Table of Contents

Introduction — Why Planetary Gear Motors Matter in Robotics

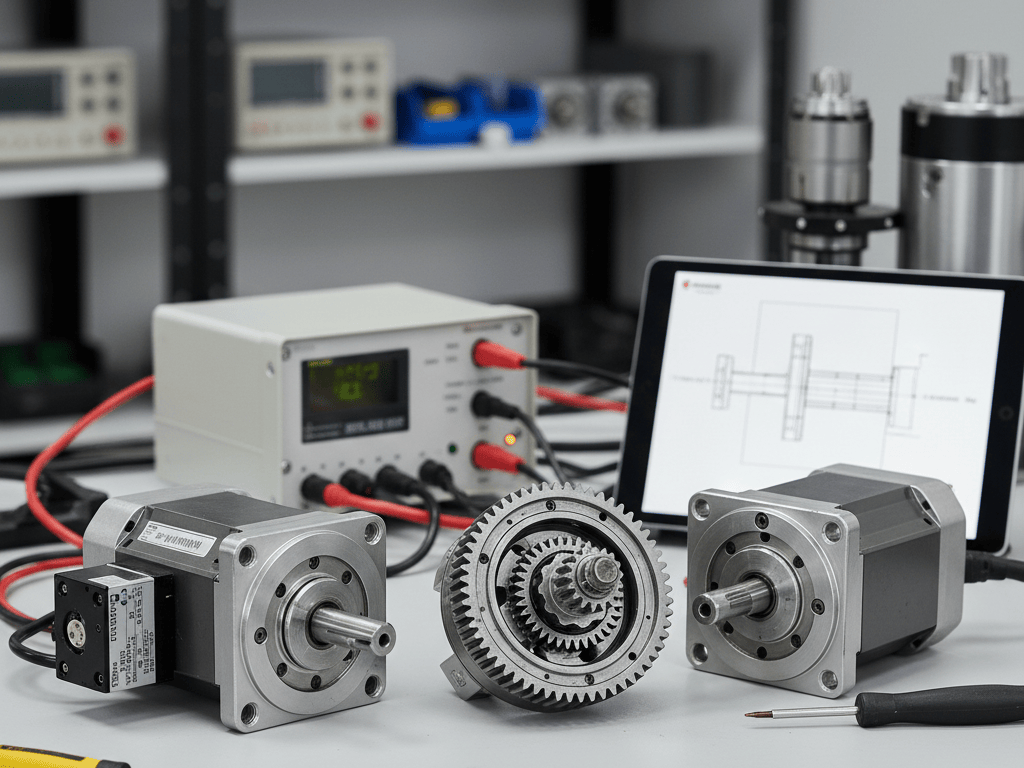

Planetary gear motors are a class of geared electric motors that use a compact cluster of gears to deliver high torque and precise motion. In their simplest form a planetary gear train consists of a central sun gear, multiple planet gears orbiting around it, and an outer ring gear. When the input shaft drives the sun gear, the planet gears rotate and roll inside the stationary ring gear, causing the carrier that holds the planets to rotate with a multiplied torque at a reduced speed. Because the load is shared among several gears, planetary gear motors provide high power density, meaning they can deliver large amounts of torque in a relatively small, lightweight package.

Planetary gear motors matter in robotics because they allow designers to create compact actuators and drivetrain modules with high torque, excellent efficiency, and precise control. Robots often need to move heavy joints or wheels while maintaining tight positional accuracy; planetary gearboxes supply the torque multiplication and low backlash required to achieve this without making the actuators bulky. Compared with spur or worm gear motors, planetary gear motors have a coaxial layout – the input and output shafts are aligned along the same axis – which makes them easier to integrate into robot arms, wheels and compact drive modules. Planetary systems also distribute the load evenly across multiple meshing gears; this reduces wear, improves efficiency and produces smoother motion. They can be driven by many motor types, including servo motors, stepper motors and brushed or brushless DC motors. Their versatility and high torque density make them indispensable components in industrial robots, collaborative cobots, mobile platforms, humanoids and specialized robotic equipment.

Working Principle of Planetary Gear Motors

A planetary gear motor integrates a gear reduction system directly onto a motor shaft. The basic components of the gear system include the sun gear (connected to the motor’s input shaft), planet gears (mounted on a carrier), a ring gear, and the planet carrier that connects to the output shaft. The sun gear drives the planet gears; as they spin around the sun gear they roll inside the ring gear. The ring gear provides a reaction force that allows torque to be transferred to the planet carrier and then to the output shaft. Because multiple planet gears engage simultaneously with the sun and ring gears, the transmitted load is split among them, multiplying torque and minimizing stress on individual gear teeth. By changing the number of planets or altering the size of the sun, planet or ring gears, designers can achieve a wide range of gear ratios.

In a planetary gear motor, the gear reduction is built into the gearbox housing. Planetary gearboxes typically use single‑stage or multi‑stage designs. A single‑stage planetary gear motor contains one set of planets and can provide gear ratios between roughly 3:1 and 10:1; multi‑stage planetary gear motors use two or more planetary sets in series to achieve higher reduction ratios (often up to 1000:1). ZHAOWEI notes that the minimum single‑stage deceleration is about 2.8 and the maximum for a single stage is less than 12.5, with common ratios of 3, 4, 5, 6, 8 and 10. Multi‑stage gearboxes allow even higher ratios while keeping the overall package compact, though each additional stage adds some loss and complexity. The gear train is enclosed in a precision-machined housing that keeps the gears aligned, lubricated and protected from contaminants. The coaxial alignment of sun, planet and ring gears produces a coaxial output: the input shaft and output shaft are aligned along the same axis, reducing bending loads and simplifying integration.

Because the planets orbit around the sun gear, the gearbox output rotates in the same direction as the motor input. Many planetary gear motors use helical gears rather than spur gears; helical teeth engage gradually, which reduces noise and increases load capacity. Some specialized planetary gearboxes incorporate right‑angle stages where the gear train turns the rotation by 90°, or harmonic‑planetary hybrids that combine planetary stages with strain‑wave gearing to achieve ultra‑high ratios. However, the standard in-line planetary gear motor remains the most common due to its simplicity and compactness.

Performance Characteristics & Control

Planetary gear motors are prized for their high torque output, high efficiency and low backlash compared with other gear types. Load sharing among multiple planets dramatically increases torque density; for a given motor torque, the gearbox multiplies the torque by the gear ratio minus friction losses. ZHAOWEI points out that planetary gear motors offer small volume, high transmission efficiency and high accuracy. Lunyee explains that the arrangement of sun, planet and ring gears distributes the load evenly across multiple gears, which enhances performance and durability. This load-sharing yields torque densities far higher than spur or worm gearboxes. Efficiency is typically above 90 % for well‑designed single‑stage gearboxes and remains relatively high even with two stages, because gear teeth remain fully engaged and rolling without significant sliding friction. Backlash (the free play between gear teeth when reversing direction) can be as low as a few arcminutes in precision planetary gearboxes. Low backlash is critical for robotics applications requiring precise positioning and bidirectional control.

Planetary gear motors can be paired with various motor types and control schemes. When combined with a servo motor, the gear motor can be operated in a fully closed loop with feedback from an encoder, providing precise position and speed control. Stepper motors with planetary gearboxes allow open-loop control with improved torque at low speeds; adding a closed-loop encoder can further improve accuracy. Brushless DC motors with planetary gearboxes deliver high efficiency and quiet operation; when combined with field‑oriented control they can achieve smooth speed and torque regulation. The type of motor and controller determines the responsiveness and stability of the system.

The following table compares planetary gear motors to other common motor/gear combinations.

| Parameter | Planetary Gear Motor | Spur Gear Motor | Harmonic Drive | Direct‑Drive Motor |

|---|---|---|---|---|

| Torque density | Very high – multiple gears share load | Moderate – single gear path | High but limited load capacity | Low – torque equals motor’s output |

| Backlash | Low (a few arcminutes with precision stages) | Moderate | Extremely low (zero backlash) | None |

| Efficiency | High (>90 %) | High | 80–90 % | Highest (no gears) |

| Size | Compact, coaxial | Longer, off‑axis | Flat but larger diameter | Bulky (large motor) |

| Noise & vibration | Low, smooth operation | Higher; may whine | Low | Depends on motor design |

| Cost & complexity | Moderate to high | Low | High | High (large motor, high cost) |

The high torque density of planetary gear motors makes them ideal for robots that need to lift or move heavy loads from a small package. Their efficiency helps conserve energy, which is critical in battery-powered mobile platforms. Low backlash ensures that joints or wheels respond accurately to control commands. However, planetary gearboxes are mechanically complex; they are more expensive than spur gearboxes and require precise manufacturing and assembly to maintain performance. Maintenance can also be more challenging due to the tightly packed gears. When cost or simplicity takes precedence over torque density, spur gearboxes may be preferable.

Integration in Robotic Systems

Planetary gear motors are used throughout robotics, from entry‑level automation to advanced humanoid platforms. Their ability to deliver high torque in a small space makes them suitable for numerous applications.

L1 Robotics (Simple Automation): Robots performing basic tasks such as small conveyor drives or simple pick‑and‑place arms benefit from planetary gear motors because they provide high torque and low speed without bulky transmissions. The coaxial design reduces overhung loads and simplifies mechanical alignment. Planetary gear motors are also used in educational robots and low-cost service robots due to their robustness and reliability.

L2 Robotics (Collaborative and Service Robots): Collaborative robots (cobots) designed to work safely with humans require quiet, smooth gearboxes with low backlash. Planetary gear motors can be paired with BLDC or servo motors to provide precise control in compact joints. The gearboxes’ low noise and vibration make them well-suited for service robots operating in offices or healthcare environments. The high efficiency also reduces heat, improving the energy efficiency of cobots.

L3 Robotics (Industrial and High‑Precision Automation): Industrial robot arms use planetary gear motors in their joints to provide high torque, high rigidity and long life. ZHAOWEI notes that planetary gear motors offer high rigidity, high accuracy and long-term maintenance, which is vital for continuous industrial operation. Multi‑stage planetary gearboxes allow high reduction ratios (e.g., 100:1 or 400:1) needed for heavy payloads while maintaining compactness. The low backlash ensures accurate path following and repeatability. Planetary gearboxes are also used in AGVs (automated guided vehicles) and AMRs (autonomous mobile robots) to drive wheels or tracks, providing the torque needed for traction and the efficiency needed to maximize battery life.

L4 Robotics (Humanoids and Cutting‑Edge Systems): Humanoid robots require actuators that combine high torque, low weight and compact size to fit within human‑proportion joints. Planetary gear motors deliver the torque density needed for leg, knee and elbow joints while allowing coaxial alignment, which simplifies the mechanical layout. Multi‑tooth meshing reduces backlash, enabling fluid, natural motion. In some high-end humanoids, planetary gearboxes are combined with strain‑wave gears to achieve extremely high reduction ratios and near‑zero backlash. Planetary gear motors also appear in exoskeletons, haptic devices and surgical robots where compact, precise actuation is crucial.

Design Considerations — Size, Cooling, Noise, Weight

When integrating planetary gear motors into a robot, designers must consider physical dimensions, thermal management, noise and weight. The gear head’s diameter, length and output shaft dimensions must match the mechanical space and support structure. A typical precision planetary gear motor may have diameters ranging from a few millimeters to several centimetres; ZHAOWEI’s precision planetary motors use gear diameters between 3.4 mm and 38 mm. For high torque applications, multiple stages can be stacked; however, each stage adds length and weight. Housing materials (aluminum or steel) and tooth geometry (helical vs spur) influence thermal dissipation and acoustic performance. Helical gears reduce noise at the expense of some axial thrust; spur gears are simpler but may be noisier.

Cooling is typically handled through conduction to the gear housing and natural convection. In high‑power servos, heat from the motor and gearbox can accumulate, so designers may add heat sinks or integrate the gear housing into the robot’s structure to dissipate heat. Some industrial robots incorporate forced air or oil cooling to maintain temperatures under continuous high-load operation. Noise and vibration are minimized through precision gear cutting, surface finishing and preloading of bearings. For safety-critical or noise-sensitive applications, low-noise gearboxes are essential.

Integration Challenges and Proven Solutions

Integrating planetary gear motors into a robot can present challenges related to backlash, lubrication, load handling and maintenance. Here are common challenges and Yana’s proven solutions:

- Backlash and Wear: Even a few arcminutes of backlash can degrade positional accuracy. The solution is to specify precision planetary gearboxes with ground gears and preloaded bearings. Selecting helical tooth profiles and preloading the sun and planet gears can reduce backlash. For ultra-precise robots, a combination of planetary and harmonic gear stages may be used to achieve nearly zero backlash. Yana audits gear manufacturers and verifies that the gear teeth are machined to tight tolerances and surface-finished to minimize micro-pitting.

- Lubrication and Maintenance: Planetary gearboxes rely on proper lubrication to minimize friction and wear. Inadequate lubrication can cause noise, increased backlash and premature failure. Yana ensures that all gearboxes are filled with appropriate grease or oil and sealed to prevent leakage. For applications requiring maintenance-free operation, Yana sources sealed, grease-filled planetary gearboxes and works with suppliers to specify long-life synthetic lubricants. For high-speed operation, oil lubrication systems may be specified.

- Load Distribution and Vibration: An unbalanced load on the planets can cause vibration and reduce life. The load distribution depends on manufacturing tolerances; if one planet gear is slightly larger or misaligned, it may carry more load. Yana performs run-out and concentricity checks on the sun, planet and ring gears and requires that all teeth are aligned to ensure equal load sharing. In addition, Yana works with suppliers to implement shaped tooth modifications (profile shifting) that reduce vibration.

- Overhung Load and Mounting: When the motor shaft is not properly supported, radial and axial loads can cause bearing wear and gear misalignment. The solution is to design the output shaft to handle the expected overhung load and to integrate rigid mounting flanges. Yana consults with customers on mechanical layouts, verifying that the gear motor is supported appropriately with external bearings if necessary.

- Assembly and Maintenance Complexity: Planetary gearboxes are more complex to assemble than spur gearboxes. Yana audits supplier assembly lines, ensuring that gear stages are assembled in cleanrooms or controlled environments to prevent contamination. Yana also monitors the suppliers’ assembly processes for proper shim adjustment and preloading.

By addressing these integration challenges, Yana ensures that customers receive planetary gear motors that perform reliably in demanding robotics applications.

Manufacturing & Sourcing Insights

Planetary gear motors are manufactured around the world, and regional differences affect quality, cost and lead times. Yana’s sourcing team evaluates suppliers based on technical capability, manufacturing maturity, quality control practices and ethical considerations.

Regional Strengths

- China: The Chinese market produces a vast range of planetary gear motors, from low-cost consumer-grade units to high-precision gearboxes for industrial use. Chinese manufacturers excel at volume production and can offer competitive pricing. They often use standardized designs, making them suitable for cost-sensitive robotics applications where ultra-high precision is not required. Yana carefully audits Chinese suppliers to ensure that gear materials, heat treatments and lubrication meet international standards.

- Japan and Germany: Japan and Germany are renowned for precision gear manufacturing. Japanese and German companies produce planetary gearboxes with very low backlash, high efficiency and long life. Their products are widely used in collaborative robots and high-end industrial robots where accuracy and reliability are critical. These suppliers often provide extensive customization options, such as special gear ratios, integrated encoders, or right-angle configurations. Lead times may be longer and prices higher, but the quality is exceptional.

- United States: Many U.S. manufacturers specialize in custom planetary gear motors and high-torque gearboxes. They serve niche markets in aerospace, medical robotics and defense, where application-specific requirements (e.g., special materials, high-temperature operation) cannot be met by catalog products. These suppliers may also offer integrated gear motors with sensors or specialized shafts. Yana partners with U.S. manufacturers for projects demanding customization and tight IP protection.

- Other Regions: Europe beyond Germany (e.g., Switzerland, Italy) produces high-precision gearboxes for scientific instruments and semiconductor equipment. Emerging players in Eastern Europe and India provide cost-effective alternatives with improving quality. Yana continuously monitors new suppliers and audits them for compliance with quality and ethical standards.

Supplier Ecosystem & Cost vs Quality

Planetary gear motors vary widely in cost depending on materials, precision and customization. Low‑cost gear motors with sintered metal gears or plastic housing may be sufficient for hobby robotics or consumer products but are unsuitable for industrial robots. High‑precision gearboxes use ground steel gears, hardened shafts, and precision ball or roller bearings. Yana segments suppliers into three tiers: volume producers (economical), mid-range quality (balanced cost and performance), and high-end precision (premium). Customers choose the tier based on performance requirements and budget.

Typical minimum order quantities (MOQs) range from 100 to 500 units for standard gear motors and 500 to 1,000 units for customized designs. Lead times vary by region: Chinese suppliers may deliver in 6–8 weeks, while custom Japanese or German gearboxes may take 10–14 weeks. When designing a robot that will scale to mass production, engineers should factor in these lead times and supplier capacity.

Quality Control Checklist

To ensure reliability, Yana’s quality control team performs or requests the following tests and inspections on planetary gear motors:

- Gear Ratio Verification: Measure the output speed and confirm the gear ratio is within specification (e.g., ±3 %).

- Torque and Load Testing: Verify the gearbox can deliver the rated torque without excessive noise or temperature rise. ZHAOWEI’s customizable planetary motors deliver output torques from 1 gf·cm to 50 kgf·cm; Yana tests across the entire torque range.

- Backlash Measurement: Measure backlash using a laser or dial indicator; verify it falls within the specified range (1–2 arcminutes for precision gearboxes).

- Concentricity and Run‑Out: Use coordinate measurement machines (CMMs) to check that the sun, planets and ring gear are concentric and aligned.

- Noise and Vibration Testing: Conduct tests at nominal operating speeds to confirm low noise levels; ZHAOWEI notes transmission noise of ≤45 dB for its precision gear motors.

- Lubricant Inspection: Verify the lubricant is correct and contaminants are absent; sample grease for wear particles.

- Environmental Testing: Perform thermal cycling and humidity tests to confirm the gearbox can operate across the expected temperature and humidity range.

Risk Factors

Planetary gear motors, while robust, present certain risks. Yana mitigates these risks through supplier audits and engineering checks:

- Backlash Increase Over Time: Poorly hardened gears or inadequate lubrication can cause wear that increases backlash. Yana ensures gears are manufactured from hardened steel and that lubrication is appropriate for the duty cycle.

- Material Substitution: Some suppliers may substitute lower-grade steel or plastic to cut costs. Yana conducts incoming material inspections and demands certificates of compliance.

- Quality Control Variability: Inconsistent assembly or gear alignment can lead to vibration and early failure. Yana performs random sample audits and requires statistical process control data from suppliers.

- Counterfeit Components: Bearings, seals or magnets may be counterfeit. Yana sources critical components from approved vendors and uses serial number tracking.

By controlling these risk factors, Yana ensures that customers receive planetary gear motors that meet or exceed their performance specifications.

Emerging Innovations & Future Trends

Planetary gear technology continues to evolve to meet the demands of next-generation robotics. Several innovations and trends are shaping the future of planetary gear motors:

- Compact Multi‑Stage Designs: Gearbox manufacturers are designing multi‑stage planetary gearboxes with higher reduction ratios and more compact envelopes. Advances in gear profile optimization and materials allow more gears to be packed into a smaller housing without sacrificing torque capacity.

- Composite and Lightweight Gears: New materials, such as fiber‑reinforced polymers and powdered metal composites, reduce weight while maintaining strength. Hybrid metal–composite gear sets reduce inertia and noise while improving efficiency.

- Integrated Sensors and Mechatronic Modules: Some planetary gearboxes now integrate torque sensors, temperature sensors and position encoders. These sensors monitor the health of the gearbox and enable predictive maintenance. Future gear motors may include built‑in motor drivers and communication interfaces, creating complete mechatronic modules.

- Harmonic‑Planetary Hybrids: To achieve extremely high reduction ratios with minimal backlash, engineers are combining planetary stages with strain‑wave (harmonic) gear stages. These hybrids provide compact size, high torque and near-zero backlash, suitable for high‑precision robotics and humanoid joints.

- Additive Manufacturing: 3D printing enables complex gear geometries, such as lattice structures and lightweight supports. Additive manufacturing also allows rapid prototyping of custom gear ratios and geometries. Some high-end gearboxes now use 3D‑printed housings with integrated cooling channels.

- Smart Lubrication Systems: Advanced lubrication systems with micro-pumps or porous materials can deliver lubricant precisely where needed, extending life and reducing maintenance. Smart grease sensors monitor lubricant health and trigger maintenance alerts.

- AI‑Based Design and Optimization: Artificial intelligence and generative design algorithms help optimize gear geometry for strength, efficiency and noise reduction. AI can also predict wear patterns, enabling condition-based maintenance.

- Eco-Friendly Materials: As sustainability becomes a key consideration, gear manufacturers are exploring biodegradable lubricants and eco-friendly materials that reduce environmental impact without compromising performance.

- Integration with Collaborative and Soft Robots: As collaborative and soft robots proliferate, the demand for gearboxes that deliver high torque with low impedance and safe interaction grows. Planetary gearboxes with low friction and integrated torque sensing will play a critical role in enabling these robots to interact safely with humans.

Yana Sourcing actively monitors these trends and partners with suppliers who innovate in planetary gear technology. By staying at the forefront of materials, design and sensor integration, Yana helps clients future-proof their robotic systems.

Choosing the Right Planetary Gear Motor for Your Robot

Selecting a planetary gear motor requires balancing torque, speed, size and cost while considering the robot’s duty cycle and environment. Use the following checklist when choosing a planetary gear motor:

- Required Output Torque: Determine the maximum and continuous torques needed. Planetary gear motors can be specified to deliver output torques ranging from a few gram‑centimeters to tens of kilogram‑centimeters. Ensure the gearbox can handle peak loads without overheating or excessive wear.

- Desired Output Speed: Select a gear ratio that produces the required output speed while keeping the motor within its optimal rpm range. Single-stage planetary gearboxes offer ratios around 3:1 to 10:1; multi-stage designs can deliver ratios up to hundreds or thousands to one.

- Power Source and Motor Type: Decide whether the motor will be brushed DC, brushless DC, stepper or servo. Planetary gearboxes can accommodate any of these but require matching shaft diameters and mounting interfaces. Some gear motors integrate the motor and gearbox as a single unit to reduce length and simplify assembly.

- Gear Ratio and Number of Stages: Higher gear ratios provide greater torque multiplication but add length and cost. Multi-stage gearboxes also increase friction and noise. Choose the minimum number of stages needed to meet torque and speed requirements.

- Size and Weight: Check the physical dimensions of the gearbox to ensure it fits the available space in the robot. Pay attention to the output shaft diameter and length for compatibility with couplings or pulleys. Use high power density gearboxes where space and weight are limited.

- Operating Environment: Consider temperature ranges, humidity, exposure to dust or chemicals, vibration and shock. For harsh environments, select gearboxes with sealed housings and high ingress protection. Materials like stainless steel or special coatings may be required for corrosive environments.

- Precision and Backlash Requirements: Determine the acceptable backlash for your application. Ultra‑precise robots may require gearboxes with backlash <1 arcminute. Others may tolerate higher backlash if cost is more critical.

- Noise and Vibration: For service robots or medical devices, low noise is essential. Helical gearboxes are quieter than spur gearboxes but may be more expensive. Ensure the gear motor meets the noise specification (e.g., <45 dB).

- Cost and Lead Time: Balance performance with budget. High‑precision gearboxes cost more; if the robot will be produced in small quantities, spending more on a quality gearbox may be justified to avoid field failures. Also account for lead times, which can range from 6 weeks for standard products to 14 weeks for custom designs.

Example Scenarios — Where Planetary Gear Motors Excel

- Industrial Robot Arms: High payload 6‑axis robots use multi‑stage planetary gearboxes in each joint to provide the torque needed for lifting and manipulating parts. The high efficiency and low backlash ensure accurate positioning during welding, painting or assembly.

- Collaborative Robots (Cobots): Planetary gear motors paired with brushless servos provide quiet, smooth motion for cobots. Their compact size allows small joint modules that do not encroach on the working envelope. Integrated torque sensing using strain gauges or current feedback adds safety.

- Mobile Robots and AGVs: Heavy-duty autonomous mobile robots use planetary gear motors to drive their wheels or tracks. High torque ensures the robots can climb ramps or carry heavy loads while maintaining energy efficiency. Planetary gearboxes also allow smooth acceleration and deceleration.

- Medical and Laboratory Robots: Planetary gear motors’ low noise and compact size make them ideal for medical devices such as surgical robots, diagnostic instruments and automated sample handling. They provide smooth, precise motion without generating heat or vibration that could disrupt delicate procedures.

- Consumer and Service Products: High-end consumer devices (robotic vacuum cleaners, power tools) use planetary gear motors to deliver strong torque in a small package. Their quiet operation and long life enhance user experience.

- Electric Vehicles and Aerospace: In e-bikes and electric scooters, planetary gear motors transmit torque from a DC motor to the wheel; they also appear in aerospace actuators controlling flight surfaces. The high power density makes them attractive for weight-sensitive applications.

Sourcing Verified Planetary Gear Motors with Yana

Yana Sourcing leverages its global network of vetted suppliers and its SMART + HEART sourcing philosophy to deliver planetary gear motors that meet the technical, commercial and ethical requirements of robotics customers.

- SMART Sourcing: Yana’s technical experts evaluate planetary gear motor suppliers on design capability, material quality, precision manufacturing, and quality control systems. The team audits facilities to ensure proper heat treatment, gear cutting, assembly practices and lubrication. Yana verifies performance through tests such as torque output, efficiency, backlash, noise, temperature rise and environmental durability. Each gearbox is traceable with serial numbers and compliance certificates. Yana also helps clients with design optimization, recommending gear ratios and motor pairings to achieve the best performance-to-cost ratio.

- HEART Sourcing: Beyond technical excellence, Yana believes in building long-term relationships based on trust and ethical business practices. Yana ensures suppliers adhere to fair labor standards, environmental regulations and intellectual property protection. The company fosters open communication and transparency throughout the supply chain, ensuring customers receive the products they expect, when they expect them.

By combining SMART technical rigor with HEART human values, Yana delivers planetary gear motors that enable robots to perform reliably and safely. Whether you need high-torque gearboxes for industrial arms, quiet and compact gear motors for service robots, or custom gearboxes for cutting-edge applications, Yana’s team will guide you from concept through production. Partner with Yana Sourcing to secure verified planetary gear motor suppliers and power your next‑generation robotics projects.