rotors and optimized electromagnetic design. However, the control drive and gear train generate heat, requiring proper thermal design, adequate heat sinking, and sometimes forced cooling to maintain continuous operation.

- Feedback and control methods: Servos use closed‑loop feedback to correct errors. Pulse width modulation (PWM) signals are commonly used in hobby servos to represent commanded positions, while industrial servos use more sophisticated current control and field‑oriented control (FOC) algorithms. Advanced servos integrate digital communication buses (e.g., EtherCAT, CANopen) for deterministic control and synchronisation across multiple axes.

To illustrate how servo motors compare to other motor types, Table 1 summarizes key differences in control architecture, precision, speed range and typical applications:

| Parameter | Servo Motor | BLDC Motor | Stepper Motor | Torque Motor |

|---|---|---|---|---|

| Control loop | Closed‑loop with feedback (encoder/resolver) | Open‑ or sensorless‑feedback (may include sensors) | Typically open‑loop (can add closed loop) | Closed‑loop direct drive |

| Position accuracy | High (± arc‑min) | Medium | High resolution at low speeds; loses torque with load | High, especially at low speeds |

| Speed range | Wide; high torque at low speed | Very wide; efficient at high speed | Moderate; slower response | Low–medium; optimized for high torque |

| Response time | Fast (high bandwidth) | Moderate | Slow (stepped) | Very fast (direct) |

| Typical uses | Industrial robots, cobots, CNC machines, camera gimbals | Drones, electric vehicles, fans | 3D printers, CNC tables, feeders | Humanoid joints, high‑torque joints |

Integration in Robotic Systems

Servo motors enable a wide spectrum of robot designs, from simple single‑axis actuation to complex multi‑joint humanoids. Their precise control and high power density make them suitable for all levels of robot complexity, L1 to L4, as defined in Yana Sourcing’s autonomy taxonomy:

L1 (task‑specific automation): In simple robotic systems such as pick‑and‑place arms, servos drive each axis, providing accurate positional control and repeatability. Precision joints ensure that robotic arms can follow programmed trajectories to assemble electronic components, weld car parts or arrange packages. Because servos maintain high torque at low speeds, they can accelerate loads quickly and then hold positions without drifting or oscillating.

L2 (adaptive automation): Collaborative robots (cobots) and service robots require servo motors that are safe to operate alongside humans. Here, servos must deliver smooth motion and allow force or impedance control, making the robot compliant and responsive to external forces. Precise torque feedback and closed‑loop control enable cobots to adjust to external disturbances and perform tasks like screw‑driving, painting and packaging. Servo motors also power camera gimbals, providing stabilized rotation for professional filming and aerial drones.

L3 (advanced automation): Mobile robots and autonomous vehicles rely on servo motors for steering, drive control and sensor positioning. For example, servo actuators can adjust LiDAR units, antennae or camera angles on the fly. In industrial AGVs (automated guided vehicles), servos drive wheels and deliver smooth acceleration and deceleration. Servo motors with high torque density allow AGVs to move heavy loads while retaining fine control over speed and positioning.

L4 (embodied AI/humanoids): The highest level of robotics demands human‑like motion. Advanced humanoid robots use arrays of servo motors to articulate joints in arms, legs and hands. High torque combined with compact size enables robots to support payloads while maintaining anthropomorphic dimensions. Servos with absolute encoders provide accurate joint positioning for robotic exoskeletons and surgical robots. In bionic prosthetics, servo actuators can replicate muscle motion, enabling natural movement.

Design Considerations

When integrating servos into robotic systems, engineers must consider size, weight, cooling, noise and cable routing. Servo motors vary in diameter and length based on torque requirements; selecting a motor with appropriate inertia matching (ratio of load inertia to motor inertia) ensures stable control. Thermal management is critical: high current operation leads to heat generation in the stator and gear train, so servos often incorporate heat‑sinks or liquid cooling in high‑duty applications. Noise and vibration can be minimized with helical gears and high‑resolution encoders, important for medical and laboratory robots.

Integration Challenges and Proven Solutions

Implementing servo motors comes with challenges. Key issues include:

- Overheating and thermal drift: Continuous high‑torque operation can raise winding temperature, reducing magnetic strength. Solutions include derating (limiting continuous torque), improved cooling (heatsinks, fans or liquid cooling), and thermal sensors integrated with the servo to actively monitor and adjust drive current.

- Inertia mismatch: If the load inertia greatly exceeds motor inertia, the servo may overshoot or oscillate. Use proper gear ratios, select a servo with higher rotor inertia, or employ advanced control algorithms (e.g., notch filters) to stabilize the system.

- Feedback integrity: Encoder signals must be accurate; mechanical backlash, vibration or electrical noise can introduce errors. To mitigate, use high‑quality absolute encoders, ensure solid mounting, and implement shielded cables and proper grounding. For long travel axes, resolver feedback can provide robustness to noise and harsh environments.

- Tuning complexity: PID tuning can be labour‑intensive. Modern servo drives incorporate auto‑tuning and adaptive control algorithms that adjust control gains based on load and inertia. Some systems employ machine learning to optimize tuning across multiple axes.

Manufacturing & Sourcing Insights

The global servo motor market is anchored by regional manufacturing hubs. Understanding the strengths of each region helps Yana Sourcing procure the right servos for each application:

- China: China hosts numerous servo motor manufacturers offering cost‑efficient integrated servo systems that bundle the motor, drive and feedback into a single module. These solutions are widely used in small‑ to medium‑sized industrial robots, packaging machines and consumer robotics. Chinese manufacturers excel in mass production and rapid customization but require careful vetting to ensure quality.

- Japan: Japanese companies (e.g., Yaskawa, Panasonic, Mitsubishi) are renowned for precision servo motors with tight tolerances, long service life and advanced control features. Japan’s servo industry sets the benchmark for reliability in robotic arms, machine tools and semiconductor equipment. The supply chain benefits from decades of robotics experience, high‑quality materials and rigorous standards.

- Europe (Germany, Switzerland, Italy): European servo producers emphasize high torque density, compact frameless designs and integration into collaborative robots and medical devices. German manufacturers often supply servo motors with certified safety functions (e.g., safe torque off). European suppliers also lead in customizing servos for extreme environments (vacuum, radiation, cryogenic conditions).

- USA: The United States hosts servo manufacturers focused on specialized applications such as aerospace actuators, defence systems and mobile robotics. American suppliers often provide custom servo solutions tailored to unique mechanical interfaces, high reliability and performance monitoring features.

Quality Control Checklist

Before sourcing servo motors, Yana Sourcing applies a rigorous quality assurance checklist:

- Performance verification: Validate the servo’s torque constant, speed, efficiency and duty cycle against datasheet specifications through laboratory testing. Ensure the motor meets continuous and peak torque requirements.

- Encoder validation: Check encoder resolution and accuracy, verifying linearity and repeatability across the full rotation. Confirm the reliability of absolute or incremental encoders in real‑world conditions.

- Thermal testing: Run the servo under continuous load to measure temperature rise. Evaluate heat dissipation and confirm the motor maintains performance within the rated thermal limits.

- Electrical testing: Test insulation resistance, back EMF constant, and current ripple. Inspect for coil balance and evaluate electromagnetic compatibility (EMC) with other equipment.

- Mechanical integrity: Inspect the gear train and bearings for smooth operation and low backlash. Measure shaft runout and verify that the housing and mounting flange meet tolerance requirements.

Risk Factors

Several risks can impact servo sourcing and deployment:

- Rare‑earth magnet supply: Permanent magnets (typically Neodymium‑Iron‑Boron) are sensitive to geopolitical supply disruptions and price volatility. Sourcing from certified suppliers and maintaining inventory buffers mitigates risk.

- Counterfeit or substandard components: In low‑cost markets, inferior copper windings or compromised magnets can reduce performance and reliability. Yana Sourcing implements supplier audits and material traceability to avoid counterfeit parts.

- Thermal misdesign: Underestimating duty cycles can lead to overheating. Selecting a servo with adequate continuous torque and designing for cooling prevents premature failure.

- Firmware and drive compatibility: Servo drives may use proprietary protocols. When mixing servo brands or integrating into existing control architectures, ensure compatibility to avoid integration issues.

Emerging Innovations & Future Trends

Servo motor technology continues to evolve, delivering higher performance and smarter features. Several innovations are shaping the next generation of intelligent robotics:

1. Integrated servo modules: Modern designs integrate the motor, encoder, drive electronics and safety functions into a single compact package. These all‑in‑one servo joints simplify wiring and reduce installation time, making them ideal for collaborative robots and exoskeletons.

2. AI‑assisted tuning and predictive maintenance: Servo drives increasingly incorporate machine learning algorithms to optimize control parameters in real time. By analysing vibration, load variation and temperature, drives can predict wear and schedule maintenance before failures occur. AI‑assisted tuning reduces commissioning time and ensures peak performance across operating conditions.

3. Rare‑earth‑free and low‑cobalt magnets: Research efforts aim to replace expensive rare‑earth magnets with ferrite or hybrid magnet structures. These sustainable magnet technologies reduce dependency on critical materials and lower costs.

4. High‑torque‑density windings: Novel coil geometries and advanced manufacturing techniques (e.g., printed windings, hairpin windings) boost torque density while reducing copper losses. Combined with improved cooling methods, these windings enable compact yet powerful servos.

5. Smart safety integration: Future servos embed safety functions (Safe Torque Off, Safe Speed Monitoring) and redundant encoders directly into the motor. These features allow robots to meet stringent safety standards without additional safety relays, enabling more intimate human–robot collaboration.

6. Multi‑axis coordination: Advances in communication protocols and synchronization allow servo systems to coordinate multiple axes with microsecond precision. This is critical for industrial robotics, pick‑and‑place machines and 3D printing, where coordinated motion ensures smooth trajectories.

7. Energy regeneration: Regenerative servo drives capture braking energy from decelerating loads and feed it back to the power supply, reducing overall energy consumption. This capability is increasingly important in mobile robotics and large-scale manufacturing lines.

Choosing the Right Servo Motor for Your Robot

Selecting the appropriate servo requires balancing technical requirements, environment and budget. Yana Sourcing recommends the following checklist:

- Define the load and torque: Determine the maximum and continuous torque required, considering acceleration and deceleration. Account for inertia and friction. A torque safety margin (e.g., 20–30 %) ensures reliability.

- Specify speed and duty cycle: Identify the required speed range and how long the motor will operate continuously. Duty cycle defines how much of the time the motor is running at rated load; higher duty cycles demand better cooling and larger motors.

- Assess positioning precision: Determine the required positional accuracy and repeatability. Choose the appropriate encoder resolution (e.g., 20‑bit or higher for sub‑arc‑minute precision).

- Environmental conditions: Consider temperature, humidity, dust and vibration. For harsh environments, select IP‑rated or sealed servos and ensure robust connectors and cabling.

- Size and integration: Evaluate available space and mechanical interfaces. Frameless servo kits allow integration into custom housings, while integrated servos save space and simplify wiring.

- Control compatibility: Ensure that the servo drive is compatible with your control architecture (EtherCAT, CANopen, Modbus, analog). Some servo systems offer built‑in motion controllers, while others require external drives.

- Budget and total cost of ownership: Balance initial cost with energy efficiency, longevity and maintenance. Higher efficiency and lower maintenance can reduce total cost over the robot’s life.

Example Scenarios

- Industrial assembly line: A high‑precision pick‑and‑place robot uses servo motors with absolute encoders and high torque density. The motors must accelerate quickly, stop precisely and hold position without drift.

- Collaborative robot (cobot): A cobot performing screw‑driving tasks uses integrated servo modules with torque sensing. The servo monitors applied torque, ensuring screws are tightened to the correct torque while detecting cross‑threading or misalignment. Built‑in safety functions limit force when the cobot interacts with humans.

- Medical robotics: Surgical robots require compact servo motors with ultra‑smooth motion and sterile housings. Servo drives with high‑resolution encoders and redundant safety channels provide stable operation and quick response. Thermal management is critical to prevent heat transfer to surgical instruments.

- Autonomous mobile robot: An AGV uses servos to control steering and lifting mechanisms. The servos must operate on low voltage (24–48 V) and provide high torque to handle heavy payloads. Efficient drives with regenerative braking extend battery life.

Sourcing Verified Servo Motors with Yana

At Yana Sourcing, we recognize that the servo motor you choose determines the precision, reliability and intelligence of your robot. Our SMART + HEART sourcing framework ensures you don’t leave critical motion decisions to chance:

- SMART: Yana conducts in‑depth supplier audits, verifying manufacturing capabilities, material traceability and quality systems. We evaluate servo designs with our engineers, confirm performance through laboratory testing, and assess drive compatibility with your control system. Our supplier network spans Asia, Europe and the Americas, allowing us to cross‑source and negotiate favourable terms while mitigating geopolitical risks.

- HEART: We believe sourcing is about more than specifications, it’s about relationships. Yana builds long‑term partnerships with suppliers who share our commitment to ethical manufacturing, sustainability and customer success. We facilitate transparent communication between you and manufacturers, ensuring that requirements are understood and expectations are met.

In today’s dynamic robotics landscape, reliable motion control is the foundation of every successful project. Partner with Yana Sourcing to secure verified servo motor suppliers and power your next‑generation robotics projects. Our expert team will help you navigate the complexities of servo selection, procurement and integration, delivering the precision and performance you need to bring your intelligent machines to life.