Table of Contents

Introduction — Why Hybrid Actuators Matter in Robotics

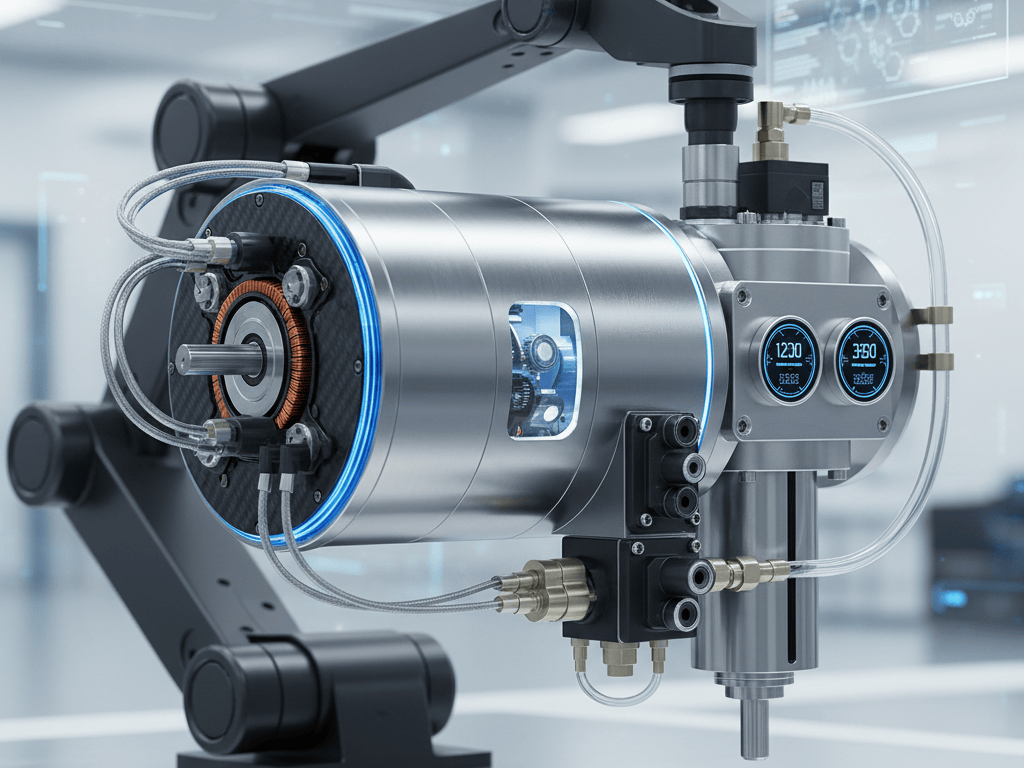

Hybrid actuators sit at the intersection of power, precision and control. While traditional actuators are powered by a single mechanism, a rotary motor driving a gear train or a linear actuator converting rotary motion into translation, hybrid actuators integrate two or more physical drive principles into a single module. They combine the strengths of different actuation technologies to overcome limitations of any individual system. For example, designers may pair an electric servo with a hydraulic circuit to deliver high force with precise electronic control, or couple a piezoelectric stage with a mechanical lead‑screw for nanometre positioning over long travel distances. The result is an actuator that is more adaptive: it can deliver high torque and fine positioning across a wide operating envelope and maintain accuracy under variable loads.

In robotics, this adaptability is critical. Robots encounter vastly different tasks, from manipulating heavy payloads to making micrometre‑level adjustments. A hybrid actuator can deliver both the strength needed to lift or clamp and the fine control required to position components precisely. This dual capability reduces the need for separate subsystems, simplifies mechanical architectures, and improves energy efficiency. As automation moves from static industrial environments into collaborative workspaces and medical devices, actuators must offer quiet operation, built‑in feedback, on‑demand power and inherent safety. Hybrid actuators deliver these capabilities by blending multiple actuation principles into compact, self‑contained modules.

Hybrid actuators differ from purely rotary or linear actuators by operating across both domains. Some hybrid units produce rotary output with integrated torque and clutch functions; others deliver linear force through hydraulic pistons driven by electric pumps. Still others merge linear and rotary stages (e.g., voice‑coil plus lead‑screw) to create multi‑degree‑of‑freedom systems. They may be described as electro‑hydraulic, electro‑mechanical, piezo‑electric, or voice‑coil‑hybrid depending on the mix of technologies used. Regardless of the specific combination, the common theme is adaptive motion: hybrid actuators sense their environment, tune their response, and adjust their actuation mode to match the task.

Working Principle of Hybrid Actuators

Hybrid actuators operate by integrating two or more force‑generating mechanisms into a single assembly. A common example is the electro‑hydraulic hybrid linear actuator. According to Kyntronics, these actuators are self‑contained units that house a hydraulic cylinder, fluid, pump, motor and closed control loop inside a sealed case. The pump is driven by an electric motor; when the motor rotates in one direction the pump pressurizes the fluid, extending the piston rod, and reversing the motor reverses the flow to retract it. Sensors monitor rod position and fluid pressure so that the actuator can provide accurate closed‑loop positioning and force feedback. Because the hydraulic fluid is contained, there are no external hoses or reservoirs and no risk of leaks, making the units maintenance‑friendly. This design merges the high power density of hydraulics with the control precision of electric servos, enabling programmable motion profiles and remote diagnostics.

Another class of hybrid actuators combines piezoelectric and mechanical screw drives. In high‑precision applications such as nanometre positioning, a pure mechanical stage may provide long travel but lacks sub‑micron resolution. A New Equipment Digest article notes that designers overcome this by using a hybrid drive: a piezo drive offers nanometre precision for fine positioning, while a classical drive screw carries heavy loads over long travel ranges. The piezo stage can make fine adjustments after the screw moves the platform into the coarse position, yielding both long travel and ultra‑high resolution. This approach is used in applications like telescopes, measuring technology and semiconductor production.

Hybrid actuators may also integrate linear motors with voice‑coil actuators. Linear motors provide long travel and high accuracy, but friction in the guides and inertia can limit dynamic response. Voice‑coil actuators (VCMs) produce precise, smooth force with limited travel. By combining these technologies, designers create systems where the linear motor handles the main travel and the voice‑coil fine‑tunes the position. The article notes that VCMs can hold the load only when powered; combining them with a linear motor extends travel and adds static holding capability. Another hybrid concept pairs a PiezoWalk® drive with a PICMA® piezo actuator, providing high stiffness and rapid focusing over long travel. Thus, hybrid actuators exploit the superposition of force sources: one mechanism provides coarse motion and high force, while the other provides fine motion and high precision.

Each hybrid architecture has its own internal control strategy. In electro‑hydraulic hybrids, an electronic controller regulates the motor speed and direction, monitors position sensors and optionally pressure sensors, and adjusts pump operation to achieve the desired force or position. The closed loop can perform PID control on position and force, enable programmable motion profiles, and integrate with external PLCs. In piezo‑screw hybrids, the control system may switch between driving the screw (for long travel) and the piezo stage (for fine adjustments). The controllers manage the transitions seamlessly to avoid vibration and ensure continuous positioning. Similarly, hybrid voice‑coil/linear motor systems rely on multi‑axis controllers that coordinate both actuators, with the voice‑coil performing high‑bandwidth micro adjustments while the linear motor manages macro positioning.

Performance Characteristics & Control

The performance of hybrid actuators depends on the combination of technologies used. General characteristics include:

- High force and torque density: Hybrid linear actuators with hydraulic cylinders provide very high force per unit size, supporting thousands of newtons of thrust. Kyntronics notes models with force ratings up to 150 000 lb (≈667 kN) and speeds up to 34.5 in/s (≈0.88 m/s). Piezo‑screw hybrids can provide nanometre resolution at high stiffness, while linear motor + voice‑coil combinations produce smooth force and high bandwidth.

- Wide travel range with high resolution: By pairing coarse and fine stages, hybrid actuators can achieve travel ranges of tens to hundreds of millimetres with sub‑micron resolution. For example, a hybrid stage might use a mechanical screw to move 50 mm and a piezo to achieve 1 nm resolution within that range.

- Dynamic response: Voice‑coil and piezo components can respond in microseconds, enabling high‑frequency control for vibration damping or scanning. Hydraulics provide strong force but slower response; combining them with electric drives allows a trade‑off between force and speed.

- Bidirectional control and backdrivability: Electro‑hydraulic hybrids and linear motor hybrids can actively control movement in both directions and resist backdriving. Piezo elements typically require continuous energy to hold position; mechanical screws or hydraulics supply holding force when unpowered.

- Closed‑loop feedback: Position sensors (linear encoders, magnetostrictive sensors or potentiometers) measure stroke or rotation; pressure transducers measure force. Controllers process these signals to adjust motor speed and pump output or voltage to the piezo, providing precise control.

To compare hybrid actuators with other motion technologies, the table below summarises key performance parameters. The hybrid column reflects typical values for electro‑hydraulic or piezo‑screw hybrids; these are generalised figures for illustrative purposes.

| Parameter | Rotary Actuator | Linear Actuator | Hybrid Actuator (typical) | Voice‑Coil Actuator |

|---|---|---|---|---|

| Output Motion | Angular | Translational | Translational/Angular | Short‑stroke linear |

| Force/Torque Density | Medium–High | Medium | High (electro‑hydraulic) | Medium–High |

| Travel Range | Full rotation | mm–m range | mm–m range with fine stage | 1–50 mm |

| Resolution | ≤0.1° | µm–sub‑µm | nm–sub‑µm (piezo‑hybrid) | nm resolution |

| Speed/Response | 0–3000 rpm | 0–2 m/s | 0–0.9 m/s | kHz bandwidth |

| Backlash/Compliance | Low | Variable | Low (hydraulic) | None |

| Energy Efficiency | High | High | High (power on demand) | High |

| Typical Applications | Robot joints | Lifts, slides | Semiconductor positioning, hydraulic pressing | Haptic feedback, autofocus |

The control strategy for hybrid actuators must handle the different dynamics of each subsystem. In electro‑hydraulic units, an AC or DC motor drives a pump. The controller modulates motor speed to achieve the desired flow, thus controlling cylinder motion. The control loop monitors a rod position sensor and optionally a pressure sensor. It executes proportional–integral–derivative (PID) algorithms to regulate position and force. Because the actuator is sealed, it can provide high efficiency and low maintenance. Some hybrid actuators support Industry 4.0 connectivity, streaming diagnostic data to remote systems and enabling predictive maintenance.

In piezo‑screw and voice‑coil/linear hybrid systems, the controller orchestrates both stages. It may run high‑bandwidth control on the piezo or voice‑coil using a high‑speed digital signal processor and run slower control on the screw or linear motor. When a move command is issued, the screw or linear motor performs the bulk of the motion, then the piezo stage makes fine adjustments. The control algorithms synchronise the two actuators to avoid overshoot and maintain smooth motion.

Integration in Robotic Systems

Hybrid actuators find a place wherever a single drive principle cannot simultaneously deliver high force, long travel, and precise positioning. In robotics, this translates into use across all levels of motion complexity.

Level 1 (Simple Motion Modules)

In basic automation such as sliding doors, conveying systems or clamping fixtures, hybrid actuators provide power and efficiency. Electro‑hydraulic hybrids can replace conventional hydraulic cylinders or linear actuators, offering built‑in control and eliminating the need for separate pumps, reservoirs and hoses. They reduce installation time and maintenance. Their energy‑efficient design, pumping fluid only when motion is needed, minimises power consumption and heat.

Level 2 (Robot Arms and Cobots)

In collaborative robots (cobots) and multi‑axis manipulators, hybrid actuators deliver high torque and high accuracy. For instance, a torque motor integrated with a hydraulic clutch can provide smooth, backdrivable motion with high payload capacity; coupling this with a harmonic reducer yields a hybrid joint. Another example is the combination of a servo motor driving a lead screw with a piezoelectric stack at the end. The servo and screw move the joint or end effector across its workspace, and the piezo stack provides micro adjustments for fine positioning. This architecture allows the cobot to handle both heavy tasks (e.g., carrying parts) and delicate operations (e.g., soldering or assembly). Because the hybrid actuator integrates position sensors and force feedback, it supports closed‑loop control, safety functions and compliance.

Level 3 (Mobile and Industrial Robots)

Mobile robots and industrial automation often require actuators that deliver long travel, high load capacity and precise positioning. Hybrid linear actuators with integrated hydraulics are ideal for high‑force pressing, lifting and gripping tasks. In assembly lines, hybrid actuators can control pressing operations with programmable force and position profiles, ensuring consistent quality. In pick‑and‑place robots handling heavy payloads, a combination of a linear motor for the main travel and a voice‑coil for final placement ensures rapid moves and accurate placement. In measurement equipment, hybrid piezo‑screw stages deliver nanometre accuracy over tens of millimetres, enabling scanning microscopes and wafer alignment systems.

Level 4 (Humanoids and Complex Systems)

Humanoid robots and exoskeletons demand actuators that can mimic human muscle behaviour: strong yet compliant, able to hold static positions without power and deliver rapid micro adjustments. Hybrid actuators achieve this by combining high‑ratio gear or hydraulic stages with elastic elements such as spring mechanisms or series elastic actuators, along with smart control to modulate stiffness. For example, a humanoid knee joint might use an electro‑hydraulic actuator for high torque and integrate a voice‑coil for fine torque feedback. The actuator senses external forces and adjusts its compliance in real time, enabling safe interaction with humans. Another example is the European Extremely Large Telescope, which uses hybrid drives to position mirror segments. Each segment is moved by three hybrid actuators that combine different drive principles, delivering travel ranges of ±5 mm and push/pull forces between 463 N and 1 050 N.

Design Considerations — Size, Cooling, Noise, Weight

Designing hybrid actuators requires balancing the physical attributes of each subsystem. Size and weight increase with the addition of secondary stages; designers minimise this through compact packaging and integrated electronics. Cooling is critical, especially in electro‑hydraulic systems: sealed fluid absorbs heat, and the unit may incorporate fins or forced air cooling. Piezo stages dissipate little heat but require stable temperatures for accuracy. Noise levels depend on the drive: hydraulic pumps produce some noise, whereas piezoelectric and voice‑coil actuators are quiet; careful acoustic isolation can achieve silent operation for medical or laboratory environments. Mounting and inertia must be considered: adding a hydraulic cylinder increases inertia and may require reinforcement; piezo stages are lightweight but have limited force capacity.

Integration Challenges and Proven Solutions

Hybrid actuators introduce complexities beyond those of single‑principle devices. Common challenges and solutions include:

| Challenge | Root Cause | Proven Solution |

|---|---|---|

| Fluid leaks in electro‑hydraulic systems | Improper seals or hose connections | Use sealed, self‑contained designs and high‑quality seals. |

| Control instability due to mixed dynamics | Combining high‑bandwidth piezo with slow mechanical stages | Employ multi‑rate controllers; decouple modes; ensure smooth transition between stages. |

| Limited travel in piezo or voice‑coil stages | Physics limits of piezo or VCM travel | Combine with a lead‑screw or linear motor for coarse travel. |

| Heat buildup | High power density in compact designs | Integrate cooling channels, heat sinks; reduce duty cycle; use power‑on‑demand control. |

| Maintenance and reliability | Complex assembly with multiple components | Design sealed units; incorporate remote diagnostics and predictive maintenance. |

Manufacturing & Sourcing Insights

Hybrid actuators require expertise across disciplines, hydraulics, precision mechanics, piezoelectric materials, voice‑coil design, electronics and control software. The global supply chain offers diverse competencies:

- China produces cost‑efficient electro‑hydraulic hybrids and voice‑coil‑linear combinations for collaborative robots and industrial machinery. Factories specialise in mass‑producing compact self‑contained units with AC or DC power options. The large manufacturing base drives competitive pricing and rapid turnaround, though buyers must carefully audit suppliers for quality and intellectual‑property protection.

- Japan excels in piezo‑screw hybrids and micro‑actuator modules for medical equipment, optics and semiconductor manufacturing. Companies such as Physik Instrumente (PI) and SMC supply high‑precision stages and micro‑electro‑mechanical actuators with nanometre resolution.

- Germany and Switzerland focus on high‑end electro‑hydraulic and electromechanical hybrids for aerospace, defence and scientific instruments. They integrate high‑stiffness mechanical components with advanced control electronics, offering long life and reliability.

- United States manufacturers provide custom hybrid actuators for robotics research, defence and heavy industry, often integrating condition monitoring and IoT connectivity. New Equipment Digest highlights that hybrid drives solve challenging positioning problems that single drives cannot handle.

Quality Control Checklist

Due to their complexity, hybrid actuators require thorough quality control. Key checks include:

- Force/torque testing across the full stroke and duty cycle, verifying continuous and peak ratings.

- Travel accuracy measurement, ensuring the fine and coarse stages work together to meet positioning specifications.

- Fluid integrity checks for leaks in sealed electro‑hydraulic units; pressure decay testing ensures the system holds pressure over time.

- Sensor calibration, verifying that position encoders and pressure transducers provide accurate feedback.

- Thermal cycle testing to evaluate heat dissipation and to ensure components remain within temperature limits.

- Vibration testing for applications requiring high dynamic performance.

Risk Factors

Sourcing hybrid actuators introduces specific risks that Yana Sourcing helps mitigate:

- Component compatibility: Mismatched motor, pump or piezo elements can create inefficiencies or failures.

- Intellectual property: Custom designs may involve proprietary control algorithms or patented mechanisms; verifying licensing and supplier integrity is critical.

- Supply chain complexity: Hybrid actuators involve multiple subcomponent suppliers (motors, sensors, electronics, hydraulics). A failure in one part can compromise the entire system. Yana performs multi‑tier supplier audits to ensure reliability.

- Counterfeit parts: High‑value components (e.g., rare‑earth magnets, piezo stacks) are susceptible to counterfeiting. Yana verifies material certificates and performs independent testing.

- Quality variation: Without rigorous QC, force ratings and travel precision may not meet specifications. Yana implements incoming inspection protocols and factory audits.

Emerging Innovations & Future Trends

Hybrid actuation is rapidly evolving as robotics moves towards adaptive, intelligent motion systems. Several emerging technologies are shaping its future:

- AI‑Tuned Hybrid Drives – controllers that use machine learning to optimise force, speed and precision in real time. They learn the dynamic behaviour of the combined stages and adjust parameters to minimise energy consumption and vibration. This self‑tuning capability will allow hybrid actuators to adapt to changing loads, reduce wear and improve performance over time.

- Integrated Sensing – embedding strain gauges, temperature sensors, accelerometers and magnetoresistive encoders directly into actuator components. This creates self‑sensing actuators that monitor their own condition and provide rich data for predictive maintenance and high‑bandwidth control. Electro‑hydraulic hybrids will integrate pressure and flow sensors to adjust pump speed automatically.

- Smart Materials – hybrid actuators will incorporate advanced materials such as shape‑memory alloys and electroactive polymers to add compliance and variable stiffness. Combining rigid actuators with soft materials will enable robots to replicate human muscle behaviour. Piezo‑ceramic materials are also evolving to deliver greater displacements at lower voltages, expanding the range of hybrid piezo systems.

- Modular Hybrid Platforms – manufacturers are developing hybrid actuator platforms with plug‑and‑play modules: electric‑hydraulic cartridges, piezo stacks, voice‑coil units and harmonic gearboxes that can be combined into customised actuators. This modularity accelerates product development and allows robotics engineers to tailor actuators to specific applications without reinventing core technologies.

- High‑Force Micro‑Actuation – innovations in ultrasonic motors and electrostatic drives will permit micro‑scale hybrid actuators with high force density. These actuators will power next‑generation medical devices, micro‑robots and optical instruments.

- Energy Regeneration – hybrid actuators will increasingly incorporate energy harvesting: capturing braking energy in linear stages and storing it in capacitors or using it to power control electronics, improving overall efficiency.

- Digital Twins and Virtual Commissioning – advanced simulation models will allow engineers to design and test hybrid actuator behaviour virtually before manufacturing. Digital twins will model the coupled dynamics of hydraulic, electric and piezo stages, enabling predictive tuning and fault detection.

- Regulatory & Safety Standards – as hybrid actuators enter more industries, new safety standards will address their unique failure modes (e.g., ensuring fluid containment in electro‑hydraulic units, safe shutdown in piezo stages). Yana monitors regulatory developments and ensures compliance.

Choosing the Right Hybrid Actuator for Your Robot

Selecting the appropriate hybrid actuator involves balancing performance, size, cost and integration requirements. Consider the following checklist:

- Application requirements: Define the force/torque, travel range and accuracy needed. For nanometre‑level positioning of heavy loads, a piezo‑screw hybrid is ideal. For heavy pressing or lifting, electro‑hydraulic hybrids provide high force.

- Duty cycle & dynamics: Determine whether the actuator will run continuously or intermittently. Electro‑hydraulic hybrids excel at intermittent high‑force tasks due to power‑on‑demand operation. If high bandwidth is required, voice‑coil/piezo hybrids deliver fast response.

- Size & weight constraints: Ensure the actuator fits within the available space and meets weight limits. Compact hybrids may use miniaturised pumps and integrated electronics or micro piezo stacks.

- Power source: Choose between AC, DC or battery power. Kyntronics hybrid actuators offer AC or DC options for different environments.

- Environment & compliance: Assess operating conditions: temperature, humidity, contamination, shock and vibration. Electro‑hydraulic hybrids are sealed against contamination; piezo hybrids may be sensitive to humidity. Evaluate compliance and backdrivability needs; if the actuator must be safe in human‑robot collaboration, integrate series‑elastic elements.

- Control integration: Ensure the hybrid actuator’s control interface (analogue, digital or bus) matches your robot’s control system. Consider built‑in diagnostics and compatibility with Industry 4.0 networks.

Example Scenarios — Where Hybrid Actuators Excel

- Precision Manufacturing: Semiconductor wafer steppers use hybrid actuators combining linear motors for long travel and piezo stages for nanometre alignment. These actuators deliver the accuracy required for photolithography and scanning electron microscopy.

- Optics & Telescopes: The European Extremely Large Telescope uses hybrid actuators with ±5 mm travel and push/pull forces up to 1 050 N to adjust mirror segments. The combination of mechanical and piezo stages ensures stable optical alignment under temperature fluctuations.

- Medical Robotics & Prosthetics: Robotic surgical instruments require lightweight, compact actuators that can deliver precise force and fine motion. Piezo‑servo hybrids provide high‑resolution control for positioning and haptics. Hybrid linear actuators with sealed hydraulics deliver smooth motion for hospital beds and rehab devices.

- Collaborative Robots (Cobots): Hybrid joints combining torque motors and voice‑coil actuators enable cobots to handle variable payloads with soft compliance. The torque stage delivers high torque for lifting, while the voice‑coil provides haptic feedback and micro adjustments.

- Industrial Pressing & Clamping: Electro‑hydraulic hybrid actuators replace air cylinders in pressing and clamping applications, offering programmable force profiles and energy savings. They provide high thrust and maintain position without continuous power.

- Exploration Robots: Planetary rovers and underwater robots need actuators that deliver high force, precise control and resistance to harsh environments. Hybrid systems sealed from contaminants handle extreme temperatures and pressures while providing fine control for sampling and manipulation.

Sourcing Verified Hybrid Actuators with Yana

Hybrid actuators represent some of the most advanced and complex motion devices in robotics. Selecting the right supplier and configuration is crucial for ensuring performance, safety and cost‑effectiveness. Yana Sourcing applies its SMART + HEART framework to hybrid actuators:

- SMART: We validate specifications, audit manufacturing processes, verify material certificates and evaluate supplier capabilities. Our engineers perform tests for force, travel, precision and durability, ensuring actuators meet the most demanding requirements. We also verify embedded electronics and control software, ensuring compatibility with Industry 4.0 systems and cyber‑security standards.

- HEART: We build long‑term relationships with trusted suppliers who share our commitment to quality, ethics and innovation. Our network spans Asia, Europe and North America, giving you access to regional strengths for electro‑hydraulic, piezo‑mechanical and hybrid voice‑coil designs. We monitor emerging technologies and regulatory changes, guiding you toward future‑proof solutions.

Sourcing hybrid actuators through Yana ensures zero‑risk procurement: every supplier is audited, every component traced, and every design validated. Our team works closely with your engineers to tailor hybrid actuators to your specific application, providing technical documentation, integration support and lifecycle management. With Yana, you can confidently adopt the next generation of adaptive motion systems.

Partner with Yana Sourcing to secure verified hybrid actuator suppliers and power your next‑generation robotics projects with adaptive intelligence.