Table of Contents

Introduction – Why Actuators Matter in Robotics

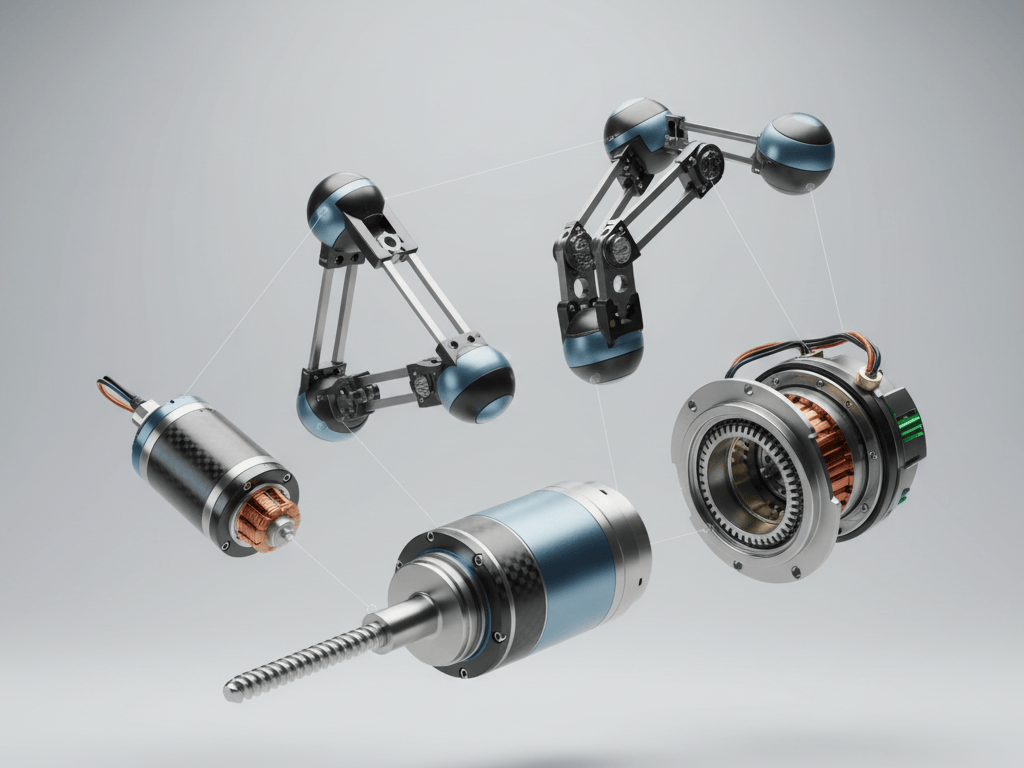

Robots perform everything from delicate surgical procedures to heavy‑duty palletizing, but none of those motions happen on their own. Actuators are the “muscles” of robotics – components that convert stored energy into movement and force. Unlike motors, which primarily generate rotary power, actuators combine motors with gears, linkages, cylinders and sensors to deliver controlled linear, rotary or hybrid motion. They are the last link in the motion chain, translating electrical, hydraulic, pneumatic or even thermal energy into precise mechanical work. Continuous advances in materials, mechanical design and control strategies mean today’s actuators offer greater durability, accuracy and lower energy consumption. Still, actuators bring unique challenges such as limited torque‑to‑weight ratios, backlash, mechanical wear and sophisticated control algorithms. This guide explores how actuators underpin robotic performance, how they differ from simple motors, and how to select and source the right actuator modules for next‑generation robots.

The Role of Actuators in Modern Robotics

Actuators make it possible for robots to grip, lift, push and navigate – essentially interacting with the physical world. While a motor provides rotational power, an actuator couples the motor to a mechanism (gearbox, screw, belt or hydraulic cylinder) and adds feedback sensors and a controller to regulate the motion. Because actuators directly touch the application, they must deliver appropriate force or torque, travel and speed while maintaining accuracy, stiffness and reliability. Common architectures include electromagnetic actuators such as geared drive and direct‑drive motors, hydraulic cylinders and pneumatic cylinders. Electromagnetic actuators are the most widely used because they combine high efficiency and precision with scalability for small or large robots. Hydraulic actuators excel in very high force applications; pneumatic actuators are ideal for fast, repetitive motions in material‑handling or packaging. Across all types, control and feedback electronics ensure the actuator moves precisely as commanded. Rapid advancements in materials, manufacturing and control algorithms continue to improve actuator performance and lower cost.

Actuator Classifications and Motion Principles

Actuators are classified by motion type and energy source. Motion types fall into three broad categories:

- Linear actuators generate straight‑line motion, typically using a lead screw, ball screw, belt, hydraulic or pneumatic cylinder. They are common in industrial machinery such as presses, pick‑and‑place systems and adjustable tables. In robotics, linear actuators lift end effectors, extend grippers and move gantry systems.

- Rotary actuators produce continuous or limited‑range angular motion by using a motor with a gearbox or a direct‑drive torque motor. Rotary actuators drive robot joints, turntables and rotary indexes. Many material‑handling components rely on rotary motion.

- Hybrid actuators integrate rotary and linear elements in one module. Examples include gantry modules with rotation and vertical lift or collaborative robot elbows combining harmonic drives with series‑elastic springs. Hybrid designs deliver multi‑axis motion with fewer components and support compliance for safe human‑robot interaction.

Energy sources dictate actuator behaviour. Electric actuators convert electricity into motion via motors, solenoids or piezoelectric elements. They offer precise, programmable control and are common in robotics and factory automation. Hydraulic actuators use pressurized fluid to move pistons or rotary actuators and provide very high force for heavy lifting. Pneumatic actuators rely on compressed air and are valued for fast actuation in pick‑and‑place tasks. Less common types include piezoelectric actuators, which create micro‑scale motions for optics, and thermal actuators, which exploit thermal expansion or shape‑memory materials. Many robotics actuators are electromechanical – combining an electric motor with a mechanical transmission to provide torque or force amplification.

Performance Metrics and Control Architectures

Selecting an actuator begins with understanding key performance metrics. These metrics provide objective criteria to match an actuator’s capabilities to the application:

- Force or torque – the maximum continuous and peak force (N) or torque (Nm) the actuator can produce. Linear actuator force often relates to the screw lead or hydraulic piston area; rotary actuator torque is tied to motor size, gear ratio and efficiency.

- Stroke length or rotation range – the travel distance (mm or degrees) the actuator must cover.

- Speed – how fast the actuator moves, defined as linear speed (mm/s) or rotational speed (rpm or rad/s). Speed requirements influence motor choice and transmission ratio.

- Duty cycle and efficiency – the percentage of time the actuator will operate under load and the electrical or hydraulic efficiency. High duty cycles require robust cooling and energy‑efficient designs.

- Backlash and stiffness – mechanical play and rigidity of the transmission, which directly affect positioning accuracy. Harmonic and planetary gearboxes reduce backlash; direct‑drive torque motors eliminate it.

- Precision and repeatability – the smallest incremental motion and the ability to return to the same position repeatedly. Electric actuators with encoders or linear scales achieve micron‑level resolution.

Actuators operate in open‑loop or closed‑loop mode. In open‑loop systems, a controller sends a command signal without measuring the actual position or force; the result depends on load and friction. Closed‑loop systems incorporate sensors (encoders, resolvers, force sensors) and adjust current, voltage or pressure to minimize the error between commanded and actual position. For example, hybrid stepper systems monitor position and switch between open and closed loop if error exceeds a threshold, ensuring reliability without continuous feedback. Closed‑loop control enables compensation for disturbances, delivers higher accuracy and allows advanced strategies like model‑predictive control and AI‑based tuning.

Selection Criteria

Choosing an actuator requires a structured evaluation of application needs. The LINAK selection guide suggests six steps: (1) identify the motion type (linear or rotary) and required force/torque and speed; (2) determine the precision needed; (3) consider environmental conditions such as temperature, dust, moisture and space constraints; (4) compare different actuator types (electric, hydraulic, pneumatic, piezoelectric) and match their characteristics to your requirements; (5) evaluate power source availability and infrastructure; and (6) assess cost and lifecycle considerations, including maintenance, expected lifespan and downtime. Finally, testing prototypes or simulations helps validate performance. JHFoster adds that movement type, energy input and desired precision are the three main factors when selecting an actuator. Electric actuators are popular when electricity is readily available; hydraulic or pneumatic systems suit applications where fluid power is abundant.

Actuator Integration Across Robotic Levels

Robotic systems can be grouped into four levels of complexity – from simple positioning devices to highly dexterous humanoids. Each level places distinct demands on actuators.

L1: Core motion modules. This level includes basic robotic axes and single‑degree‑of‑freedom actuators such as conveyor drives, rotary indexing tables and simple lift mechanisms. Linear actuators with lead screws or belt drives provide straightforward position control, while rotary actuators with gearboxes deliver torque multiplication. At this level, reliability and cost efficiency are priorities; open‑loop control may suffice for non‑critical positioning.

L2: Modular robotic systems. Robots at this level incorporate multi‑axis manipulators, SCARA arms and collaborative robot joints. Actuators must deliver higher precision and support multi‑axis synchronization. Hybrid actuators that integrate harmonic drives with torque sensors enable safe, compliant interactions, while frameless torque motors reduce weight and increase torque density. Closed‑loop control with high‑resolution encoders becomes standard, and thermal management is critical due to sustained duty cycles.

L3: Industrial and service robots. Applications such as palletizing, welding and AMRs demand actuators capable of high loads, continuous operation and harsh environments. Sealed electric actuators with planetary gearboxes or harmonic reducers provide high torque density and low backlash. Integrated linear modules combine actuators, guides, limit switches and sometimes controllers, simplifying installation. Designers must account for heavy payloads, vibration damping and robust sealing to protect components.

L4: Humanoids and embodied AI. The highest level uses actuators as anatomical equivalents for shoulders, elbows, knees and ankles. Requirements include high torque at low speed, back‑drivability for compliance, minimal noise and integration of force/torque sensors. Series‑elastic actuators combine a motor, gearbox and spring to deliver controlled compliance; dual‑actuator modules provide both rotation and translation. As robots interact closely with humans, actuators must meet strict safety standards and integrate diagnostics for predictive maintenance.

Design Considerations – Size, Cooling, Noise and Weight

Actuator design is a balance between compactness, heat dissipation, noise and weight. For linear actuators, the screw diameter and lead determine force and speed. Smaller diameters reduce weight but increase stress and wear; larger diameters increase stiffness but add mass. Rotary actuators face similar trade‑offs with motor diameter and stator length. Frameless actuators allow integration into robot joints, reducing enclosure mass. Cooling method (natural convection, forced air or liquid) depends on duty cycle; high‑duty actuators often require liquid cooling to dissipate heat from windings and gearboxes. Noise arises from gear meshing or airflow; helical gears reduce noise but can introduce axial loads. Weight and inertia affect dynamic response, so designers often use lightweight materials such as aluminium housings and composite gear trains. Safety features like brakes or redundant encoders are essential in human‑collaborative robots.

Integration Challenges and Proven Solutions

The ewadirect paper highlights common actuator challenges: limited torque‑to‑weight ratio, backlash and mechanical wear, control complexity and environmental sensitivityewadirect.com. These issues stem from gear transmissions, misalignment, friction and limitations of control algorithms. Solutions include:

- High‑torque density materials – using rare‑earth magnets, high‑pole motors and harmonic or cycloidal gearboxes to increase torque without adding weight.

- Precision gears and preloading – using harmonic or planetary reducers with micro‑backlash and employing preload springs to eliminate backlash. Proper lubrication and hardened surfaces extend gear life.

- Advanced control algorithms – implementing field‑oriented control, model‑predictive control and adaptive damping to stabilize motion and reduce vibration. Hybrid systems monitor position and automatically switch between open and closed loop.

- Environmental protection – sealing actuators against dust and moisture, selecting materials with high thermal stability and corrosion resistance, and integrating temperature and vibration sensors for predictive maintenance.

Yana Sourcing engineers often co‑design actuators with suppliers to solve integration challenges, ensuring proper alignment, lubrication and sensor calibration before actuators leave the factory.

Global Manufacturing and Sourcing Insights

The robotics industry is expanding rapidly; the International Federation of Robotics reported that 542,000 robots were installed globally in 2024, with Asia accounting for 74 % of new deployments. This growth fuels a rising demand for actuators, and supply chains span the globe. China dominates high‑volume manufacturing of standard actuators and integrated modules, offering cost‑effective solutions for consumer and light‑industrial robotics. Japan leads in precision micro‑actuators and hybrid systems for medical devices and optics. Europe, particularly Germany and Switzerland, excels at high‑torque and high‑reliability actuators for automotive and aerospace. The United States is home to many R&D‑oriented companies developing smart actuators with embedded sensors and integrated drivers.

When sourcing actuators, factors such as minimum order quantities (MOQs), lead times, customization capability and quality control vary by region. Chinese suppliers often accommodate low MOQs and flexible customization but require rigorous quality audits. European suppliers may have higher MOQs and costs but provide long‑term reliability and certifications. Yana’s sourcing network spans these regions and performs factory audits, lifecycle testing and supplier vetting to ensure components meet compliance and ethical standards.

Quality Control Framework

Yana’s actuator quality control process includes:

- Specification verification – confirming force, torque, speed and stroke meet design requirements. Factory tests evaluate continuous and peak performance under load.

- Backlash and stiffness measurement – using laser interferometers or torque sensors to quantify mechanical play and rigidity. Acceptable limits vary by application.

- Thermal and environmental tests – subjecting actuators to temperature cycling, humidity and vibration to evaluate durability. Hydraulic units undergo pressure testing and leak detection.

- Sensor calibration – verifying encoder resolution, linearity and repeatability. Force sensors, Hall devices and thermistors are calibrated to ensure accurate feedback.

- Endurance and lifecycle testing – running actuators through millions of cycles to reveal wear patterns. Data from these tests feed predictive maintenance algorithms.

Risk Mitigation

Common actuator procurement risks include inconsistent manufacturing quality, substandard materials, counterfeit components and poor documentation. Gearbox misalignment and inadequate lubrication can cause premature wear; cheap encoders may lead to feedback errors. Environmental factors like high temperature and humidity can degrade insulation and seals, especially in hydraulic or pneumatic units. Yana mitigates these risks by auditing suppliers, demanding traceability of magnets, bearings and electronics, and maintaining contingency supply lines to avoid single‑source vulnerabilities. Our SMART + HEART approach evaluates suppliers not only on performance metrics but also on ethical practices and long‑term partnership potential.

Next‑Gen Actuator Innovations and Future Trends

Research into actuators is accelerating. Zehao Yuan’s review notes that advances in materials, design and control strategies have increased actuator durability, precision and energy efficiency. Yet limitations in torque‑to‑weight ratio, backlash and control complexity remain. Several emerging trends promise to shape the next decade of robotic actuation:

- Soft and compliant actuators – inspired by biological muscles, soft robotics employs pneumatic, hydraulic or electroactive polymers to deliver safe, adaptive motion. These actuators deform continuously rather than hinging around joints, enabling robots to grasp delicate objects and interact intimately with humans. Applications include wearable exosuits, flexible grippers and medical devices.

- Artificial muscles and electroactive polymers – materials that contract when subjected to electric fields or chemical stimuli are being developed for high‑performance artificial muscles. Shape memory alloys, dielectric elastomer actuators and twisted polymer fibres offer high power‑to‑weight ratios and are suitable for micro‑robots and morphing structures.

- Integrated smart actuators – combining motors, drivers, sensors and control electronics into a single compact package reduces wiring complexity and improves reliability. Smart actuators can self‑calibrate, monitor health and adjust performance using embedded AI algorithms. They are key to modular, plug‑and‑play robotics systems.

- Energy‑efficient designs – as robots operate longer and carry their own batteries, actuator efficiency becomes critical. Magnetic materials with higher flux density, lamination technologies and regenerative drive electronics reduce losses. Counterbalance and gravity compensation mechanisms lower steady‑state power draw.

- Miniaturization and microactuators – developments in MEMS (micro‑electromechanical systems) and printed electronics allow actuators to shrink to millimetre scales. These are used in micro‑grippers, optical alignment, medical implants and swarm robotics.

- AI‑driven control and adaptive actuation – machine learning algorithms tune control parameters in real time, predicting load variations and compensating for disturbances. Combined with sensor fusion, these actuators can adapt stiffness, damping and speed to the task, improving safety and efficiency.

- Hybrid actuation systems – combining different actuation mechanisms (e.g., integrating hydraulic power for high force with electric drives for precise control) yields versatile motion modules. Future robots may use hybrid cylinders with electric priming and hydraulic boost for heavy tasks, or integrate voice‑coil elements into torque motors for micro‑adjustments.

These innovations will broaden the range of capabilities, making actuators smarter, lighter and more responsive.

Selecting the Right Actuator for Your Robot

Choosing the optimal actuator is a multi‑disciplinary task. Beyond technical metrics, decision makers must consider cost, supply chain, maintenance and scalability. A structured selection checklist includes:

- Define the motion profile. Specify whether the motion is linear, rotary or hybrid; define stroke length or angle, and establish acceleration, speed and duty cycle requirements.

- Determine force/torque and load. Calculate the continuous and peak force or torque required, accounting for payload, friction and inertia. Over‑specifying leads to unnecessary cost and size; under‑specifying results in performance shortfalls.

- Identify precision and control needs. Evaluate position resolution, repeatability and control bandwidth. Determine whether open‑loop control is sufficient or if closed‑loop feedback is necessary.

- Assess environment and integration. Consider temperature range, exposure to dust or fluids, and installation space. Evaluate mounting interfaces, cable routing and cooling. Yana’s design team often co‑develops custom housings and brackets to ensure proper alignment and thermal management.

- Choose power source and infrastructure. Match the actuator type (electric, hydraulic, pneumatic) to the available power infrastructure. Electric actuators offer clean operation; hydraulic and pneumatic systems handle high force or explosion‑proof environments.

- Evaluate lifecycle and cost. Compare initial purchase cost, energy consumption, maintenance requirements and expected service life. Some actuators require regular lubrication or seal replacement; others offer maintenance‑free operation for tens of millions of cycles.

- Prototype and test. Whenever possible, build prototypes or run simulations to validate performance and identify unforeseen issues. Yana Sourcing can arrange prototype actuators from qualified suppliers and coordinate testing.

Example Scenarios – Matching Actuators to Applications

- Heavy‑duty manufacturing robot: A palletizing arm lifting 50 kg cartons repeatedly may require a high‑torque rotary actuator with a harmonic reducer for low backlash and high stiffness. A hydraulic cylinder could provide vertical lift if the factory has existing hydraulic infrastructure.

- Precision pick‑and‑place robot: A small pick‑and‑place robot in electronics assembly demands micron‑level positioning and low inertia. Electric linear actuators with ball screws and high‑resolution encoders deliver smooth, precise motion. Voice‑coil or piezo actuators handle micro‑adjustments.

- Collaborative robot (cobot): Cobots interact safely with humans, so actuators must be back‑drivable and compliant. Series‑elastic actuators and torque‑controlled motors provide built‑in compliance and force sensing. Hybrid actuators combining rotation and compliant springs enable safe elbow joints.

- Autonomous mobile robot: An AMR navigating a warehouse uses electric wheel actuators with planetary gearboxes for high torque and regenerative braking. Linear actuators adjust the height of grippers or shelves, while sealed actuators protect against dust and moisture.

- Medical or surgical robot: Robots used in minimally invasive surgery require extremely smooth, silent and sterile actuators. Brushless linear actuators with integrated encoders and sterile housings provide precise control. Piezoelectric and voice‑coil actuators handle micro‑scale adjustments.

These scenarios show how force, motion type, environment and safety drive actuator selection. Crosslinking to specific motor pages – such as servo, torque, linear and hybrid motors – helps engineers understand the underlying motor technologies that pair with actuators.

Sourcing Verified Robotics Actuators with Yana

Yana Sourcing approaches actuators with its SMART + HEART methodology. SMART stands for Specification, Manufacturing, Audit, Risk and Traceability. We verify that every actuator meets torque, force, speed and life requirements; we audit factories and supply chains to ensure materials and processes meet quality standards; we identify risk factors such as magnet supply volatility or counterfeit bearings; and we insist on full traceability for all components. HEART stands for Human‑centric, Ethical, Adaptive, Reliable and Trusted. We build partnerships with suppliers who treat employees fairly, maintain environmental compliance and share our long‑term vision. Our deep cultural understanding and on‑site presence ensure clear communication and rapid resolution of issues.

Partnering with Yana gives buyers access to a global network of actuator manufacturers across China, Japan, Europe and the U.S. We handle qualification, negotiate pricing and lead times, and manage logistics, allowing engineers to focus on design and innovation. Whether you need off‑the‑shelf electric actuators or custom hybrid modules, Yana provides guidance from specification to installation.

Ready to Power the Future?

Robotic innovation depends on actuators that deliver the perfect blend of strength, speed and intelligence. By understanding motion principles, performance metrics, integration challenges and market dynamics, you can select and source actuators that enhance your robot’s capabilities and reliability. Yana Sourcing stands ready to help you navigate this complex landscape. Partner with Yana Sourcing to secure verified actuator suppliers and power the motion intelligence behind your next‑generation robots.