Table of Contents

Introduction — Why BLDC Motors Matter in Robotics

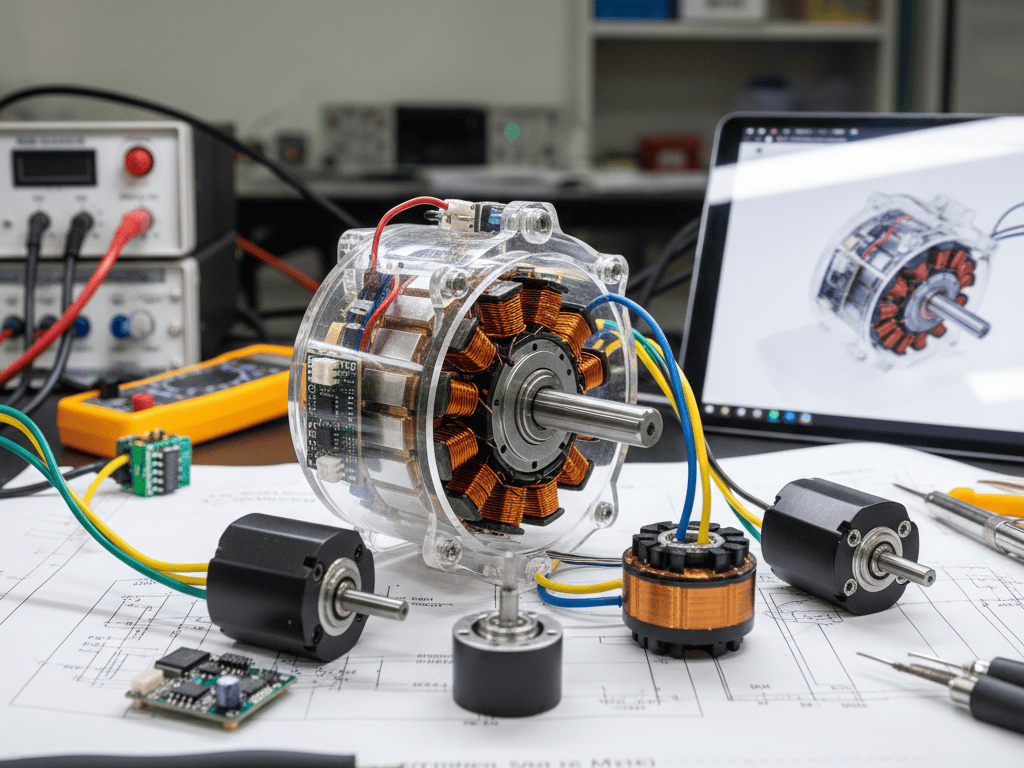

Robotics is undergoing a revolution in energy efficiency and reliability, and brushless DC (BLDC) motors are at the heart of that transformation. A BLDC motor, also known as an electronically commutated motor, is a synchronous electric motor powered by direct current but driven by a solid‑state controller rather than brushes. The controller sequentially energizes the stator windings, generating a rotating magnetic field that the permanent magnet rotor follows. By replacing mechanical brushes and commutators with electronic switching, BLDC motors achieve higher power density, near‑instantaneous control of speed and torque, and vastly improved efficiency. These traits have made BLDC motors the default choice for modern robotics, from agile drones and autonomous vehicles to industrial arms and cobots. Compared with brushed DC motors, BLDC units offer a higher torque‑to‑weight ratio, produce less electrical noise, require minimal maintenance and eliminate ionizing sparks. Unlike steppers, BLDC motors provide continuous rotation and high speed capabilities, and compared with servo motors they balance cost, simplicity and efficiency, making them the efficiency backbone of contemporary robotic platforms. In this article, we unpack how BLDC motors work, what makes them unique, and why Yana Sourcing views them as a cornerstone for building intelligent machines.

Working Principle of BLDC Motors

BLDC motors differ from brushed DC motors by eliminating mechanical commutation. A typical BLDC motor consists of a stator wound with three (sometimes more) phase windings and a rotor with permanent magnets mounted on or embedded in its core. The key to brushless operation is an electronic controller (often called an electronic speed controller, or ESC) that uses semiconductor switches (MOSFETs or IGBTs) to sequentially energize the stator windings. By switching the phases at the right time, based on rotor position feedback, the controller creates a rotating magnetic field that the rotor follows. The electronic commutation is commonly executed in either trapezoidal (six‑step) or sinusoidal (field‑oriented) patterns. Trapezoidal commutation provides simplicity and high efficiency at moderate speeds, while sinusoidal control yields smoother torque and less acoustic noise but requires more sophisticated algorithms.

Rotor position is detected via Hall effect sensors, encoders or inferred from back electromotive force (back‑EMF) in sensorless designs. Hall sensors produce digital signals representing rotor sector, enabling six‑step commutation. Sensorless BLDC drives measure back‑EMF on unenergized windings to determine commutation timing, reducing cost and eliminating sensors but making startup and low‑speed operation more challenging. Some BLDC motors include integrated resolvers or magnetic encoders for closed‑loop control, improving precision and enabling servo‑like performance.

The elimination of brushes and commutators means there are no sliding contacts, removing friction losses, mechanical wear and arcing. Consequently, BLDC motors can achieve very high rotational speeds (tens of thousands of revolutions per minute) and exhibit long operating lifetimes, with service intervals defined mainly by bearing wear. Cooling is also improved, as windings mounted to the stator can be conduction cooled via the motor housing, allowing BLDC motors to be fully enclosed for use in dusty, explosive or sterile environments.

Performance Characteristics & Control

BLDC motors offer a compelling mix of high efficiency, compactness and controllability. Their performance is defined by:

- High power‑to‑weight ratio: BLDC motors deliver more torque per unit mass than brushed motors due to their optimized electromagnetic design and strong permanent magnets. Some designs achieve efficiency levels above 90%, reducing energy losses and heat generation.

- Instantaneous torque response: With direct electronic control of phase currents, BLDC motors can rapidly change torque and speed. This makes them ideal for dynamic applications such as quadcopter propulsion, robotic joint actuation and high‑speed conveyors.

- Wide speed range: BLDC motors sustain high torque from zero speed up to their rated speed and can operate efficiently at tens of thousands of RPM. Their torque–speed curve is relatively flat up to the rated speed, providing consistent performance across a broad operating range.

- Low electrical and mechanical noise: The lack of commutator sparks and the use of smooth sinusoidal control reduce electromagnetic interference (EMI) and audible noise. This quality is critical for robots working near sensitive sensors or in quiet environments.

- Minimal maintenance and long life: Without brushes to wear out, BLDC motors offer long service life and require only periodic bearing lubrication or replacement. This reduces downtime and total cost of ownership, especially in environments where maintenance access is difficult.

- Flexible control: BLDC motors can be run in sensorless open‑loop mode (simpler, lower cost) or sensor‑based closed‑loop mode for precise speed and position control. Closed‑loop BLDC systems behave similarly to servo motors but at a lower cost, albeit with slightly lower precision. Modern ESCs include features like field‑oriented control (FOC) for sinusoidal commutation, regenerative braking, and bus communications (CAN, RS‑485, EtherCAT) for integration into robotics networks.

The following table summarizes how BLDC motors compare to servo motors, steppers and brushed DC motors:

| Parameter | BLDC Motor | Servo Motor | Stepper Motor | Brushed DC Motor |

|---|---|---|---|---|

| Control method | Electronic commutation (sensorless or sensor‑based) | Closed‑loop with encoder/resolver | Typically open‑loop (can be closed) | Mechanical commutator (brushes) |

| Efficiency | High (up to 90–95 %) | High | Moderate | Moderate |

| Torque characteristics | Flat torque up to rated speed; high torque density | High torque with precise control | High holding torque at zero speed | High starting torque, torque decreases linearly with speed |

| Maintenance | Very low (no brushes) | Medium (gear wear, calibration) | Low | High (brush replacement) |

| Noise | Low electrical/mechanical noise | Low–medium (depending on gears) | Medium (cogging noise) | High (brush sparking) |

| Ideal applications | Drones, robotic arms, AGVs, fans | Precision motion (arms, cobots, CNC) | Low‑cost automation, 3D printers | Simple, low‑cost drives |

Integration in Robotic Systems

BLDC motors are ubiquitous across all levels of robotics, from simple automation to advanced AI-driven machines. Their versatility stems from a combination of high efficiency, robust construction and compatibility with various transmissions. In Yana’s L1–L4 taxonomy, BLDC motors appear in the following roles:

L1 (task-specific automation): BLDC motors power conveyors, grippers and simple axes where efficiency and longevity are more important than sub‑arc‑minute positioning. For example, pick‑and‑place machines may use BLDC motors to drive lead screws or belt stages, providing high throughput with minimal maintenance. Small BLDC motors also drive fans and pumps within robots, ensuring thermal management and fluid transport.

L2 (adaptive automation): In collaborative robots (cobots) and service robots, BLDC motors combine with gearboxes (planetary or harmonic) to produce compact, efficient joint modules. Compared with stepper motors, BLDC‑based joints deliver smoother motion and higher torque density, enabling cobots to lift heavier payloads without sacrificing compliance. BLDC drives also control the wheels of automated guided vehicles (AGVs) and autonomous mobile robots (AMRs), providing smooth acceleration and deceleration, regenerative braking and energy efficiency.

L3 (advanced automation): For high‑performance industrial robots and manufacturing equipment, BLDC motors often serve as spindle drives or auxiliary axes. Their high speed capabilities, combined with low vibration, make them suitable for CNC tool changers, laser scanners and pick‑and‑place deltas. In aerospace and defence robots, BLDC motors power actuators for gimbals, antenna pointing systems and flight control surfaces.

L4 (embodied AI/humanoids): Although servo motors dominate high‑precision joints in humanoid robots, BLDC motors are increasingly used in lightweight humanoids and exoskeletons, particularly when integrated into frameless designs. For example, outrunner BLDC motors paired with harmonic drives deliver high torque density for shoulder or hip joints while keeping weight low. BLDC outrunners are also standard in multirotor drones, the smallest flying robots, where efficient, high‑speed propulsion is critical.

Design Considerations

When integrating BLDC motors into robots, designers must account for:

- Cooling: BLDC windings are on the stator, enabling conduction cooling via the housing. This is advantageous for sealed environments, but in compact joints additional cooling (e.g., passive fins or liquid cooling) may be necessary.

- Inertia and gear reduction: BLDC motors often require gearboxes to multiply torque. Choosing the right gear ratio balances torque, speed and backdrive friction. Frameless BLDC kits combined with harmonic or planetary reducers can achieve compact, high‑torque joints.

- Noise and vibration: Though BLDC motors are quieter than brushed motors, cogging torque (torque ripple due to stator slot design) can cause vibration. Slotless or skewed stator designs, as well as sinusoidal commutation, minimize cogging. Soft mounts or elastomer couplings further isolate vibration in sensitive systems.

- Electromagnetic interference (EMI): High switching frequencies and back‑EMF signals can introduce electrical noise that affects nearby sensors. Adequate shielding, twisted pair cabling and proper ground referencing help maintain signal integrity.

Integration Challenges and Proven Solutions

- Cogging torque and torque ripple: Cogging arises from the interaction of rotor magnets and stator teeth. To mitigate, manufacturers optimize tooth geometry, use skewed stator laminations or adopt slotless motor designs. In control, implementing sinusoidal commutation (field‑oriented control) smooths torque output.

- Sensorless startup: Sensorless BLDC controllers struggle at very low speeds because back‑EMF is too weak to measure. Hybrid approaches start the motor using pre‑programmed commutation sequences until back‑EMF becomes detectable, or they employ integrated position sensors for startup only.

- Thermal management: High‑power BLDC motors can generate significant heat. Ensuring adequate conduction paths to the housing, integrating heat pipes or liquid cooling and derating continuous torque helps maintain longevity. Active temperature monitoring allows the controller to reduce load when temperatures rise.

- Mechanical integration: Pairing BLDC motors with gearboxes requires precision alignment to avoid runout and vibration. Using frameless BLDC kits allows custom integration into robot joints, reducing weight and increasing torque density. Ensuring proper lubrication and mechanical clearances prevents premature wear.

Manufacturing & Sourcing Insights

BLDC motors are produced by a global network of manufacturers, each offering unique strengths. Yana Sourcing evaluates suppliers using our SMART + HEART framework to ensure technical excellence and cultural alignment.

- China: Chinese factories produce a vast range of BLDC motors, from outrunner drone motors to integrated servo modules. Their strengths lie in high‑volume production, cost efficiency and rapid customization. For example, Shenzhen and Zhejiang serve as hubs for drone propulsion motors and electric scooter drives. However, quality varies widely, and Yana conducts in‑depth audits to distinguish reputable suppliers from low‑quality producers. Minimum order quantities (MOQs) for standard motors may start at a few hundred units, while customized designs require higher volumes.

- Japan: Japanese manufacturers (e.g., Nidec, Maxon Japan) excel in miniature, high‑precision BLDC motors used in robotics, medical devices and instrumentation. They emphasize quality, reliability and continuous improvement. Lead times can be longer and costs higher, but the products offer longevity and consistency.

- Europe: European companies develop specialized BLDC systems, including medical pumps, high‑end gimbals and aerospace actuators. Switzerland and Germany are known for slotless BLDC motors with exceptionally smooth torque and low cogging. Many of these companies supply integrated motor‑drive modules for collaborative robots and AGVs.

- USA: The United States hosts suppliers focused on custom, high‑performance BLDC motors, often for aerospace, defense and research laboratories. American companies emphasize innovation and are quick to adopt cutting‑edge materials (e.g., composite rotors, high‑temperature magnets) and integrated sensing.

Quality Control Checklist

To ensure BLDC motors meet performance and longevity expectations, Yana Sourcing uses a rigorous quality control checklist:

- Electrical verification: Measure coil resistance, inductance and back‑EMF constant to verify performance against specifications. Test high‑voltage insulation and dielectric strength.

- Dynamic balance and vibration: Evaluate rotor balance using accelerometers and ensure vibration levels remain within acceptable limits under rated speed and load. Verify the mechanical integrity of adhesives and rotor magnet attachment.

- Torque and efficiency testing: Use dynamometers to measure continuous and peak torque across the speed range. Calculate efficiency at multiple operating points to confirm manufacturer claims.

- Thermal cycling: Run motors under load in environmental chambers to assess temperature rise. Check for demagnetization or coil insulation degradation after multiple thermal cycles.

- EMI and noise assessment: Test electromagnetic emissions and susceptibility to ensure compliance with relevant standards (e.g., CE, FCC) and to guarantee reliability near sensitive electronics.

Risk Factors

- Magnet supply volatility: BLDC motors rely on rare‑earth magnets, particularly neodymium. Price fluctuations and geopolitical constraints can impact supply. Yana tracks suppliers’ magnet sourcing and encourages diversification.

- Overstated specifications: Some low‑cost manufacturers advertise inflated torque or power values. Yana’s independent testing verifies actual performance and identifies unrealistic ratings.

- Controller mismatch: Choosing a controller with incorrect phase current or commutation algorithm can cause poor performance or motor damage. Yana ensures controller‑motor compatibility and helps select suitable ESCs.

- Counterfeit components: Inferior wire, magnets or hall sensors can degrade performance. Yana sources from audited manufacturers with traceable components and uses secure supply chains to avoid counterfeit parts.

Emerging Innovations & Future Trends

The BLDC landscape continues to evolve, with innovations that push efficiency and functionality into new realms:

1. High torque density designs: Concentrated windings, segmented stator cores and axial flux architectures are raising torque density while reducing weight. These motors enable compact cobot joints and lightweight exoskeleton drives.

2. Integrated motor‑drive modules: Next‑generation motors incorporate power electronics, sensors and communication interfaces into the motor housing. This integration simplifies wiring, reduces EMI issues and enables plug‑and‑play installation.

3. Smart commutation and AI tuning: Using machine learning, modern ESCs adapt commutation angles and current profiles in real time to maximize efficiency and torque across varying loads. Adaptive algorithms also identify incipient faults and adjust operating parameters to prolong motor life.

4. Rare‑earth‑free magnets: Research into ferrite or composite magnets aims to reduce dependence on rare‑earth materials. Hybrid magnet architectures (ferrite with small neodymium inserts) maintain high performance at a lower cost.

5. Energy regeneration: Improved FOC controllers and bidirectional converters allow BLDC systems to capture kinetic energy during deceleration or gravitational return, feeding it back to power supplies or batteries. This feature is particularly valuable in mobile robots and cranes.

6. Integrated sensing and diagnostics: Motors now embed sensors for temperature, vibration and current. They transmit health data to predictive maintenance systems, enabling remote diagnostics and reducing downtime.

7. Multi‑phase BLDC motors: Beyond three phases, five‑ and nine‑phase motors offer improved fault tolerance, smoother torque and lower harmonics. Multi‑phase designs also allow partial operation if one phase fails, enhancing reliability for mission‑critical applications.

Choosing the Right BLDC Motor for Your Robot

Selecting a BLDC motor involves balancing performance requirements, efficiency, integration and cost. Yana recommends the following procedure:

- Define torque and speed: Determine the required continuous and peak torque, as well as the operating speed range. Factor in gear reduction if using a gearbox.

- Select the appropriate motor type: Decide whether to use inrunner (high speed, lower torque), outrunner (high torque, lower speed) or axial flux designs. Outrunners are common in drones and gimbals; inrunners often power pumps and spindles.

- Choose sensor configuration: Sensorless drives are cost‑effective and robust but require higher startup speed. Sensor‑based drives (Hall sensors, encoders) enable closed‑loop control, smoother torque and precise positioning.

- Determine cooling and housing: For sealed or harsh environments, use motors with enclosed housings and conduction cooling. Open‑frame motors may suffice in ventilated enclosures.

- Match the controller: Select an ESC or servo drive that supports the motor’s current and voltage ratings, commutation type (trapezoidal vs. sinusoidal) and control protocol (PWM, CAN, EtherCAT). Ensure the controller can deliver the required dynamic response.

- Consider integration form: Decide between a standard housed motor, a frameless stator‑rotor kit (for integration into custom joints) or a fully integrated servo module. Frameless kits allow higher torque density and design flexibility, while integrated modules simplify installation.

- Assess cost and lifecycle: Evaluate not just purchase price but also efficiency (impact on battery life), expected maintenance, and potential downtime. Higher initial investment in quality motors and controllers often yields lower total cost of ownership.

Example Scenarios

- Drones and aerial robots: Use outrunner BLDC motors with high Kv (rpm per volt) ratings and lightweight construction. Paired with sensorless ESCs for weight savings, these motors deliver fast acceleration and fine thrust control.

- Collaborative robot joints: Combine a frameless BLDC motor with a harmonic drive reducer and high‑resolution encoder. This configuration provides high torque density, smooth motion and low power consumption.

- Automated guided vehicles (AGVs): Choose hub BLDC motors or integrated drive wheels with high efficiency and regenerative braking. Sensor‑based drives enable precise speed control and quick response to navigation commands.

- Industrial conveyor systems: Select inrunner BLDC motors with high efficiency and high torque at moderate speeds. Use controllers with field‑oriented control and network connectivity to coordinate multiple conveyors.

Sourcing Verified BLDC Motors with Yana

Robotics companies must source BLDC motors from partners who deliver both technical excellence and ethical reliability. Yana’s SMART + HEART framework ensures every component meets rigorous standards:

- SMART: We validate suppliers against stringent technical metrics, measuring torque, efficiency, thermal behaviour and quality of materials. Our engineers review magnetic designs, winding schemes and controller compatibility. We audit manufacturing facilities for process control, traceability and environmental compliance.

- HEART: Beyond specs, we build relationships. We assess suppliers’ history, responsiveness, agility and cultural alignment. Yana fosters trust and long‑term collaboration, ensuring that suppliers stand behind their products and support our clients through the entire lifecycle.

By partnering with Yana Sourcing, robotics companies access a curated network of verified BLDC motor manufacturers across Asia, Europe and the Americas. We handle supplier negotiation, quality audits, customization and logistics, freeing you to focus on innovation. Partner with Yana Sourcing to secure verified BLDC motor suppliers and power your next‑generation robotics projects, ensuring brushless efficiency, reliability and performance that redefine the future of automation.