Introduction: motion’s other axis

Rotational motion gets the spotlight, but every robot also needs precision push‑and‑pull. Linear Actuators convert energy into straight‑line movement that lifts parts, positions tools and gives robots their reach. Without linear motion there are no lifts, no grippers and no stable bases for arms to swing from. While rotary joints bring elegance, Linear Actuators deliver power and precision in one dimension. In robotics they handle Z‑axis lifts, linear slides, adjustable end‑effectors and telescoping mechanisms. This guide explores how to select, source and integrate linear motion modules while staying ahead of market trends and technological shifts.

A spectrum of motion modules

In the past you had to assemble rails, motors and guides yourself. Today manufacturers provide motion modules that integrate Linear Actuators, guides, bearings and sensors into plug‑and‑play units. These modules reduce design time and ensure alignment, leaving you to focus on higher‑level robotics functions. A motion module may contain a ball‑screw actuator, linear guide rails, end plates and limit sensors. Advanced modules include controllers and feedback built in. Throughout this guide we use Linear Actuators as the anchor; motion modules represent higher‑order assemblies built around them. Selecting modules requires evaluating performance, integration ease and supplier reliability.

What are Linear Actuators?

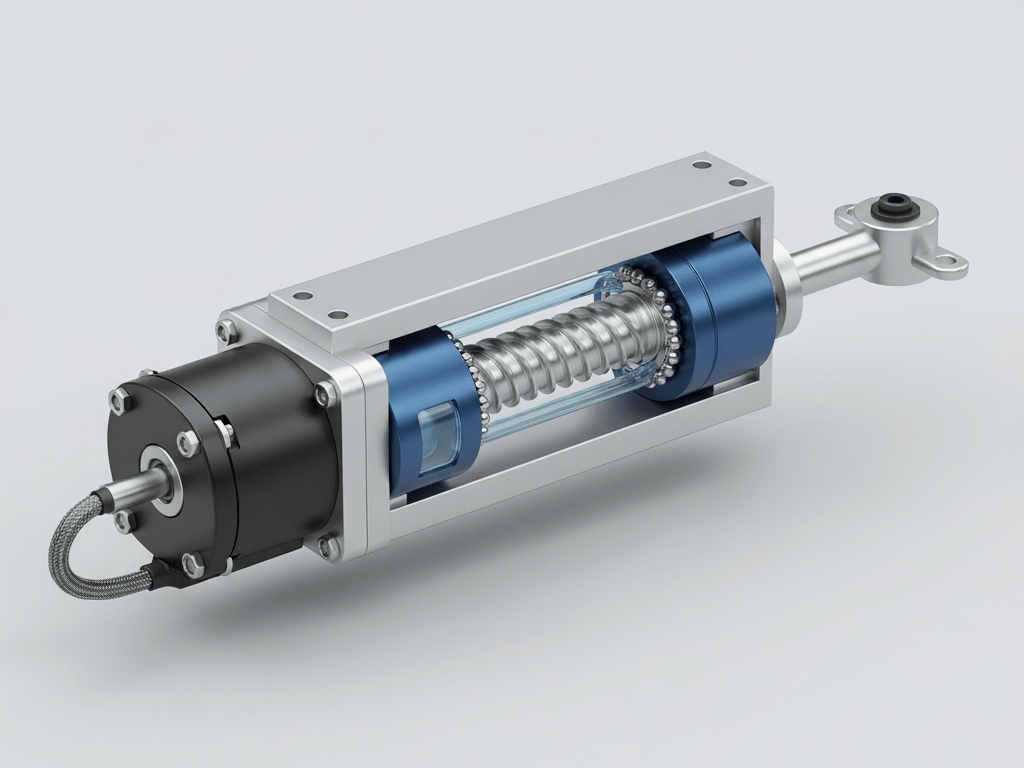

At the simplest level Linear Actuators translate rotary or fluid energy into linear displacement. They consist of a drive mechanism, such as a screw, belt, hydraulic cylinder or pneumatic piston, paired with a motor or pressure source. Components include housing, bearings, shaft or rod, seals, and often integrated sensors. Electric screw actuators use a rotating ball or lead screw to drive a nut that moves the output rod. Belt‑driven types use a motor to pull a belt attached to a carriage. Hydraulic and pneumatic Linear Actuators rely on pressurized fluids to push pistons. Each design offers trade‑offs in accuracy, load, speed, cost and environmental resilience.

Motion modules: pre‑engineered subassemblies

Motion modules combine Linear Actuators with structural and sensing elements to create ready‑to‑install stages. A typical module includes a rigid extrusion or machined base, precision guides, drive mechanism, mounting flanges and limit switches. Integrated modules reduce alignment errors and simplify cable management. They are ideal for gantries, pick‑and‑place machines, 3D printers and Cartesian robots. Selecting a module involves matching stroke length, load capacity, positional accuracy and duty cycle to your application. Because modules are often bespoke, collaboration with suppliers ensures the Linear Actuators inside meet your specifications and the assembly fits seamlessly into your system.

Why linear motion matters in robotics

Robotic arms get attention, but Linear Actuators underpin many tasks you see in factories, laboratories and warehouses. They raise and lower Z‑axes, open and close grippers, push items along conveyors and adjust camera focus. In mobile robots, linear lifts enable multi‑level picking. In laboratory automation, syringe pumps use miniature Linear Actuators to dispense microliters of liquid. In semiconductor tools, piezo linear drives position wafers within nanometers. Without reliable linear motion you risk misplacing parts, dropping payloads or damaging products. With proper actuators, robots achieve the repeatability and safety required for collaborative operations.

Cross‑industry applications

Beyond robotics, Linear Actuators find homes in aerospace, automotive, packaging, furniture and healthcare. Aircraft use hydraulic rods to extend flaps and adjust landing gear. Car factories use electric linear cylinders for welding, painting and battery installation. Adjustable hospital beds rely on compact screw drives for smooth repositioning. Smart home devices use micro Linear Actuators to adjust shades and display screens. In each case the motion must be precise, quiet and reliable. The same suppliers who make robotics components often supply industrial and consumer sectors. Understanding these cross‑industry synergies helps you identify stable partners and scale volumes.

Ball‑screw actuators: high precision

Ball‑screw Linear Actuators convert rotational motion into linear displacement via a screw and re‑circulating ball nut. They offer high efficiency, minimal backlash and long life. Because the balls reduce friction, ball screws achieve positioning accuracies under 10 micrometers. They handle loads from a few kilograms to several tons. Robotics applications include CNC stages, vertical lifts and precise XY tables. When choosing ball‑screw Linear Actuators, consider screw pitch, lead accuracy, dynamic load rating and lubrication. For high duty cycles ensure the recirculating balls can dissipate heat and that the preload reduces backlash without causing excessive friction.

Lead‑screw actuators: simplicity and cost efficiency

Lead‑screw Linear Actuators also use screws but rely on friction between the screw and nut rather than rolling elements. They are simpler and cheaper than ball screws but exhibit higher friction and wear. In robotics they suit low‑to‑moderate loads, shorter strokes and applications where occasional backlash is acceptable. Many adjustable tables, lab instruments and small robots use lead‑screw Linear Actuators because they provide smooth motion at low speeds. To optimize life, select materials with low friction coefficients and design for consistent lubrication. Keep stroke lengths modest to limit whip, and avoid high‑speed cycles that generate heat.

Belt‑drive actuators: speed and long strokes

Belt‑driven Linear Actuators use a timing belt looped around pulleys to move a carriage. They achieve high linear speeds, often over 5 m/s, making them ideal for pick‑and‑place and packaging systems. Belts allow long stroke lengths without screw whip and require little maintenance. However, belt‑driven Linear Actuators trade off accuracy; belt stretch can produce backlash and position error. To mitigate this, designers integrate tensioners and use high‑tension belts. Belt drives excel where cycle time is critical and precision demands are moderate. When specifying, match belt width, pulley diameter, tooth profile and tension to your expected load and acceleration.

Hydraulic actuators: heavy lifters

Hydraulic cylinders dominate heavy‑duty Linear Actuators. They use incompressible fluid to push pistons and generate high force. Common in construction equipment, aerospace and large robotics, hydraulic actuators handle loads of many tons at moderate speeds. They offer robust performance in harsh environments and maintain force even when stationary. Drawbacks include the need for pumps, reservoirs, hoses and seals, which add weight and maintenance. In robotics, hydraulic Linear Actuators serve exoskeletons, heavy payload manipulators and humanoid legs. When selecting hydraulic components, consider maximum pressure, rod diameter, seal materials and the availability of redundant sealing for safety.

Pneumatic actuators: speed and simplicity

Pneumatic cylinders are another family of Linear Actuators powered by compressed air. They are inexpensive and capable of rapid actuation, making them ubiquitous in factory automation. Pneumatic cylinders offer high cycle rates and simple control—opening or closing with solenoid valves. However, air compressibility limits positional accuracy and creates bounce at the end of stroke. To improve repeatability, some robotics designs combine pneumatic Linear Actuators with mechanical stops or sensors. When evaluating pneumatics, examine bore size, stroke length, pressure range, cushioning mechanisms and the availability of clean, dry air. They excel in tasks like pick‑and‑place or simple clamps.

Piezoelectric and voice‑coil actuators: micro motion

For nano‑scale positioning and high‑bandwidth control, piezoelectric and voice‑coil Linear Actuators come into play. Piezoelectric stacks expand when voltage is applied, generating small displacements with micrometer resolution. They move loads quickly and maintain position without power. Voice‑coil actuators use the Lorentz force on a coil in a magnetic field to generate linear motion; they provide fast response and smooth force control. These specialized Linear Actuators appear in microscopes, optical stages, vibration control and high‑end audio. Because strokes are short, often less than a millimeter, applications require mechanical amplification when longer travel is needed.

Integrated motion modules: plug‑and‑play platforms

Integrated motion modules expand the utility of Linear Actuators by combining them with rails, drives and sensors into complete subassemblies. Pre‑engineered modules range from single‑axis stages to multi‑axis gantries. They come with machined surfaces and alignment pins to ensure accuracy. Integrated modules often include servo amplifiers, encoders, limit switches and sometimes embedded controllers. By purchasing modules you reduce design time, lower risk and ensure that the Linear Actuators interact properly with guides and bearings. Yana Sourcing evaluates module suppliers using both quantitative metrics and qualitative factors like engineering competence, responsiveness and willingness to customize.

Engineering parameters: load and stroke

Selecting Linear Actuators begins with defining load and stroke requirements. Load includes both static weight and dynamic forces from acceleration or impact. Over‑specifying increases cost and size; under‑specifying leads to failure. Stroke length determines travel distance; long strokes require attention to screw buckling, belt sag or cylinder length. Consider orientation: vertical applications demand higher load margins to prevent back‑driving. When designing lifts, incorporate safety factors and braking mechanisms. For motion modules, confirm that the selected Linear Actuators and guides can handle combined loads and moments from multi‑axis assemblies.

Engineering parameters: speed, accuracy and duty cycle

Speed and accuracy often conflict. High‑speed Linear Actuators like belt drives excel at fast cycles but may lack micron‑level precision. High‑precision ball screws provide sub‑micron positioning but operate at lower speeds to avoid vibration. Duty cycle defines how long the actuator can operate continuously before cooling; continuous operation requires appropriate motor sizing and heat dissipation. Excessive duty cycles reduce life and can overheat motors or degrade lubrication. Match Linear Actuators to your cycle profile—rapid moves followed by idle times need different solutions than continuous feed. Always verify manufacturer ratings for speed, repeatability and duty cycle.

Engineering parameters: sensors and control

Feedback and control are critical in Linear Actuators. Most electric units integrate encoders or Hall sensors to report position and speed. Higher‑end actuators use absolute encoders with multi‑turn capability. Limit switches define home positions and prevent over‑travel. For force control, load cells or integrated torque sensors provide feedback. Many motion modules include built‑in drivers that communicate via EtherCAT, CANopen or IO‑Link. When sourcing Linear Actuators, assess the available communication protocols and their compatibility with your robot controllers. Integrated diagnostics, temperature, vibration, current, enable predictive maintenance and reduce downtime.

China’s motion ecosystem: clusters and innovation

China dominates industrial robotics deployment. The International Federation of Robotics’ 2025 statistics report 542,000 robots installed in 2024, with Asia accounting for 74 % of new deployments. The same report notes that 4.66 million robots were in operation worldwide in 2024. China installed around 295,000 units, about 54% of global deployments, and domestic suppliers captured 57% of their home market. Such scale fuels adjacent industries: factories that build robots also build Linear Actuators and motion modules. Clusters in Suzhou, Ningbo and Shenzhen co‑locate motor manufacturers, screw producers, gearbox makers and electronics firms. Rapid iteration and real‑world testing accelerate innovation and reduce costs.

Market momentum: installations and regional shares

The Asia‑centric expansion continues. In 2022, IFR recorded 553,052 industrial robots installed worldwide. Asia accounted for 73 % of these deployments, Europe for 15 % and the Americas for 10%. This concentration implies that suppliers of Linear Actuators and motion modules must align with Asian production clusters to stay competitive. It also signals that local government policies, such as China’s five‑year plan for robotics, shape supply and demand. For buyers, understanding regional dynamics helps mitigate geopolitical risk and ensures supply continuity. Yana’s local teams monitor these trends to anticipate shifts in capacity and pricing.

Market size: robotics and automation actuators

The broader robotics and automation actuators market is booming. Market analysts expect it to grow from $29.38 billion in 2024 to $32.89 billion in 2025, representing an 11.9 % compound annual growth rate. The same forecast projects the market to reach $58.4 billion by 2029 with a 15.4 % CAGR. Drivers include industrial automation, healthcare robotics, automotive electrification, energy efficiency and miniaturization. In other words, demand for actuators, both rotary and linear, will more than double within a decade. For manufacturers of Linear Actuators, this growth translates into economies of scale and opportunities to invest in advanced design and manufacturing technologies.

Market size: linear actuator segment

Within the actuator family, Linear Actuators enjoy their own growth trajectory. Market researchers forecast that the linear actuator segment will grow at a 7.45 % compound annual rate, rising from $32.34 billion in 2022 to $53.47 billion by 2029. The increase is driven by rising industrial machinery utilization, robotics installations, automotive production and aerospace applications. Electric linear actuators meet the needs of automation and can be used in many industries; therefore demand will continue to rise. For sourcing teams, this means more suppliers will enter the market, but not all will meet your quality and trust standards. Selecting the right partners becomes a strategic differentiator.

Demand drivers and regional patterns

Industrial growth in Asia fuels demand for Linear Actuators. Manufacturing exports in India reached $447 billion with 6 % growth in FY23. The European car market surged 10.1 % in February 2024, reflecting increased vehicle production. Aerospace and defense applications also rely on high‑precision linear motion. Asia‑Pacific will hold a significant share of the linear actuator market due to government policies like China’s Five‑Year Plan aiming to strengthen robotics manufacturing. Understanding such regional demand drivers helps you align sourcing volumes, lock in favorable terms and avoid capacity crunches during growth cycles.

Smart actuators and predictive maintenance

Technological innovation is reshaping Linear Actuators. A linear motion industry survey notes that electric actuators are replacing hydraulics and pneumatics across sectors, and the global linear actuator market could surpass $52.67 billion thanks to electric options. Experts highlight the rise of smart actuators integrating encoders, feedback and onboard electronics; these features enable enhanced connectivity, automated optimization and predictive maintenance. Smart modules communicate with plant systems to report status, schedule service and adapt performance. In robotics, predictive maintenance reduces downtime and extends life. When sourcing, prioritize suppliers who offer Linear Actuators with built‑in diagnostics and remote monitoring.

Sourcing strategy: the SMART + HEART framework

Yana operates at a higher dimension where technical rigor meets human insight. Our SMART + HEART framework filters suppliers. SMART covers supplier basics, market and financial health, assurance certifications, references and transparency. HEART examines history, execution, agility, reliability and trust. Together these tests ensure your Linear Actuators and motion modules come from partners who deliver quality and act ethically. We audit factories, verify ISO certifications and test samples for stroke accuracy, backlash and torque. We also interview engineers and managers to assess culture and responsiveness. Only suppliers who pass both SMART and HEART become long‑term partners.

Risk management and diversification

Risk management is central to sourcing Linear Actuators. Dependence on a single supplier or region exposes you to disruptions. Yana mitigates risk through dual‑sourcing and geographic diversification. We secure NNN (non‑disclosure, non‑use, non‑circumvention) agreements under Chinese law to protect intellectual property. We manage currency hedging and inventory buffers to handle price volatility. We monitor geopolitical developments and advise clients when to qualify additional suppliers in Southeast Asia or Europe. Because the robotics and actuator markets are growing quickly, capacity constraints and export restrictions can emerge suddenly. Proactive diversification keeps your production schedule safe.

Integration and system design

Sourcing quality Linear Actuators is only half the battle; integration determines success. Start with mechanical design: mountings must support load paths without introducing deflection. Check alignment between the actuator and the guided load to prevent binding. Provide space for cable management and consider how the module will be assembled into the robot frame. Thermal management matters; motors and electronics generate heat, especially in sealed modules. Use heat sinks or forced convection if necessary. With motion modules ensure that flanges, bolt patterns and connectors match your design or that suppliers can customize them. Yana engineers assist clients with design reviews to ensure integration goes smoothly.

Control and software integration

Modern robots rely on sophisticated control loops. When integrating Linear Actuators, choose drivers that support your communication protocols, EtherCAT for synchronized motion, CANopen for rugged industrial networks, or IO‑Link for simple sensor connectivity. Tuning servo parameters like proportional, integral and derivative gains depends on load inertia and compliance. For collaborative robots, implement current limits and closed‑loop torque control to detect collisions. Many motion modules provide API libraries and software tools for configuration. Yana ensures that actuators come with clear documentation and support. By integrating software early, you avoid delays during commissioning and reduce the risk of mismatches.

Case study: vertical lift module for a mobile robot

A client developing an autonomous mobile robot needed a vertical lift to pick items from shelves at different heights. The design required 500 mm stroke, 150 N continuous load and 600 N peak. Speed had to exceed 0.5 m/s for throughput. After evaluating several Linear Actuators we selected a ball‑screw unit with a 10 mm lead, paired with a 48 V brushless servo and absolute encoder. The actuator delivered sufficient torque and positional accuracy. To simplify integration, we chose a motion module including linear guides, limit switches and a compact servo drive. Yana audited the supplier’s factory and tested samples for backlash and noise. The final lift met performance targets at 40 % lower cost than a European equivalent.

Case study: Cartesian pick‑and‑place module

Another customer needed a gantry for high‑speed pick‑and‑place of electronic components. The design required 1 m travel in X and 0.5 m in Y with repeatability of ±0.02 mm. Belt‑driven Linear Actuators provided the necessary speed and long stroke. However, to achieve the required accuracy we selected high‑tension steel‑reinforced belts and integrated magnetic linear encoders. The supplier offered a motion module with dual‑belt drives, aluminum extrusion, cable chain and servo amplifiers. We verified that the belt tensioning system minimized stretch and cross‑talk. By working with the supplier early we modified mounting flanges to match the client’s tooling. The resulting module increased throughput by 30 % and reduced assembly time.

Emerging trends: hybrid designs and sustainability

The future of Linear Actuators includes hybrid designs combining screw drives with belts to achieve both speed and precision. Roller screw actuators are gaining traction in humanoid robotics because they offer high power density and fit into compact packages. Smart actuators with built‑in sensors, wireless connectivity and on‑board processing will become common. Predictive maintenance algorithms will analyse vibration and temperature to schedule service, reducing downtime. Sustainability is also influencing design: manufacturers are using recyclable materials and developing energy‑efficient motors. Government policies favouring low‑energy automation and circular manufacturing will further accelerate adoption. Robotics companies must stay agile to leverage these innovations.

Conclusion: the high‑dimensional motion landscape

Linear motion is the unsung hero of robotics. While rotary joints capture imagination, Linear Actuators provide the push, pull and precision that turn ideas into physical reality. The market is expanding quickly: hundreds of thousands of robots installed each year and billions of dollars invested in actuators. As suppliers proliferate, risk increases. Yana Sourcing navigates this high‑dimensional landscape with rigorous analysis and human insight. We bridge engineering, supply chain and culture to deliver motion modules that work flawlessly. Contact us when precision motion matters. Together, we will build robots that move with certainty.