Table of Contents

Introduction — Why Linear Motors Matter in Robotics

Electric motors power nearly every motion system in robotics, but most produce torque around a central axis. Linear motors overturn that paradigm. Instead of converting rotary motion to linear travel via screws, belts or gears, a linear motor “unrolls” the stator and rotor of a conventional motor to generate direct linear force. The result is a contact‑free, backlash‑free actuator that can move payloads in a straight line with nanometer precision and meter‑per‑second speed. In robotics this translates to frictionless, rigid and highly repeatable motion that stays accurate over millions of cycles. Because linear motors eliminate intermediate mechanics, only the guide bearings see wear; accuracy and repeatability remain high for the machine’s life.

As factory automation accelerates and robots migrate from simple pick‑and‑place operations to complex, high‑throughput tasks, engineers need actuators that deliver higher speeds and smoother motion without adding mechanical complexity. Linear motors meet this need. They excel in medical equipment, industrial automation, packaging and semiconductor manufacturing, but their impact on robotics runs deeper. In Level 1 robots, linear motors enable fast, precise Cartesian pick‑and‑place axes. Level 2 SCARA and gantry robots use them for coordinated multi‑axis travel. At Level 3 and Level 4, where robots perform delicate assembly or wafer handling in cleanrooms, linear motors provide nanometer‑scale positioning and vibration‑free motion that other drive mechanisms cannot match. Compared with rotary servo or BLDC motors that require transmissions, linear motors generate thrust directly with no gears or couplings. This direct drive eliminates backlash, reduces maintenance and frees designers to build compact, modular robots.

Linear motors come in several flavours. Ironcore linear motors embed laminated iron in the primary (moving) part, which amplifies magnetic flux for high thrust. Ironless (coreless) linear motors remove iron from the primary, creating a lighter mover and eliminating cogging. Slotless designs further reduce cogging by removing slots in the stator. Each type offers different trade‑offs in force density, smoothness, cost and thermal behaviour. Because the choice influences robot performance and sourcing strategy, the rest of this article dives into how linear motors work, how to integrate them, what the market landscape looks like and how Yana Sourcing can help you select and procure the optimal solution.

Working Principle of Linear Motors

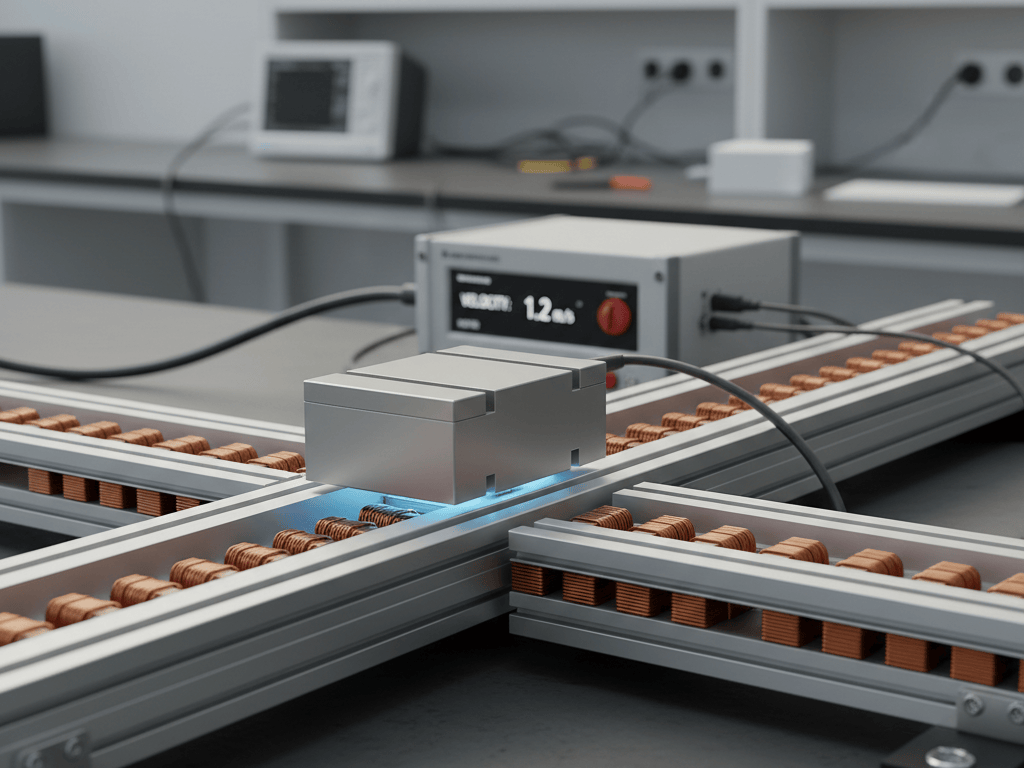

Linear motors operate on the same electromagnetic principles as rotary motors but with the geometry flattened out. In a conventional rotary motor, alternating currents in stator windings create a rotating magnetic field that interacts with magnets on the rotor, producing torque. If you “unroll” that cylindrical geometry into a straight line, the rotor becomes a forcer and the stator becomes a track. Alternating magnetic poles are arranged along this track so that when current flows through the windings the resulting magnetic fields repel and attract the permanent magnets, generating a linear force. This Lorentz force drives the mover without any physical contact, enabling smooth, wear‑free actuation. Linear motors may be configured in flat form (stator and forcer arranged face‑to‑face) or tubular form (forcer surrounds the stator or vice versa).

At its simplest a linear motor comprises two main parts: the stator, which houses coils that create the magnetic field when energised, and the mover (forcer), which carries permanent magnets and the load. When current flows through the stator coils, a magnetic field forms and interacts with the magnets on the mover, pushing the mover along the track. Because this interaction happens directly and continuously, there is no need for gears, belts or screw drives. The active portion of a linear motor is not closed like a rotary motor; it has two ends, which places special requirements on travel length and positioning feedback.

Ironcore linear motors incorporate laminated iron within the mover windings. The iron concentrates the magnetic flux, which increases the force constant and makes these motors high‑force workhorses. This design also dissipates heat efficiently through the iron structure, allowing continuous high‑duty cycles. However, the interaction between the iron teeth and the magnet track causes cogging, a periodic variation in force that can lead to velocity ripple. Manufacturers mitigate cogging with skewed magnet arrays and advanced current shaping, but some residual detent force remains.

Ironless (coreless) linear motors remove the iron from the mover entirely. Instead, the coils are embedded in a lightweight, non‑magnetic carrier such as epoxy or aluminium. The mover rides in a U‑shaped magnet track, so there is no magnetic attraction between the mover and stator. This architecture is completely cog‑free, delivering uniform velocity and vibration‑free motion even at extremely low speeds. With no iron, the moving mass is low, enabling rapid acceleration and short settling times. The trade‑off is lower force density and less efficient heat dissipation; ironless motors typically deliver lower continuous force than ironcore motors and require careful thermal management.

Slotless linear motors combine features of both: they use a laminated iron backplate but avoid slotted teeth that can cause cogging. Slotless designs offer smoother motion than ironcore motors with higher force density than ironless versions. They are popular in robotics when moderate thrust and smooth travel are required.

Regardless of type, position feedback is critical for precise control. Most linear motors operate in a closed‑loop servo architecture using linear encoders (optical, magnetic or capacitive) to measure the mover’s position and correct errors in real time. In direct‑drive linear motor stages, the servo loop is often closed on the feedback from the linear encoder rather than a rotary encoder, enabling nanometer resolution and accurate motion along long strokes. Because the force constant is linear with current until saturation, the motor controller can regulate force precisely by modulating current.

Performance Characteristics & Control

Linear motors offer a unique combination of high force density, high acceleration, smooth motion and direct drive efficiency. The absence of mechanical transmission means that stiffness is high and backlash is zero. This section examines the key performance metrics and control considerations.

Force Output and Density. Ironcore linear motors generate higher continuous and peak forces because their laminated iron core concentrates magnetic flux. This makes them ideal for heavy‑load applications such as CNC machining centres, press machines and high‑speed packaging lines. Ironless motors, by contrast, trade force for smoothness; their lightweight coil offers lower inertial mass and dynamic responsiveness but produces less thrust. Slotless designs fall in between.

Smoothness and Cogging. Cogging occurs when the mover’s magnetic teeth align with the stator slots, causing periodic attractive forces. Ironless motors are completely cog‑free because there is no iron to create tooth interactions. Ironcore motors experience detent force that can cause jerkiness, though manufacturers mitigate this with skewed magnets. Slotless motors reduce cogging by eliminating slots.

Acceleration and Inertia. With no screw or gear train, linear motors can achieve accelerations of several g’s. Ironless motors excel here because their moving coil is lightweight and free from magnetic attraction, giving them fast dynamic response and minimal overshoot. Ironcore motors still provide high acceleration but require more force to overcome the higher moving mass and magnetic attraction.

Thermal Performance. The ability to dissipate heat determines continuous duty capability. Ironcore motors conduct heat through the iron backplate, allowing efficient cooling and higher continuous current. Ironless motors cannot dissipate heat as easily; they rely on convection and may require external cooling or short duty cycles.

Control and Feedback. Linear motors are typically controlled via servo loops that regulate current and position. Current control schemes (commutation) ensure sinusoidal drive to minimize torque ripple, while position control uses linear encoders for feedback. Open‑loop control is rare; closed‑loop servo control is essential for precision. The servo controller can perform real‑time force control, enabling advanced functions like haptic feedback or force‑limited insertion tasks in robotics.

The following table summarises the key performance differences between linear motor types:

| Parameter | Ironcore Linear Motor | Ironless Linear Motor | Slotless Linear Motor |

|---|---|---|---|

| Force Density | Very high; suitable for heavy loads | Lower force density; prioritizes precision | Moderate; balances force and smoothness |

| Cogging | Present; mitigated by skewed magnets | None | Very low |

| Acceleration/Inertia | High, but moving mass heavier | Very high due to lightweight coil | High |

| Thermal Performance | Excellent; iron core dissipates heat | Limited; needs external cooling | Good |

| Ease of Integration | Easy to integrate but heavier | Lightweight and easier to assemble | Moderate |

| Typical Applications | Heavy-duty machining, stamping | Semiconductor & metrology | Robotics & multi‑axis stages |

| Cost | Lower cost per force unit | Higher cost; specialised materials | Moderate |

Integration in Robotic Systems

Linear motors lend themselves to many robotic architectures because of their direct drive nature. However, integrating them requires understanding how they interact with the robot’s mechanics, sensors and environment.

Level 1 – Pick‑and‑Place and Simple Cartesian Robots. In entry‑level robots such as Cartesian pick‑and‑place machines and basic gantries, linear motors provide fast, precise travel for short strokes. Their high acceleration and zero backlash reduce cycle times and improve placement accuracy. Packaging, assembly and electronics manufacturing lines often deploy ironcore linear motors to move parts quickly along production cells, where high continuous force and moderate precision are sufficient.

Level 2 – SCARA and Multi‑Axis Gantries. In Level 2 robots, multiple axes must coordinate. Linear motors can drive the Z‑axis of SCARA arms or the X/Y axes of gantry systems. Because there is no screw or belt to stretch, multi‑axis synchronisation improves, enabling smooth path following and high throughput. The lack of mechanical transmission reduces maintenance and eliminates backlash, which is crucial for pick‑and‑place speed and repeatability.

Level 3 – Precision Assembly and Inspection. Robots performing precision tasks, such as optical inspection, lens assembly or DNA sequencing, require sub‑micron positioning and vibration‑free motion. Ironless linear motors shine here. Their cog‑free operation delivers uniform velocity and ultra‑smooth travel. Combined with high‑resolution linear encoders, they enable nanometer positioning over long strokes. Semiconductor manufacturing uses linear motors in lithography machines and wafer handlers for their high precision, smooth operation and low heat generation.

Level 4 – Advanced Robots in Cleanrooms and Collaborative Settings. High‑end robots working in vacuum or cleanroom environments, such as wafer fabrication, photonics alignment and biotech instrumentation, demand actuators that are vibration‑free, particle‑free and vacuum compatible. Ironless linear motors meet these requirements because they generate minimal heat and no magnetic attraction, reducing contamination and ensuring reliability. Their lightweight coil also lends itself to collaborative robots that need to minimise moving mass.

Design Considerations — Size, Cooling, Noise and Weight

Successful integration requires attention to several design parameters:

- Physical Size and Stroke Length. Linear motors can be scaled from a few millimetres to several metres. Long strokes are possible by connecting magnet tracks end‑to‑end; THK notes that strokes can exceed 2 m and even tens of metres. However, longer systems demand careful alignment of magnets and coils and may require multiple feedback sensors.

- Cooling Strategy. Ironcore motors dissipate heat through the iron core, but high‑duty applications may still need heat sinks or liquid cooling. Ironless motors, with limited heat paths, often require external cooling or operate at lower duty cycles. Base‑plate cooling channels or forced air can remove waste heat.

- Noise and Vibration. Contactless operation results in low noise and vibration. THK emphasises that linear motors produce low noise because there is no rotation of ball screws and no recirculating elements. This makes them ideal for medical and laboratory environments.

- Weight and Moving Mass. The moving mass affects acceleration. Ironcore motors have heavier movers due to the iron core, whereas ironless motors have lightweight coils and thus achieve higher accelerations.

- Environmental Protection. Linear motors are sensitive to ferromagnetic debris and dust. Linear Motion Tips notes that dust and metal shavings can stick to magnets, particularly in ironcore designs. Dustproof enclosures and non‑ferromagnetic materials mitigate this risk.

Integration Challenges and Proven Solutions

Heat Buildup: Continuous high‑duty cycles can overheat the windings, leading to demagnetisation or coil insulation breakdown. Solution: incorporate liquid‑cooled base plates or forced‑air cooling and select motors with high thermal ratings. Ironcore motors dissipate heat well, but high‑performance ironless motors may need water jackets or heat sinks.

Magnetic Attraction and Cogging: Ironcore designs exert strong attractive forces between the coil and magnet track, causing cogging and vertical sagging. Solution: use ironless or slotless motors in applications requiring smooth motion; if high force is needed, select ironcore motors with skewed magnet arrays and pair them with closed‑loop controllers to compensate for detent force.

Vertical Axis Challenges: Linear motors are non‑contact and have no intrinsic braking mechanism; loads can fall during power loss. Solution: add counterweights, brakes or redundant support systems for vertical axes.

Contamination and Debris: Magnetic tracks attract ferrous dust, especially in machining environments. Solution: implement dustproof enclosures and use stainless‑steel covers or bellows to shield magnets. In cleanrooms, choose ironless motors with enclosed magnet tracks to minimise particle generation.

Integration Complexity: Installing a linear motor system requires precise alignment of the magnet track and mover, proper routing of cables and encoders, and selection of guide bearings. Misalignment can lead to uneven force or increased wear. Solution: partner with experienced integrators and use pre‑assembled linear motor stages that integrate guides, encoders and cable management. Yana’s engineering network can help co‑design custom stages for specific robotic architectures.

Manufacturing & Sourcing Insights

The global market for linear motors is growing steadily. Vynz Research estimates that the linear motor market was valued at about USD 1.4 billion in 2023 and is projected to reach USD 2.8 billion by 2030, reflecting a compound annual growth rate around 4.8 %. The demand is driven by industries such as semiconductors, electronics and packaging, which require high‑precision automation. Linear motors are advanced synchronous brushless machines with unrolled stator and rotor that produce linear force.

Regional Strengths. Asia‑Pacific (APAC) dominates the linear motor market, holding the largest share due to rapid adoption of new technologies and government initiatives that boost manufacturing automation. China supplies large volumes of ironcore and slotless motors for cost‑sensitive applications, while Japan is renowned for high‑precision, vacuum‑compatible systems used in semiconductor and biomedical equipment. Europe (Germany, Switzerland) excels at metrology‑grade linear motors with ultra‑low vibration; these suppliers often integrate encoders and thermal sensors. North America focuses on high‑force tubular and servo‑driven stages with integrated drives. Understanding the regional ecosystems helps buyers balance performance, cost and lead time.

Supplier Ecosystem Maturity. The linear motor supply chain comprises magnet suppliers, coil winding manufacturers, encoder specialists and integrators. In China, economies of scale drive down costs but quality varies; careful supplier qualification is required. Japanese and European suppliers emphasise quality management, traceability and cleanroom manufacturing. Typical minimum order quantities (MOQ) range from 10‑50 units for custom coils to hundreds of units for standard motors. Lead times can vary from 4–12 weeks, depending on magnet availability and coil manufacturing complexity. Suppliers offer customisation such as winding length, magnet grade, mounting features and integrated encoders.

Quality Control Checklist

Ensuring a linear motor meets specifications requires rigorous quality checks:

- Force and Back‑EMF Testing. Verify the force constant over the operating current range and measure back‑EMF to ensure proper commutation and magnet strength.

- Flatness and Alignment Inspection. Inspect the straightness and flatness of the magnet track to within a few microns to prevent force variations. Confirm the mover runs without contact and verify coil alignment.

- Magnetic Uniformity Mapping. Use gaussmeters or Hall sensors to map the magnetic field along the track and ensure uniform flux density; non‑uniform fields cause cogging and force ripple.

- Coil Resistance and Insulation Tests. Measure coil resistance and insulation breakdown voltage to detect manufacturing defects and ensure thermal reliability.

- Encoder Calibration. Calibrate linear encoders and check repeatability across the full stroke. Validate the servo loop stability at different speeds.

Risk Factors

The linear motor supply chain is subject to several risks:

- Rare‑Earth Magnet Supply: High‑performance linear motors use NdFeB magnets. Price volatility and export restrictions can affect cost and lead times. Dual‑sourcing or using alternative magnet grades can mitigate this.

- Counterfeit Components: Unverified suppliers may use substandard magnets or encoders. Always audit suppliers and request test reports.

- Thermal and Mechanical Failures: Overheating or misalignment can demagnetise magnets or damage coils. Implement robust thermal management and proper mounting.

- Dust and Contaminants: In dirty environments, ironcore motors can attract ferrous particles that degrade performance. Use sealed housings and schedule maintenance.

- Integration Complexity: Inexperienced installers may misalign tracks or miswire encoders, causing performance issues.

Emerging Innovations & Future Trends

The linear motor field is evolving rapidly. Materials science and magnetic technology are improving both ironcore and ironless motors, blurring their performance differences. CSK notes that advances in magnet materials and coil technologies are improving precision and efficiency, while developments in ironless designs are boosting force output and reducing cost.

High‑Torque‑Density Designs. Novel magnet topologies (such as Halbach arrays) and soft magnetic composites enable motors with higher force density and lower cogging. Additive manufacturing is being explored to fabricate complex coil geometries and integrate cooling channels directly into the motor body, enhancing thermal performance.

Integrated Smart Encoders and Condition Monitoring. Future linear motors will embed sensors to monitor temperature, vibration and position, enabling predictive maintenance and self‑tuning. AI‑based algorithms will analyse encoder data to compensate for wear and adapt motion trajectories in real time.

Low‑Voltage, Compact Modules. To meet the needs of mobile robots and collaborative cobots, manufacturers are developing low‑voltage (24–48 V) linear motors with integrated drives, reducing system cost and complexity.

Vacuum‑Ready and Cleanroom‑Compatible Motors. The semiconductor and biotech sectors drive demand for motors that operate in vacuum or extreme cleanroom conditions. Ironless motors with vacuum‑compatible materials, magnetic shunts and outgassing‑free adhesives are becoming more common.

Rare‑Earth Alternatives. Research into ferrite‑based and hybrid magnet materials aims to reduce reliance on rare earths while maintaining force density. Advances in coil design, such as printed conductors and flat wire, also increase efficiency.

Choosing the Right Linear Motor for Your Robot

Selecting a linear motor requires balancing performance, cost and integration complexity. Use this checklist to evaluate options:

- Stroke Length and Travel Requirements. Determine the required stroke and consider whether a single motor or modular segments will achieve it. Linear motors can be scaled to tens of metres.

- Force Requirements (Peak and Continuous). Estimate the peak acceleration and continuous force needed. Choose ironcore motors for high thrust and heavy loads and ironless motors for lighter loads and ultra‑smooth motion.

- Precision and Smoothness. If nanometer‑level precision or vibration‑free motion is required (as in semiconductor or metrology applications), prioritise ironless or slotless motors.

- Duty Cycle and Thermal Constraints. Assess how long the motor will operate continuously and its ambient environment. For continuous high‑duty cycles, ironcore motors with good thermal paths are advantageous. For intermittent operation or vacuum environments, ironless motors can suffice with proper cooling.

- Environmental Conditions. Consider whether the robot operates in a cleanroom, vacuum, dusty workshop or vertical orientation. Choose dustproof enclosures and counterweights accordingly.

- Control Architecture. Decide whether the system will use separate drives and controllers or integrated linear modules. Ensure compatibility with the robot’s servo network and safety requirements.

- Budget and Total Cost of Ownership. Ironcore motors generally offer a higher force‑to‑cost ratio, while ironless motors cost more up front but can reduce maintenance and increase uptime. Factor in the cost of encoders, cooling and integration.

Example Scenarios

• High‑Speed Packaging Line (L1–L2). A pick‑and‑place robot on a packaging line requires 1 m/s travel and 10 kg payload. An ironcore linear motor with integrated cooling provides the necessary thrust and continuous duty.

• Wafer Inspection Robot (L3–L4). A semiconductor inspection system demands nanometer precision and vibration‑free motion. An ironless linear motor with air or vacuum cooling and high‑resolution linear encoder achieves sub‑micron repeatability.

• Collaborative Medical Robot (L4). A medical robot performing delicate procedures in a cleanroom requires quiet operation and low magnetic interference. An ironless, low‑voltage linear motor integrated into a modular stage ensures smooth, safe motion and meets cleanroom standards.

Sourcing Verified Linear Motors with Yana

Linear motors underpin next‑generation robotics, but choosing and procuring the right motor involves navigating a complex landscape of suppliers, technologies and risks. Yana Sourcing bridges this gap by applying a SMART + HEART framework:

- SMART sourcing means evaluating suppliers across technical capability, quality control, supply chain stability and innovation potential. Yana audits factories in Asia, Europe and North America to verify magnet quality, coil winding processes and encoder calibration. Our engineers help co‑design custom stages and ensure integration with your robot’s control architecture.

- HEART sourcing emphasises long‑term partnerships, transparent communication and ethical practices. We select suppliers who adhere to environmental and labour standards, prioritise traceability and invest in R&D.

By partnering with Yana, you get access to a global network of verified linear motor manufacturers and integrators. Whether you need high‑force ironcore units for industrial automation or cog‑free ironless modules for semiconductor robots, Yana manages the sourcing process from specification to final acceptance. We minimise risk by auditing magnet supply chains, testing motors against your duty cycle and ensuring documentation for regulatory compliance.

Partner with Yana Sourcing to secure verified linear motor suppliers and power your next‑generation robotics projects with frictionless precision and unwavering reliability.