Table of Contents

Frameless motors – sometimes called motor kits – are the hidden workhorses inside many modern robots. Instead of arriving as a fully housed unit like a servo motor or conventional brushless DC motor, a frameless motor is delivered as two separate components: a stator wound with copper wire and a rotor equipped with high‑energy magnets. These components are meant to be integrated directly into the mechanical structure of the robot or machine. By eliminating the usual motor housing, shaft, bearings and end bells, frameless motors free designers to create highly compact and efficient actuation systems. They unlock freedom in packaging and power in torque density – the two pillars behind their recent proliferation across robotics, medical devices, aerospace, and mobility applications.

Frameless motors matter in robotics because they combine the torque density of direct‑drive servo technology with the packaging flexibility of custom actuation. A robot joint can be designed around the motor instead of forcing a standard motor to fit the design. The open centre allows cabling, hollow shafts, gears or sensors to pass through the motor, enabling compact joints that require fewer parts and less space. Compared with servo and BLDC motors, frameless motors excel when engineers need high torque, minimal inertia and maximum integration flexibility. While a standard servo motor arrives as a single sealed unit ready to bolt in place, a frameless motor kit requires careful integration of bearings, housing and feedback devices; however, the payoff is a joint that is lighter, smaller and more efficient. This article explores eight design insights that illustrate why frameless motors are a compelling choice for modern robotics.

Introduction — Why Frameless Motors Matter in Robotics

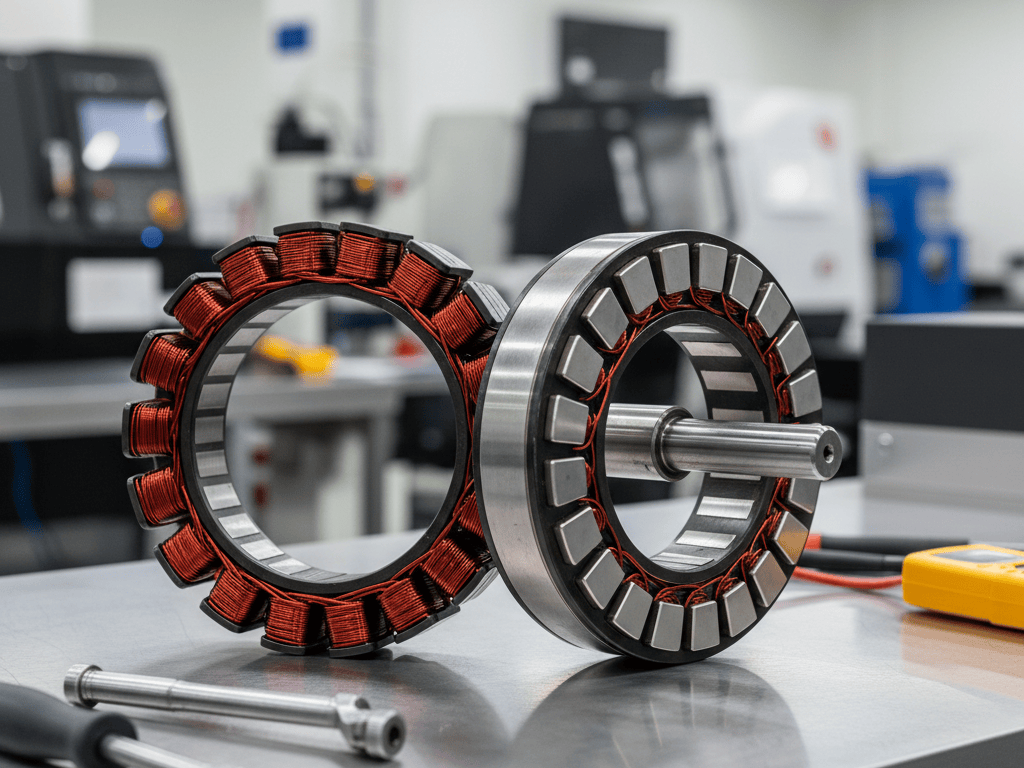

A frameless motor is essentially a brushless DC (BLDC) motor stripped down to its essentials: a stator with copper windings and a rotor carrying permanent magnets. It lacks a frame, shaft, bearings and feedback device. This minimalist package is integrated directly into the robot’s mechanical assembly, where the engineer provides the housing, shaft, bearings and encoder to complete the servo system. The absence of a frame allows designers to embed the motor within the joint structure, making the motor an integral part of the robot rather than an add‑on component.

Frameless motors unlock several benefits:

- Ultra‑compact packaging and light weight: because the motor lacks a housing, it can be sized precisely to fit within tight spaces. The open centre can serve as a passage for cables or shafts, further reducing the overall footprint.

- High torque density: frameless motors use strong rare‑earth magnets and can be designed with large diameters relative to their axial length, leading to high torque output per unit volume. They can provide direct drive without gear reductions.

- Design freedom and customisation: engineers can choose the bearing system, mounting method and cooling strategy that best suit their application. They can optimise the motor’s diameter, axial length and slot/pole configuration to balance torque, speed and inertia.

- Direct integration reduces parts and improves efficiency: by mounting the stator and rotor directly into the machine structure, the need for couplings, brackets and extra bearings is eliminated, reducing weight and mechanical complexity.

These advantages make frameless motors ideal for applications where space is at a premium, such as collaborative robot joints, exoskeletons, gimbals and medical instruments. The ability to integrate the motor into the robot’s structure also improves thermal management and reduces the number of interfaces, improving reliability. However, frameless motors differ from servo motors in that they require precise integration: the engineer must align the rotor to the stator, select appropriate bearings, and implement an encoder or resolver for feedback. The trade‑off between integration effort and performance is a key theme explored in this article.

Working Principle of Frameless Motors

Frameless motors are based on brushless DC (BLDC) technology. The stator comprises laminated steel cores and copper windings arranged in slots. When a three‑phase current is applied, a rotating magnetic field is produced. The rotor consists of a ring of permanent magnets (typically rare‑earth materials like neodymium) attached to a hub. As the stator’s magnetic field rotates, it exerts torque on the rotor magnets, causing the rotor to spin. Unlike a brushed DC motor, there are no commutator brushes; electronic commutation via a drive amplifies efficiency and eliminates wear.

A frameless motor operates similarly to a standard BLDC motor but without a frame. The rotor and stator are delivered separately and must be assembled within the mechanical system. Because there is no built‑in shaft or bearings, the machine’s own shaft becomes the rotor hub, and the machine’s bearings support both the rotor and the load. A Hall effect sensor or resolver typically senses the rotor’s position and sends information to a drive amplifier, which continually adjusts current to maintain the desired torque and speed. This closed‑loop control is identical to standard servo operation, but the integration tasks (housing, shaft and bearings) are performed by the system designer.

Torque production in frameless motors follows the same principles as in BLDC motors. The motor constant (Kt) relates torque output to current, and the back EMF constant (Ke) relates induced voltage to speed. By customising the stator length or increasing the rotor diameter, designers can adjust the motor’s torque–speed curve to suit their application. A longer axial length yields more continuous torque (proportional to length), whereas increasing the diameter significantly boosts torque because torque is proportional to rotor radius squared (D²L rule). A larger diameter also increases the inertia, which must be considered when sizing the motor for dynamic applications. Frameless motors often adopt axially short, large‑diameter designs to maximise torque density while minimising axial length, enabling slim, disc‑like profiles well suited to robotic joints.

Performance Characteristics & Control

Torque and Speed Characteristics

Frameless motors offer high torque density because the rotor and stator can be sized independently. By increasing the motor diameter, the torque increases roughly with the square of the radius. Frameless motors thus achieve torque outputs comparable to housed torque motors but with less mass and volume. The absence of an external frame allows designers to increase stator and rotor diameter up to the limits of the joint housing. Typically, frameless motors are used in direct‑drive configurations where the motor’s continuous torque is adequate for the load without gear reduction; however, they can also be paired with harmonic or planetary gearboxes to increase output torque.

The speed range of a frameless motor depends on the winding design and back EMF constant. Because frameless motors are integrated into the machine, they can be optimised for the application’s specific speed and torque requirements. High‑pole‑count frameless motors provide high torque at low speeds, while low‑pole‑count designs can rotate faster. However, at very high speeds the rotor must be securely retained and balanced within the joint housing, and appropriate cooling must be provided.

Efficiency and Thermal Performance

Efficiency in frameless motors is influenced by copper losses (I²R) and core losses (hysteresis and eddy currents) in the stator. Because the motor is integrated directly into the machine, thermal paths can be optimised for better cooling. For example, the robot joint’s housing can serve as a heat sink, allowing continuous operation at higher currents and torque. Frameless motors can also support liquid cooling when very high continuous power is required, as emphasised by Kollmorgen’s whitepaper, which notes that designers can evaluate ambient and maximum winding temperatures and integrate liquid cooling for enhanced continuous torque.

Feedback and Control Modes

Frameless motors require an external feedback device for closed‑loop control. Engineers may use Hall sensors for coarse commutation, resolvers for robust position feedback, or encoders for high‑precision control. Some frameless motors integrate a resolver coil inside the stator, while others rely on external encoders. Closed‑loop control ensures that the motor produces accurate torque and position despite load changes. In some applications, open‑loop operation is acceptable if the motor is used as part of a stepper system or operates at constant speed with low dynamic requirements. However, for robotic joints requiring precision, closed‑loop control is preferred.

Comparison with Servo, BLDC and Stepper Motors

| Parameter | Frameless Motors | Servo Motors | BLDC Motors (housed) | Stepper Motors |

|---|---|---|---|---|

| Control Loop | Requires external drive and feedback; can achieve high precision if integrated properly | Integrated servo drive with encoder; high performance out of the box | Electronic commutation; often open‑loop speed control or closed‑loop with sensor | Typically open‑loop position control via step pulses; can be closed‑loop in hybrid systems |

| Housing | No housing; rotor/stator integrated into machine | Fully housed unit with shaft, bearings and encoder | Housed motor with end bells and bearings | Housed motor with fixed step angle |

| Torque Density | High torque per volume due to large diameter and custom integration | High but limited by standard frame sizes | Moderate to high; limited by housing size | Moderate; limited by heat buildup |

| Customisation | Highly customisable (diameter, length, mounting, bearings) | Limited to available frame sizes and gear ratios | Off‑the‑shelf options; limited customization | Off‑the‑shelf; limited customization |

| Integration Effort | Requires precise alignment and external assembly | Minimal; plug‑and‑play | Moderate; requires drive and sometimes encoder | Low; simple driver and mechanical integration |

Frameless motors thus combine the precision and performance of servo motors with the customisability of BLDC kits. They require more integration effort but offer superior torque density and packaging flexibility. Designers must balance these factors when choosing between motor types.

Integration in Robotic Systems

Application Mapping Across Robot Levels

In L1 (industrial automation) robots, frameless motors may be overkill because simple stepper or housed BLDC motors often suffice. However, in L2 (advanced automation) robots such as articulated arms, frameless motors enable high joint torque with minimal backlash and compact size. They allow robots to achieve high payloads relative to their arm mass, improving energy efficiency and cycle times.

In L3 (collaborative robots), frameless motors are particularly attractive because they facilitate lightweight joints with high torque density and smooth backdrivability. Cobots must be safe for humans; frameless motors support direct drive with no gears, resulting in low inertia and the ability to implement series elastic actuators (SEAs) or compliance elements for force control.

At L4 (humanoid and dexterous robots), frameless motors become essential. Humanoid robots require compact joints that house multiple functions (motors, sensors, cooling, cables). The open‑centre design of frameless motors allows co‑axial routing of cables and sensors, enabling slender limbs and ankles. Frameless motors also appear in exoskeletons, haptic devices and gimbals where weight and compactness are critical.

Design Considerations — Size, Cooling, Noise and Weight

Because a frameless motor’s diameter and length can be chosen independently, designers must consider the following:

- Torque versus inertia: Increasing the diameter increases torque but also increases rotor inertia. For dynamic joints, a balance is required to achieve fast acceleration without overshoot.

- Thermal management: Frameless motors rely on the robot’s structure for cooling. Materials with high thermal conductivity (e.g., aluminium or copper heat sinks) can be used. Liquid cooling channels may be integrated into the housing for high continuous loads.

- Noise and vibration: Frameless motors generally operate quietly due to the absence of gear trains and can produce smooth torque. However, precise rotor balancing and alignment are critical to minimise vibration.

- Weight: The absence of an extra frame reduces weight, but the added bearings and housing must be designed carefully to avoid unnecessary mass. The open centre can be used to route cables or shafts to further reduce external hardware.

Integration Challenges and Proven Solutions

Integrating frameless motors into a robot presents engineering challenges that must be addressed to realise the promised benefits.

Challenge 1 — Aligning the rotor and stator: Unlike pre‑assembled motors, frameless kits require precise concentric alignment between the rotor and stator. Misalignment can cause torque ripple, noise and premature wear. Solution: use precision machined housings and alignment fixtures during assembly. Employ axial clamping or interference fits as appropriate. Some manufacturers provide alignment guides or sub‑assemblies to simplify integration.

Challenge 2 — Bearing selection and pre‑load: The system designer must choose bearings that support both radial and axial loads of the application. Solution: select high‑quality ball or cross‑roller bearings with appropriate pre‑load. If gearboxes or transmissions are used, ensure bearings can handle the load without inducing misalignment.

Challenge 3 — Thermal dissipation: The motor’s copper losses and core losses generate heat. Solution: integrate heat sinks or cooling channels into the housing. Use thermal modelling to predict temperature rise and implement liquid cooling for high continuous torque applications.

Challenge 4 — Feedback integration: Frameless motors require external encoders or resolvers. Solution: choose compact feedback devices that fit within the open centre or mount externally. Integrate cable management through the hollow shaft or around the periphery to protect wires.

Challenge 5 — Assembly complexity: Building joints from frameless kits requires mechanical and electrical expertise. Solution: partner with experienced suppliers who provide integration guidelines, application engineering and pre‑validated kits. Yana Sourcing’s network includes manufacturers who offer engineering support and pre‑aligned assemblies.

These solutions transform integration challenges into opportunities. By addressing alignment, bearing selection, thermal management and feedback integration early in the design process, engineers can leverage the full potential of frameless motors. The resulting robot joints are robust, efficient and elegantly integrated.

Manufacturing & Sourcing Insights

Regional Strengths and Supplier Ecosystems

The global market for frameless motors is growing quickly, driven by robotics, aerospace and medical sectors. China has developed significant manufacturing capacity for frameless and torque motors, particularly in Shenzhen and Suzhou. Chinese suppliers offer competitive pricing and short lead times but may vary in quality. Japan and Germany are renowned for high‑precision motors, with companies specialising in custom rotor designs and advanced winding processes. Europe (Germany, Switzerland) emphasises high torque density and reliability, making their motors popular in aerospace and medical applications. United States manufacturers often focus on aerospace, defense and robotics markets, offering tailored designs and robust support. 2025 market reports project the global frameless motor market to grow at a CAGR above 6 %, with demand rising for custom torque motors in collaborative robots and high‑performance automation.

Cost vs Quality Zones

Frameless motors vary widely in cost depending on materials, magnet type, manufacturing tolerances and customisation level. High‑end motors with precision laminations, rare‑earth magnets and integrated resolvers command premium prices but offer superior efficiency and torque density. Low‑cost options may use lower‑grade magnets or less stringent winding processes and may require additional sorting or calibration. Buyers should consider the total cost of ownership, including integration effort, reliability and maintenance. Yana Sourcing can help evaluate suppliers and negotiate cost‑quality trade‑offs.

MOQ and Lead Time

Some frameless motor manufacturers require minimum order quantities (MOQs), especially for fully custom designs. Off‑the‑shelf stator/rotor kits may be ordered in small quantities for prototyping, while large‑scale production typically offers better pricing. Lead times range from 4–8 weeks for standard kits to 10–14 weeks for custom designs. Supply chain disruptions (e.g., rare earth magnet shortages or geopolitical issues) may lengthen lead times; diversifying suppliers across regions helps mitigate risks.

Quality Control Checklist

To ensure high performance and reliability, Yana recommends the following quality checks for frameless motors:

- Rotor and stator concentricity: verify alignment within microns using dial indicators or coordinate measuring machines (CMM). Misalignment can cause torque ripple and noise.

- Magnet quality and adhesive strength: inspect magnets for chip defects; ensure adhesives or retention sleeves withstand centrifugal forces at maximum speed.

- Winding resistance and insulation: measure coil resistance; perform hipot (high potential) tests to check insulation integrity and avoid electrical breakdown.

- Back EMF constant (Ke) verification: measure induced voltage at known speed to confirm the motor constant matches specifications.

- Temperature rise test: run motor at rated current and measure temperature rise; verify that it meets thermal design limits.

- Vibration and noise test: run the motor in the intended housing and measure vibration levels. Excessive vibration indicates imbalance or misalignment.

- Lifecycle testing: perform accelerated life tests to assess wear of bearings, insulation and magnetisation.

Implementing rigorous QC ensures that the final assembly meets performance expectations and reduces field failures.

Risk Factors

Magnet supply constraints: Rare‑earth magnets (NdFeB) are key to frameless motors’ high torque density. Supply disruptions or price spikes can impact availability. Sourcing from multiple suppliers and considering alternative magnet compositions can mitigate this risk.

Counterfeit or sub‑standard components: Low‑quality stator laminations or inferior magnets may slip into the supply chain, reducing performance and reliability. Working with audited suppliers and performing incoming inspections protects against counterfeit parts.

Poor thermal design: Inadequate cooling can lead to demagnetisation of the rotor or insulation degradation. Designers must plan for worst‑case thermal conditions and validate with thermal simulations.

Over‑specification or under‑specification: Choosing a motor that is too large wastes space and weight; choosing one too small leads to overheating and premature failure. Accurate sizing, as discussed in the performance section, is essential.

Yana Sourcing’s audits and supplier network help mitigate these risks, ensuring that your frameless motor procurement is both cost‑effective and reliable.

Emerging Innovations & Future Trends

Frameless motors are evolving rapidly. Here are several trends shaping their future:

- High‑torque‑density materials and topologies: Manufacturers are experimenting with advanced steel laminations, improved magnetic materials and novel winding patterns to maximise torque per volume. Axial flux frameless motors, for instance, use discs instead of cylinders and promise even higher torque density.

- Integrated sensors and smart motors: Some frameless motors now include built‑in encoders or resolvers, reducing integration complexity. Others embed temperature and vibration sensors, enabling real‑time health monitoring and predictive maintenance.

- Rare‑earth alternatives: Research into ferrite magnets or hybrid magnet designs seeks to reduce dependence on rare‑earth materials, which are subject to geopolitical constraints. These innovations may reduce cost and improve sustainability.

- Variable reluctance and flux‑switching designs: These emerging topologies aim to combine the simplicity of synchronous reluctance motors with the torque density of permanent magnet motors. They may enable frameless motors with lower magnet content and high performance.

- AI‑driven control and adaptive tuning: Machine learning algorithms are being used to optimise commutation and torque control in real time, adapting to load changes and minimising energy consumption. These techniques can also detect early signs of failure and adjust operating parameters to extend life.

- Additive manufacturing and custom windings: 3D printing of stator laminations and custom conductor shapes allows manufacturers to create winding patterns that reduce copper loss and improve cooling channels. This could accelerate prototyping and open novel geometries.

- Integration of gearboxes and harmonic drives: Hybrid solutions combine frameless motors with compact gearboxes integrated inside the motor’s open centre, providing high torque with minimal backlash and maintaining a slim profile.

These innovations will make frameless motors even more attractive for robotics. Yana Sourcing monitors these trends and collaborates with innovators to ensure our customers have access to cutting‑edge technology.

Choosing the Right Frameless Motor for Your Robot

Selecting a frameless motor requires a methodical approach. Here is a selection checklist to guide engineers and procurement teams:

- Define torque and speed requirements: Determine continuous and peak torque, maximum speed and duty cycle. Use the D²L rule to estimate how changing diameter or length affects torque. Avoid overspecifying, which adds unnecessary mass, or underspecifying, which leads to overheating.

- Assess space constraints: Measure the available diameter and axial length in the joint or mechanism. If axial space is limited, consider a wide, short motor; if radial space is tight, a longer, narrower motor may be better.

- Establish thermal limits: Evaluate ambient temperature, cooling methods (air or liquid) and acceptable winding temperature rise. Choose a motor with sufficient thermal margin or plan to implement additional cooling.

- Select feedback and control: Decide between Hall sensors, resolvers or encoders based on required precision and environment (e.g., resolvers for high temperatures). Ensure the drive amplifier supports the motor’s current and voltage.

- Consider integration method: Choose axial clamping, bonding, press fit or a combination for mounting. Consider how the housing will support the stator and rotor and how to route cables.

- Evaluate supply voltage and current: Ensure the motor’s winding matches the system’s bus voltage and that the drive can supply the required current.

- Account for regulatory and environmental requirements: If the robot will operate in medical, aerospace or hazardous environments, verify that the motor meets applicable standards (e.g., ISO 13485, DO‑160).

- Review supplier capability and lead time: Choose suppliers with consistent quality, support for custom designs and reliable lead times.

Example Scenarios

- Collaborative robot arm: A cobot joint requires high torque at low speed with minimal backlash and backdrivability. A large‑diameter, short frameless motor integrated into the elbow provides continuous torque, while a series elastic element yields compliance for safe human interaction. Feedback is provided by a resolver and torque sensors integrated through the hollow shaft.

- Surgical robot: A surgical robotic wrist demands compact size and zero backlash to perform delicate manipulations. A frameless motor with high pole count and integrated harmonic gear inside the open centre delivers the required torque, while a high‑resolution encoder enables sub‑degree positional accuracy. The motor’s stator is immersed in a sterile, sealed housing with conductive cooling to dissipate heat.

- Drone gimbal: A camera gimbal on a drone needs lightweight, precise rotation with limited power consumption. A frameless motor integrated around the camera axis provides smooth, direct drive with minimal inertia. The open centre accommodates wiring and slip rings, and the motor is tuned for low torque ripple to avoid vibration.

- Exoskeleton joint: An exoskeleton knee joint requires high torque to support a human’s weight and must be compact and quiet. A frameless motor is embedded in the joint, combined with a harmonic reducer for torque multiplication. The open centre houses load sensors and wiring.

These scenarios illustrate how frameless motors enable innovative robotic designs by delivering high torque in compact form factors. Crosslinking with other motor types, such as servo or BLDC motors, is important: servo motors may still be used in base axes requiring plug‑and‑play convenience, while frameless motors are reserved for joints requiring maximum integration freedom and torque density.

Sourcing Verified Frameless Motors with Yana

Sourcing frameless motors can be challenging due to the need for customisation, quality control and reliable supply. Yana Sourcing bridges this gap with our SMART + HEART framework:

- SMART: We apply data‑driven analysis and deep technical understanding to match your torque, speed, space and budget requirements with the right frameless motor suppliers. Our engineers evaluate D²L trade‑offs, thermal management strategies and integration methods, ensuring that the motor kit selected will meet performance goals from prototype through volume production.

- HEART: Beyond technical specifications, we understand that project success depends on trust, communication and long‑term partnerships. We audit suppliers for ethical sourcing, labour practices and environmental stewardship. We also provide logistical support, helping to navigate customs, tariffs and lead‑time uncertainties.

Yana’s network includes suppliers across China, Japan, Europe and North America. Our experts assess each factory’s capabilities, from magnet quality to winding processes, and perform on‑site inspections. We work closely with you to develop custom frameless motors or find cost‑effective off‑the‑shelf kits, ensuring that quality is maintained across all orders. For clients requiring high volumes or stringent certifications (e.g., ISO 13485 for medical devices), we coordinate factory audits and certification support.

Partner with Yana Sourcing to secure verified frameless motor suppliers and power your next‑generation robotics projects. With deep technical expertise and a trusted supply network, we deliver motors that are not only compact and powerful but also sourced ethically and reliably. Let us handle the complexity of procurement so you can focus on innovation.